Patents

Literature

31results about How to "Shorten the dimensional chain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flashlight component and electronic equipment

ActiveCN104614918AShorten the dimensional chainImprove assembly accuracyPhotographyElectricityPrinted circuit board

The invention discloses a flashlight component and electronic equipment. The flashlight component comprises a rear shell component, a flashlight, a flashlight shade and a flashlight circuit board, the flashlight shade is fixed on the rear shell component, the flashlight is fixed on the flashlight circuit board, and the flashlight circuit board is fixed on the rear shell component and in electric contact with a main circuit board. Through fixing the flashlight shade on the rear shell component, fixing the flashlight on the flashlight circuit board, fixing the flashlight circuit board on the rear shell component and enabling the flashlight circuit board to electrically contact with the main circuit board, the flashlight and flashlight shade assembly dimension chain is shortened, the assembly precision thereof is improved, and the deviation phenomenon is avoided.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

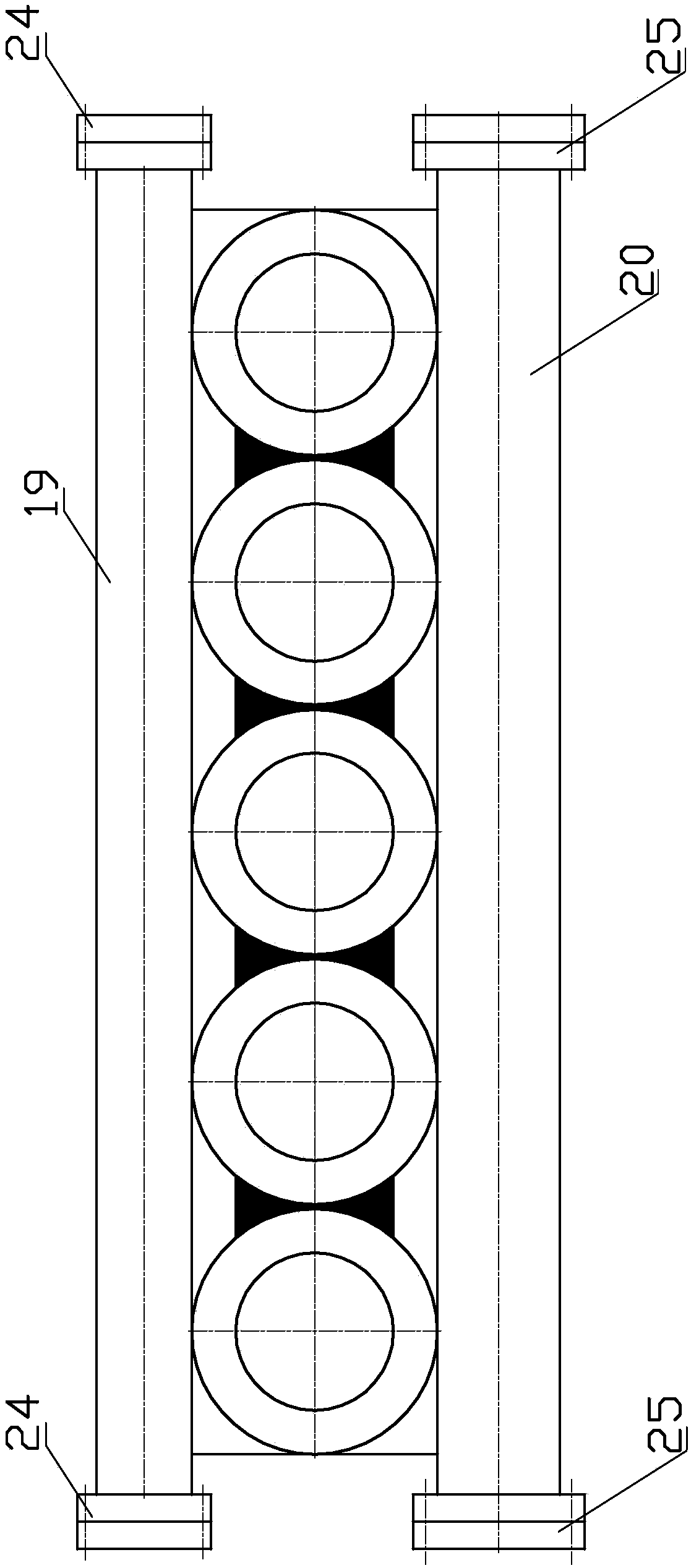

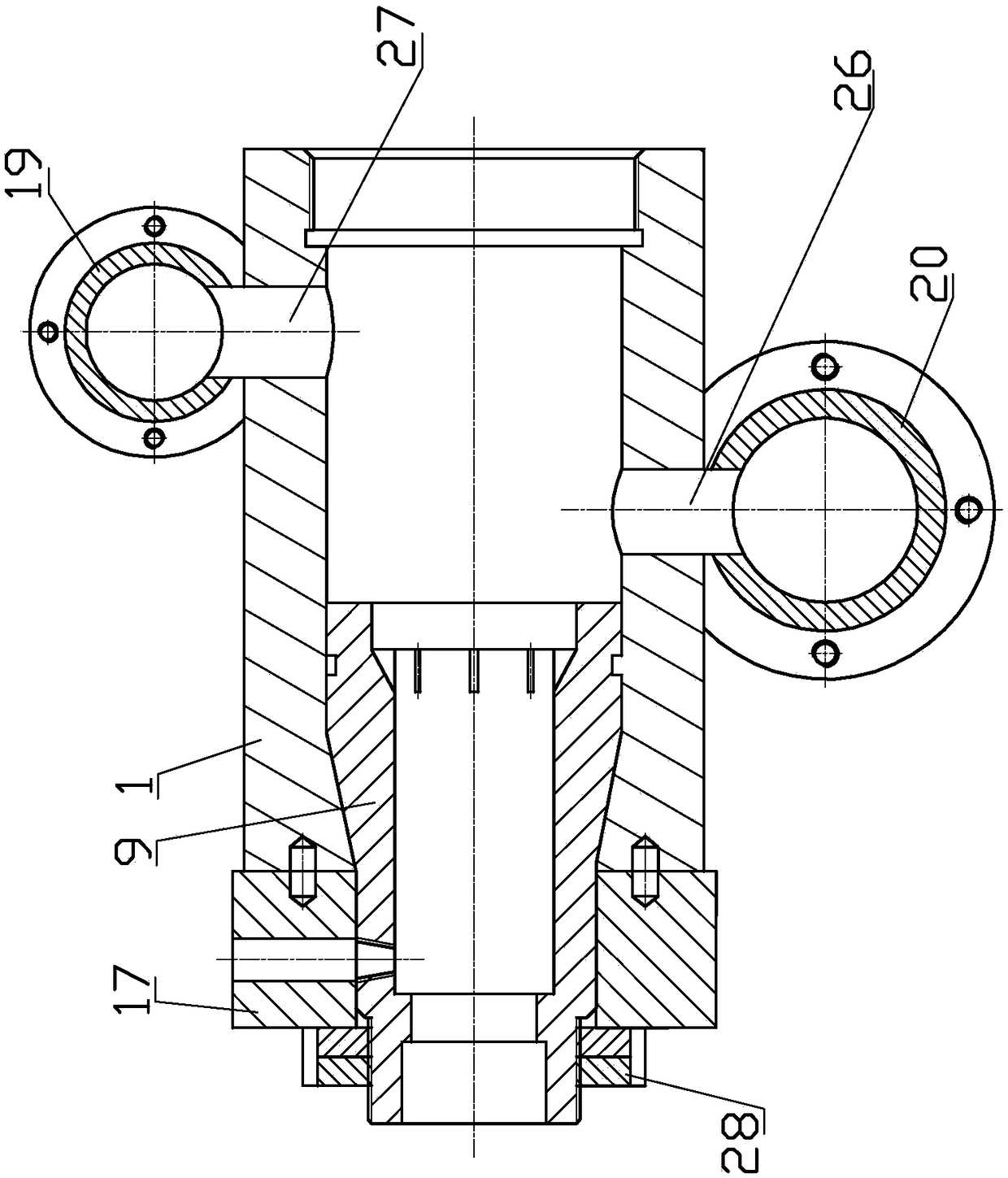

Travelling mechanism of wall-climbing robot

InactiveCN107444512AStrong ability to overcome obstaclesReduce typesPhotovoltaicsPhotovoltaic energy generationComputer moduleClosed loop

The invention provides a travelling mechanism of a wall-climbing robot. The travelling mechanism is characterized by comprising a plurality of suction foot modules and travelling transmission devices; the travelling transmission devices comprise two closed-loop arc-shaped guide rails, rectangular thread lead screws, guide sliding blocks and transmission rollers, wherein the two closed-loop arc-shaped guide rails are arranged symmetrically relative to the central point, and the transmission rollers are arranged at the front ends of the traveling transmission devices and matched with threads on the rectangular thread lead screws; each suction foot module is fixedly connected with the corresponding guide sliding bock; and every two adjacent guide sliding blocks are mutually hinged, the guide sliding blocks are uniformly distributed on the closed-loop arc-shaped sliding rails, and each guide sliding block is slidably connected with the corresponding closed-loop arc-shaped guide rail. Compared with the prior art, the travelling mechanism of the wall-climbing robot can travel and operate on a smooth work face, can further adapt to work faces with bulge obstacles and large cracks and has good obstacle crossing capacity.

Owner:SIASUN CO LTD

Fluid end of culvert body and pump body and machine body series combined structure

PendingCN108278201AReduce crackingShorten the lengthPositive displacement pump componentsLiquid fuel engine componentsIntegrated designEngineering

The invention discloses a fluid end of a culvert body and pump body and machine body series combined structure. The fluid end is characterized in that a culvert body of the fluid end is located in aninner cavity of a pump body by a conical surface; male threads are formed in the tail end of the culvert body; the pump body is fixed to a machine body stand plate through a splicing cap connected tothe male threads; a combined valve comprises a valve seat provided with a front valve face and a rear valve face, the valve seat is arranged in the inner cavity of the pump body and is bonded with theend face of the culvert body for forming a working cavity; a liquid inlet valve core is arranged on the rear valve face of the valve seat; a liquid inlet spring and a self-sealing adjusting spring ofa filling are integrated; and a draining valve core and a draining spring are arranged on the front valve face of the valve seat. The fluid end adopts culvert body and liquid inlet valve integrated design, so that the length of the pump body is reduced, parts and components are simplified, the useless volume is reduced, the pump efficiency is improved, the cost is reduced, and the lightweight design requirement is met.

Owner:NINGBO HELI MECHANICAL PUMP CO LTD

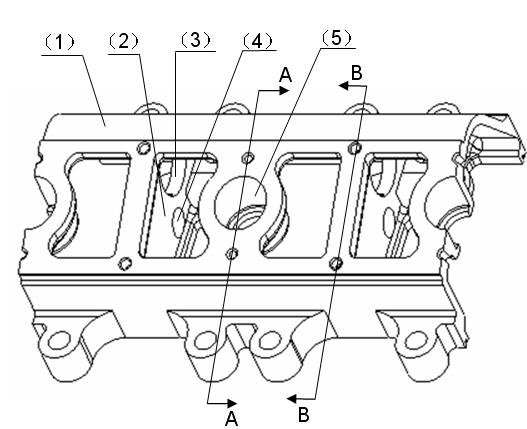

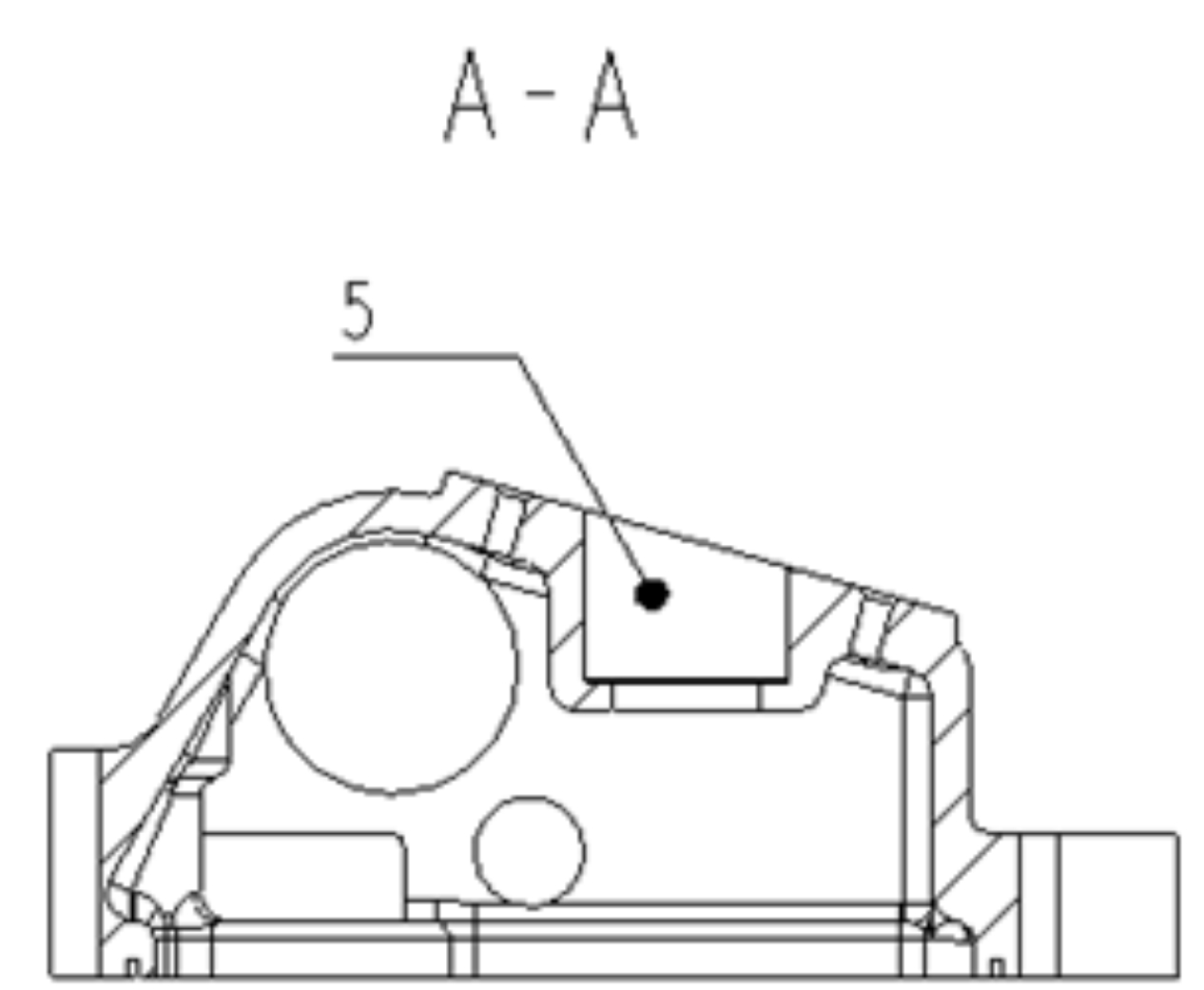

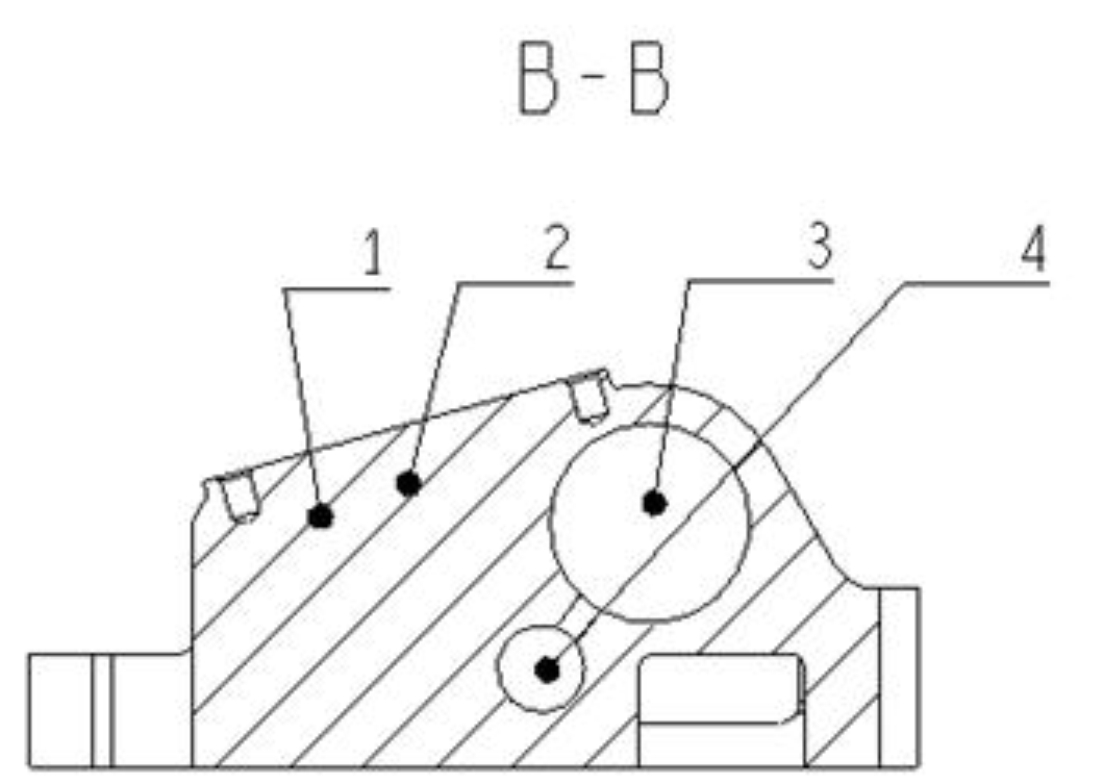

Novel integrated valve chamber cover

The invention relates to a novel integrated valve chamber cover. The novel valve chamber cover comprises a cover body (1), wherein at least one camshaft installing hole (3), an air intake rockshaft installing hole (4) and an oil sprayer installing hole (5) are formed in the cover body (1); a baffle plate (2) is arranged inside the cover body (1); the camshaft installing hole (3) and the air intake rockshaft installing hole (4) are formed in the baffle plate (2); the camshaft installing hole (3) is formed on the upper part of the air intake rockshaft installing hole (4); and the oil sprayer installing hole (5) is formed on the top of the cover body (1). The novel integrated valve chamber cover has the advantages that the novel integrated valve chamber cover has a compact structure; a few parts are required to be assembled, so that an assembling process can be simplified; a dimensional chain is shortened, so that installation precision is easy to control compared with that of the conventional structure; and a camshaft and an oil sprayer are convenient to disassemble and can be removed without the removal of related parts such as the valve chamber cover.

