Assembly type seismic insulation house structure

A prefabricated and seismic isolation technology, applied in the direction of earthquake resistance and building components, can solve the problems of lack of confidence in the anti-seismic performance of prefabricated structures, low anti-seismic performance of prefabricated structures, and low integrity and rigidity of prefabricated structures, so as to improve anti-seismic Effects on Performance, Seismic Response Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

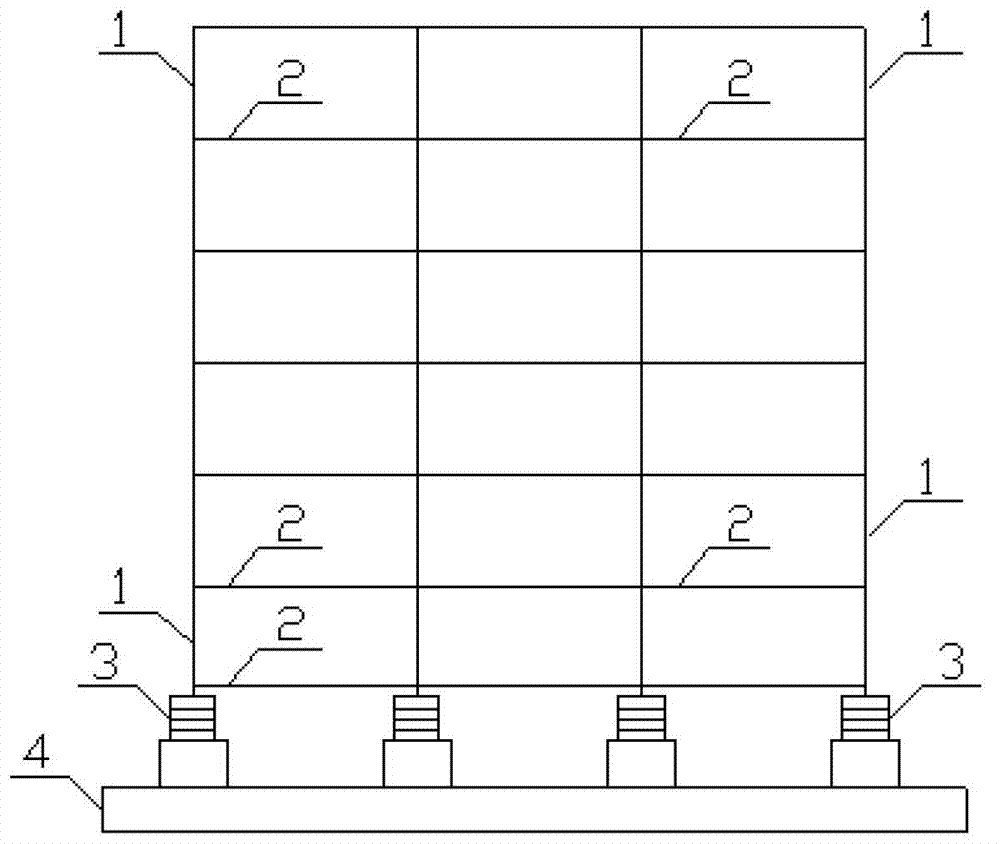

[0024] Such as figure 1 As shown, a seismic isolation support 3 is set between the prefabricated column 1 and the foundation 4 on the ground floor, and the two ends of the seismic isolation support 3 are respectively fixed on the lower end of the prefabricated column 1 and the upper end of the foundation 4 . The vibration-isolation bearing 3 can adopt laminated rubber bearings, lead rubber bearings, sliding bearings or other types of vibration-isolation bearings. A semi-rigid connection is adopted between the prefabricated beam 2 and the prefabricated column 1, and the semi-rigid connection between the prefabricated column 1 and the prefabricated beam 2 refers to reducing the bolt connection, welding connection or prestressed connection between the prefabricated column 1 and the prefabricated beam 2 Connection strength, so that the bending stiffness of the connection is lower than that of the cast-in-place structure, but the connection can still bear a certain bending moment. ...

