Mounting nut plate for automobile door hinge and mounting structure thereof

A technology for door hinges and nut plates, which is applied to doors, hinges, and vehicle components, can solve the problems of multiple welding layers, multiple influencing factors, and poor stability of the dimensional accuracy of steering supports and door hinge mounting plates, achieving Improve relative position accuracy, reduce cost, and ensure the effect of appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

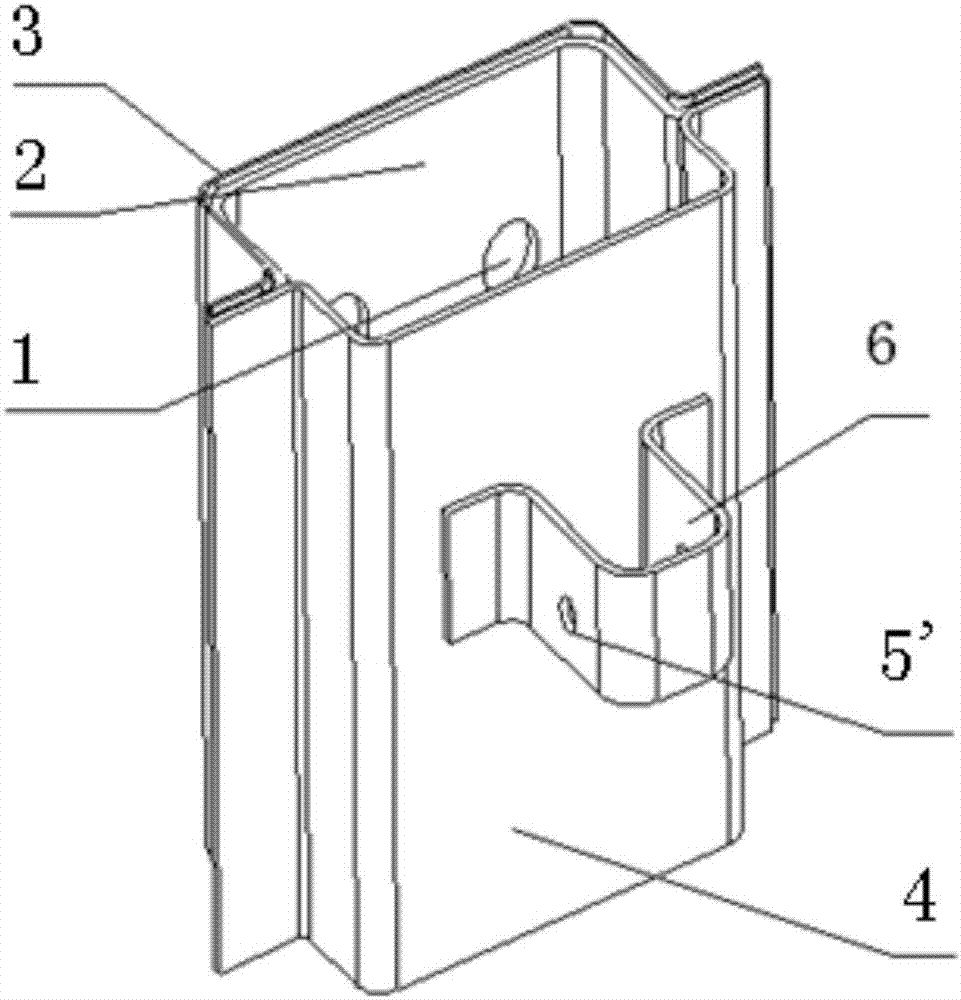

[0026] The present invention will be further described below in conjunction with accompanying drawing.