Owner:NO 70 INST OF CHINA NORTH IND GRP

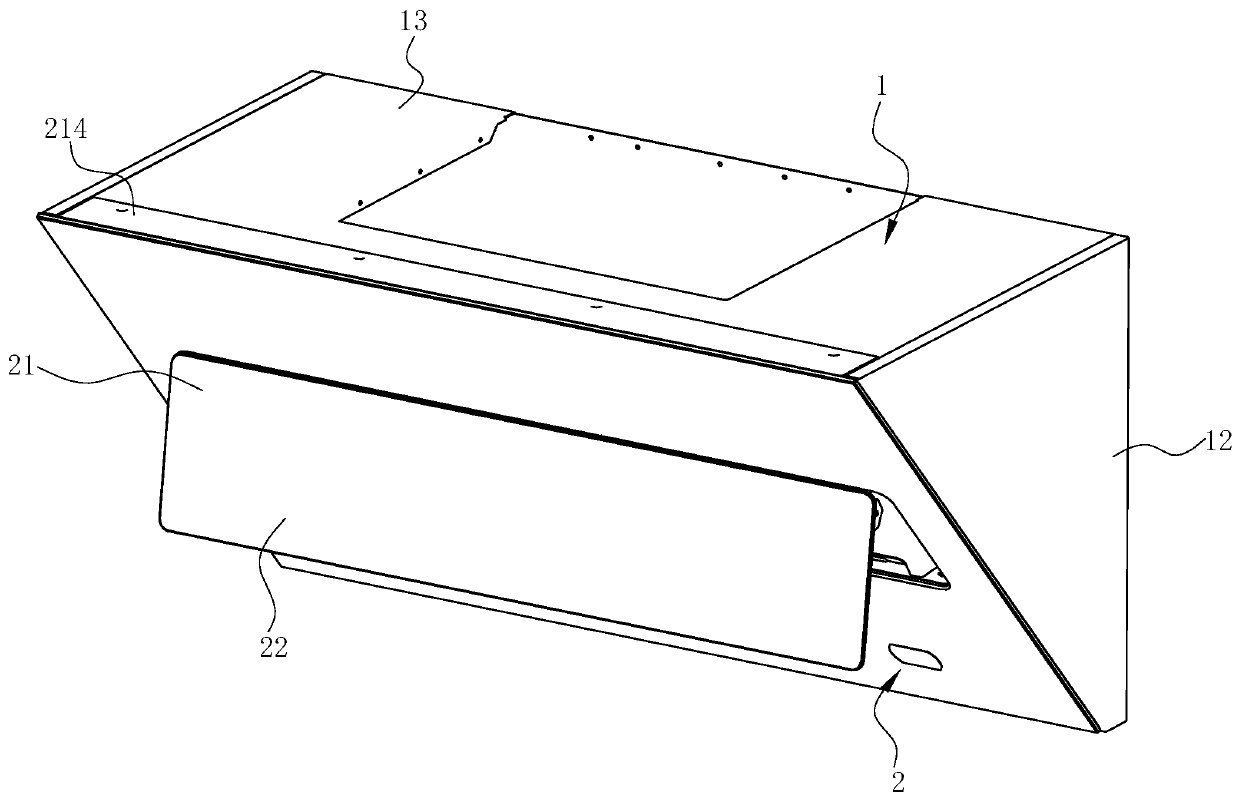

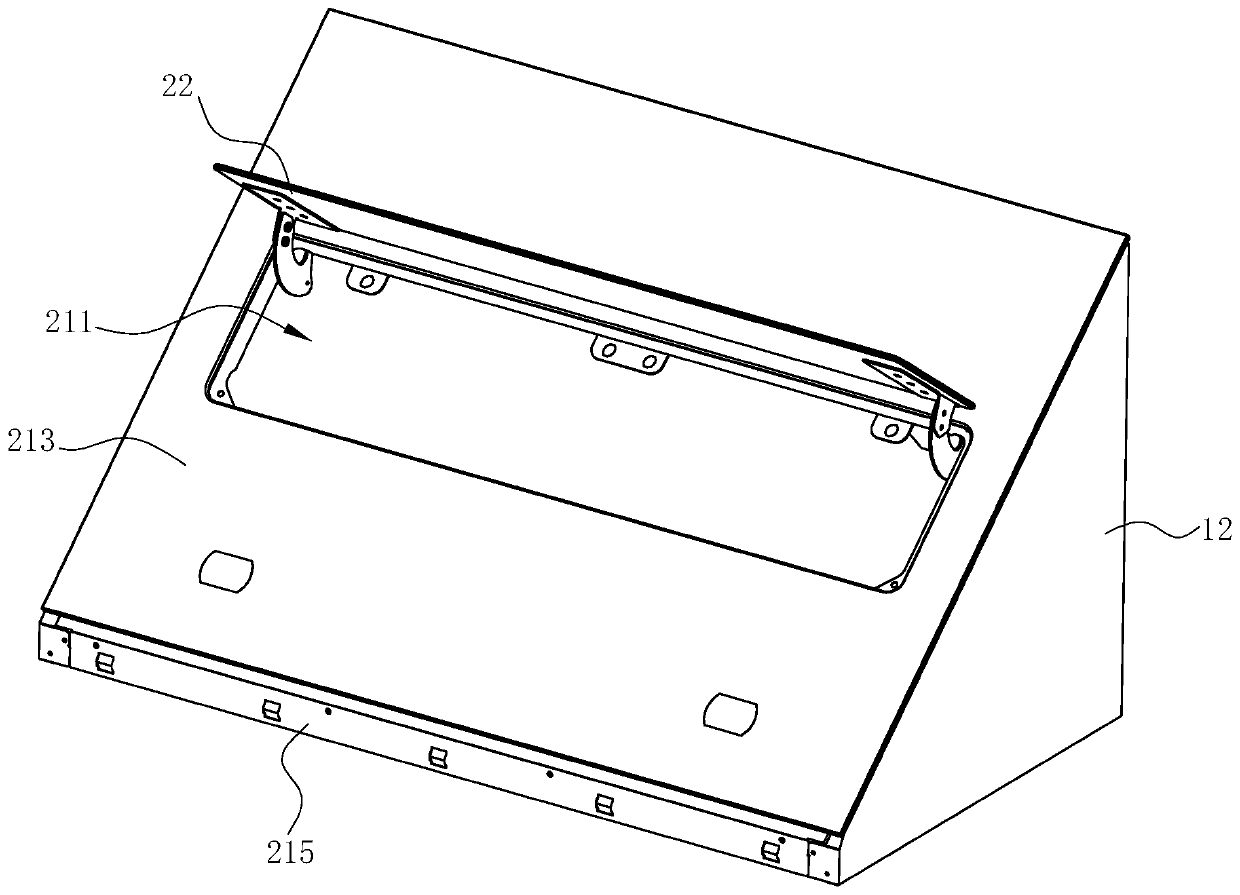

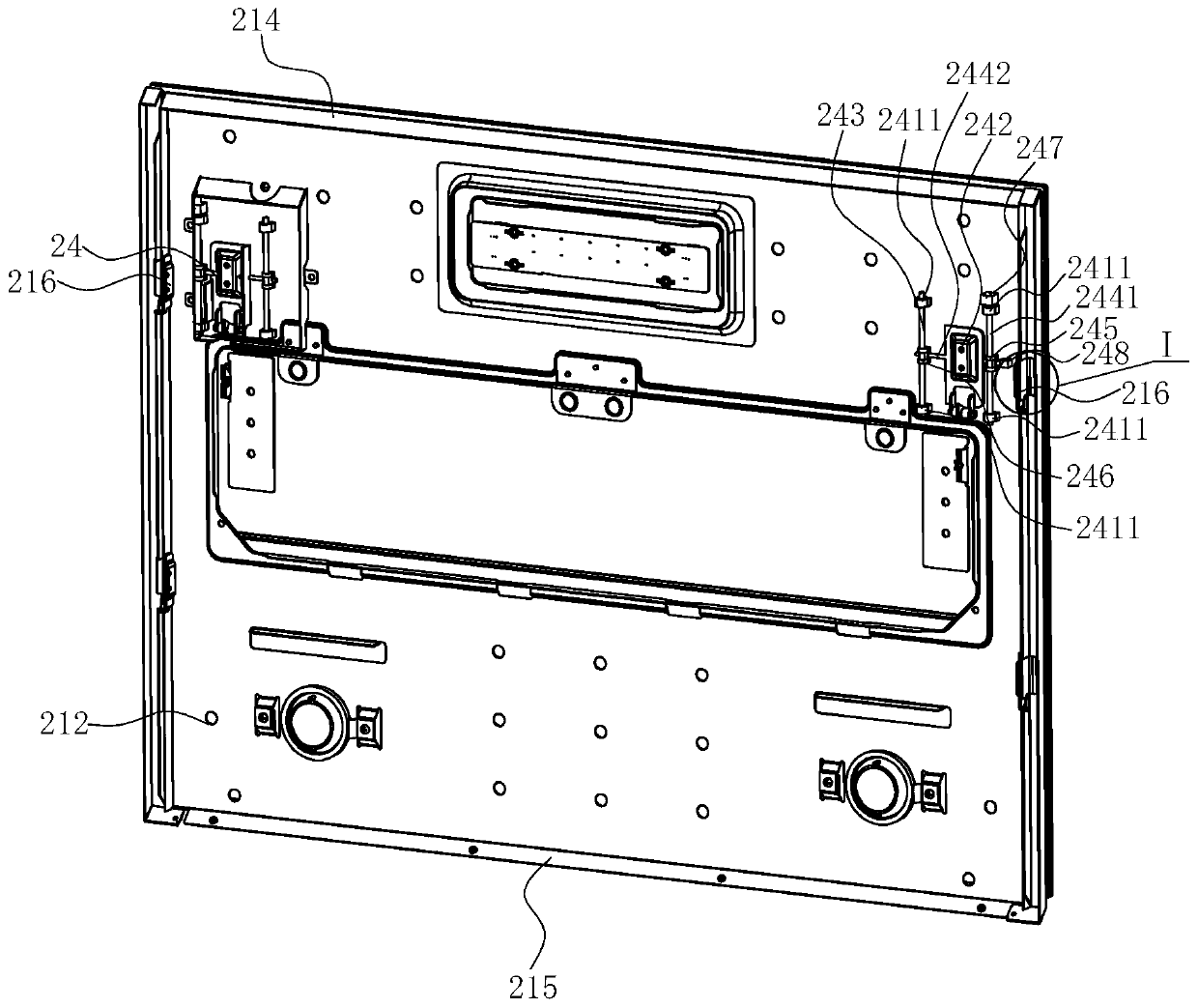

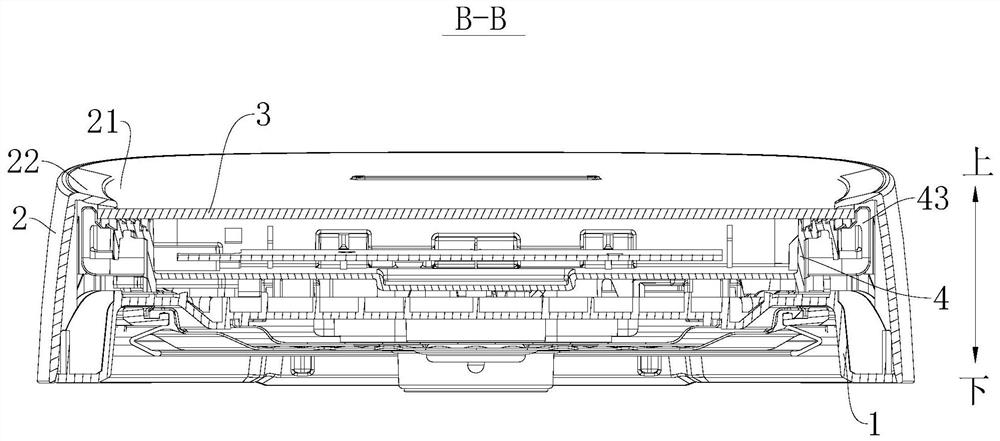

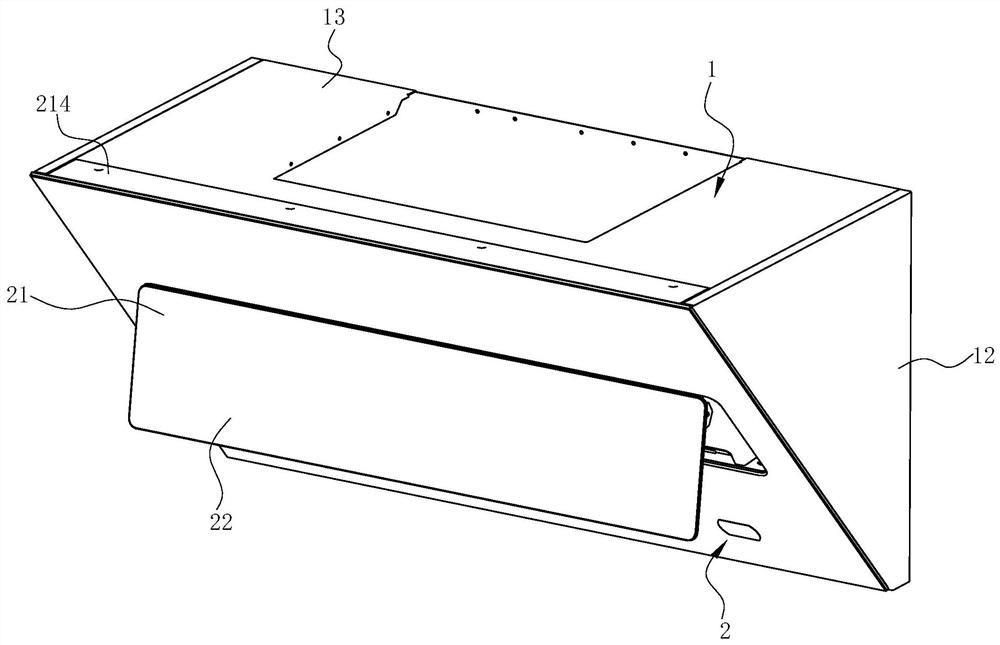

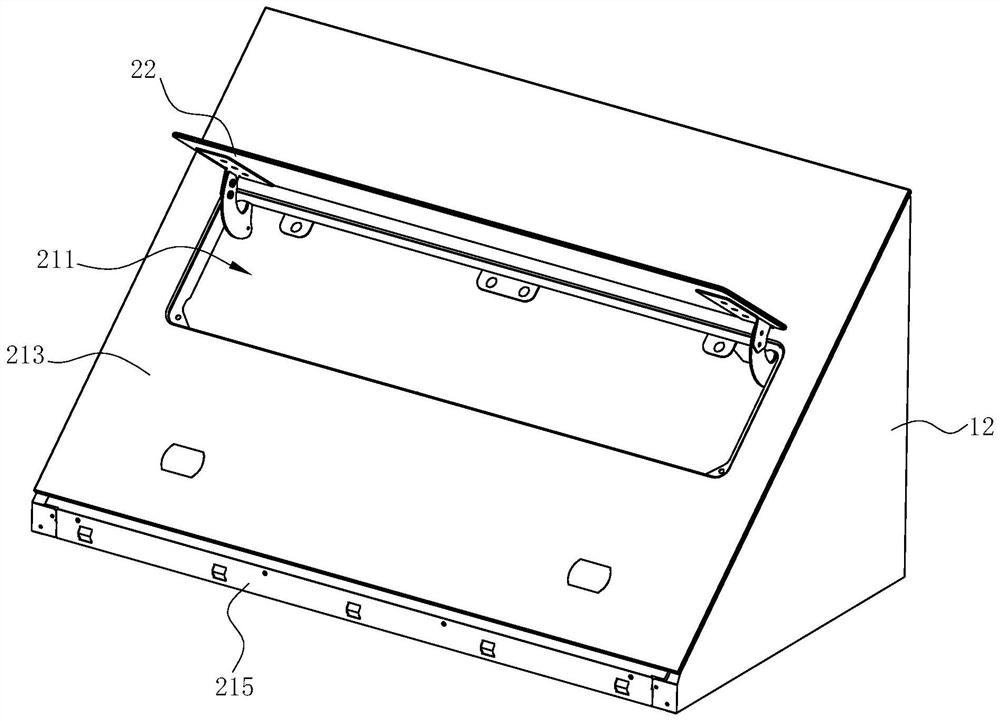

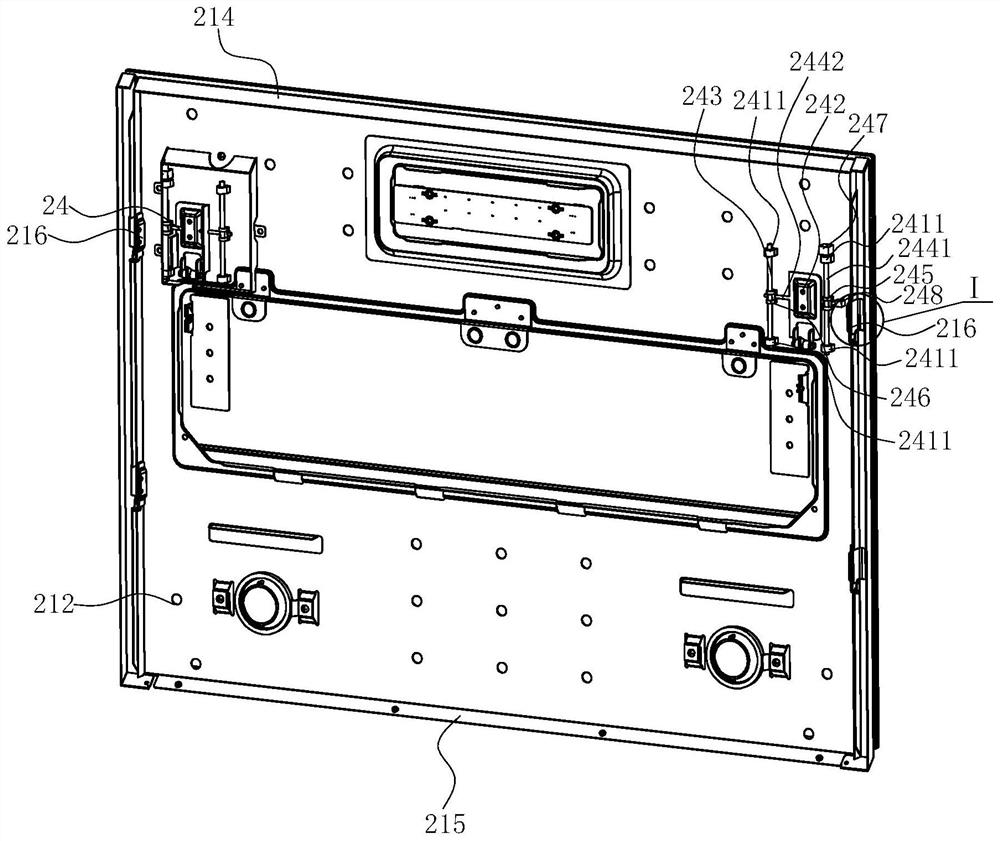

Side suction-type range hood and gap adjusting method thereof

ActiveCN111380092AEffective control clearanceGuaranteed clearanceDomestic stoves or rangesLighting and heating apparatusFastener

The invention discloses a side suction-type range hood. The side suction-type range hood comprises a housing and a panel assembly arranged at the front side of the housing; the panel assembly includesa panel and a smoke barrier arranged on the panel. The side suction-type range hood is characterized in that the panel includes a first fixing portion arranged at the top part and bent backwards, anda second fixing portion arranged at the bottom part and bent backwards; and the first fixing portion and the second fixing portion are both connected with and fixed to the housing. The invention further discloses a gap adjusting method of the side suction-type range hood. Compared with the prior art, the side suction-type range hood has the advantages that gaps at upper and lower connection positions of the panel assembly and the housing can be effectively controlled by forming the fixing portions, fixed to the housing, at the top part and the bottom part of the panel respectively by bending;gaps at left and right connection positions of the panel assembly and the housing can be effectively controlled by installing sliding fasteners and foam strips, fitting in with a left side plate anda right side plate of the housing, at the left side and the right side of the panel.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

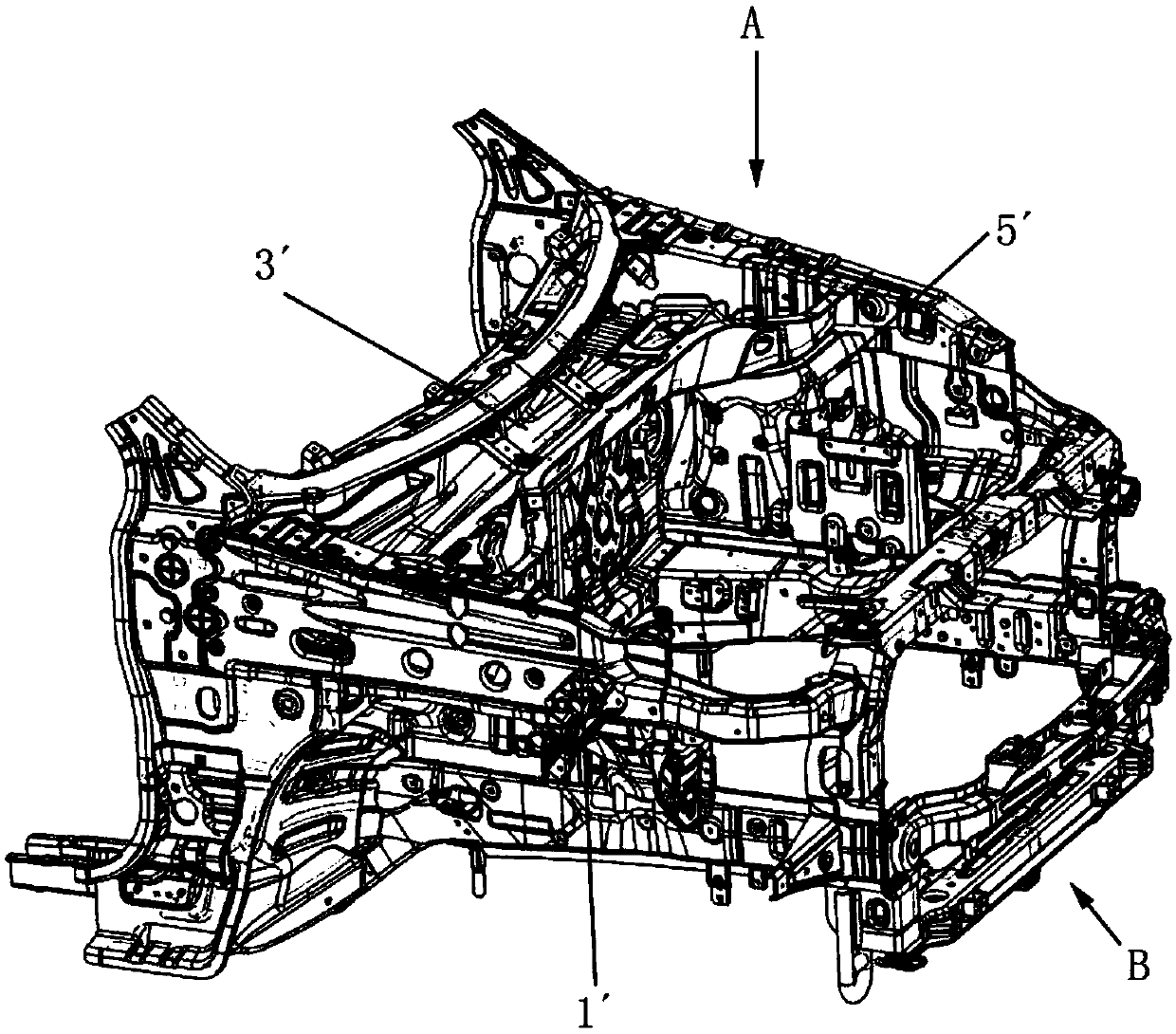

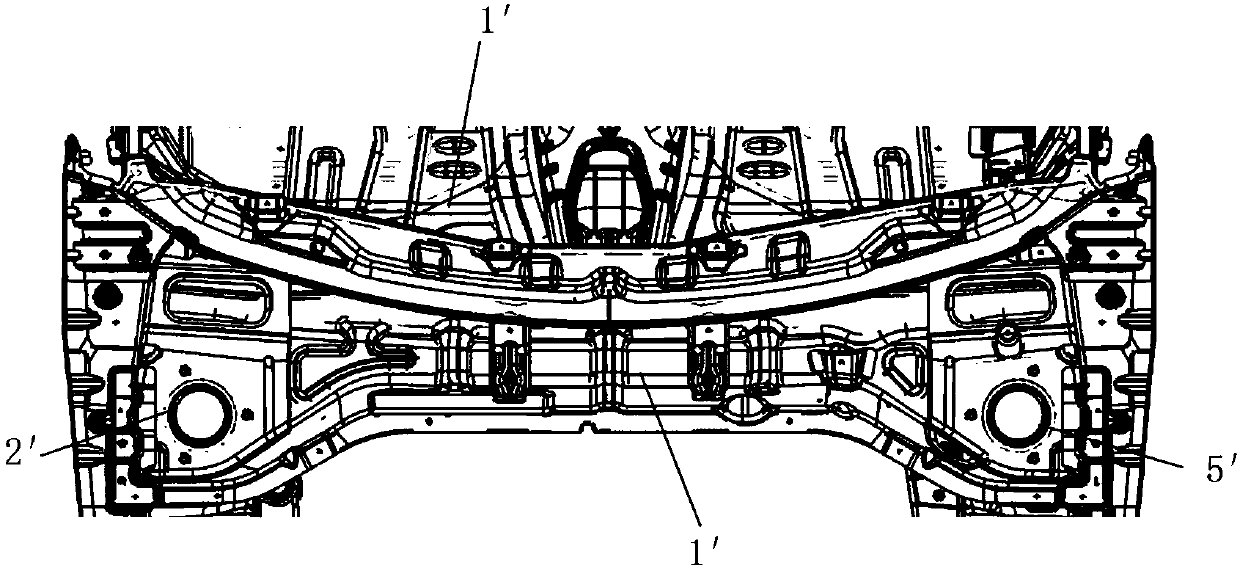

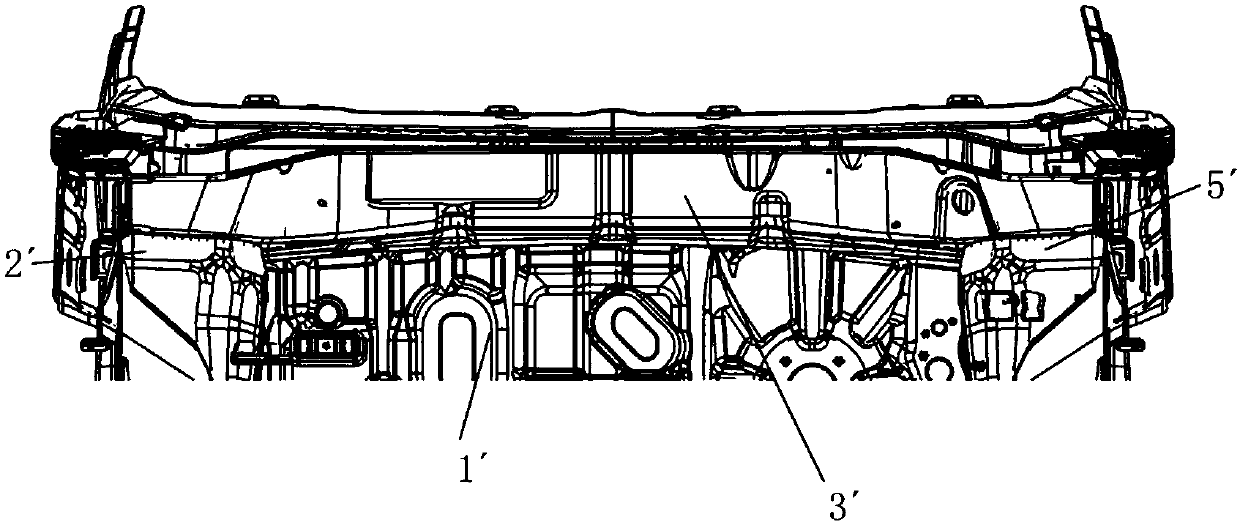

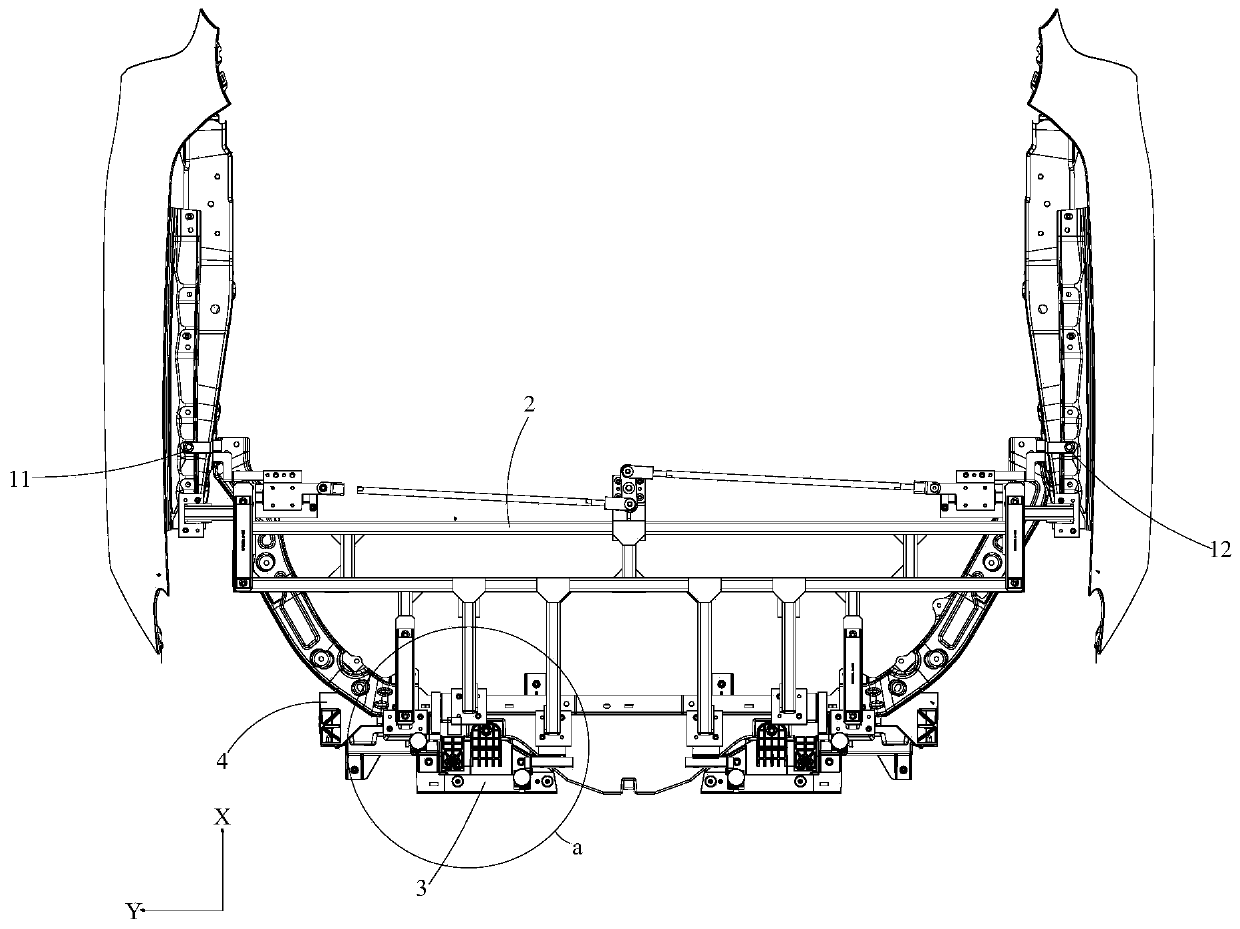

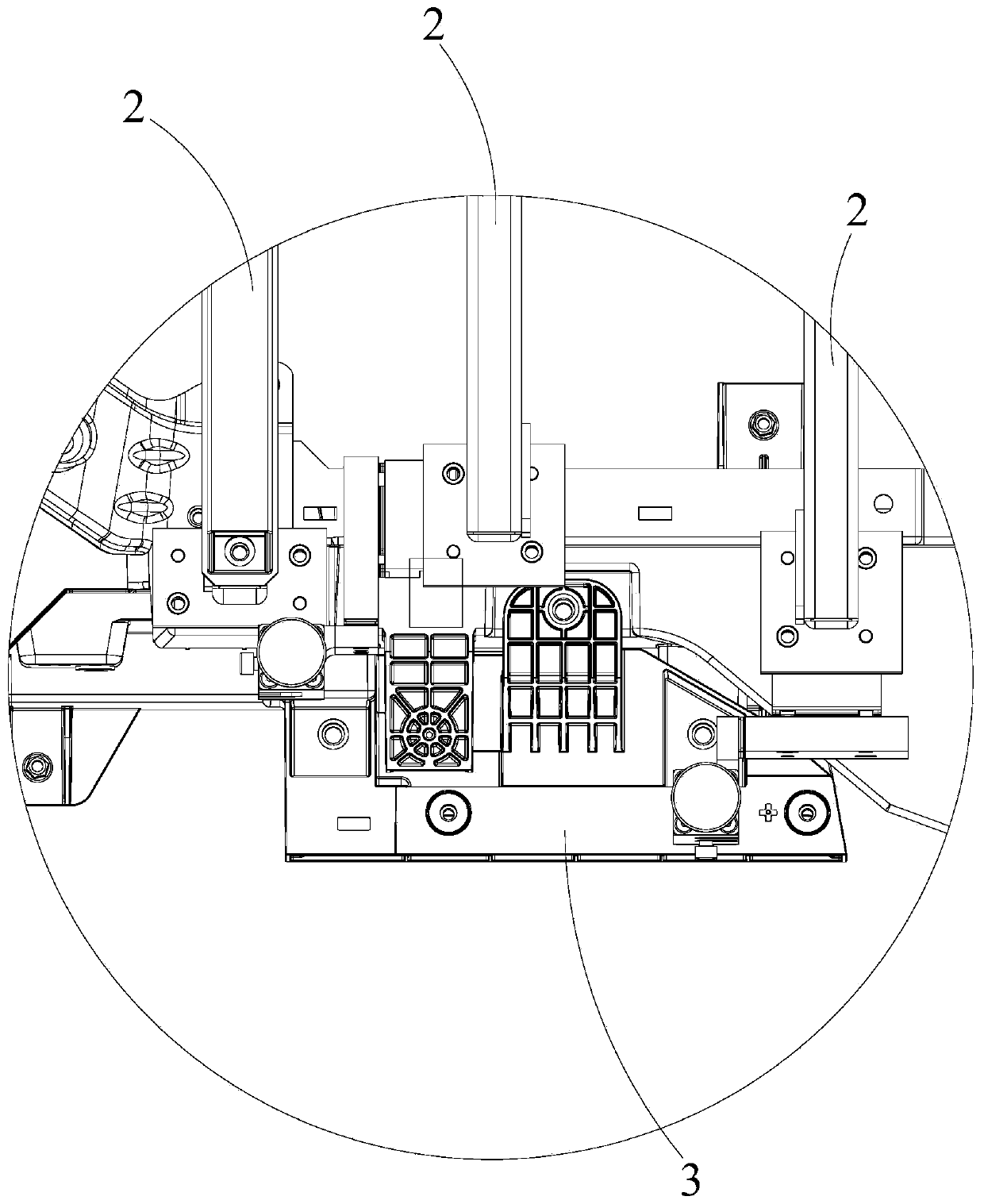

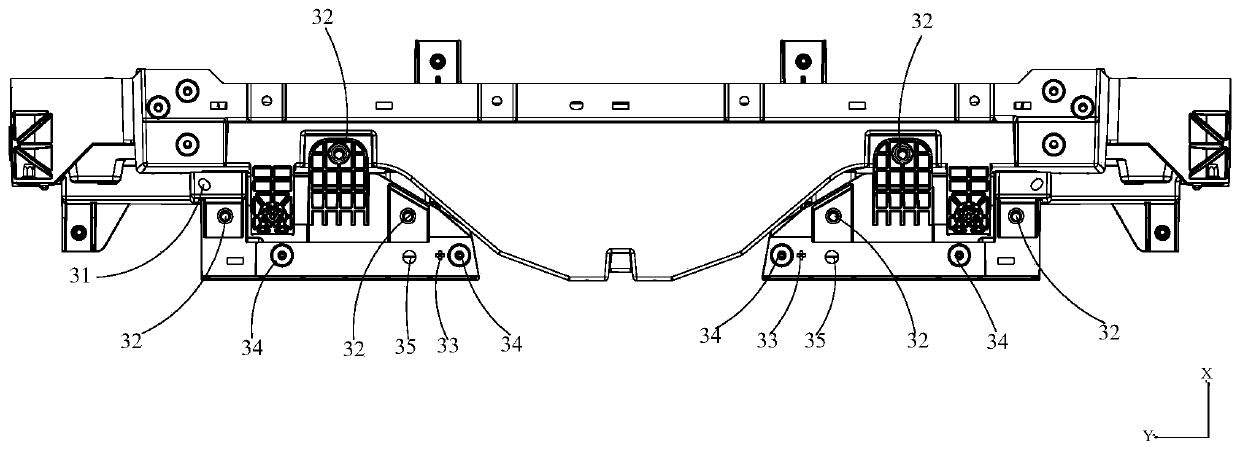

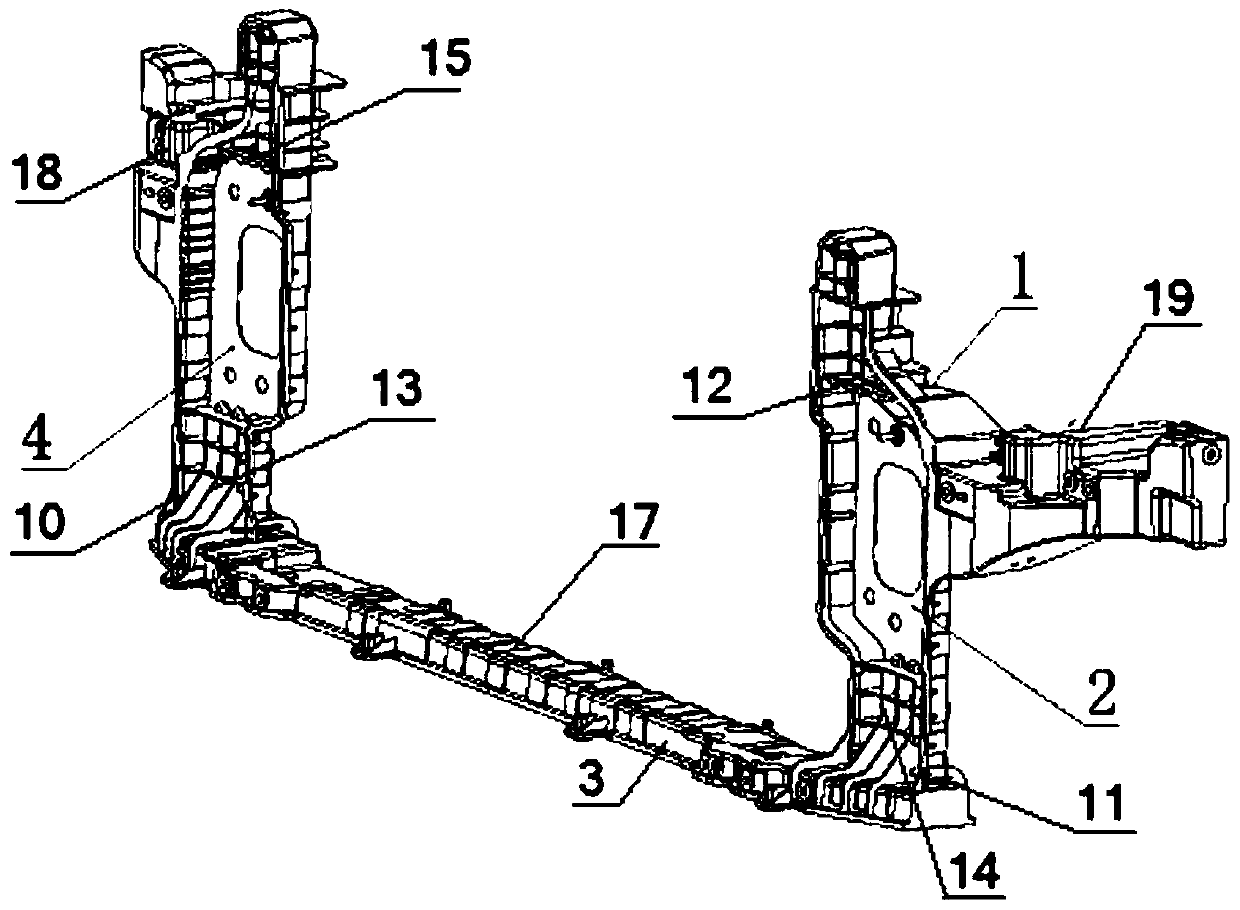

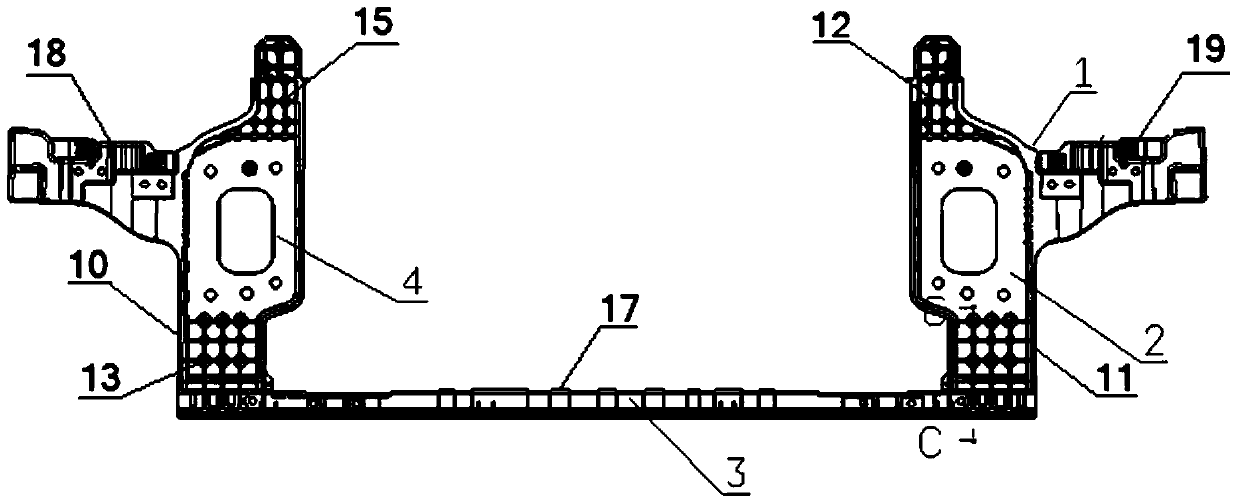

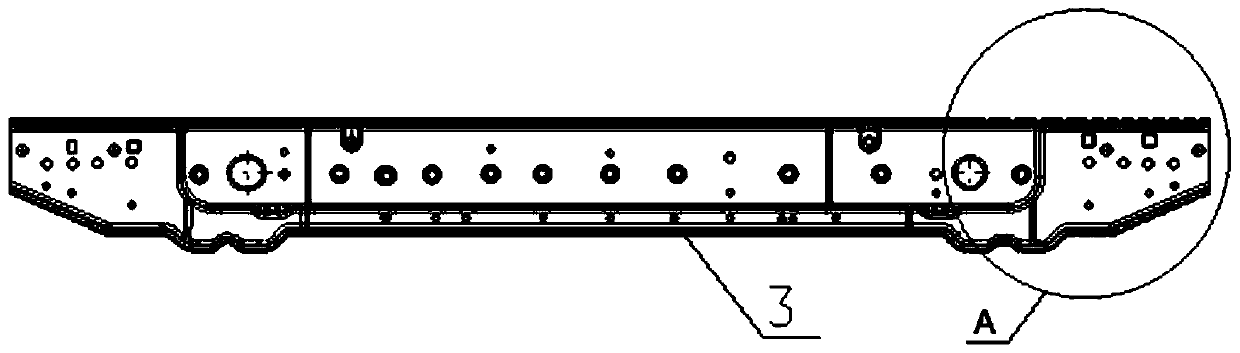

Front partition plate lower mounting plate and cross beam assembly

PendingCN110466620AIncreased torsional stiffnessSimple structureSuperstructure subunitsTorsional rigidityAerospace engineering