Embodiment 2

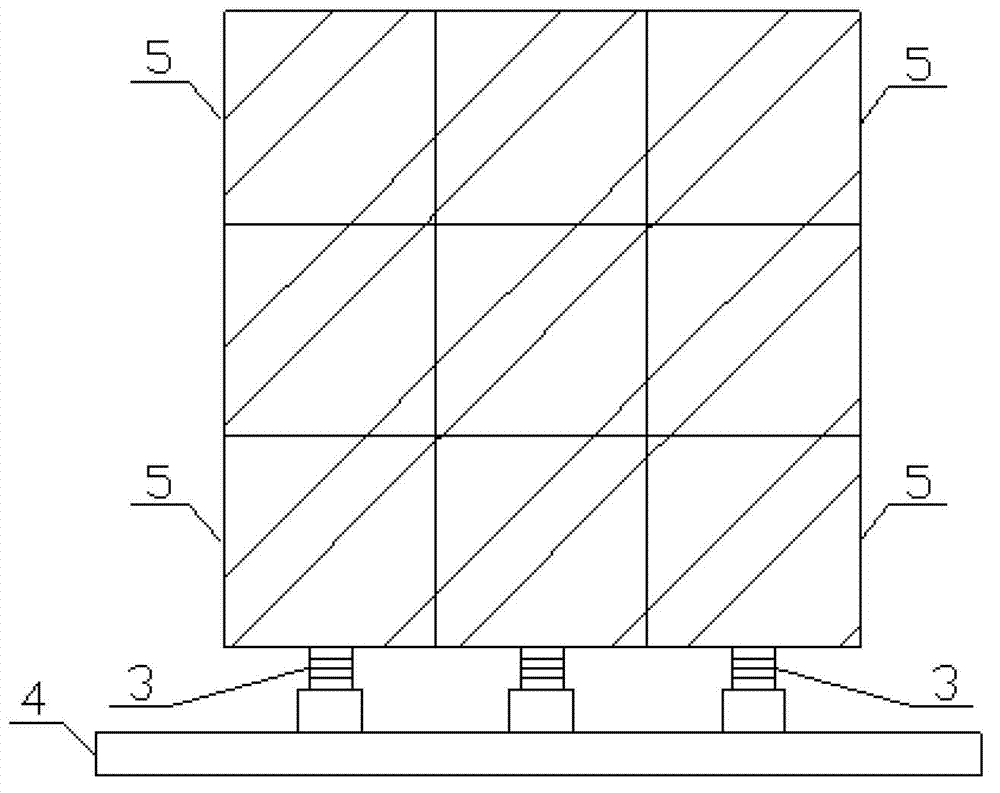

[0026] Such as figure 2 As shown, a seismic isolation support 3 is set between the prefabricated shear wall 5 and the foundation 4 on the ground floor. The vibration-isolation bearing 3 can adopt laminated rubber bearings, lead rubber bearings, sliding bearings or other types of vibration-isolation bearings. The horizontal joints between adjacent prefabricated shear walls 5 are connected by slurry anchors or polygonal shear keys. The vertical joints between adjacent prefabricated shear walls 5 can be connected by polygonal shear keys, welded or bolted, and energy-dissipating elements can be used for the connection of important structures with higher seismic rating requirements. The energy-dissipating element in the present invention refers to an element that can dissipate the energy input to the structure by seismic waves, such as a mild steel damper and the like.

Embodiment 3

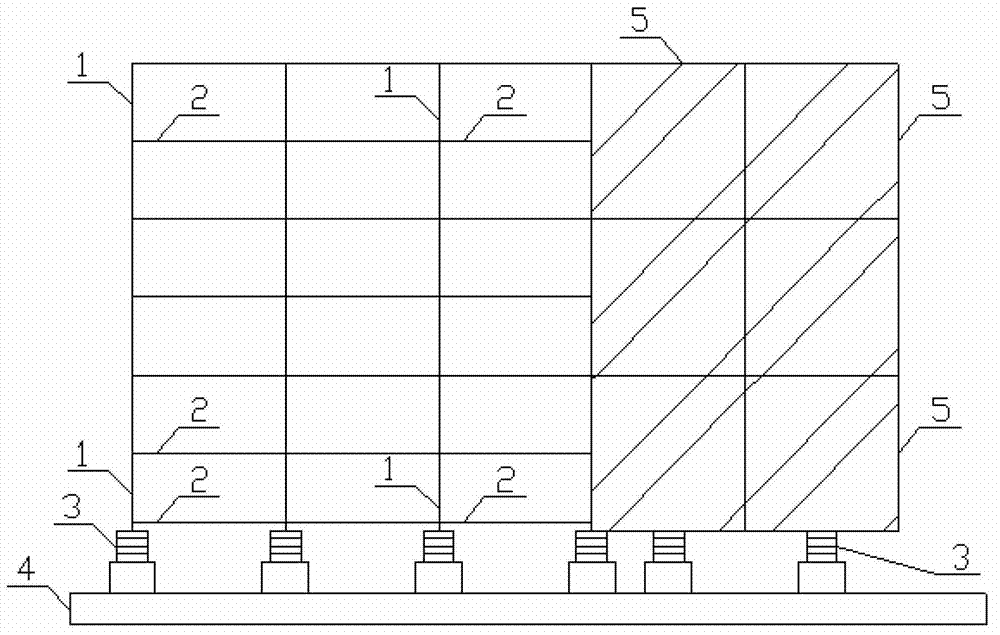

[0028] Such as image 3 As shown, the seismic isolation support 3 is set between the prefabricated column 1, the prefabricated shear wall 5 and the foundation 4 on the ground floor. Connection, the lower end is connected with the upper end of foundation 4 respectively. The vibration-isolation bearing 3 can adopt laminated rubber bearings, lead rubber bearings, sliding bearings or other types of vibration-isolation bearings. The prefabricated beam 2 and the prefabricated column 1 are connected by a hinge, and the hinged connection between the prefabricated column 1 and the prefabricated beam 2 refers to reducing the connection strength of the bolt connection, welding connection or prestressed connection between the prefabricated column 1 and the prefabricated beam 2 , so that the bending stiffness of the connection is much lower than that of the semi-rigid connection, so that the connection can bear axial force and shear force, but cannot bear bending moment. The connection b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com