Structural system of industrial low storied dwelling

A residential and system technology, applied in residential buildings, building structures, buildings, etc., can solve the problems of poor thermal insulation performance of building materials, unreasonable steel consumption per unit, unfavorable industrial production, etc., and achieve good wind resistance , reduce construction costs, and achieve reasonable force effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

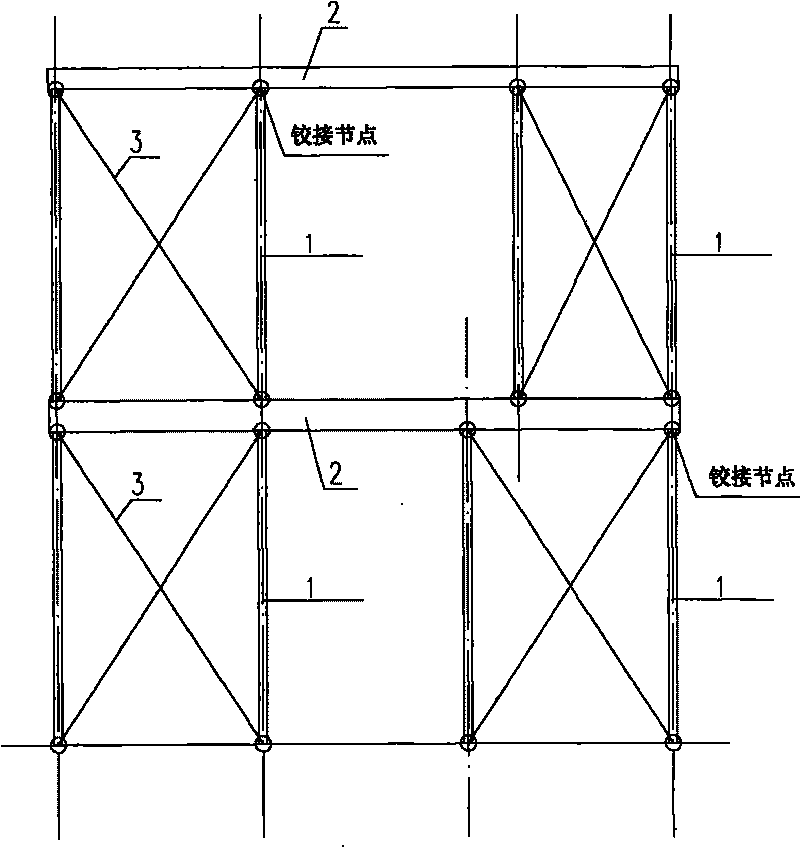

[0046] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 As shown, the industrialized low-rise residential structure system of the present invention includes steel column 1, steel beam 2, inter-column support 3, steel beam horizontal support 4, floor slab 5, connection node between steel column 1 and foundation, steel column 1 and steel beam 2 The connection node of steel column 1 and inter-column support 3, the connection node of steel beam 2 and steel beam horizontal support 4, the rigid connection node of steel beam 2, the connection node of steel beam 2 and floor 5, and the roof enclosure system , Wall enclosure system.

[0047] Among them, steel column 1 adopts rectangular tube, steel beam 2 adopts high-frequency welded H-shaped steel, inter-column support 3 and steel beam horizontal support 4 adopt round steel such as Φ16 and Φ20.

...