The invention discloses a front partition plate lower mounting plate and cross beam assembly, which comprises a front partition plate lower mounting plate and a cross beam. The front partition plate lower mounting plate comprises a partition plate horizontal wall, a first vertical wall and a second vertical wall; the first vertical wall and the second vertical wall horizontally extend upwards to be fixed to the front side and the rear side of the partition plate horizontal wall correspondingly; and the cross beam is horizontally fixed to the front side of the upper surface of the partition plate horizontal wall, and a front hoarding is fixed to the rear end of the second vertical wall. According to the front partition plate lower mounting plate and cross beam assembly, the overall rigidityof a front partition plate lower mounting part is effectively improved, the overall torsional rigidity of an engine cabin is increased, thus the overall torsional rigidity of an engine in the Y direction is increased to from 15415 Nm to 16503 Nm, and the torsional rigidity is increased by about 7%.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

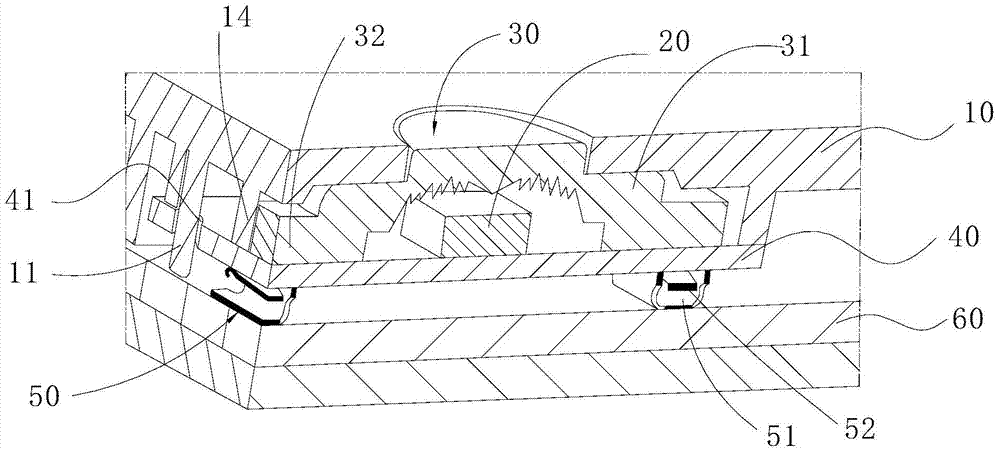

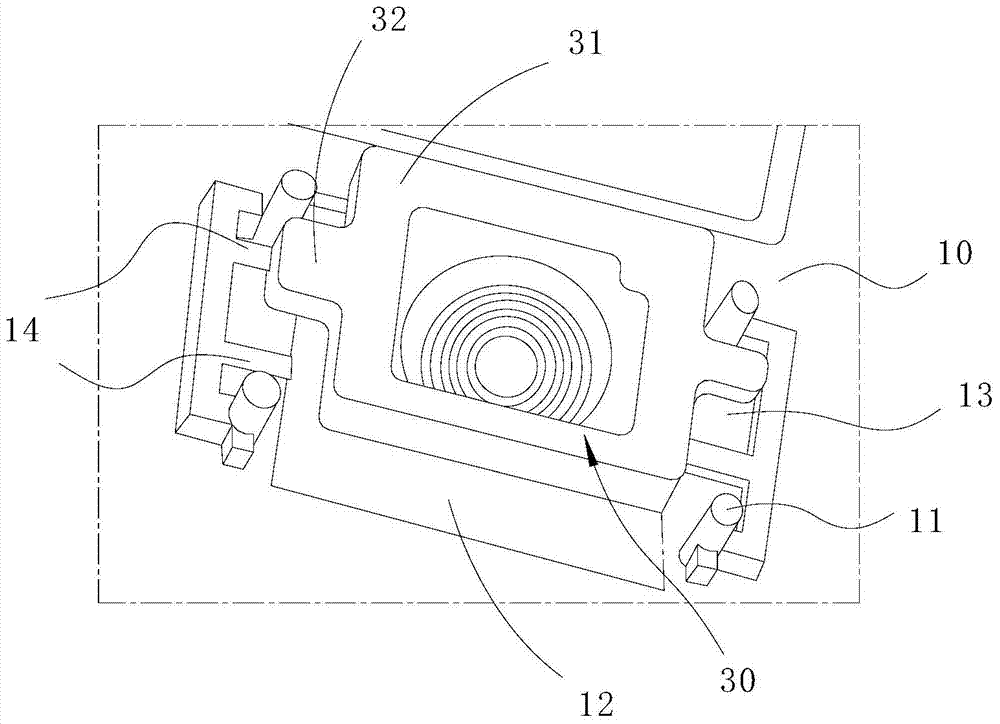

Driving device, transmission device and power tool for linear motion

The invention discloses a driving device, a transmission device and a power tool for linear motion. The driving device comprises a power source, an actuator and a transmission part driven by the powersource to reciprocate linearly, the transmission part comprises an input part, a support part and an output part, a first sliding groove is formed in one of the input part and the support part, a shaft hole is formed in the other one of the input part and the support part, a second sliding groove or a circular hole is formed in the position of the output part, a driving shaft driven by the powersource to reciprocate linearly is arranged in one of the first sliding groove and the shaft hole, a fixed support shaft is arranged in the other one of the first sliding groove and the shaft hole, a driven shaft connected with the actuator is arranged in the second sliding groove or the circular hole, and all shafts are parallel to each other. According to the scheme, when the power source drivesthe transmission part, the shafts can move in the first sliding groove, so that the rotation of the transmission part is not restricted, the second sliding groove always exerts downward pressure or upward lifting force on an output shaft, the impact on the actuator can be reduced, the vibration of the actuator is reduced, and the impact strength is increased.

Owner:苏州品匠机电技术有限公司

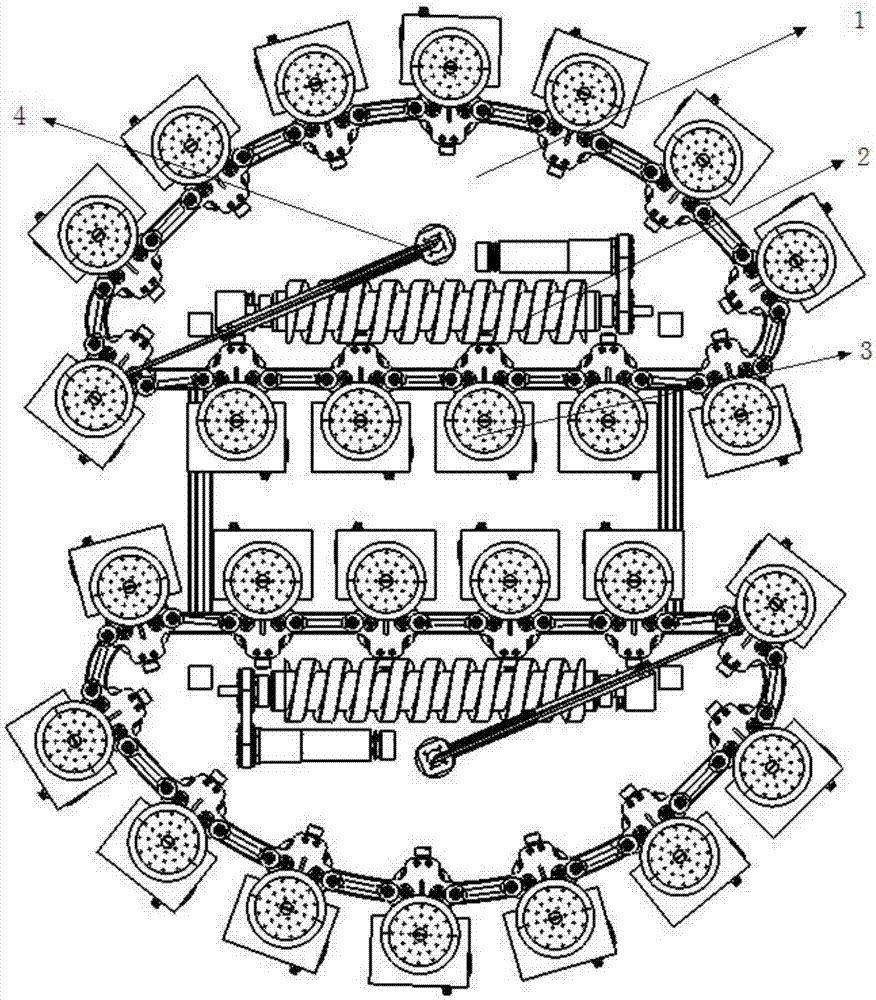

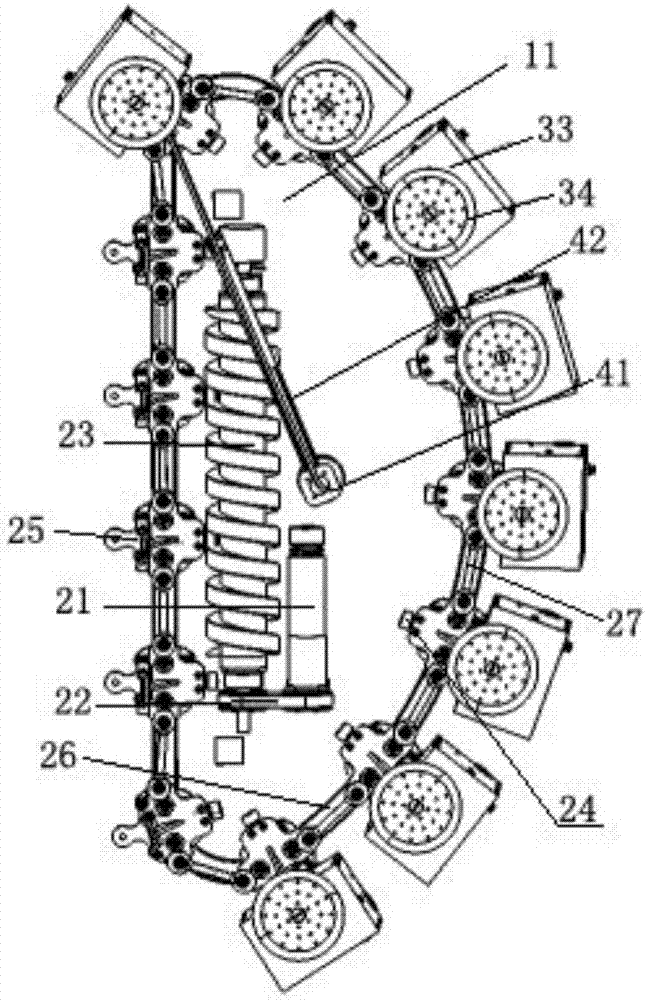

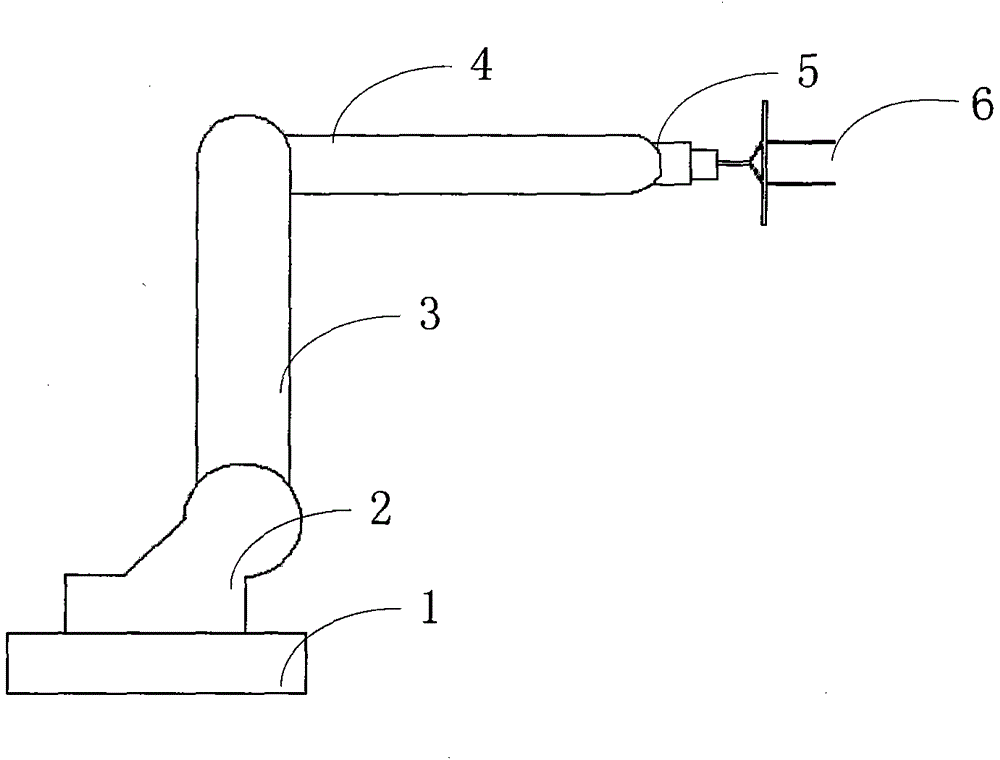

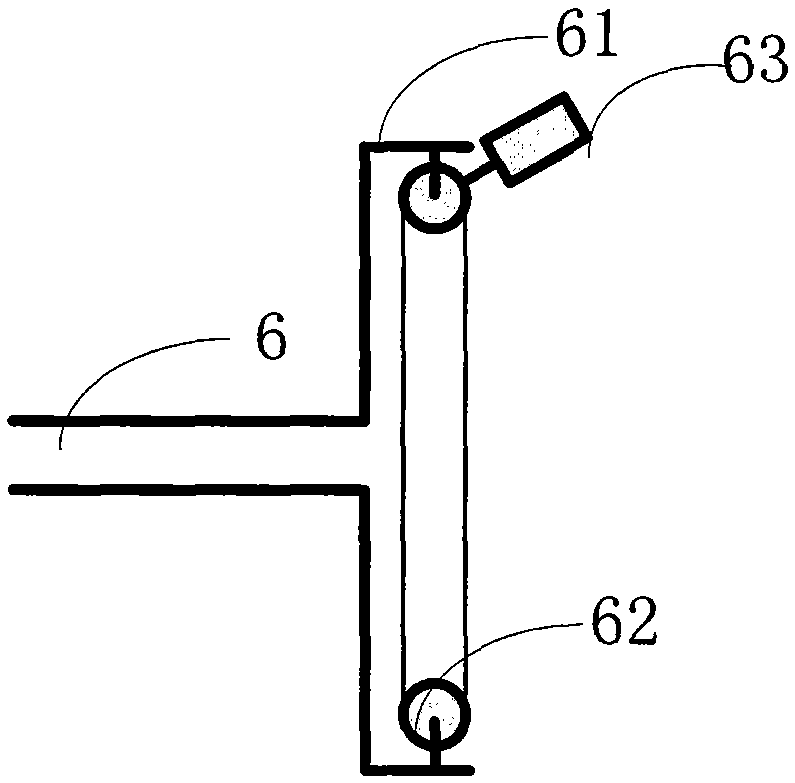

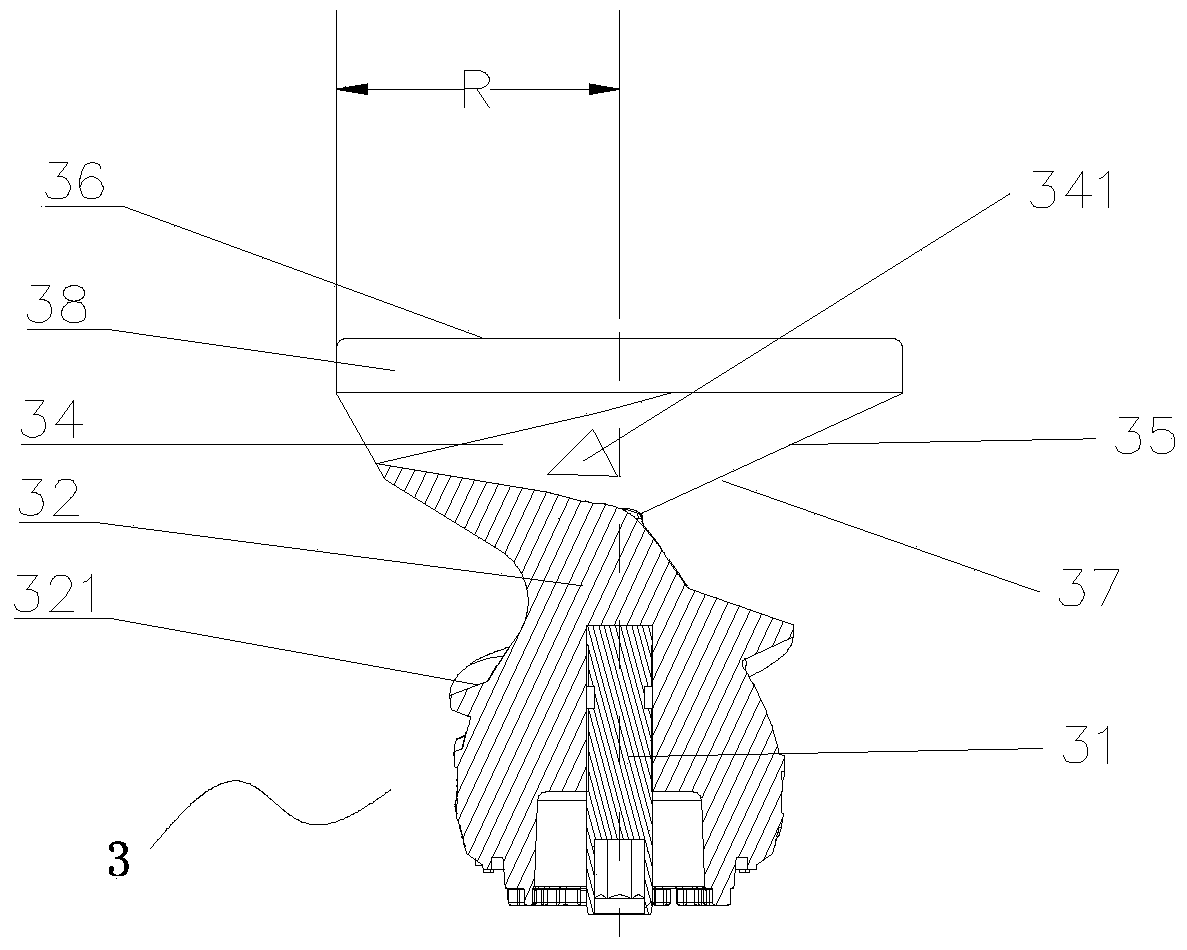

A wire cutting robot for machining complex curved surfaces

InactiveCN103752967BSimple structureLarge working spaceProgramme-controlled manipulatorGripping headsEngineeringMachine tool

The invention relates to a wire-electrode cutting robot for machining a complex surface. According to the wire-electrode cutting robot for machining the complex surface, an arm of a series robot comprises a base, a waist, a large arm body, a small arm body, a wrist and a finger tip wire electrode holder, wherein the waist is installed on the base through a first bearing, a first servo motor is installed on the waist, the large arm body is connected with the waist through a second bearing, the small arm body is connected with the tail end of the large arm through a third bearing, one end of the wrist is connected with the tail end of the small arm body through a fourth bearing, and the other end of the wrist is connected with the finger tip wire electrode holder through a fifth bearing. According to the wire-electrode cutting robot for machining the complex surface, the structure of a machine tool can be simplified, a dimension chain can be shortened, and the advantages, of the series robot, that the working space is large, the control method is advanced, and the repeated positioning precision is high can be fully utilized.

