A wire cutting robot for machining complex curved surfaces

A complex surface, wire cutting technology, applied in the field of robots, can solve the problems of difficult to control machining accuracy, complex structure, extended dimension chain, etc., to achieve the effect of high repetitive positioning accuracy, simplified machine tool structure, and advanced control methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

[0020] The invention adopts the series robot arm to replace the traditional machine tool cross table and other auxiliary linkage equipment, and constructs the theory and realization method of the multi-axis linkage wire cutting robot.

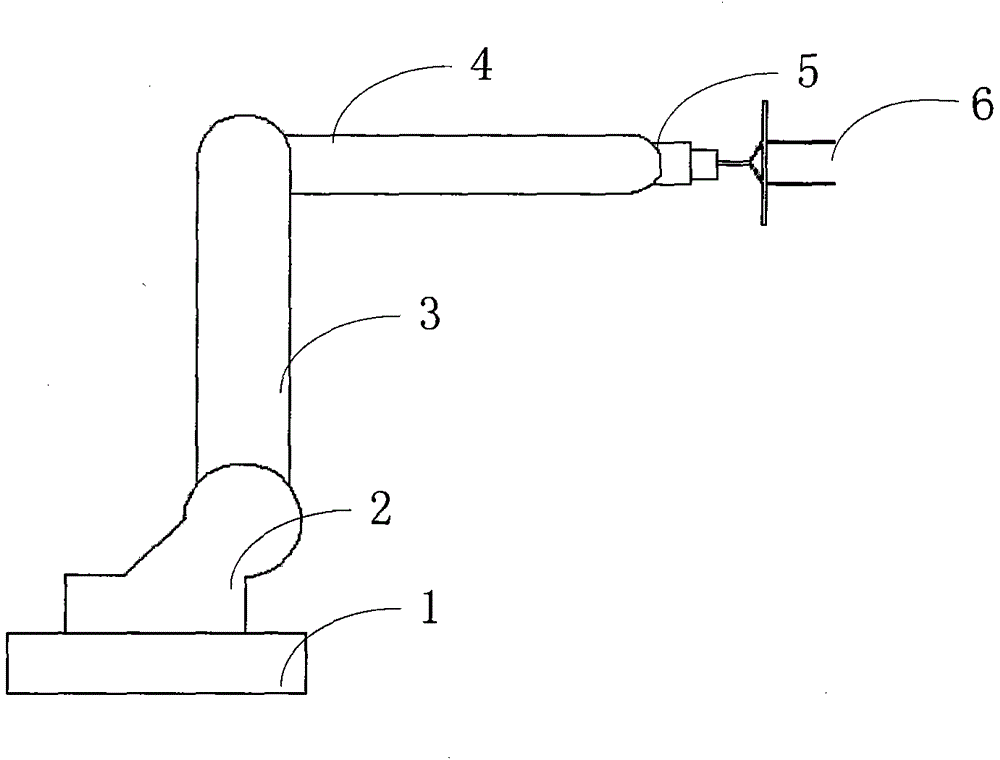

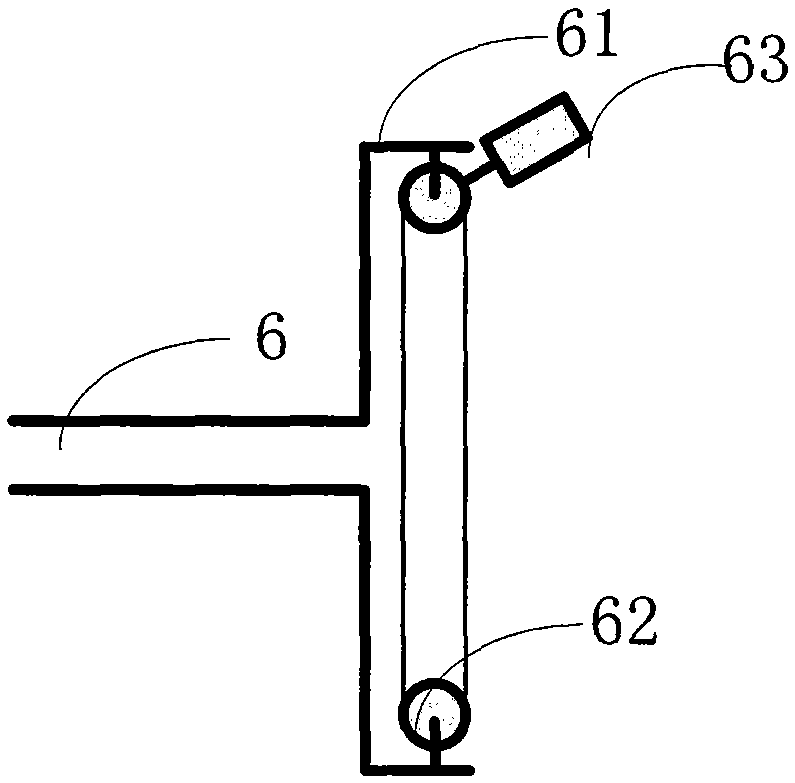

[0021] see figure 1 As shown, it is a schematic diagram of the three-dimensional structure of the wire cutting robot arm of the present invention. The series robot arm in the present invention includes a base 1, a waist 2, a large arm 3, a forearm 4, a wrist 5 and a fingertip electrode wire holder 6 , wherein, the waist 2 is installed on the base 1 through the first bearing, and the first servo motor is installed on the waist 2 to control the rotation of the waist 2 in the horizontal direction around the axis of the base; the large The arm 3 is connected to the waist 2 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com