Embodiment 2

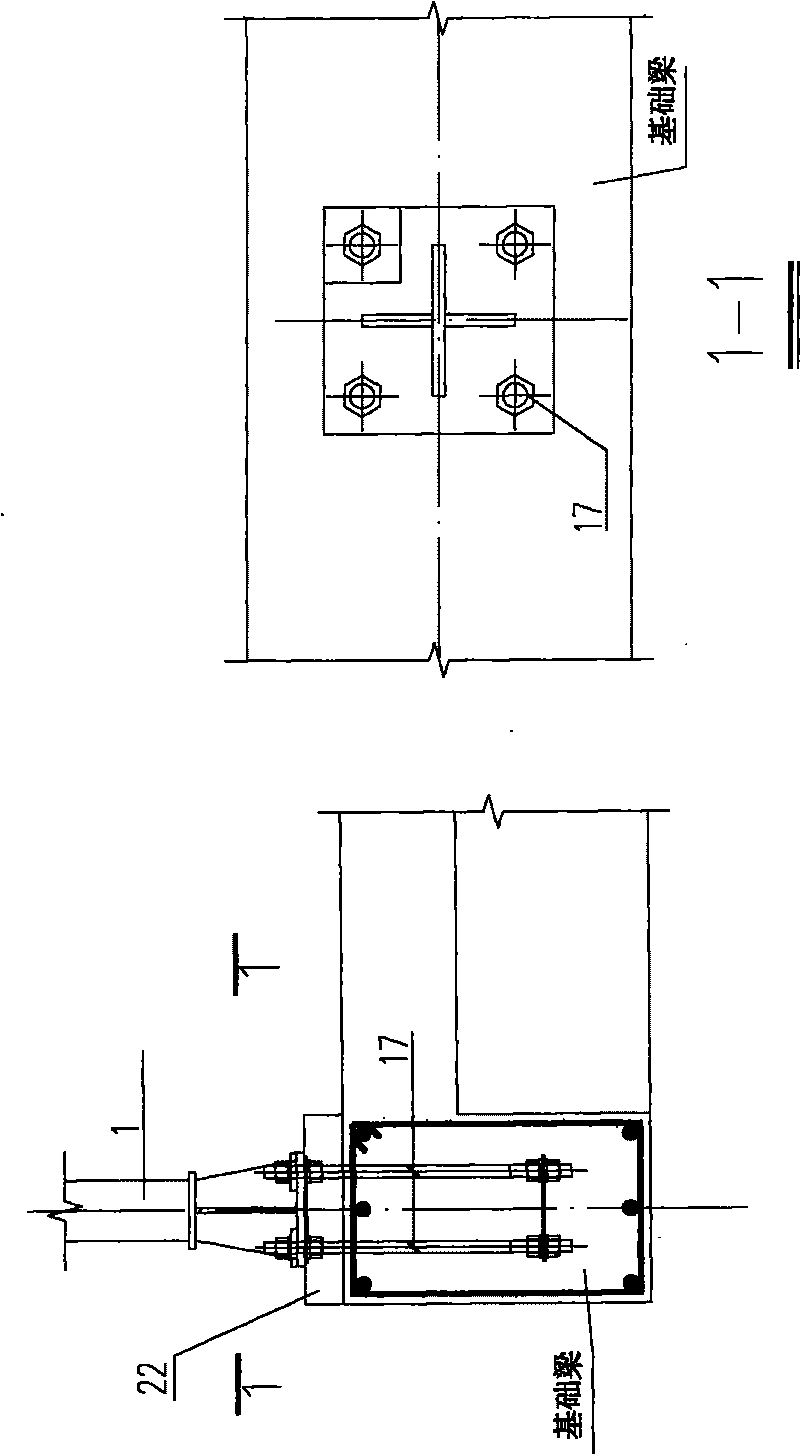

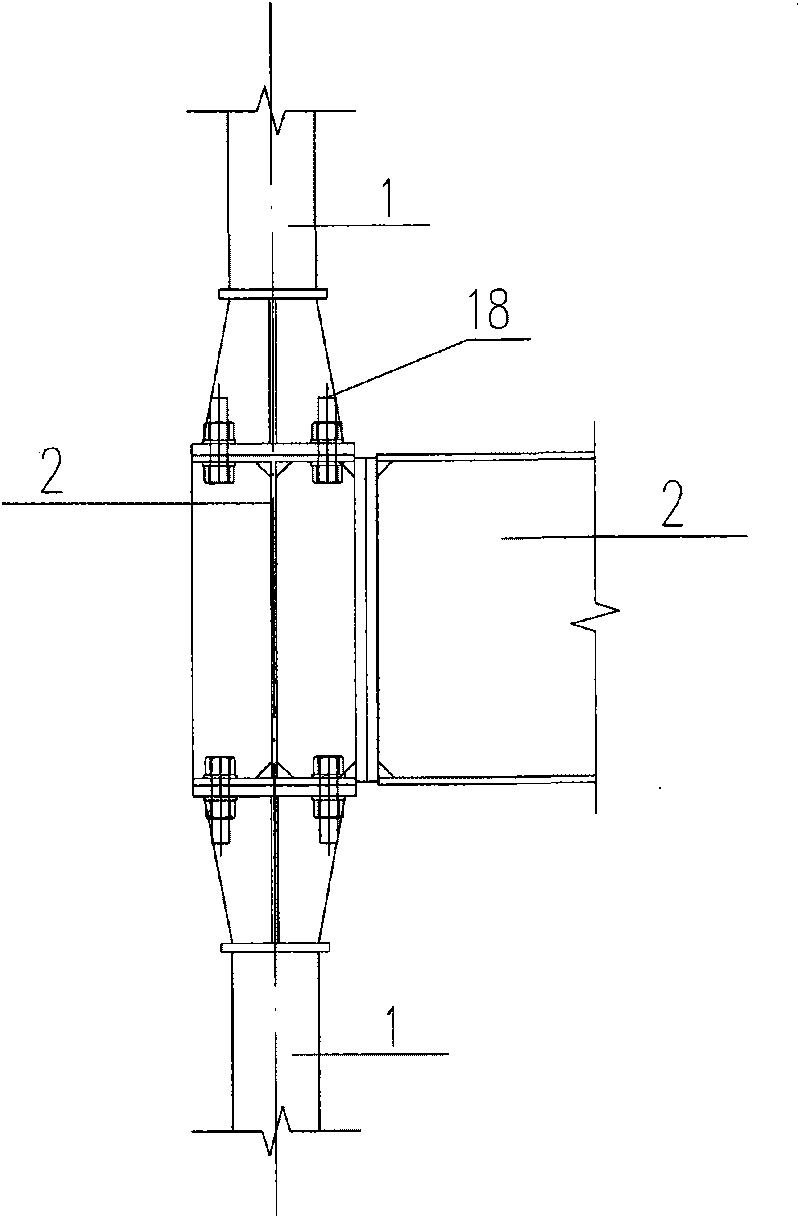

[0057] An industrialized low-rise residential structure system, comprising steel columns 1, steel beams 2, inter-column supports 3, steel beam horizontal supports 4, prefabricated floor slabs or cast-in-place slabs 5, a roof enclosure system, and a wall enclosure system. Such as figure 2 As shown, the steel column 1 and the foundation are connected by anchor bolts 17 . Such as image 3 As shown, the steel column 1 and the steel beam 2 are connected by high-strength bolts. Such as Figure 4 As shown, the steel column 1 and the inter-column support 3 are connected by ordinary bolts, and the inter-column support 3 is set according to calculations to meet the requirements of horizontal loads such as earthquake force and wind load.

[0058] Such as figure 2 As shown, when the steel column 1 is connected to the foundation, in order to improve the pre-embedded precision of the anchor bolt 17, the anchor bolt 17 is precisely positioned with a special fixture. There is also a ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com