Owner:JIAMUSI UNIVERSITY

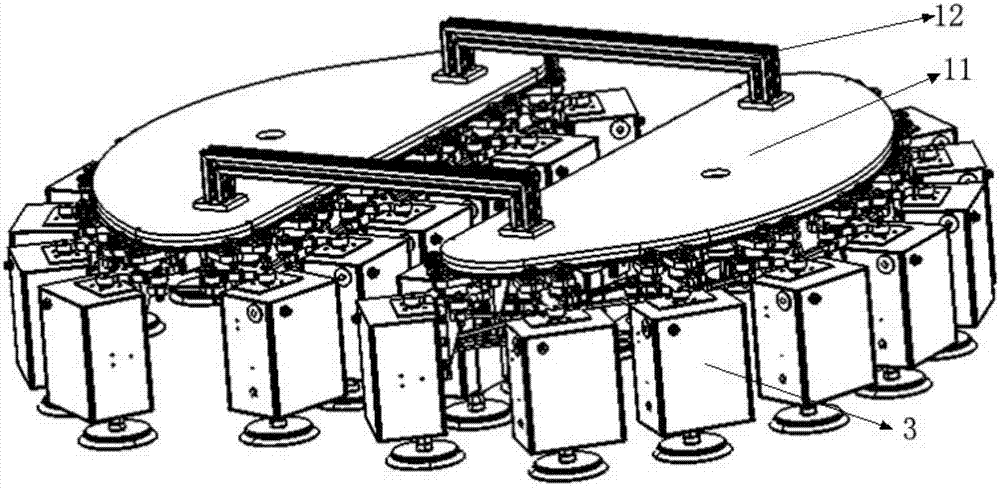

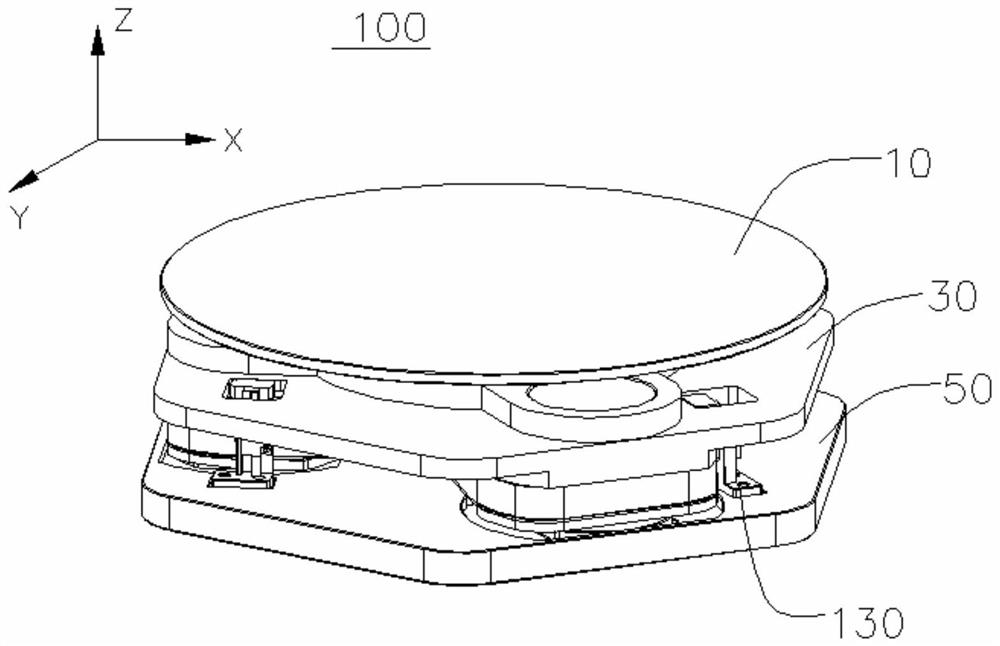

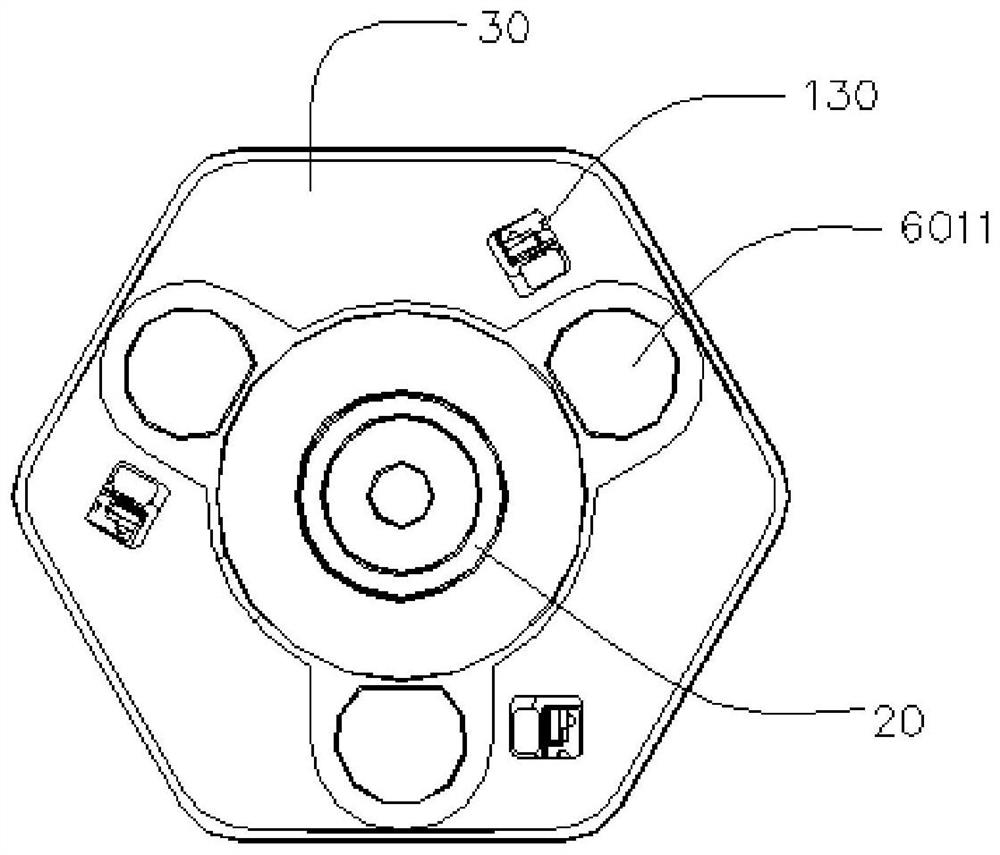

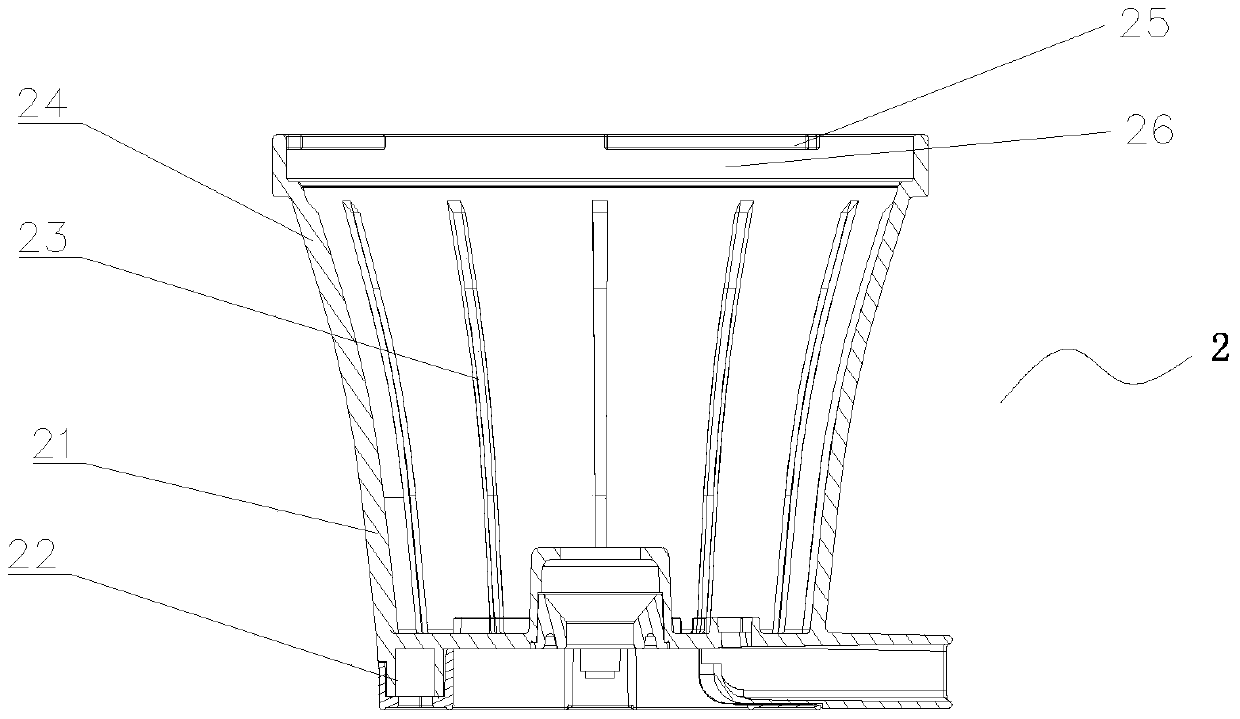

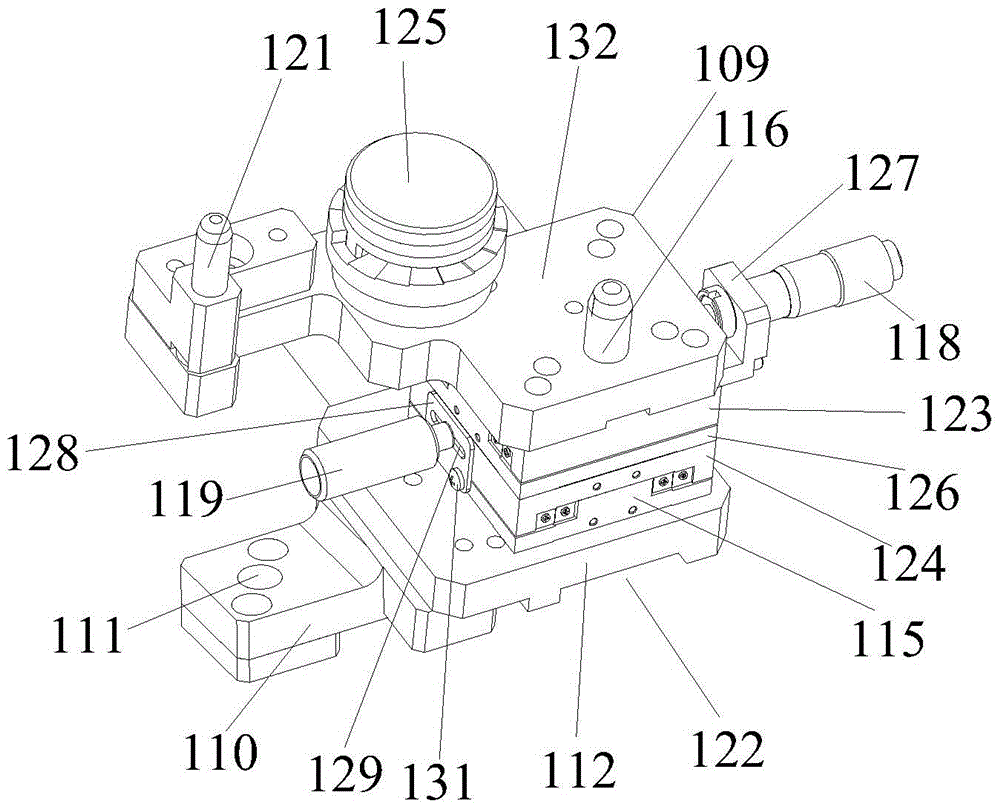

Multi-axis positioning device

The invention discloses a multi-axis positioning device. The multi-axis positioning device comprises a rotary table assembly, a supporting base located below the rotary table assembly, multiple vertical driving devices sequentially arranged on the supporting base at intervals in the circumferential direction of the rotary table assembly, at least one floating gravity compensation device and a guide device. Each vertical driving device is used for driving the rotary table assembly to move vertically. The floating gravity compensation devices are arranged between the rotary table assembly and the supporting base and used for conducting gravity compensation on the rotary table assembly. The guide device is provided with flexible pieces, is arranged between the rotary table assembly and the supporting base, and is connected with the rotary table assembly and the supporting base. Compared with the prior art, the multi-axis positioning device is simple in structure, few in size chain and convenient to assemble.

Owner:YINGUAN SEMICON TECH CO LTD

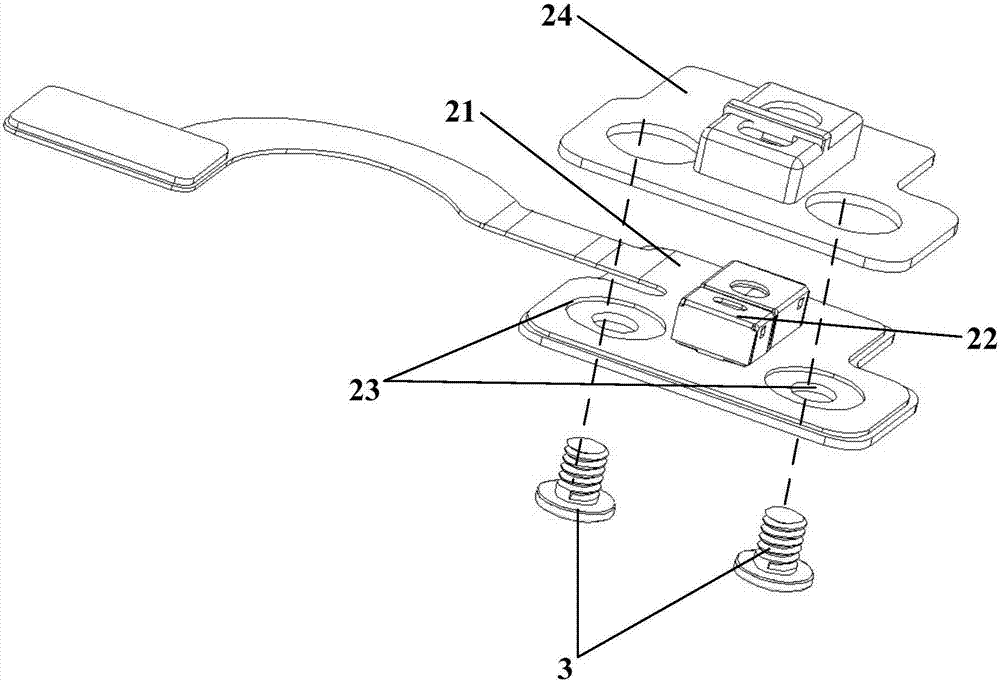

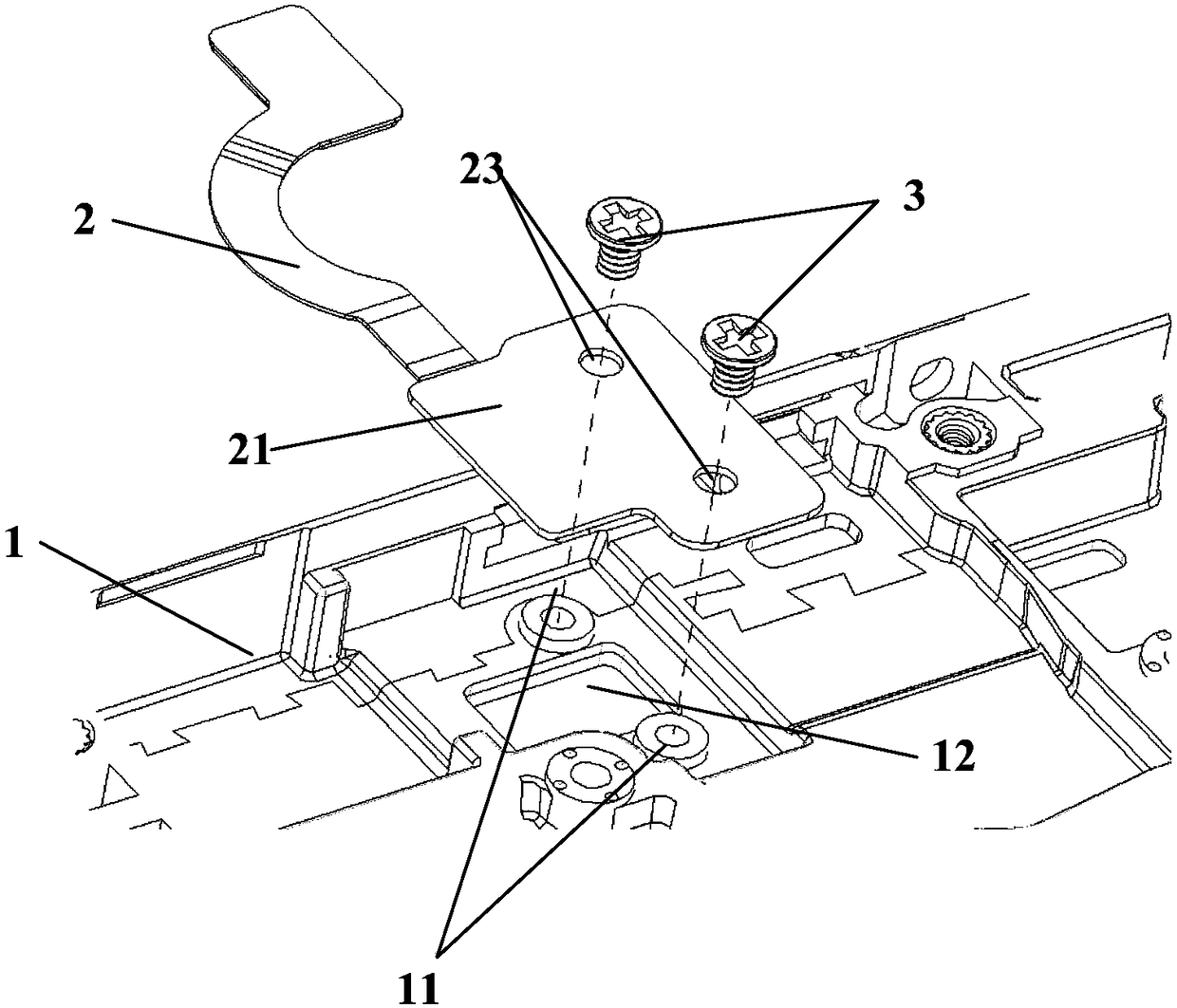

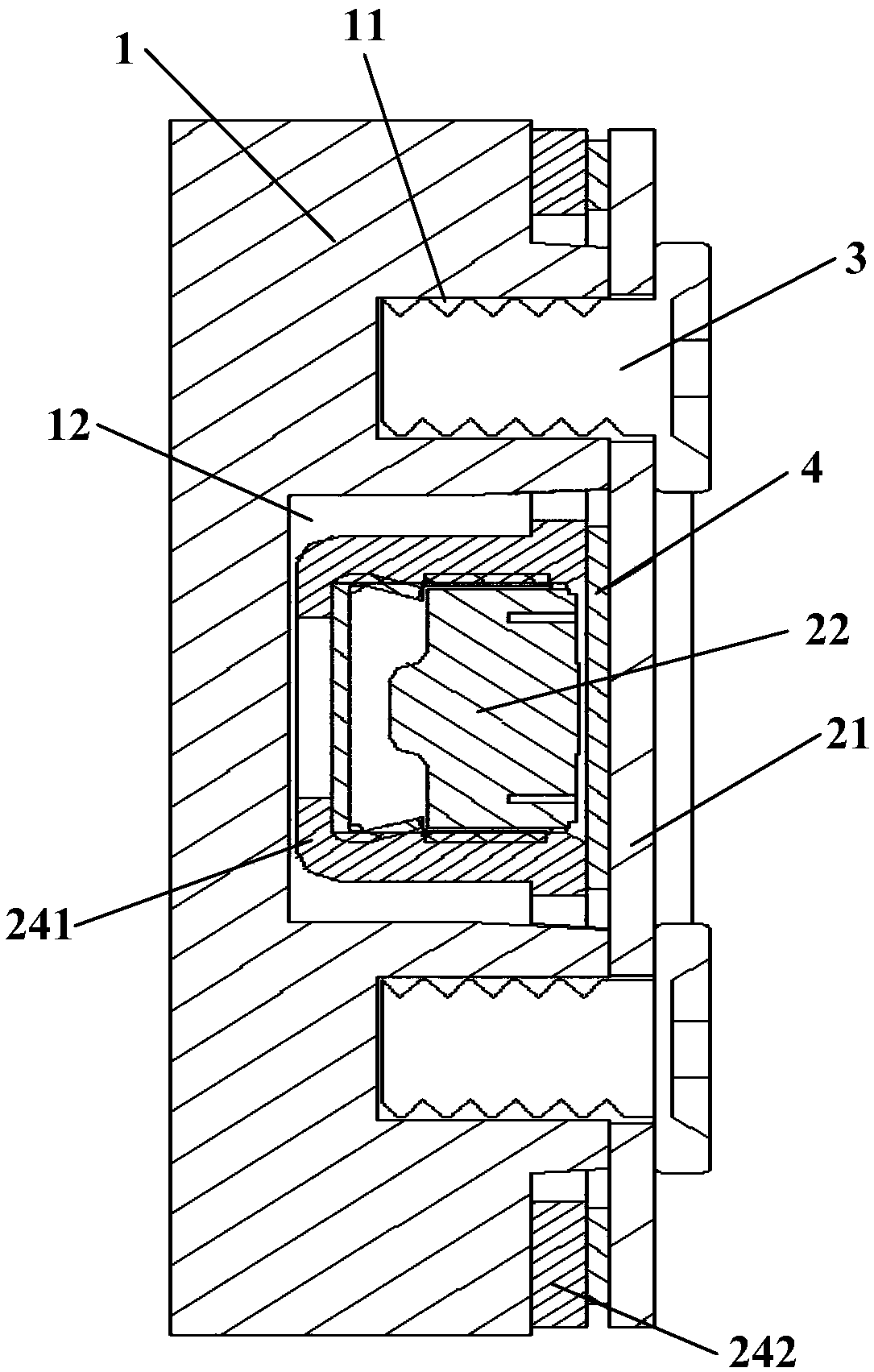

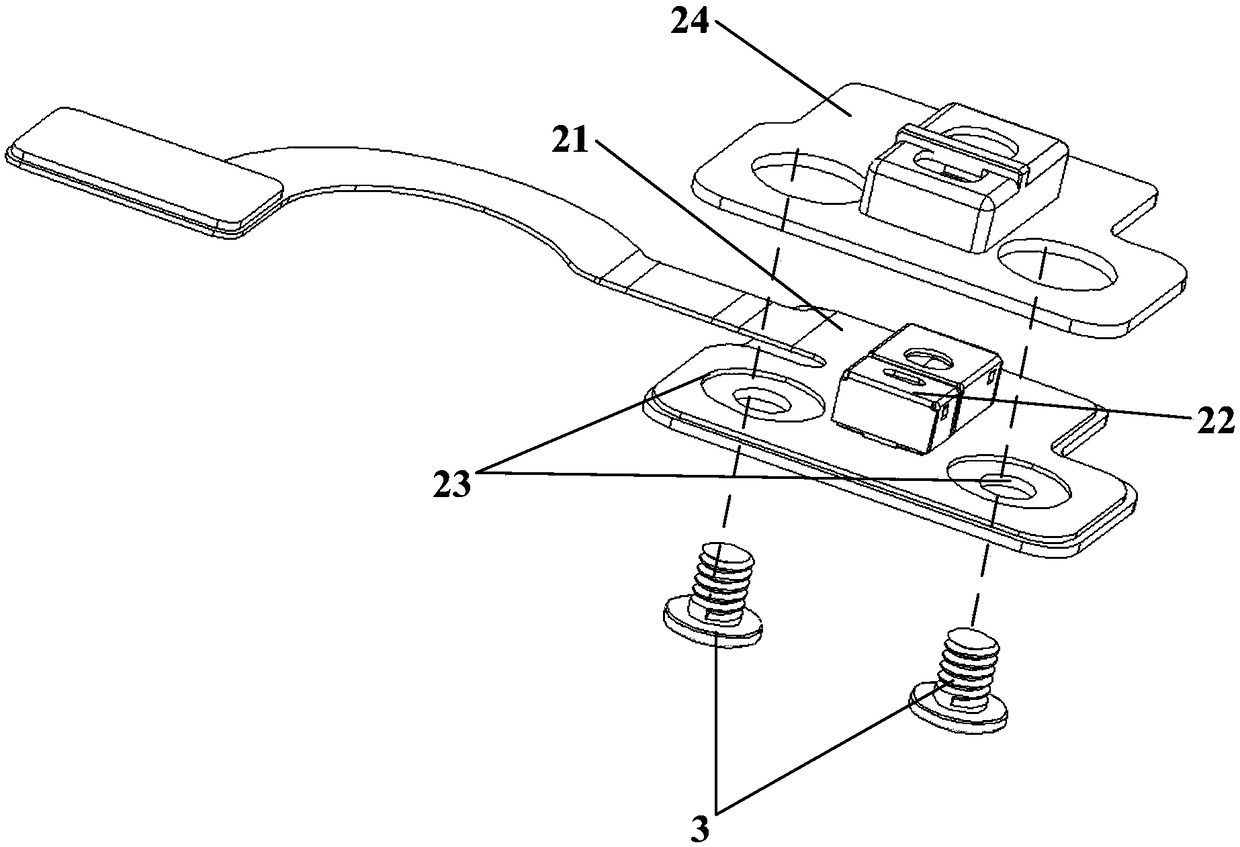

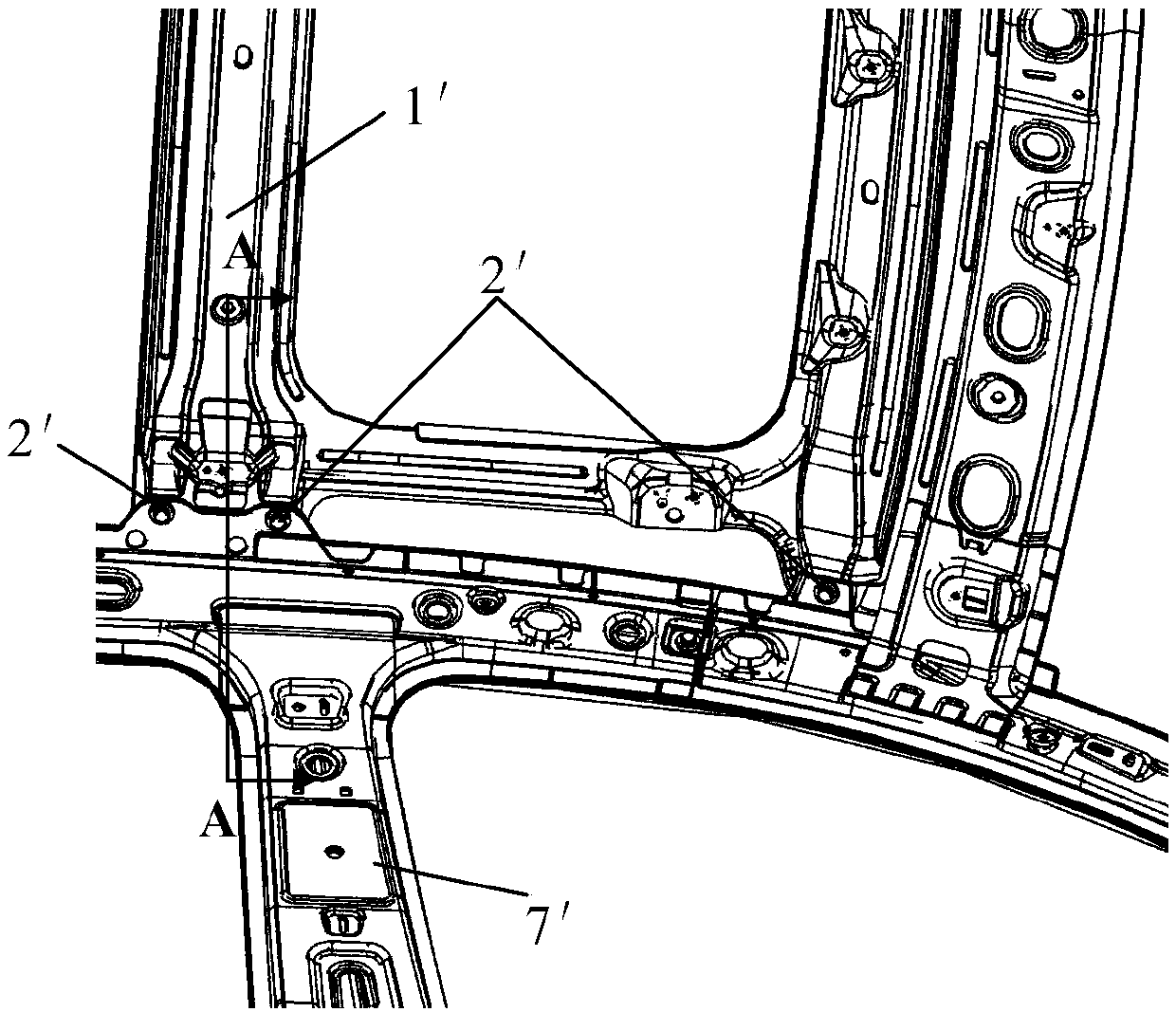

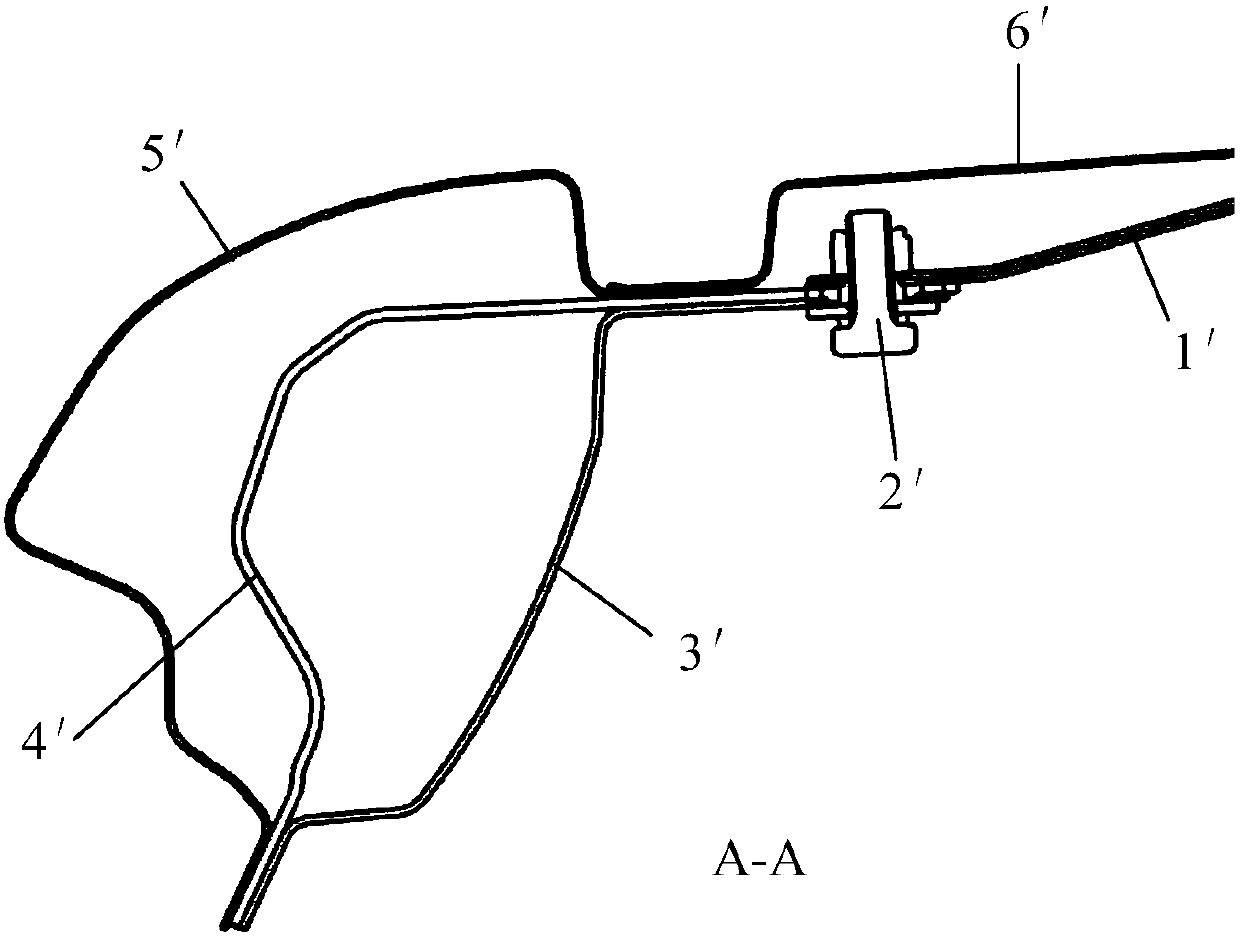

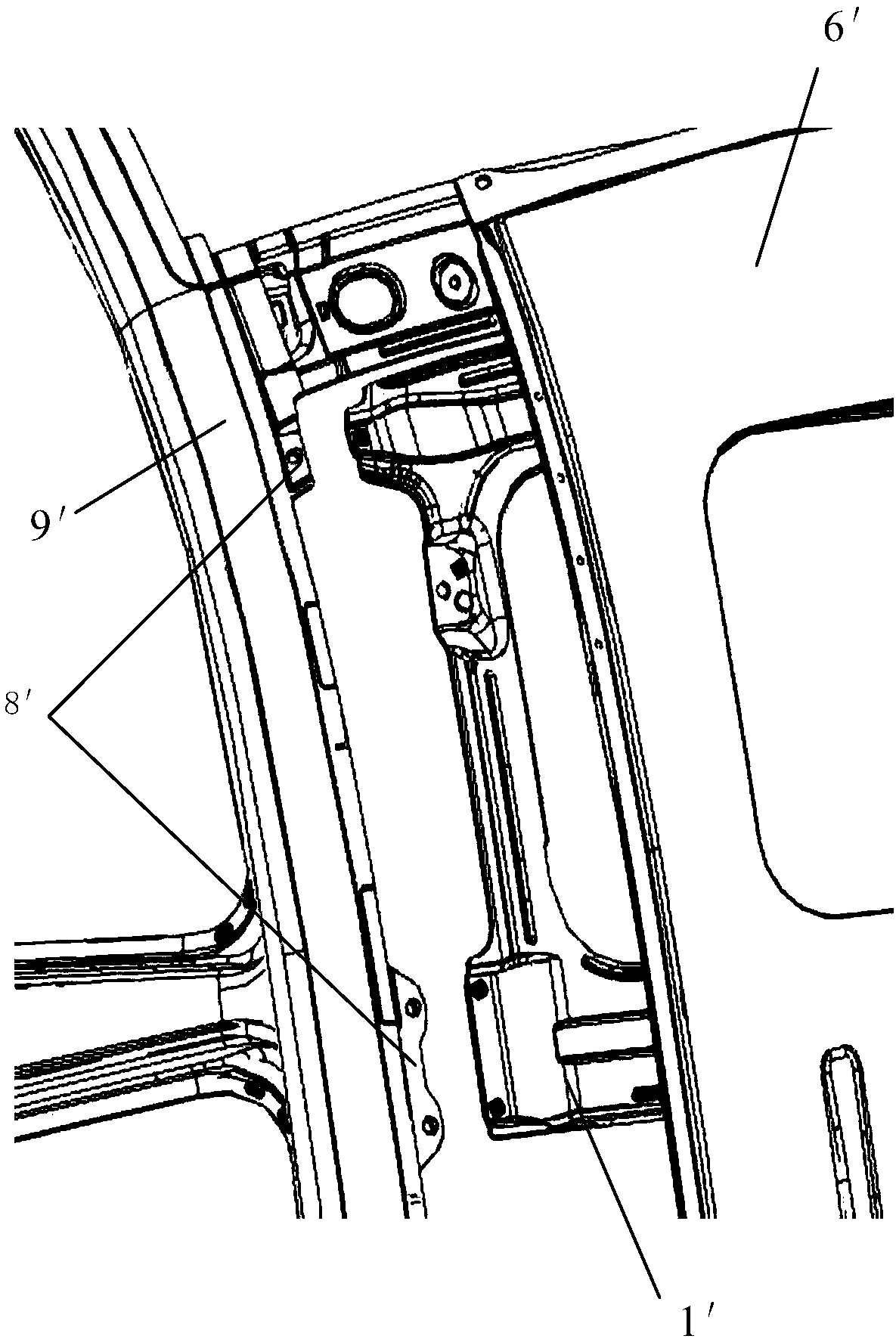

Mounting nut plate for automobile door hinge and mounting structure thereof

InactiveCN107054020AShorten the dimensional chainHigh positioning accuracyHingesDoorsEngineeringWelding