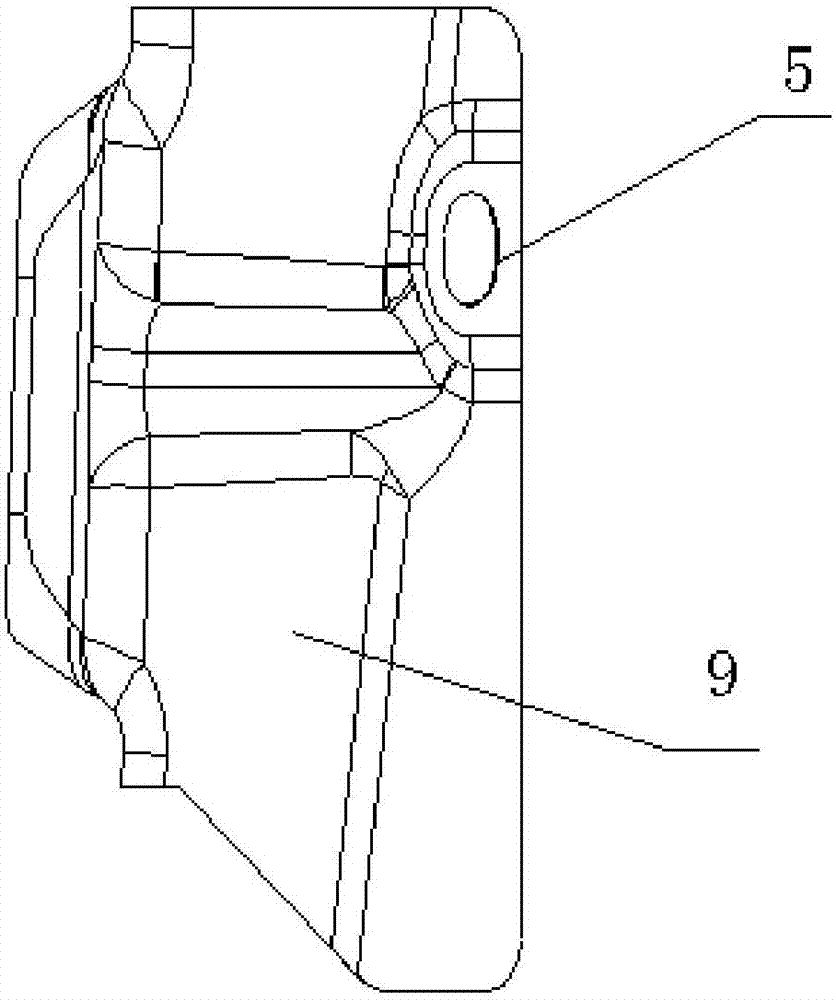

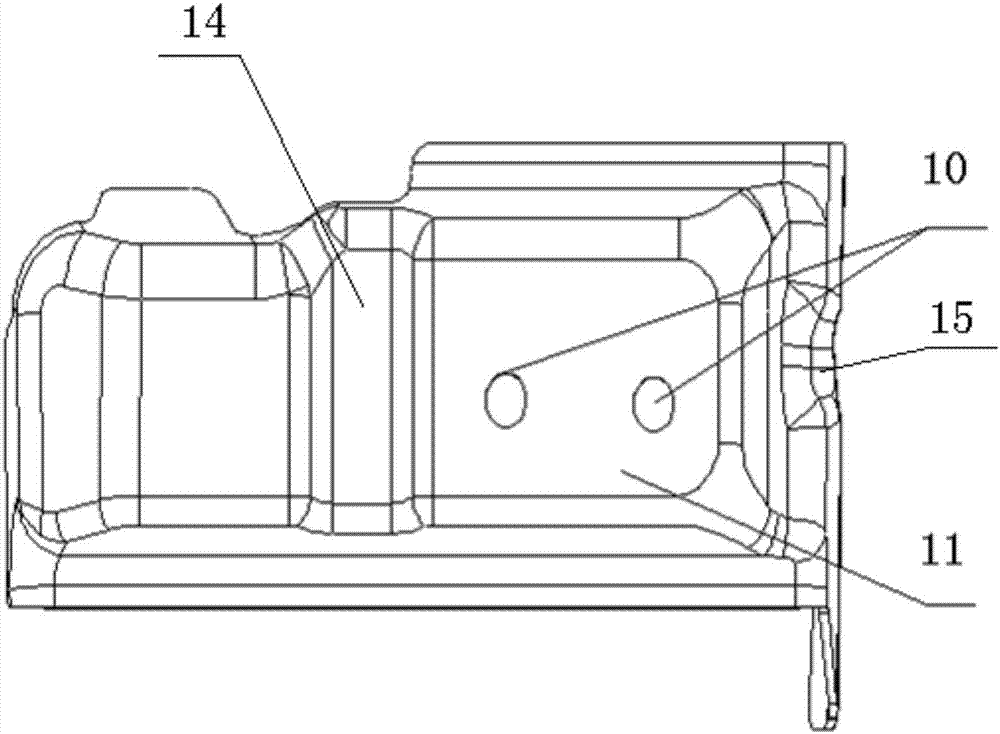

[0027] like Figure 2 to Figure 5 The shown door hinge mounting nut plate includes a mounting nut plate body, the mounting nut plate body is an L-shaped bent plate, including a hinge mounting plate 11 and a steering support positioning plate 9, and on the hinge mounting plate 11 there are two A hinge mounting nut hole 10 with a projection welding nut is provided with a steering support positioning hole 5 on the steering support positioning plate 9, and this steering support positioning hole 5 is an oblong hole for the positioning of the steering support on the upper part of the vehicle body.

[0028] like Figure 2 to Figure 5 As shown, the surrounding edges of the mounting nut plate body are provided with flanges 12 to increase the strength of the mounting nut plate body.

[0029] like Figure 2 to Figure 5 As shown, the hinge mounting plate 11 is provided with a first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com