Novel integrated valve chamber cover

A new type of integrated valve technology, applied in the direction of engine components, machines/engines, shells, etc., can solve the problems of difficult control of installation accuracy, long size chain, and insufficient compact structure, and achieve easier control of installation accuracy, simplified assembly procedures, and size The effect of chain shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] specific implementation

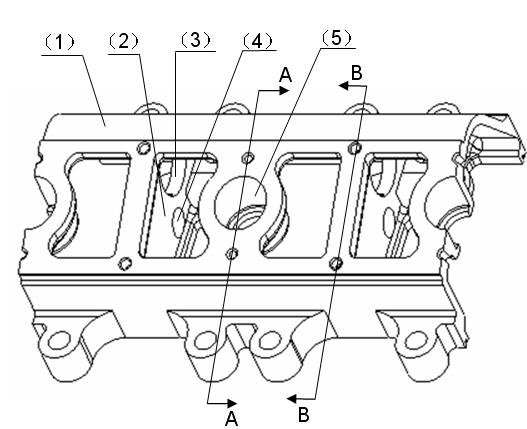

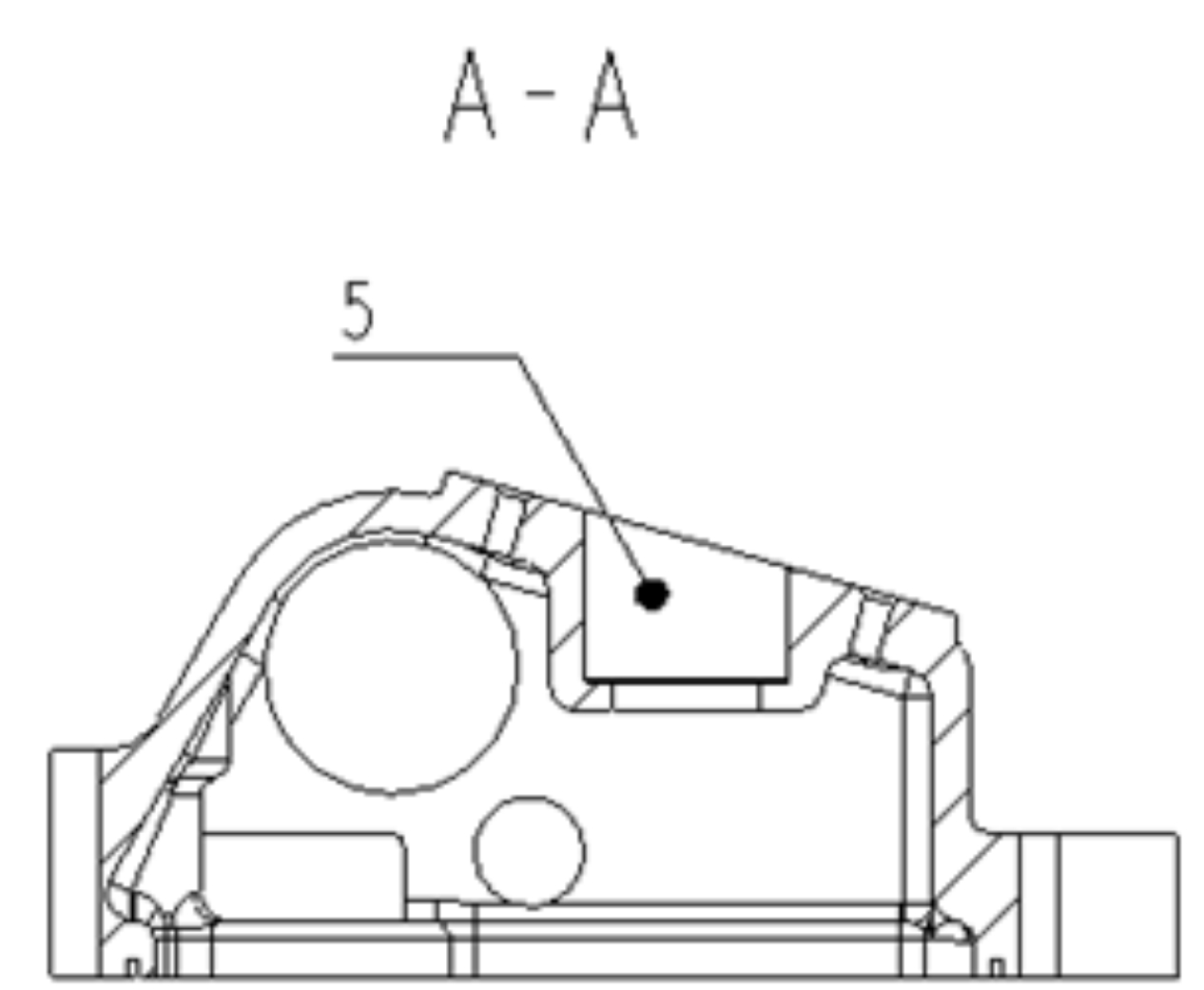

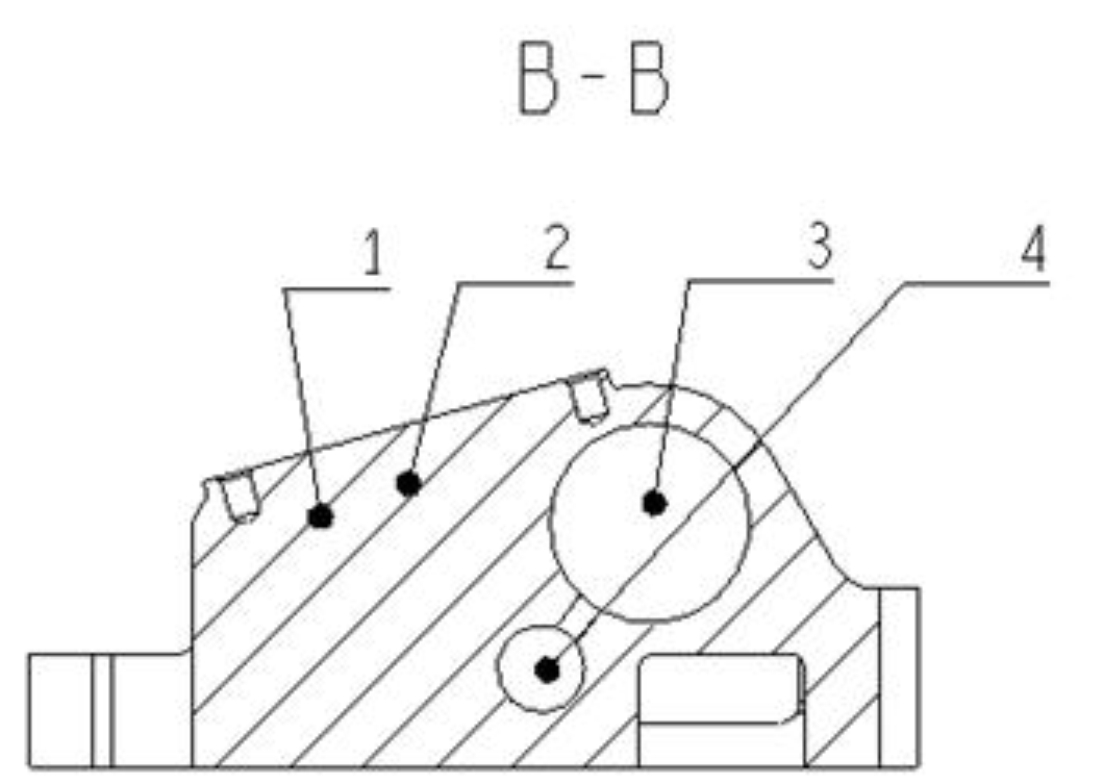

[0011] A new type of integrated valve chamber cover, which includes a cover body 1, on which at least a camshaft installation hole 3, an intake rocker shaft installation hole 4 and a fuel injector installation hole 5 are provided, the cover The inside of the body 1 is provided with a first partition 2 and a second partition 2, and the camshaft installation hole 3 and the intake rocker shaft installation hole 4 are respectively arranged on the first partition 2 and the second partition 2, and the camshaft The installation hole 3 is arranged on the upper part of the intake rocker shaft installation hole 4 , and the fuel injector installation hole 5 is arranged on the second partition plate 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com