The invention discloses a mounting nut plate for an automobile door hinge comprising a mounting nut plate body which is an L-shaped bending plate, a hinge mounting plate and a rotation supporting and position-fixing plate, wherein two hinge mounting nut holes with projection welding nuts are arranged on the hinge mounting plate; and the rotation supporting and position-fixing plate is provided with a rotation supporting and position-fixing hole. The invention also discloses a mounting structure of the mounting nut plate for the automobile door hinge. The mounting nut plate for the automobile door hinge and the mounting structure thereof can improve the accuracy of a relative position between the rotation supporting and an automobile body.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

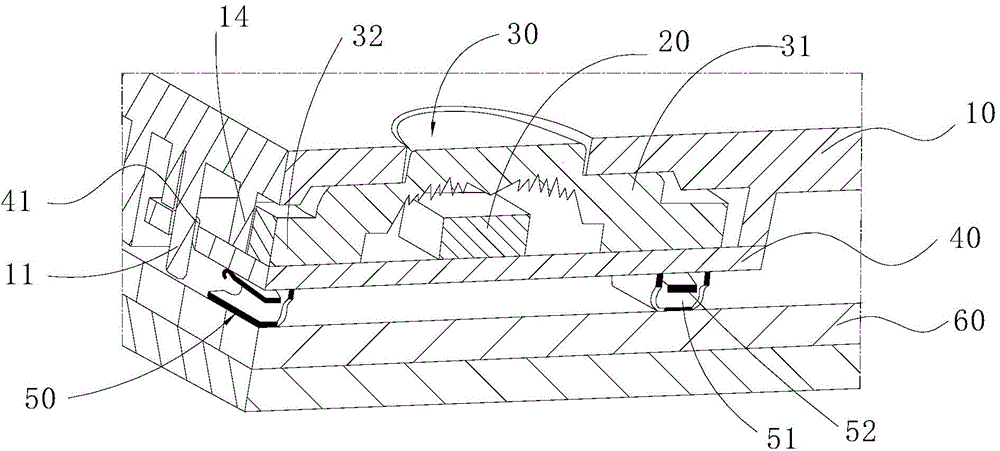

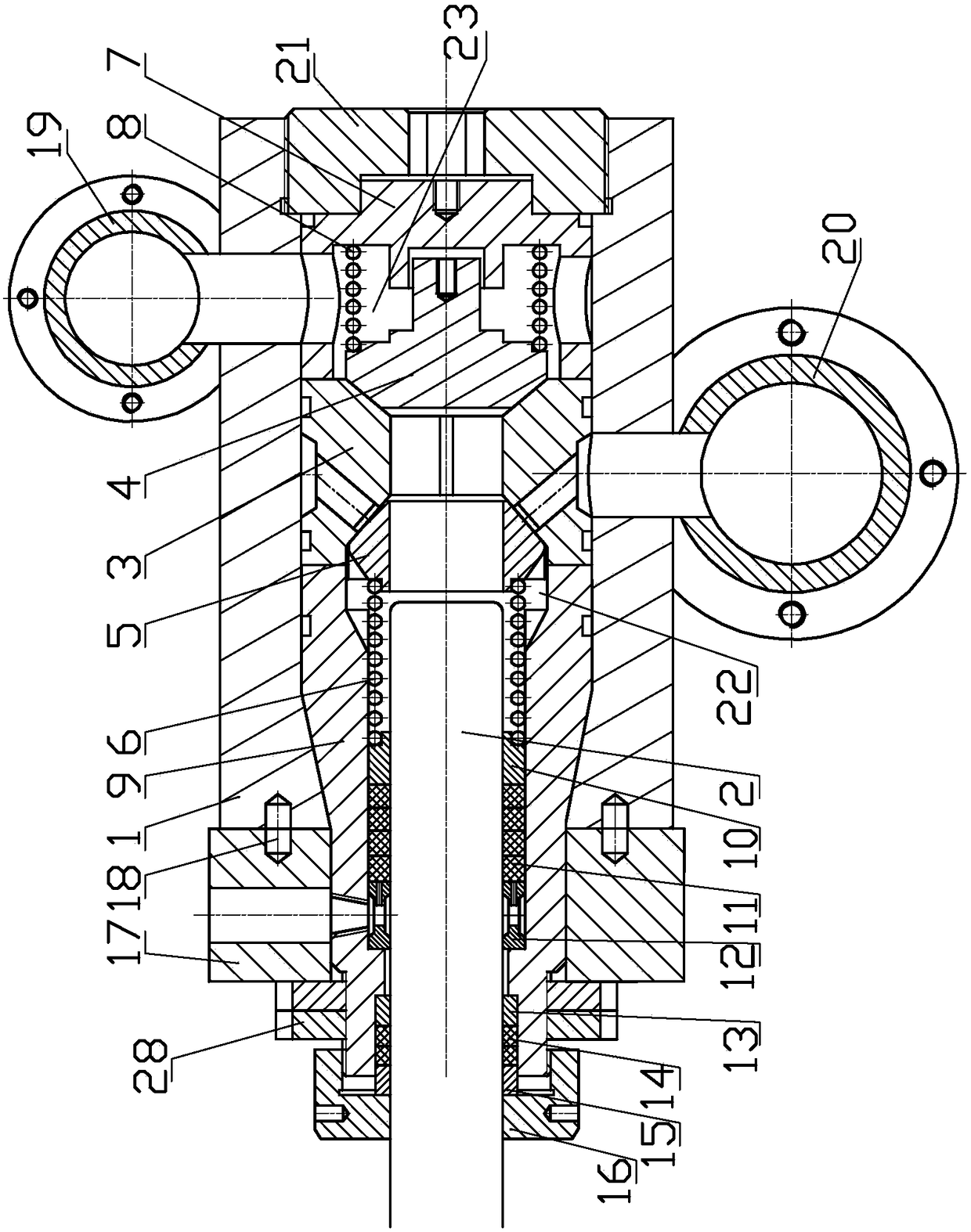

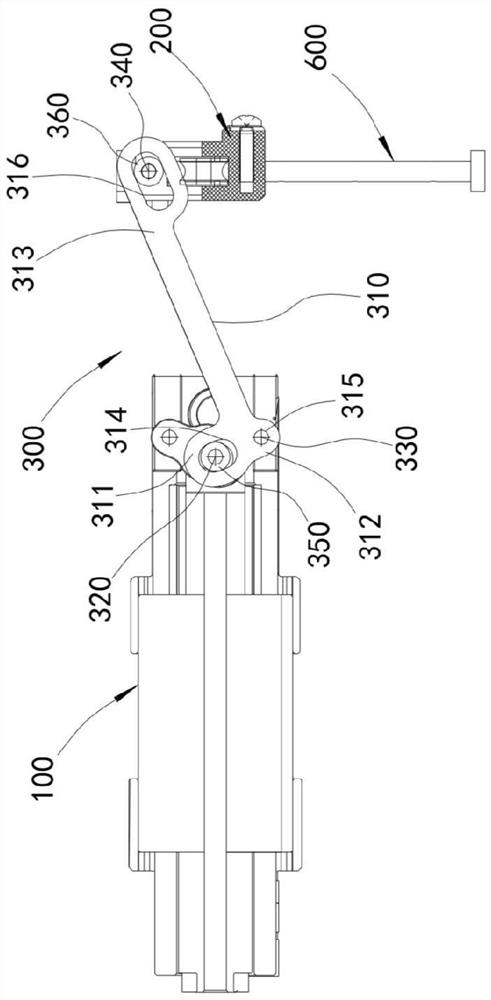

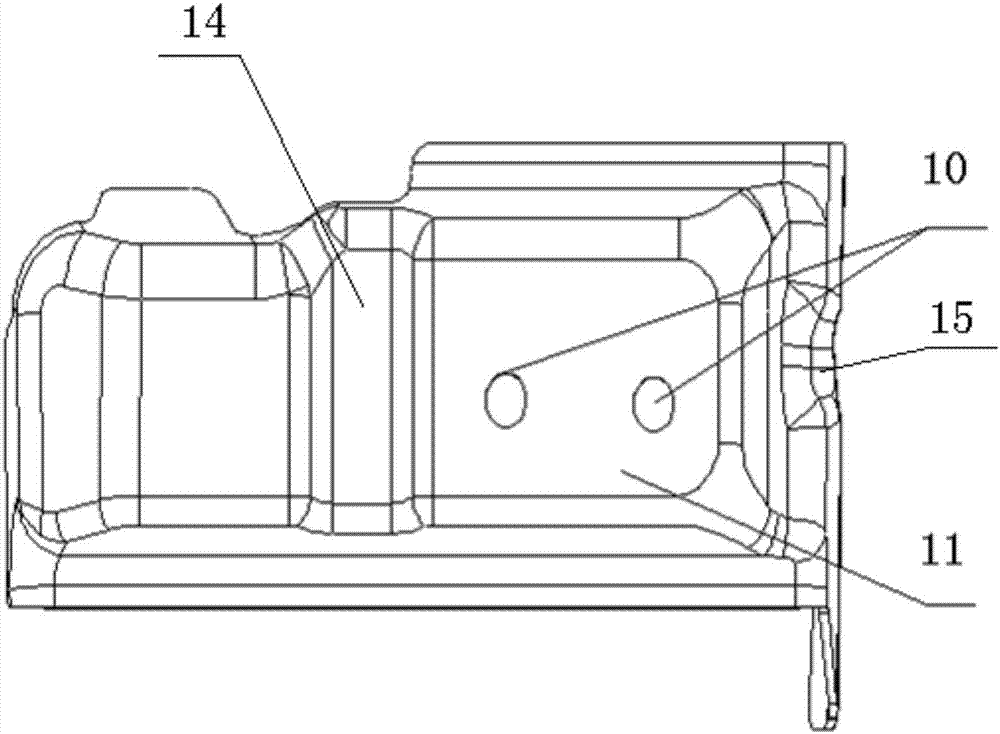

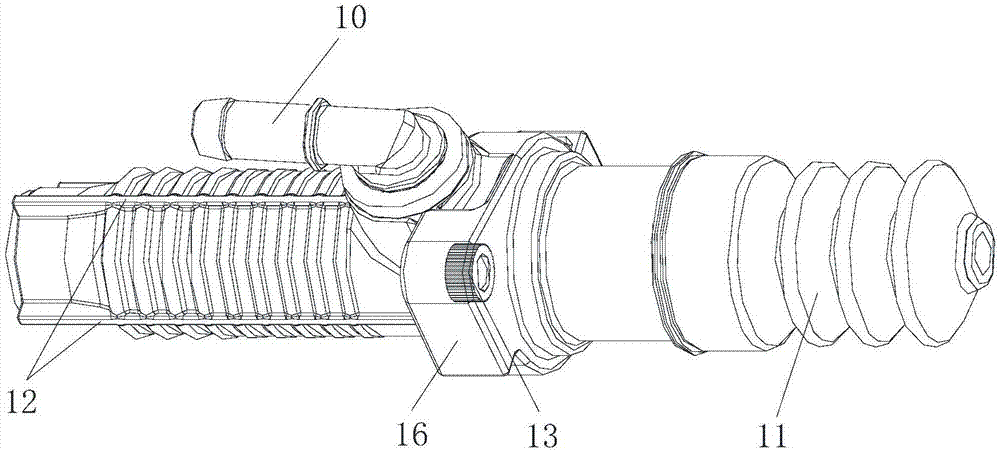

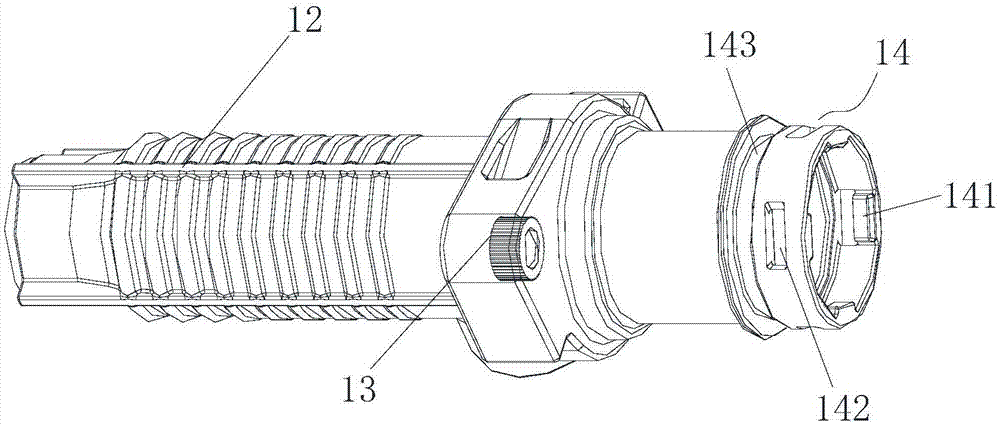

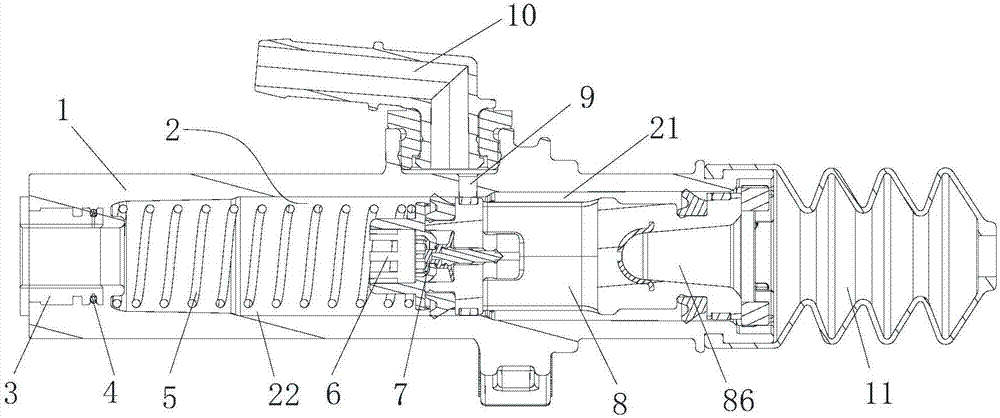

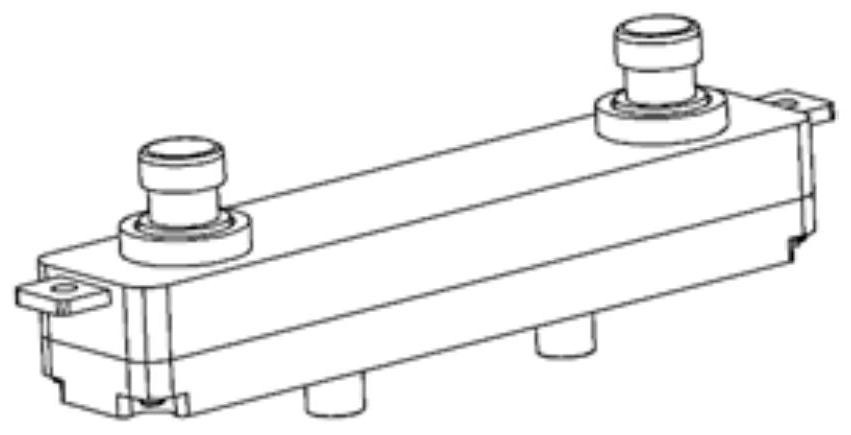

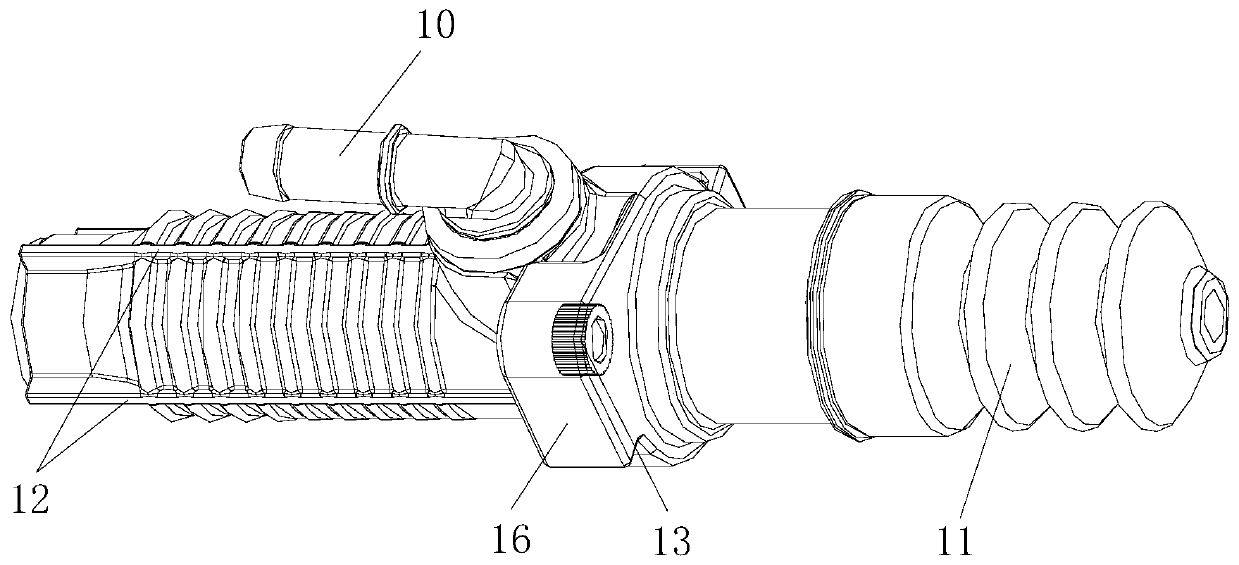

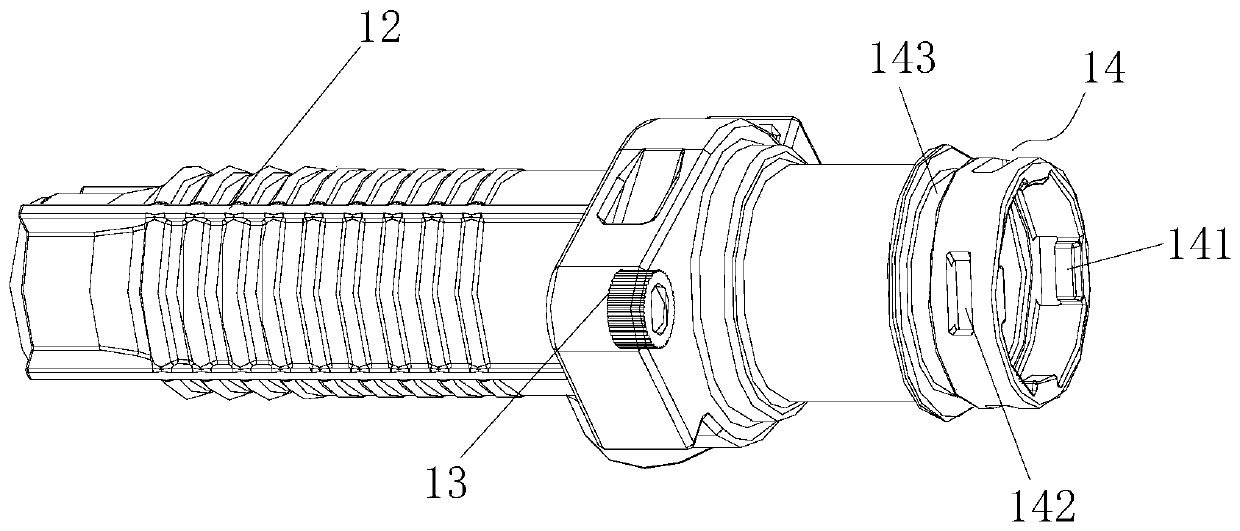

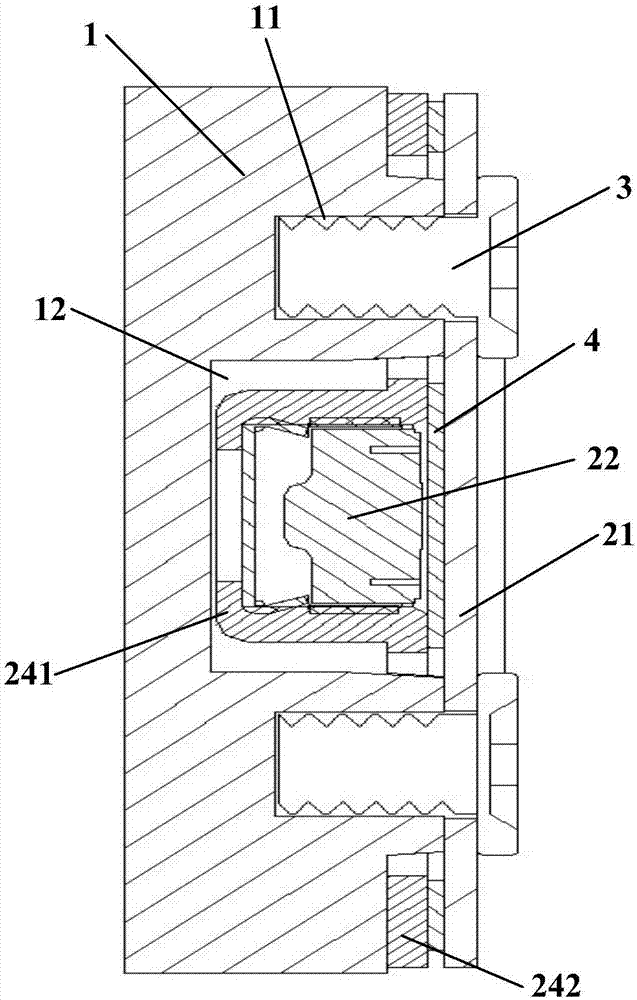

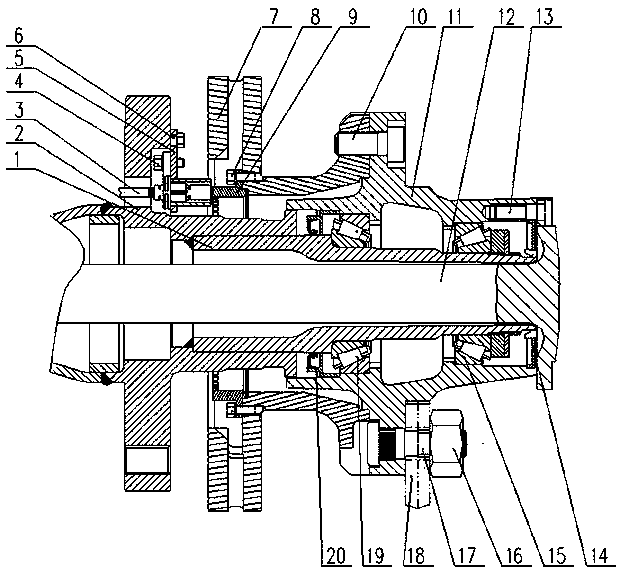

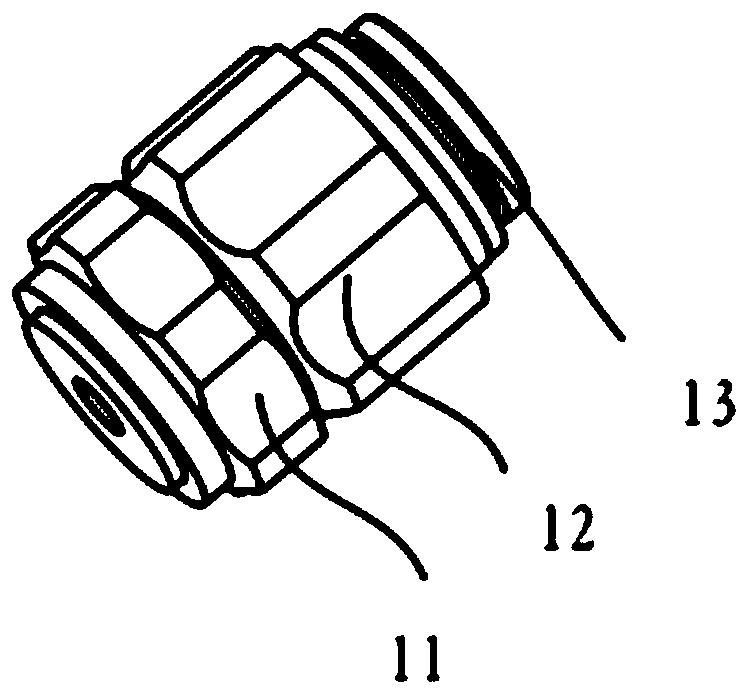

Clutch master cylinder

ActiveCN107989920ACompact designImprove structural strengthEngine sealsPiston ringsMaster cylinderEngineering

The invention discloses a clutch master cylinder, and belongs to the technical field of automobile parts. The clutch master cylinder comprises a shell. An oil inlet and an oil outlet are formed in theshell. A cavity and a piston are arranged in the shell. A connector insert is arranged at the oil outlet and is made of metal. A seal ring is arranged between one end of the connector insert and theinner wall of the oil outlet. A seal groove matched with the seal ring is formed in the periphery of the connector insert in the circumferential direction. The shell is made of a plastic base materialthrough injection molding, the seal ring is assembled into the seal groove of the connector insert before injection molding, and the shell is formed by the connector insert, the seal ring and the plastic base material through injection molding. According to the clutch master cylinder, the shell is made of plastic suitable for a brake fluid environment, and metal inserts are arranged at the oil outlet of the shell and the installation interface of a flange plate, so that the structural strength of the clutch master cylinder is improved, the clutch master cylinder can replace most existing clutch master cylinders with metal shells, and the purposes of machining cost reduction and lightweight design of automobiles are realized.

Owner:ZF COMMERCIAL VEHICLE SYSTEMS (QINGDAO) CO LTD

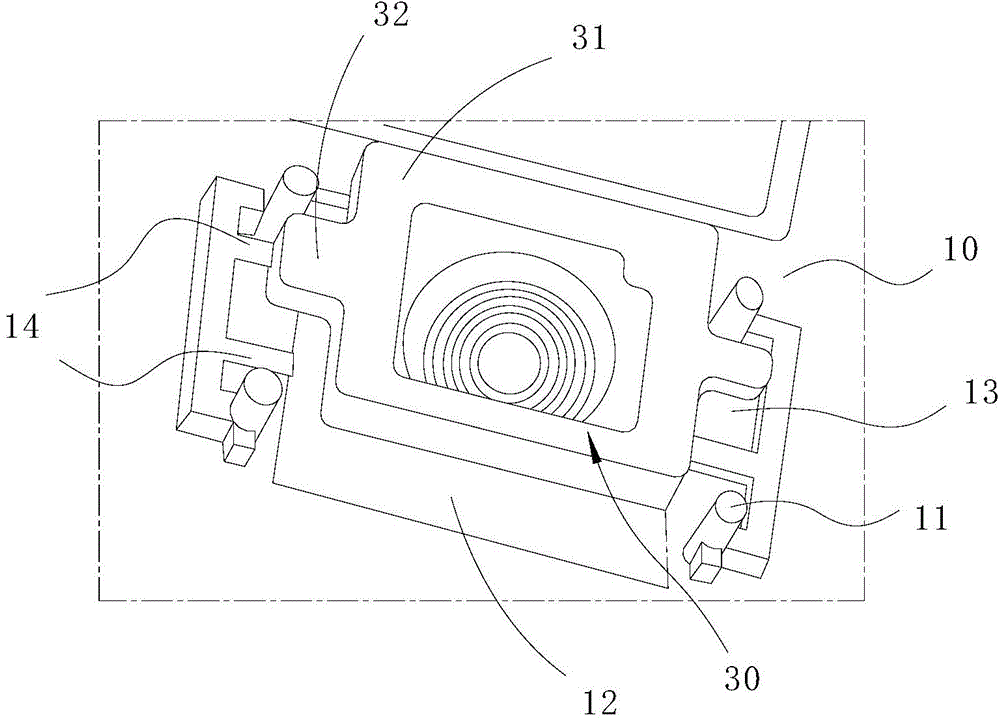

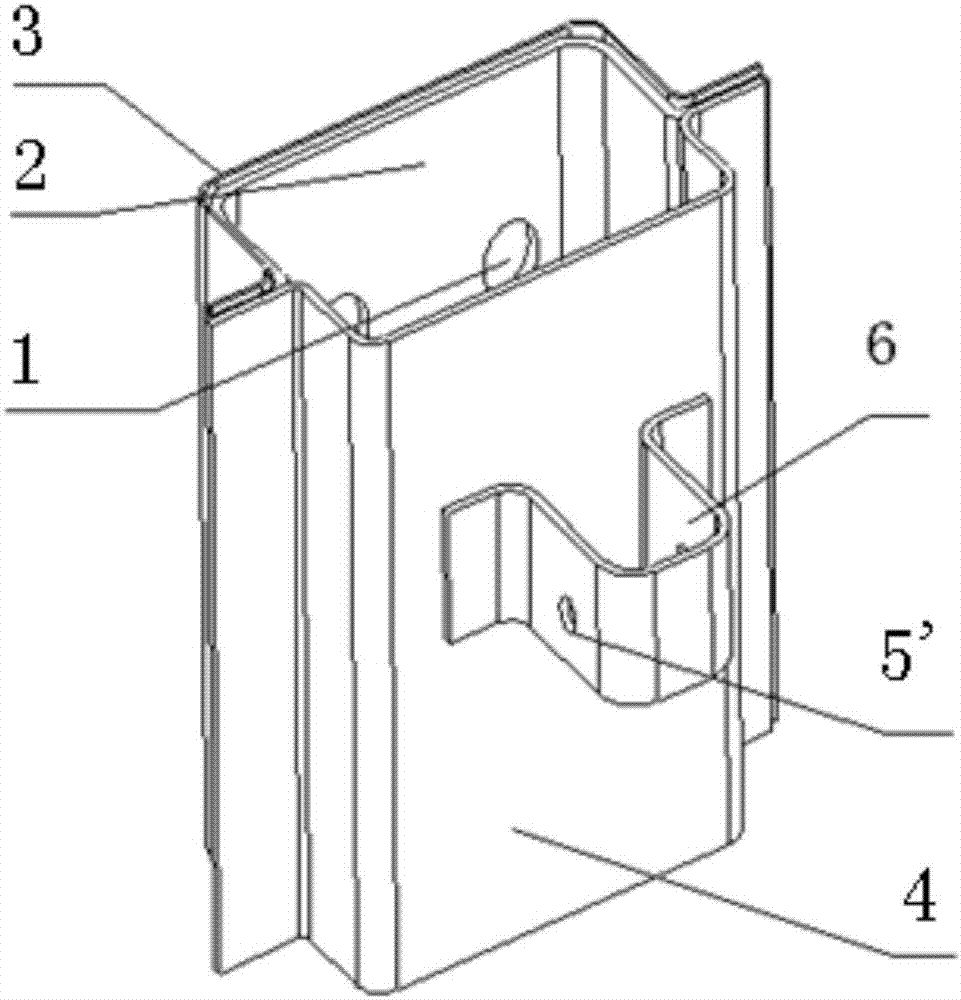

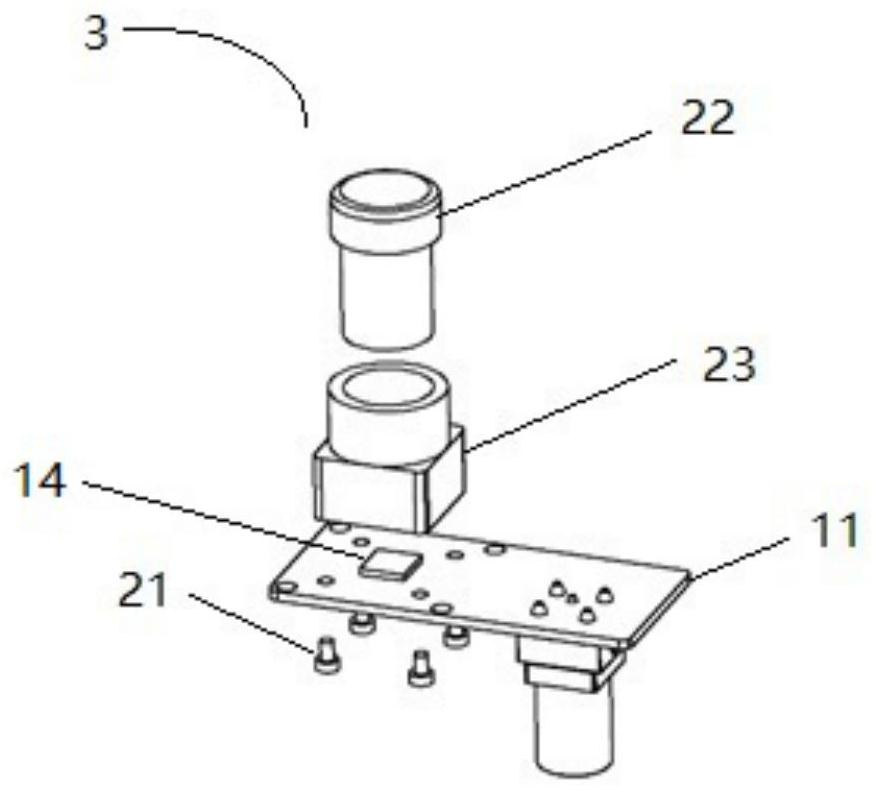

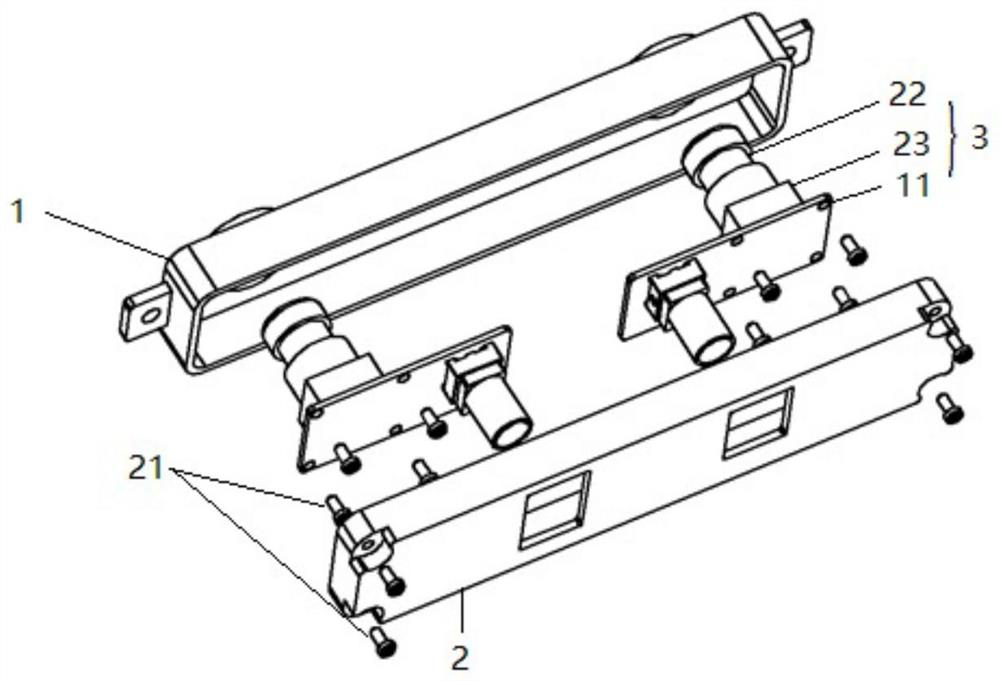

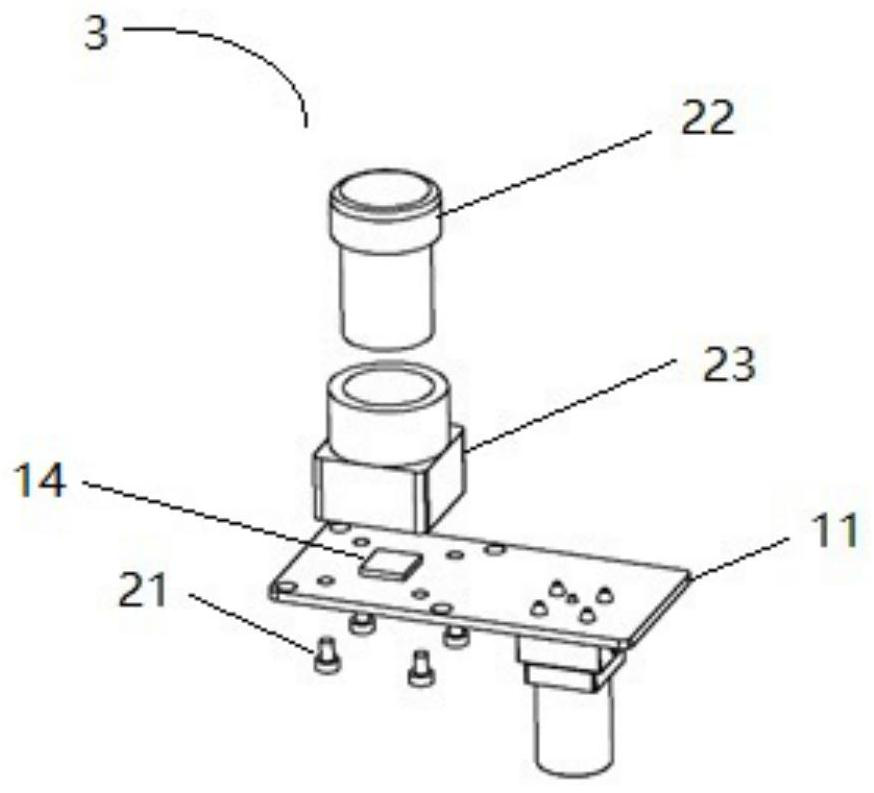

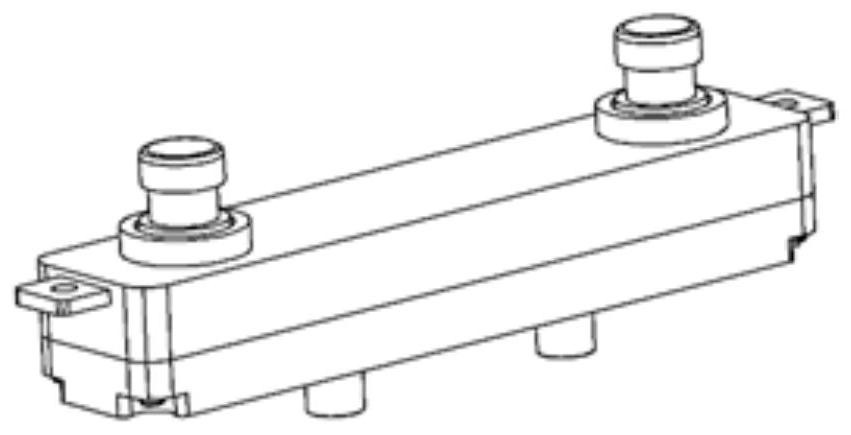

Camera device with at least two lenses

PendingCN112929553AShorten the dimensional chainEasy to controlTelevision system detailsColor television detailsOphthalmologyOptical axis

The invention relates to a camera device with at least two lenses. The camera device comprises at least two lens modules 3, a front shell 1, a rear shell 2 and a fastening mechanism, the front shell 1 is provided with one or more through holes 6 or 6', at least one of the through holes 6 or 6' is a long-strip-shaped through hole 6', the lens module 3 comprises a lens module 15, a sensor plate 10 and a printed circuit board 11 connected with the sensor plate 10, the lens module 15 comprises a lens barrel 7, the sensor plate 10 is fixedly connected to the lens barrel 7, and the fastening mechanism is used for fixing the lens module 15 penetrating through the through hole 6 or 6' to the front shell 1. The camera device with at least two lenses has high stability and high reliability, the distance between the lenses of the at least two lens modules 3 can be conveniently adjusted, and each lens module 3 can conveniently rotate around the optical axis of the corresponding lens barrel.

Owner:ZHEJIANG SUNNY SMARTLEAD TECH CO LTD

Car headlamp mounting structure and car

The invention provides a car headlamp mounting structure and a car, and relates to the technical field of cars. The car headlamp mounting structure comprises wings, a mounting support assembling toolwith two ends fixedly connected with the wings, and a mounting support fixedly connected with the mounting support assembling tool and used for mounting a headlamp and a front guard, wherein the headlamp and the front guard are fixedly connected with the wings and the mounting support. The technical problem that in the prior art, the car headlamp and the front guar are mounted on a front end module, and have the large fluctuation due to car body influence can be solved.

Owner:重庆赛力斯新能源汽车设计院有限公司

Camera device with at least two lenses

PendingCN112929551AAccurate control of distance toleranceShorten the dimensional chainTelevision system detailsColor television detailsOphthalmologyOptical axis

The invention relates to a camera device with at least two lenses, the camera device comprising at least two lens modules 3, a front housing 1 having a through-hole 6, a rear housing 2 and a fastening mechanism. Each lens modules 3 comprises a lens module 15, a sensor plate 10 and a printed circuit board 11 connected to the sensor plate 10, each lens module 15 comprises a lens barrel 7, the sensor plate 10 is fixedly connected to the lens barrel 7, and the fastening mechanism is used for fixing the lens module 15 penetrating through the through hole 6 to the front housing 1. The camera device with at least two lenses has high stability and high reliability, and each lens module 3 can conveniently rotate around the optical axis of the corresponding lens barrel.

Owner:ZHEJIANG SUNNY SMARTLEAD TECH CO LTD

clutch master cylinder

ActiveCN107989920BCompact designImprove structural strengthEngine sealsPiston ringsMaster cylinderInjection moulding

The invention discloses a clutch master cylinder, and belongs to the technical field of automobile parts. The clutch master cylinder comprises a shell. An oil inlet and an oil outlet are formed in theshell. A cavity and a piston are arranged in the shell. A connector insert is arranged at the oil outlet and is made of metal. A seal ring is arranged between one end of the connector insert and theinner wall of the oil outlet. A seal groove matched with the seal ring is formed in the periphery of the connector insert in the circumferential direction. The shell is made of a plastic base materialthrough injection molding, the seal ring is assembled into the seal groove of the connector insert before injection molding, and the shell is formed by the connector insert, the seal ring and the plastic base material through injection molding. According to the clutch master cylinder, the shell is made of plastic suitable for a brake fluid environment, and metal inserts are arranged at the oil outlet of the shell and the installation interface of a flange plate, so that the structural strength of the clutch master cylinder is improved, the clutch master cylinder can replace most existing clutch master cylinders with metal shells, and the purposes of machining cost reduction and lightweight design of automobiles are realized.

Owner:ZF COMMERCIAL VEHICLE SYSTEMS (QINGDAO) CO LTD

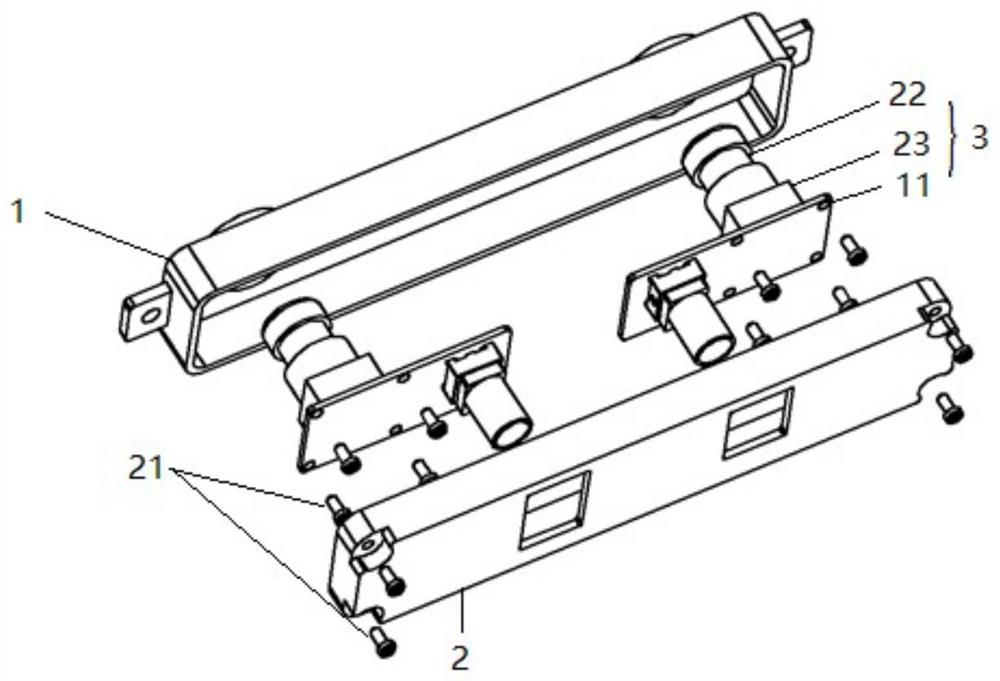

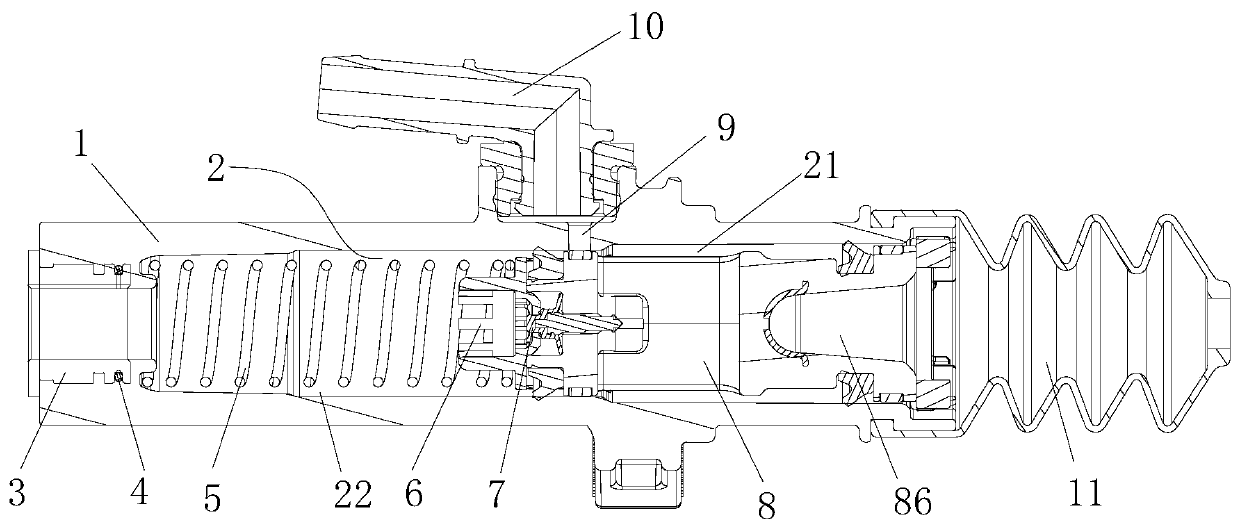

A kind of limited and reliable juicer

Owner:JOYOUNG CO LTD

A kind of flashlight unit and electronic equipment

ActiveCN104614918BShorten the dimensional chainImprove assembly accuracyPhotographyComputer hardwareFlashlight

The invention discloses a flash light assembly, which comprises a rear shell assembly, a flash light, a flash light cover and a flash light circuit board, the flash light cover is fixed on the rear shell assembly, the flash light is fixed on the flash light circuit board, the The flashlight circuit board is fixed on the rear shell assembly and is in electrical contact with the main circuit board. The present invention fixes the flashlight lampshade on the rear shell assembly, the flashlight lamp is fixed on the flashlight circuit board, and the flashlight circuit board is fixed on the rear shell assembly and is in electrical contact with the main circuit board. The assembly accuracy of the two is improved, and the occurrence of deviation phenomenon is avoided.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

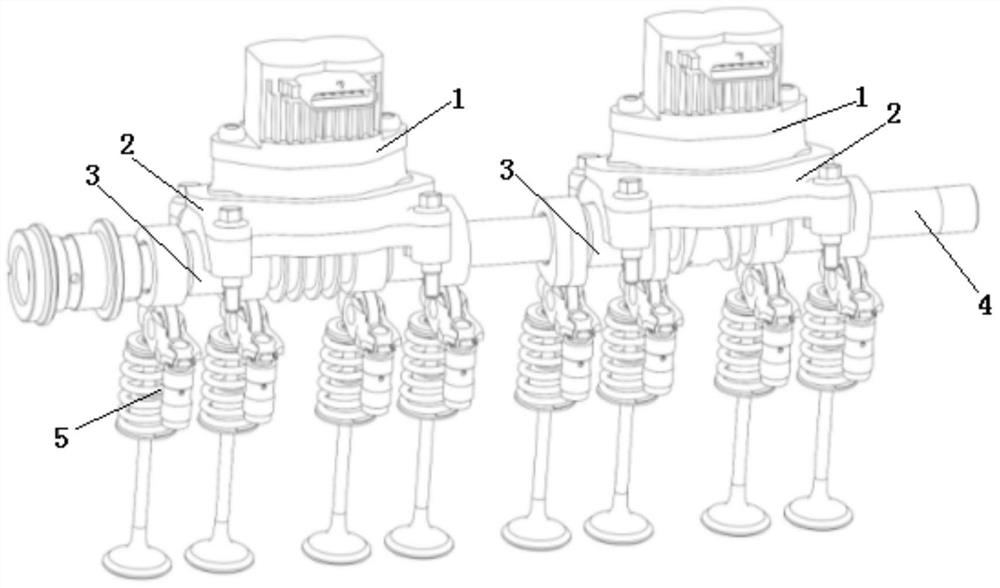

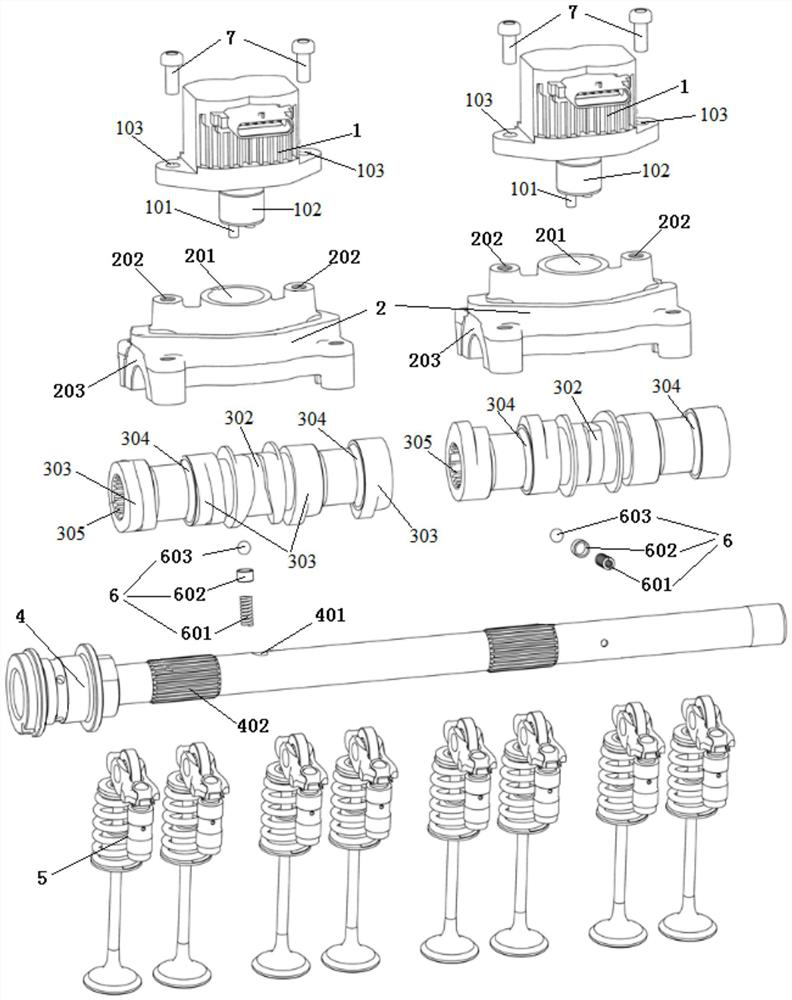

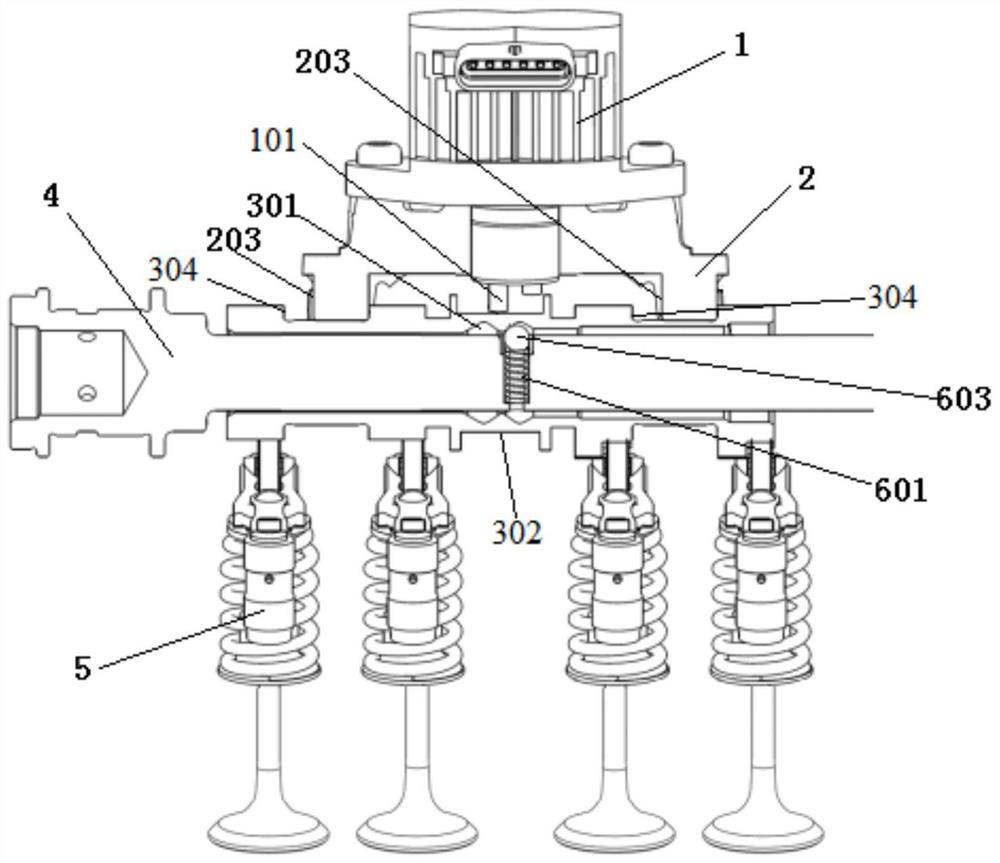

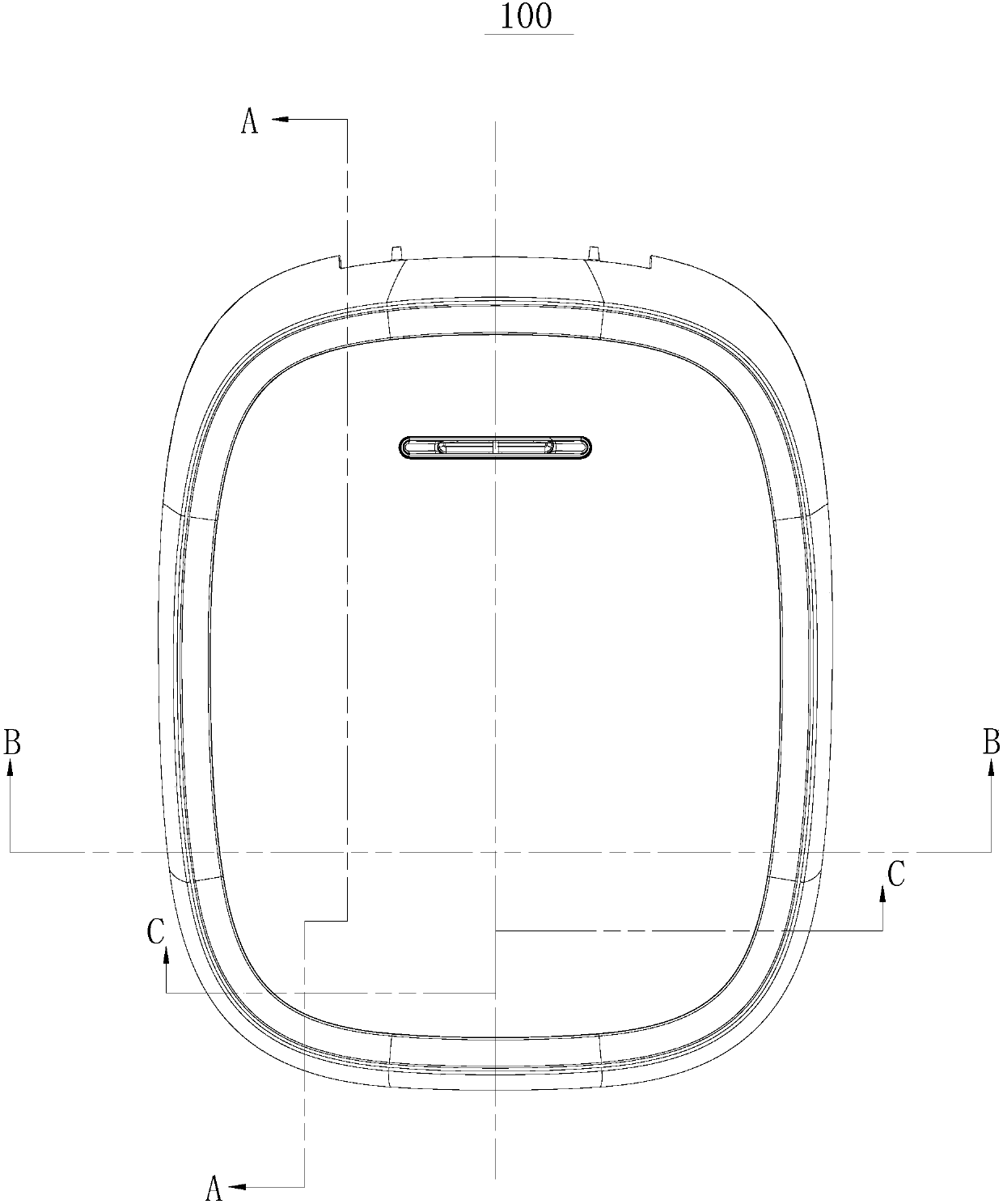

Cam sliding type variable valve lift system, engine and vehicle

PendingCN114165309AAvoid the problem of high tolerance control requirementsSolve problems with high tolerance control requirementsValve arrangementsMachines/enginesCamActuator

The invention relates to a cam sliding type variable valve lift system, an engine and a vehicle. The lift system comprises an actuator which is installed on the cam shaft cover and acts on the one-piece cam sliding sleeve. The one-piece cam sliding sleeve is assembled on the cam shaft mandrel, a stop ring groove is formed in the inner wall of the one-piece cam sliding sleeve, the cam shaft mandrel is matched with the stop ring groove through an elastic connecting piece to stop the one-piece cam sliding sleeve, and a switching spiral groove is formed in the outer wall of the one-piece cam sliding sleeve and used for being matched with a pin of an actuator. The one-piece cam sliding sleeve is provided with two groups of cams corresponding to the valve assembly; when the valve lift is switched, the cam shaft mandrel rotates to drive the one-piece cam sliding sleeve to move, the elastic connecting piece moves from one check ring groove to the other check ring groove, and switching of the valve assembly is achieved. The invention provides an engine. The engine comprises a lift system. The invention provides a vehicle including an engine. The problems that an existing sliding type cam shaft is numerous in parts, and the tolerance control requirement between the parts is high are solved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

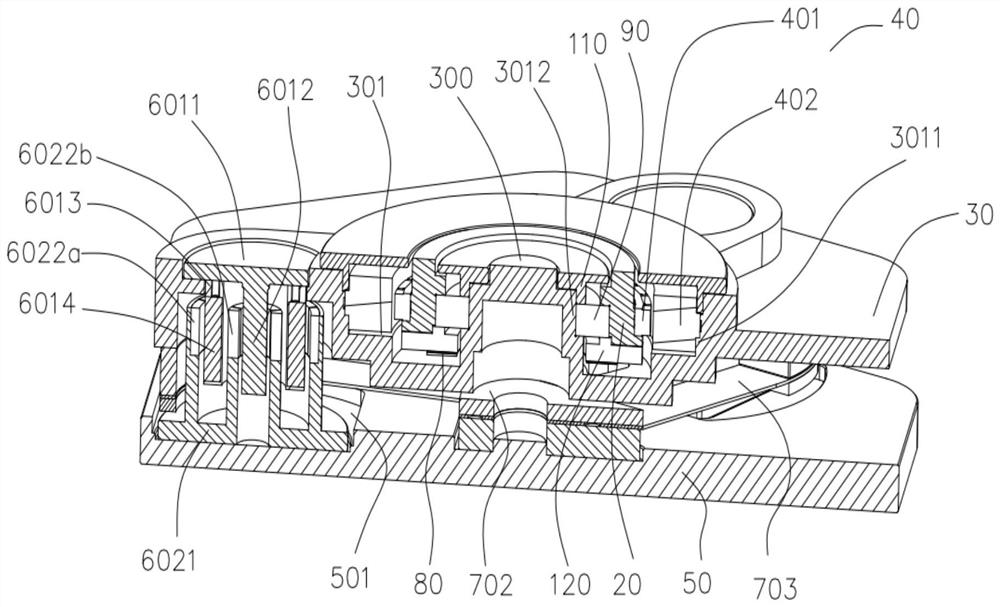

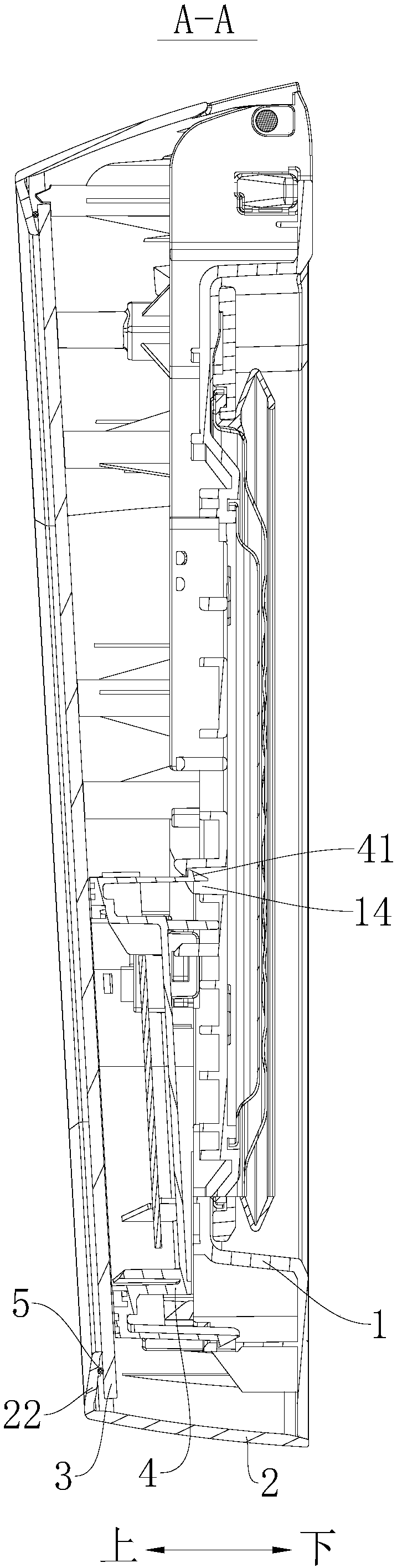

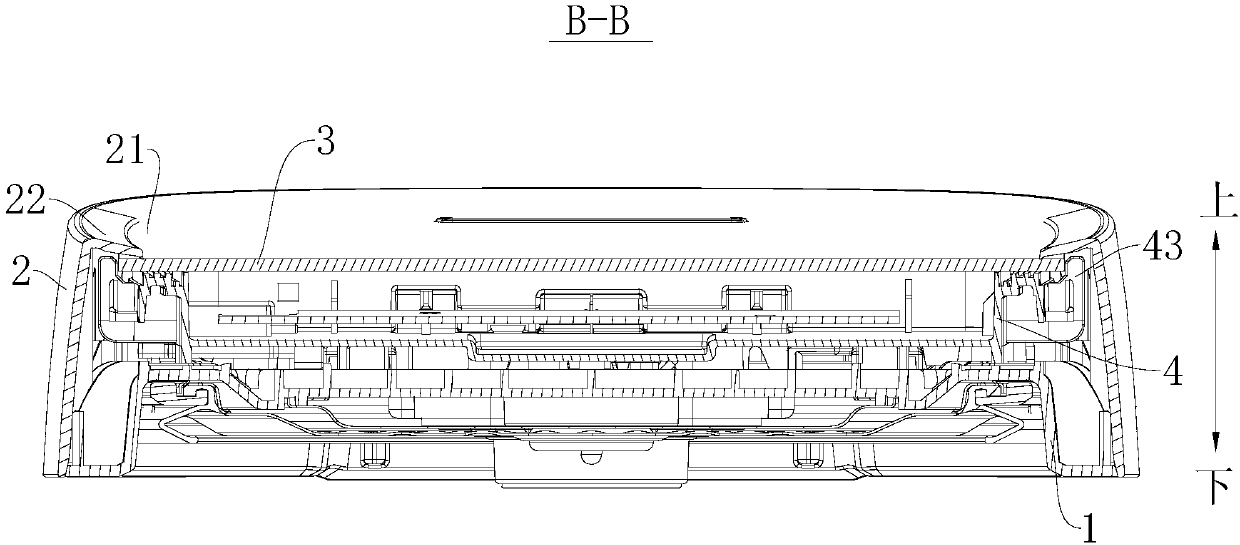

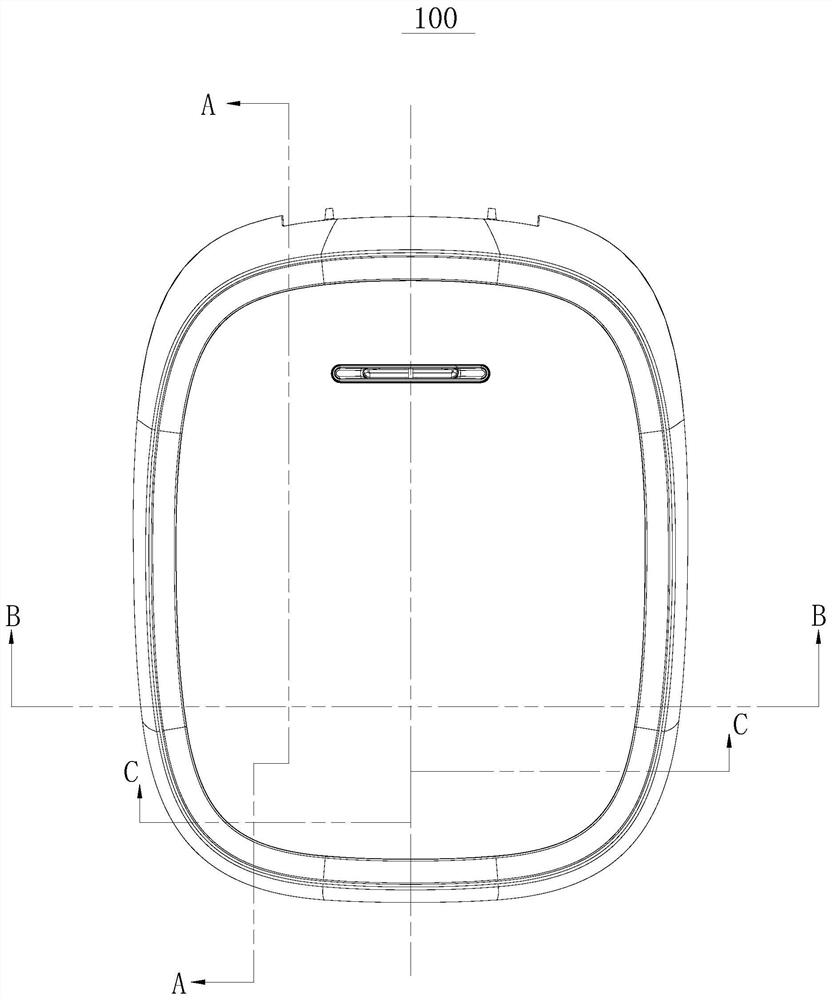

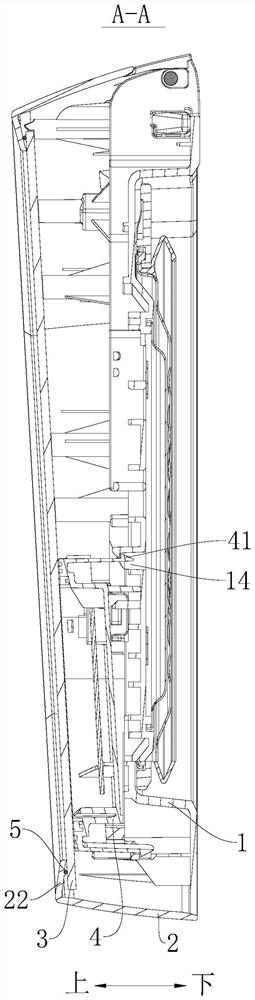

Upper cover assembly used for cooking utensil and cooking utensil with upper cover assembly

ActiveCN109549495AShorten the dimensional chainAvoid misalignmentCooking-vessel lids/coversEngineeringMechanical engineering

The invention discloses an upper cover assembly used for a cooking utensil and the cooking utensil with the upper cover assembly. The upper cover assembly comprises an inner cover, a face cover, a face plate and a display box, wherein the face cover is arranged above the inner cover in a covering manner, and an opening is formed in the top face of the face cover; the face plate is arranged at theinner side of the face cover and closes the opening; and the display box is in clamping connection with the face plate, at least one part of the display box is positioned below the face plate, and thedisplay box is suitable for upwards displaying information towards the face plate. According to the upper cover assembly used for the cooking utensil provided by the invention, the display box is mounted on the face plate, so that the dimension chain between the face plate and the display box can be shortened, then the noncoincidence of the display box and a silk printing lamp hole in the face plate is avoided, and thus the assembly quality is improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Lid assembly for cooking appliance and cooking appliance having same

ActiveCN109549495BShorten the dimensional chainAvoid misalignmentCooking-vessel lids/coversStructural engineeringMechanical engineering

The invention discloses an upper cover assembly for a cooking utensil and a cooking utensil with the same. The upper cover assembly includes: an inner cover; The top surface of the top surface has an opening; a panel, the panel is arranged inside the cover and closes the opening; a display box, the display box is clamped with the panel, and at least a part of the display box is located under the panel, The display box is adapted to present information upwardly towards the panel. According to the upper cover assembly for cooking utensils of the present invention, by installing the display box on the panel, the dimensional chain between the panel and the display box can be shortened, avoiding misalignment between the display box and the silk screen light holes on the panel, and improving assembly efficiency. quality.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

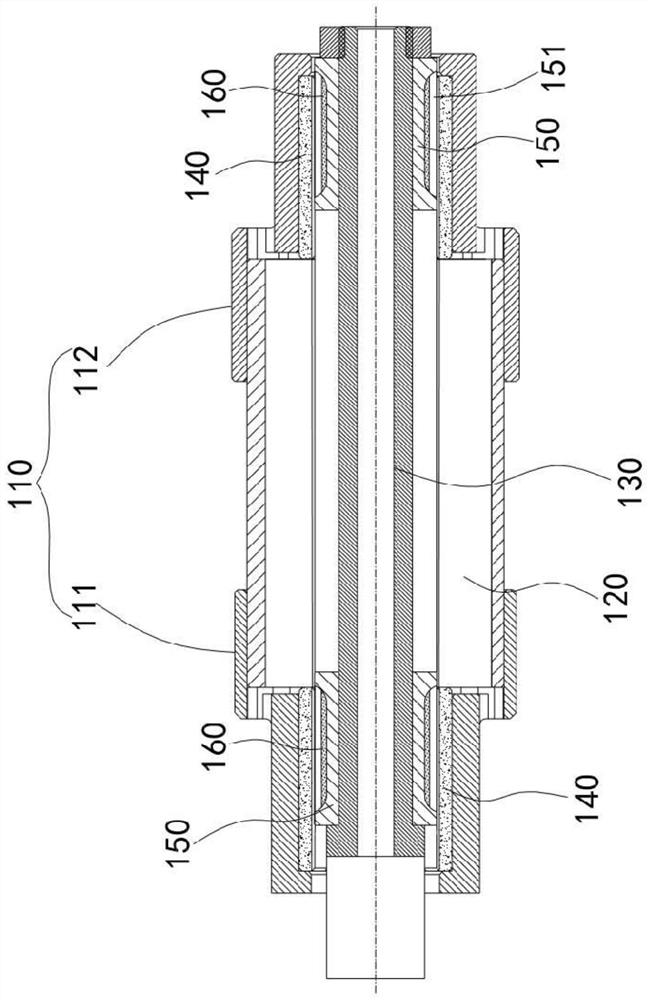

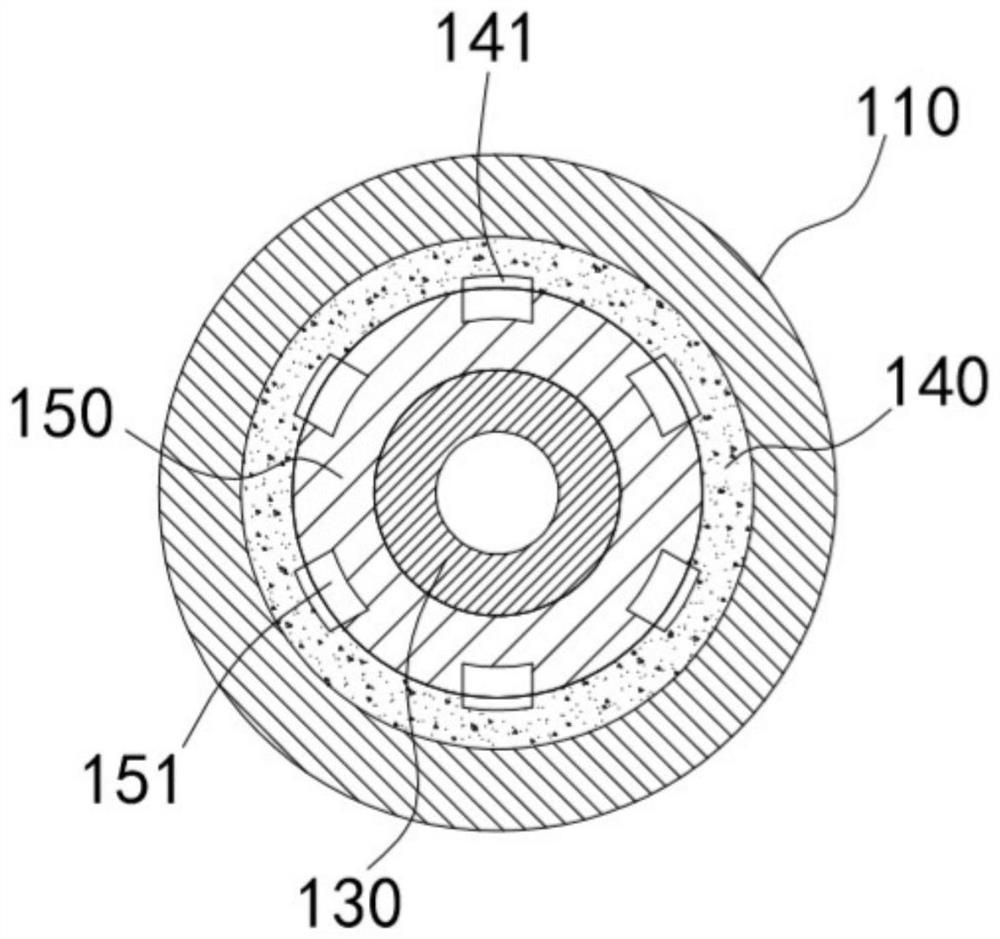

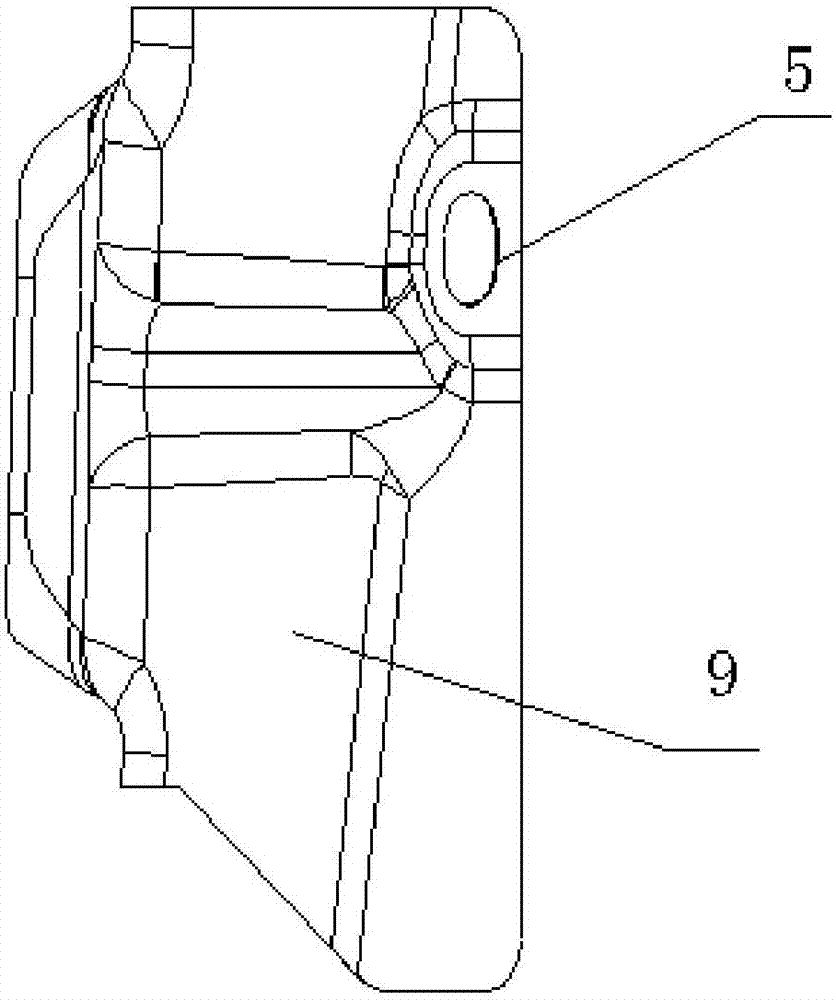

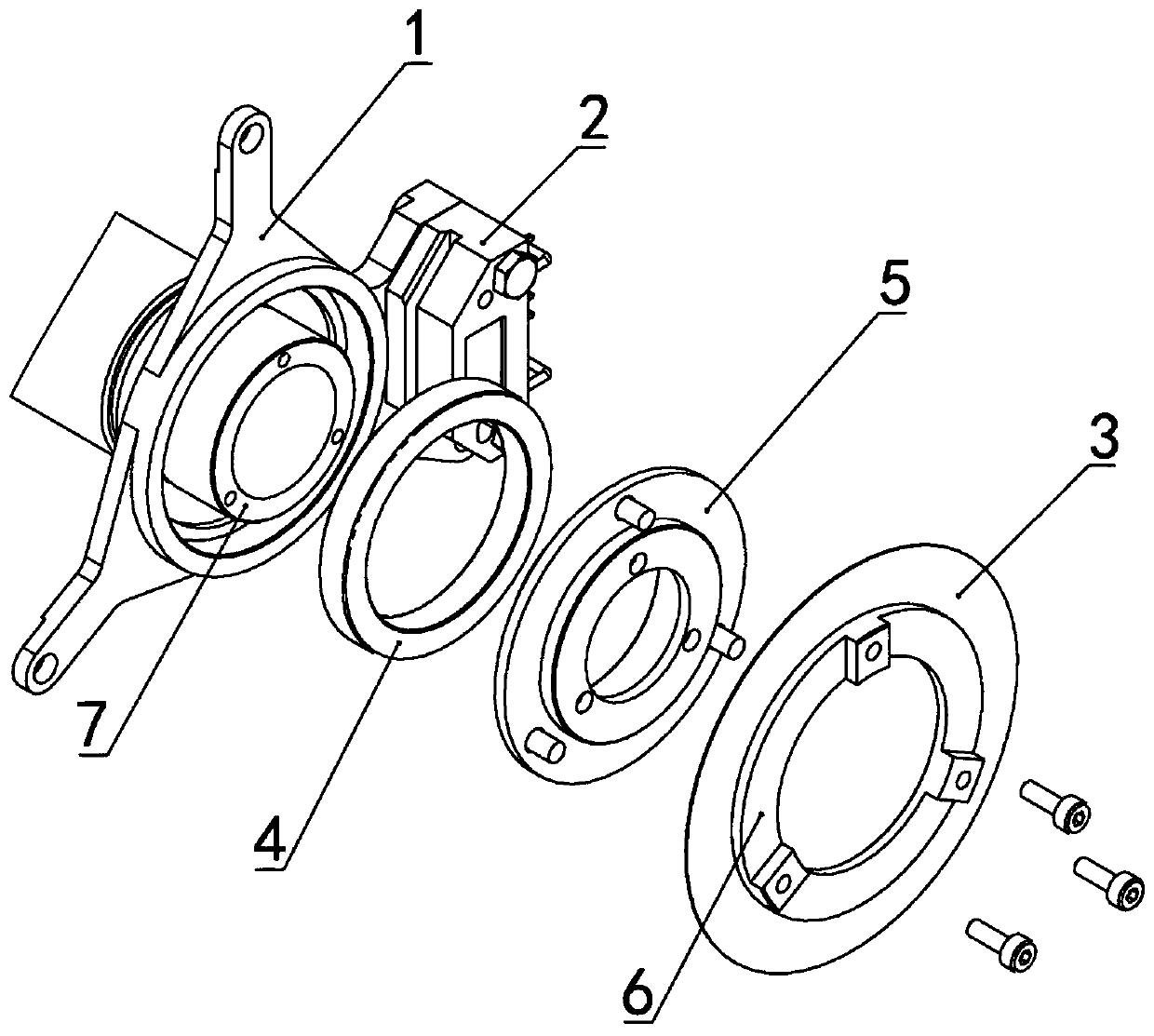

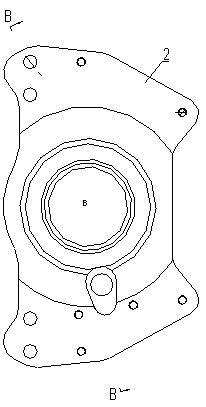

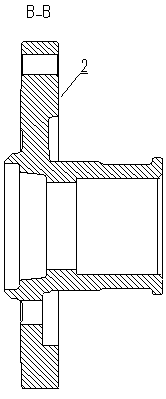

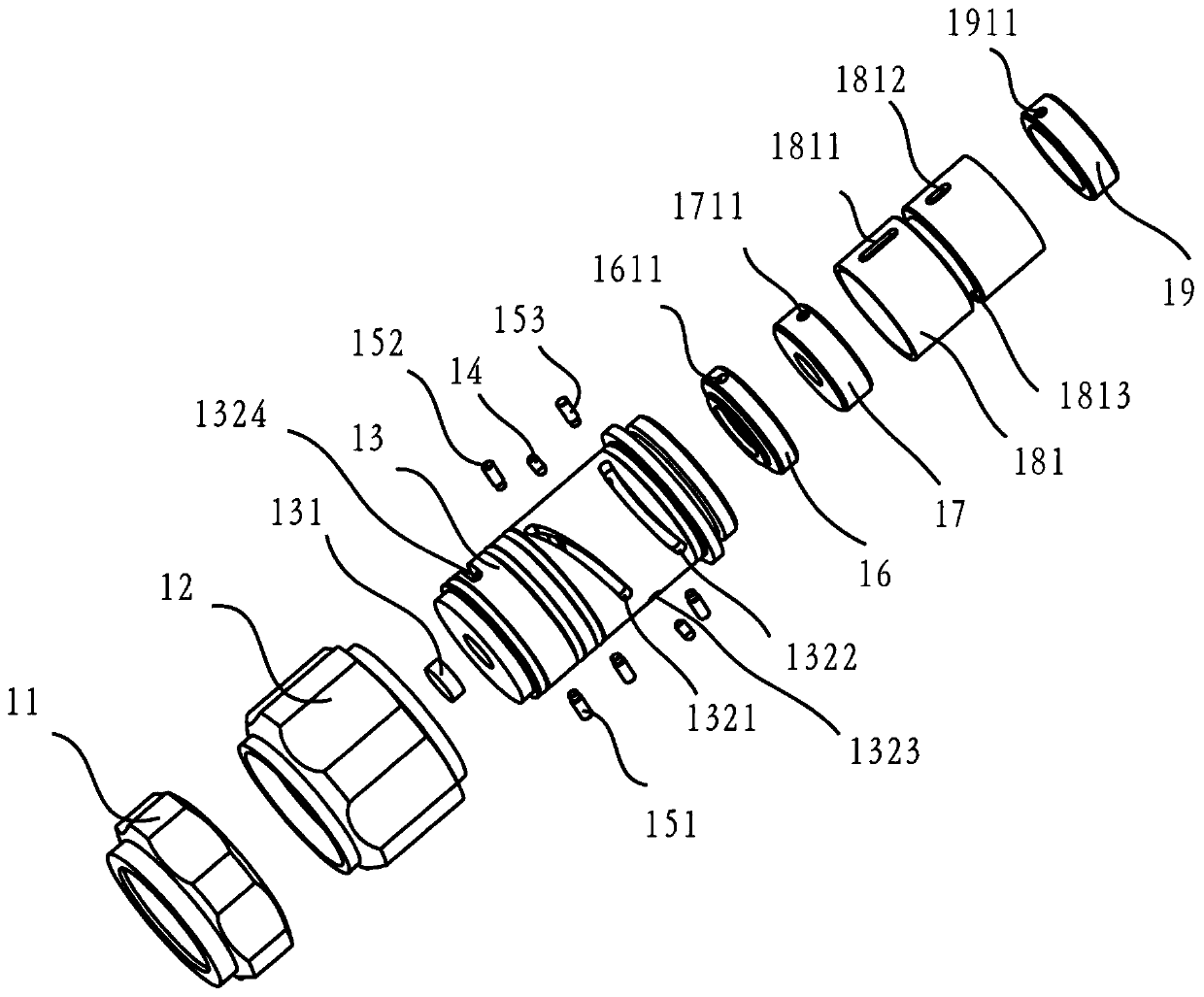

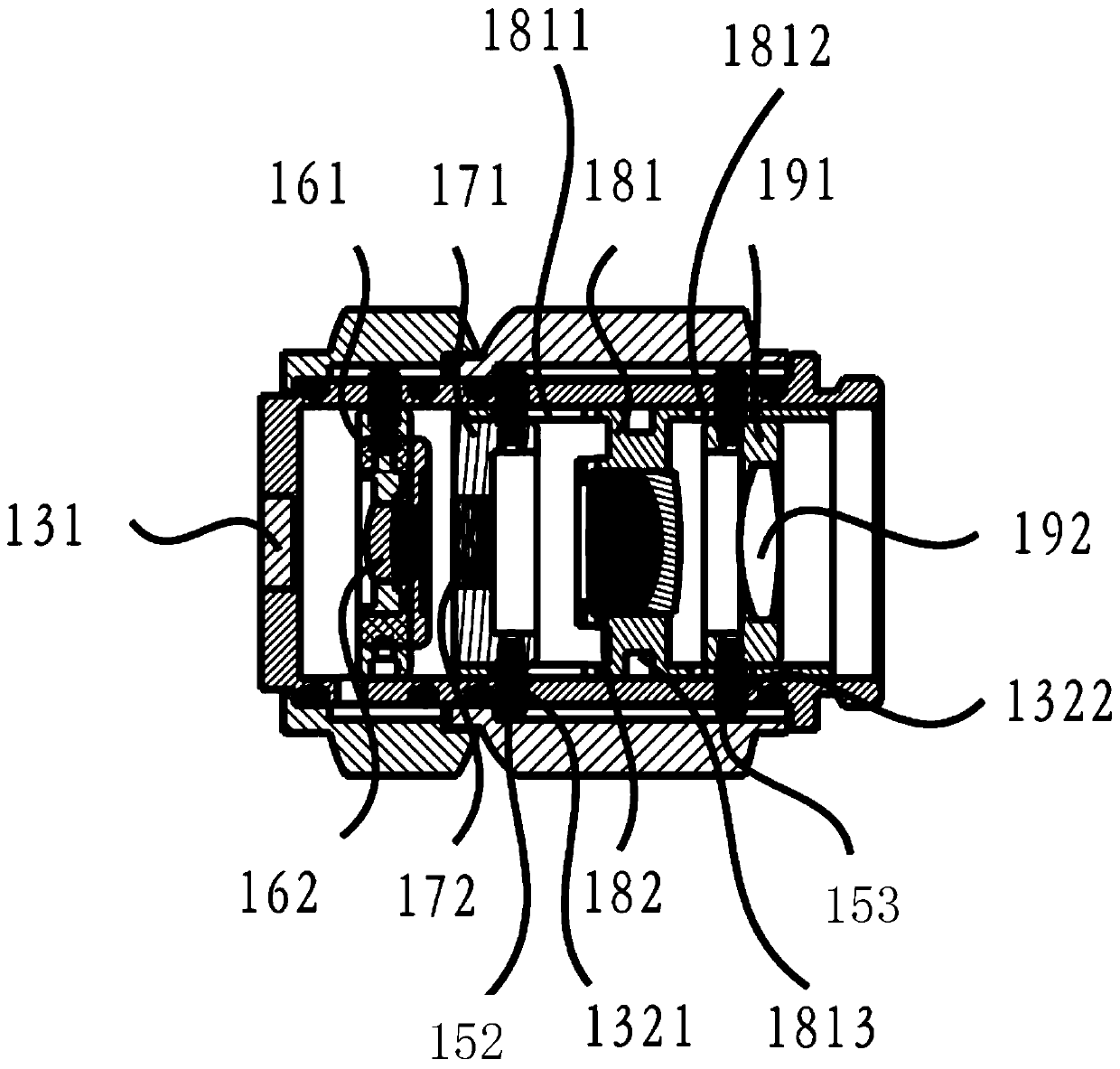

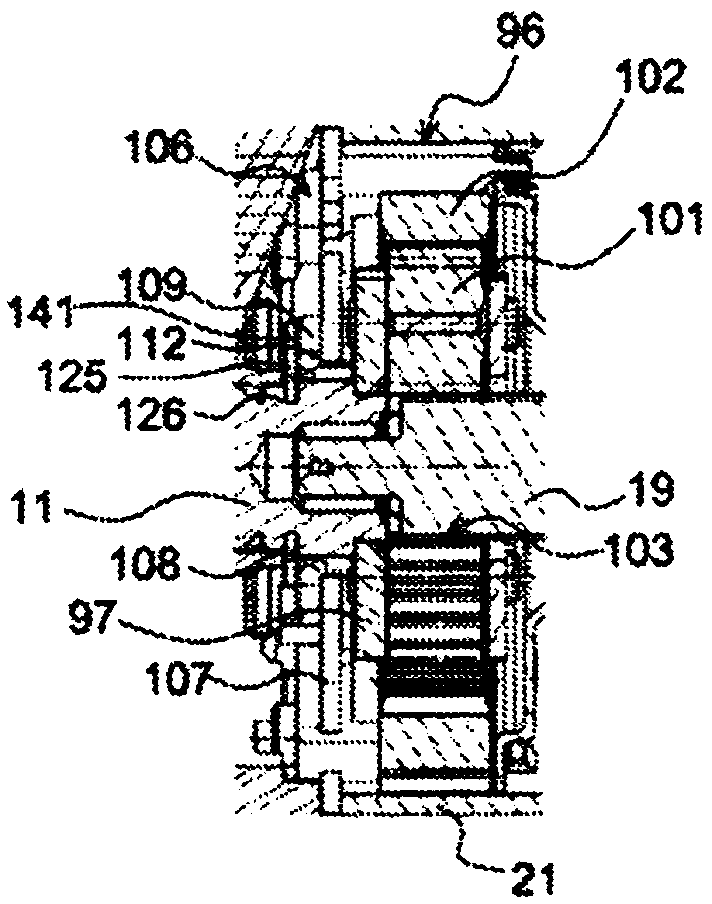

Positioning structure of joint encoder of robot, joint of robot and robot

InactiveCN110948514AShorten the dimensional chainImprove installation accuracyJointsComputer hardwareEngineering

The invention provides a positioning structure of a joint encoder of a robot, a joint of the robot and the robot. The positioning structure of the joint encoder of the robot comprises a mounting support, wherein a speed reducer shaft is arranged at the center position of the mounting support, and a read head is arranged at the outer edge of the mounting support to form a fixed group. The speed reducer shaft is sequentially sleeved with a bearing, an adapter and a locking piece, a code disc is clamped between the adapter and the locking piece through screws to form a moving group, the size chain between the read head and the code disc is greatly shortened, the mounting precision of the encoder is improved, the modularization of the encoder is realized, and debugging and trimming are facilitated.

Owner:MH ROBOT & AUTOMATION

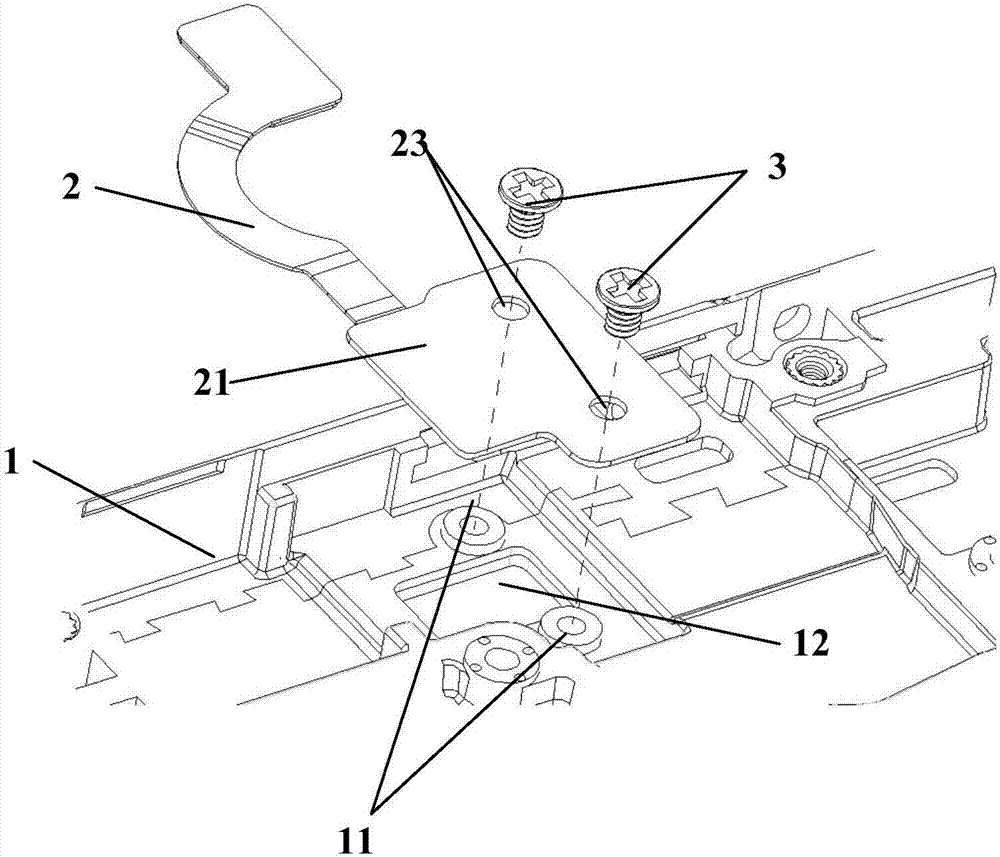

Photosensitive device fixing structure and mobile terminal

ActiveCN106896869AShorten the dimensional chainEasy to detectDigital data processing detailsTelephone set constructionsEngineeringComputer terminal

The invention discloses a photosensitive device fixing structure and a mobile terminal. The photosensitive device fixing structure comprises a mainboard upper cover and a FPC (Flexible Printed Circuit) assembly fixed to the mainboard upper cover, wherein the FPC assembly comprises a reinforcement plate, a photosensitive device directly fixed to the reinforcement plate, a first locating mounting part arranged on the reinforcement plate, and a seal sleeve arranged on the photosensitive device in a sleeving manner; and the FPC assembly is fixed to the mainboard upper cover through the locating mounting part. The FPC assembly of the mobile terminal is fixed to the mainboard upper cover, the photosensitive device is directly fixed to the reinforcement plate of the FPC assembly to serve as a part of the FPC assembly, and the FPC assembly can be fixed with the mainboard upper cover without a mounting bracket, so that a dimension chain of assembling of the photosensitive device is shortened; and an accumulated tolerance is reduced for improving the consistency of detection performance of the photosensitive device. In addition, the seal sleeve is arranged outside the photosensitive device in a sleeving manner, so that the mobile terminal has waterproof performance.

Owner:VIVO MOBILE COMM CO LTD

ABS induction mode structure of automobile drive rear axle

PendingCN111016863AShorten the dimensional chainStable signalBraking componentsAutomotive engineeringRolling chassis

The invention relates to an ABS induction mode structure of an automobile drive rear axle. An ABS sensor fixing structure comprises a half shaft sleeve, a flange plate, an ABS sensor and a support. The ABS sensor is fixed to the flange plate through the support. One end of the flange plate is in a butterfly shape and the other end of the flange plate is tubular; the inner diameter of the flange plate is larger than that of the half shaft sleeve; and the flange plate is welded to the half shaft sleeve; a groove and a circular hole are formed in the flange plate and correspond to the ABS sensorand the support. An ABS gear ring fixing structure comprises a brake disc, an ABS gear ring, a brake chassis bolt, a hub, a half shaft and a half shaft bolt. The ABS gear ring is fixed on the hub through the brake disc, the hub is fixedly connected with the half shaft through the half shaft bolt, the ABS gear ring is cylindrical, one end of the ABS gear ring is provided with a flange surface and aseam allowance; the brake disc is in an I shaped and annular, one end of the brake disc is provided with an inner seam allowance and a threaded hole, and the ABS gear ring and the brake disc are located by seam allowance fitting; and ; the other end of the brake disc is provided with a seam allowance in positioning connection with the hub. The air gap is easy to control, signals are stable, and the controllability of the automobile braking process is improved.

Owner:JIANGXI JIANGLING CHASSIS CO LTD

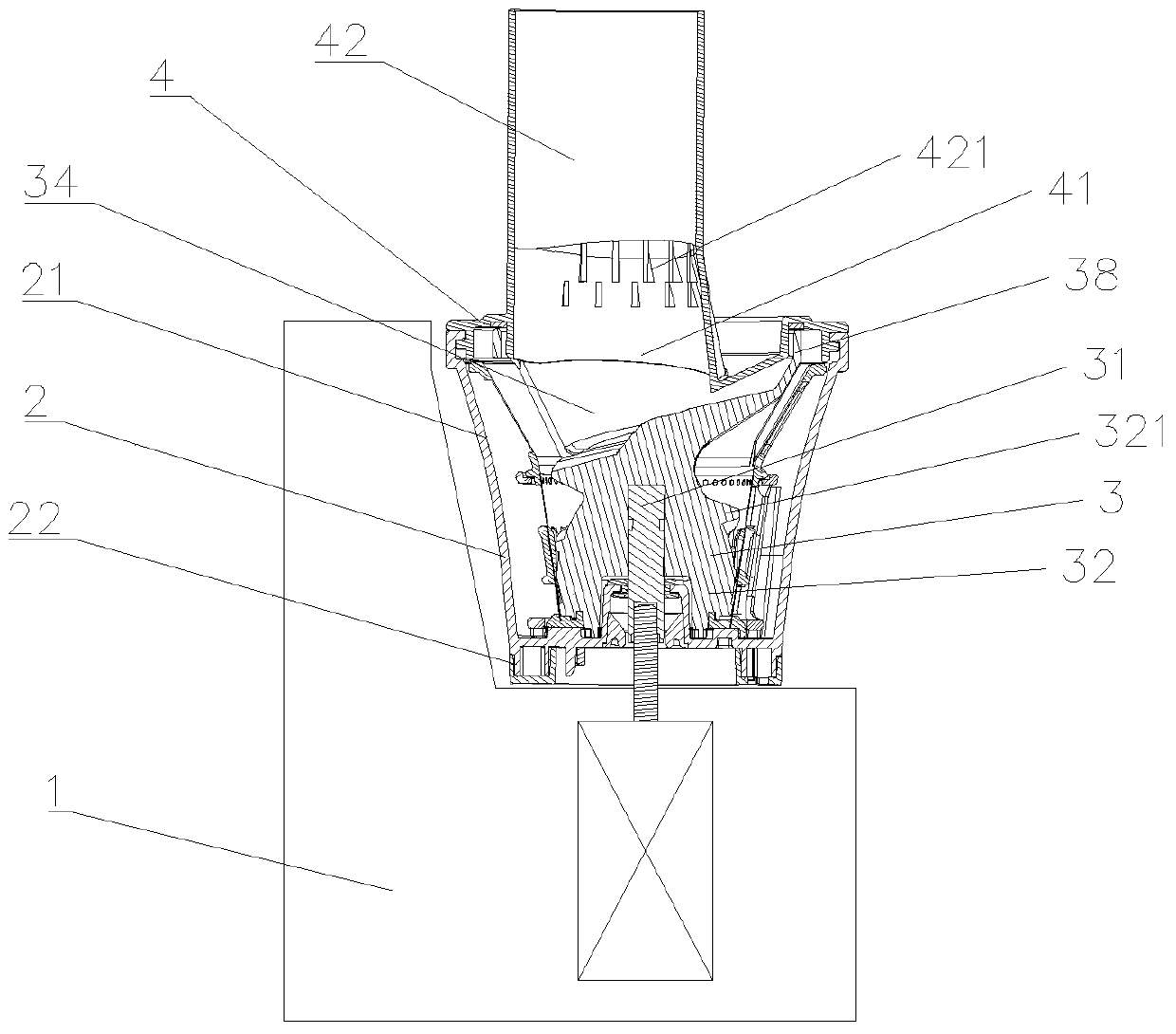

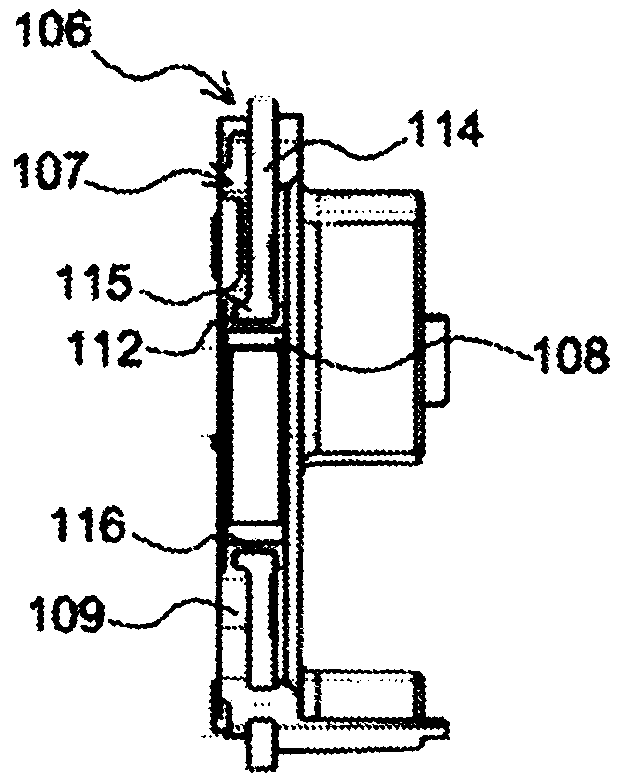

Medical endoscope optical parfocal lens

PendingCN111221092AImprove axial positioning accuracyImprove coaxialitySurgeryEndoscopesParfocal lensOphthalmology

The invention relates to a medical endoscope optical parfocal lens. According to the technical scheme, the medical endoscope optical parfocal lens is characterized in that the medical endoscope optical parfocal lens comprises a cam groove sleeve, a focusing lens group assembled in the cam groove sleeve, a fixed base rotationally assembled in the cam groove sleeve, a fixed lens assembled in the fixed base, a plurality of zoom lens assemblies assembled in the fixed base, a focusing driving assembly assembled on the cam groove sleeve and used for driving the focusing lens group to move along theoptical axis; and a zoom driving assembly assembled on the cam groove sleeve, used for driving the plurality of zoom lens assemblies to move along the optical axis, and synchronously rotating around the optical axis with the fixed lens in the fixed base. Therefore, the coaxiality, the inclination and the axial positioning precision between the zoom lens assembly and the fixed lens are improved, and the problems of image bounce and image blurring caused by position errors between the zoom lens assembly and the fixed lens assembly in the zoom process are effectively solved.

Owner:深圳英术生命科技有限公司

A car radiator bracket structure

ActiveCN105522909BHigh strengthIncrease connection forcePropulsion coolingEngineeringInjection moulding

The invention relates to an automobile radiator bracket structure which comprises a bracket for bearing a radiator, wherein the bracket comprises a bracket body made of enhanced plastics and a metal insert embedded on the bracket body, mounting and positioning holes are formed in the metal insert, and the bracket body and the metal insert are formed by injection molding in one step to obtain an integrated composite component. The scheme solves the problems in the prior art that the radiator bracket is high in investment of welding fixture and complicated in process.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

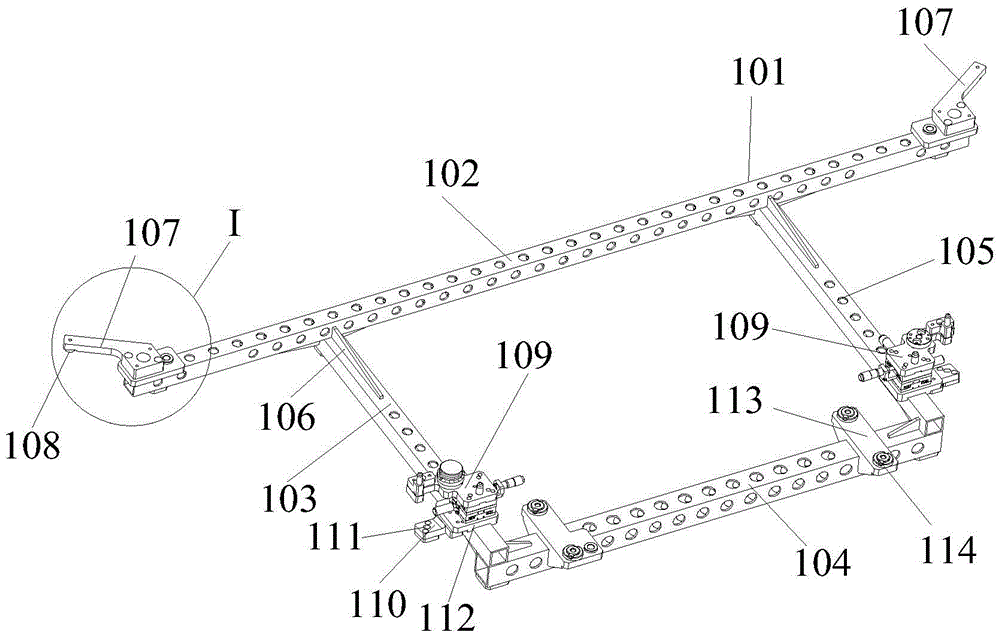

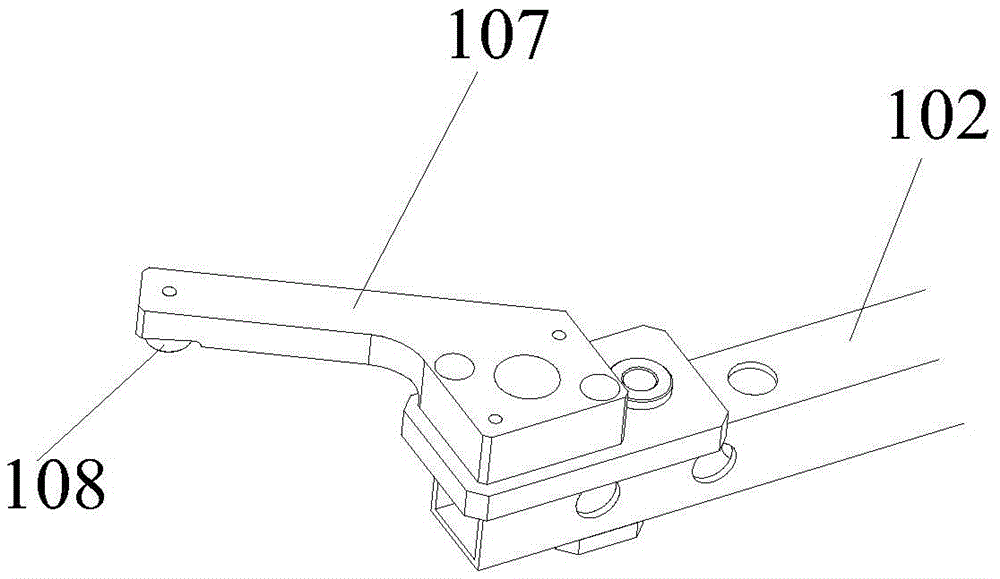

Detection device and method for machine cover on body-in-white

ActiveCN103557765BEasy to operateReduce the span of the gageMechanical measuring arrangementsLocking mechanismProsthesis

The invention relates to a detection device with a machine cover on a body in white, and belongs to the technical field of automobile detection. It includes a front retaining frame assembly and a front retaining frame dummy, the front retaining frame assembly includes a first bracket, a second bracket, a third bracket and a fourth bracket connected in sequence to form a rectangular frame structure, the first bracket The two ends are provided with a positioning structure for positioning with the vehicle body in the Z direction, and the second bracket and the fourth bracket are provided with a slider mechanism, and the slider mechanism is provided with a first fixing structure for fixing with the vehicle body in the Z direction. Positioning pins for X-direction and Y-direction positioning, X-direction adjustment and locking mechanism, and Y-direction adjustment and locking mechanism. The third bracket is provided with a second fixing structure for fixing with the front retaining frame dummy. The invention has precise positioning and can effectively shorten the size chain.

Owner:DONGFENG PEUGEOT CITROEN AUTOMOBILE

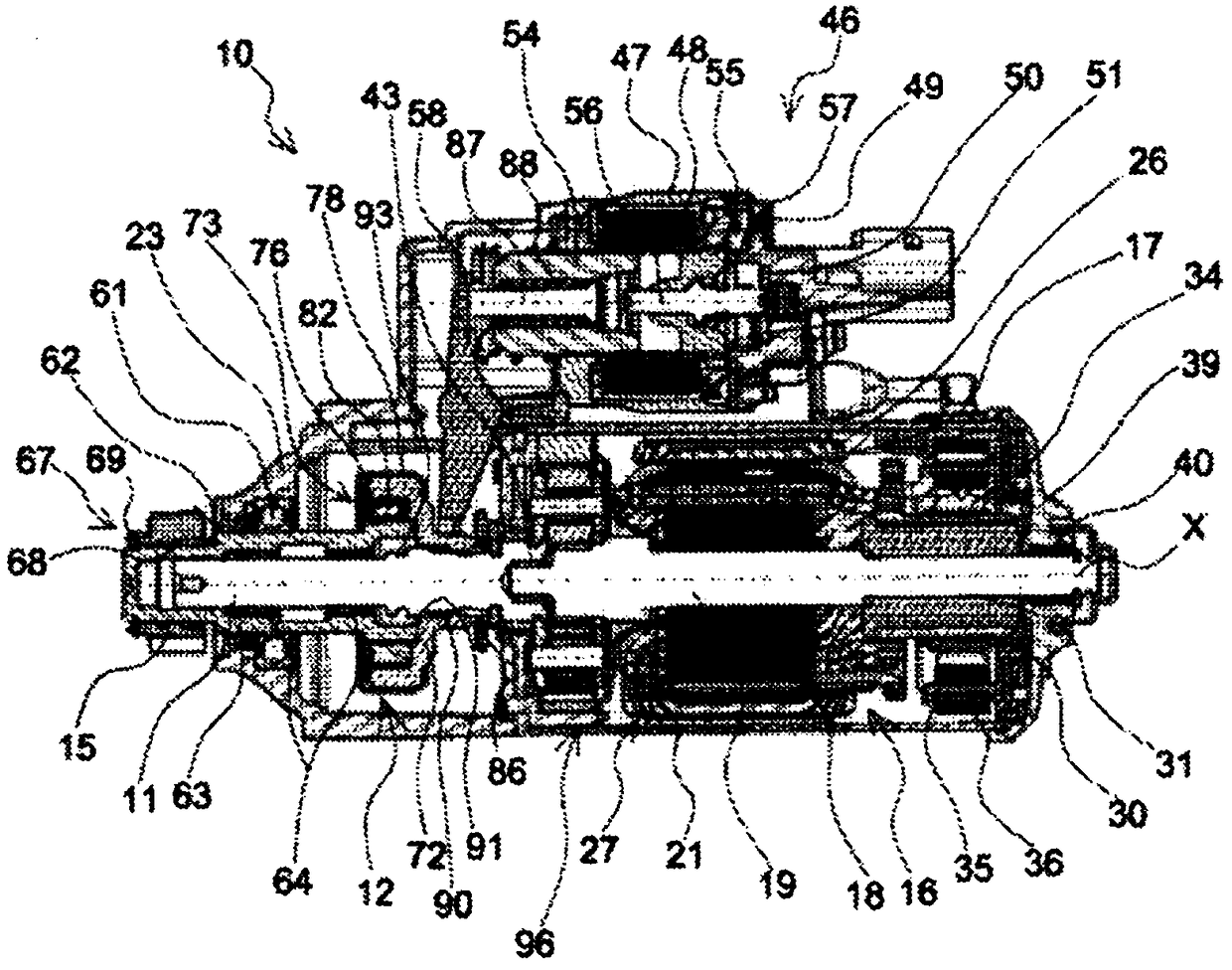

Motor vehicle heat engine starter with optimised-shape damping pads

ActiveCN109072857AExtended service lifeShorten the dimensional chainPower operated startersYielding couplingEngineeringPlastic materials

The invention relates mainly to a heat engine starter for a motor vehicle, comprising: a planetary-type speed reduction gear mounted between the rotor shaft and the drive shaft; and a base plate (106)having a plastic-material portion comprising abutment portions (120), wherein the ring gear (102) has tabs (121) at its outer periphery and damping pads (122) are mounted between said tabs (121) andsaid abutment portions (120), characterized in that each damping pad (122) has at least one rounded corner (145) on the side of a projecting edge (146) of a corresponding tab (121) of said ring gear (102), which rounded corner is rounded along a radius of curvature located in a plane containing all the corners of said damping pad (122) such that a space is provided between said rounded corner (145) and a right-angled corner defined by the intersection of planes passing through side faces joined by this rounded corner (145).

Owner:VALEO EQUIP ELECTRIC MOTEUR

A photosensitive device fixing structure and mobile terminal

ActiveCN106896869BShorten the dimensional chainEasy to detectDigital data processing detailsTelephone set constructionsComputer terminalMotherboard

Owner:VIVO MOBILE COMM CO LTD

A side-suction range hood and a gap adjustment method thereof

ActiveCN111380092BEffective control clearanceGuaranteed clearanceDomestic stoves or rangesLighting and heating apparatusStructural engineeringMechanical engineering

The invention discloses a side-suction type range hood, comprising a casing and a panel assembly arranged on the front side of the casing, the panel assembly comprising a panel and a smoke baffle arranged on the panel, and characterized in that: the panel is characterized in that: It includes a first fixing part bent backwards provided at the top, and a second fixing part bent backwards set at the bottom, the first fixing part and the second fixing part are respectively connected and fixed with the casing. Also disclosed is a clearance adjustment method for the above-mentioned side-suction range hood. Compared with the prior art, the present invention has the advantages that: by respectively bending the top and bottom of the panel to form fixing parts fixed to the casing, the gap at the upper and lower connection positions of the panel assembly and the casing can be effectively controlled; The left and right sides of the panel are provided with sliders and foam strips that cooperate with the left and right side panels of the casing, which can effectively control the gap between the left and right connection positions of the panel assembly and the casing.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Skylight frame reinforcing assembly

The invention discloses a skylight frame reinforcing assembly comprising a skylight reinforcing frame, a top cover, two upper edge beam inner plates and two A column upper reinforcing plates. The twoA column upper reinforcing plates are fixed to the inner sides of the two corresponding upper edge beam inner plates correspondingly. The skylight reinforcing frame is fixed among the top cover and the upper edge beam inner plates. The upper and lower sides of the skylight reinforcing frame are each provided with a fixed overlap edge. The two upper edge beam inner plates are each provided with a first avoiding notch. The two A column upper reinforcing plates are each provided with a second avoiding notch. The fixed overlap edges are fixed to the corresponding upper edge beam inner plates and the corresponding A column upper reinforcing plates in a crossing mode through the first avoiding notches and the second avoiding notches. Vehicle body side periphery outer plates are fixed to the upper edge beam inner plates and the outer side of the skylight reinforcing frame. According to the skylight frame reinforcing assembly, the number of layers of fixed plates is reduced effectively, the connection problem of multiple layers of plates is solved effectively, and thus after dimension chains are reduced, the problem of the large surface difference of a finally assembled skylight and the vehicle body top cover is solved.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com