Motor vehicle heat engine starter with optimised-shape damping pads

A heat engine, motor vehicle technology, applied in the direction of engine starting, engine motor starting, machine/engine, etc., can solve the problems of strong, rapid pad tearing, etc., to shorten the size chain, increase the service life, and reduce noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

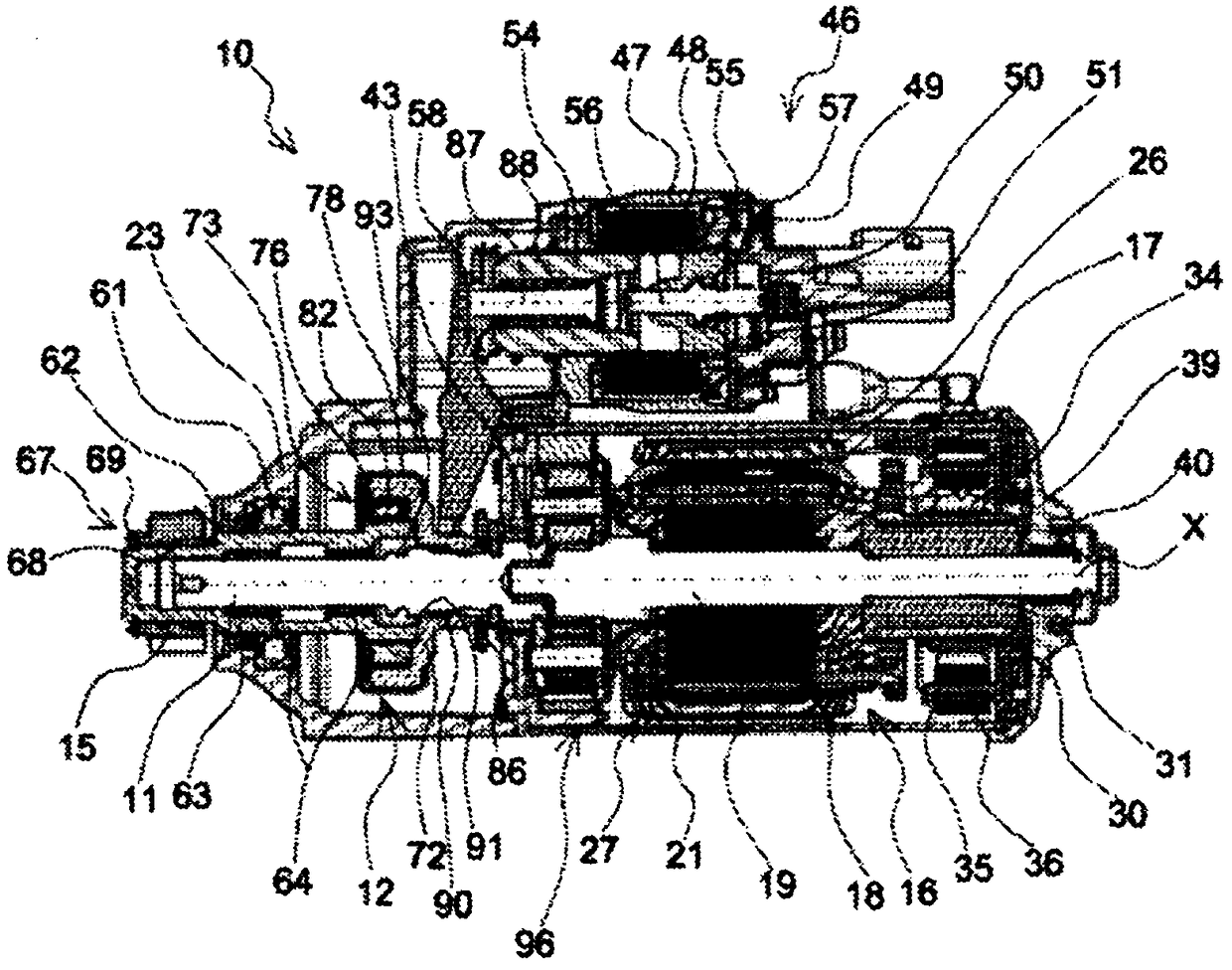

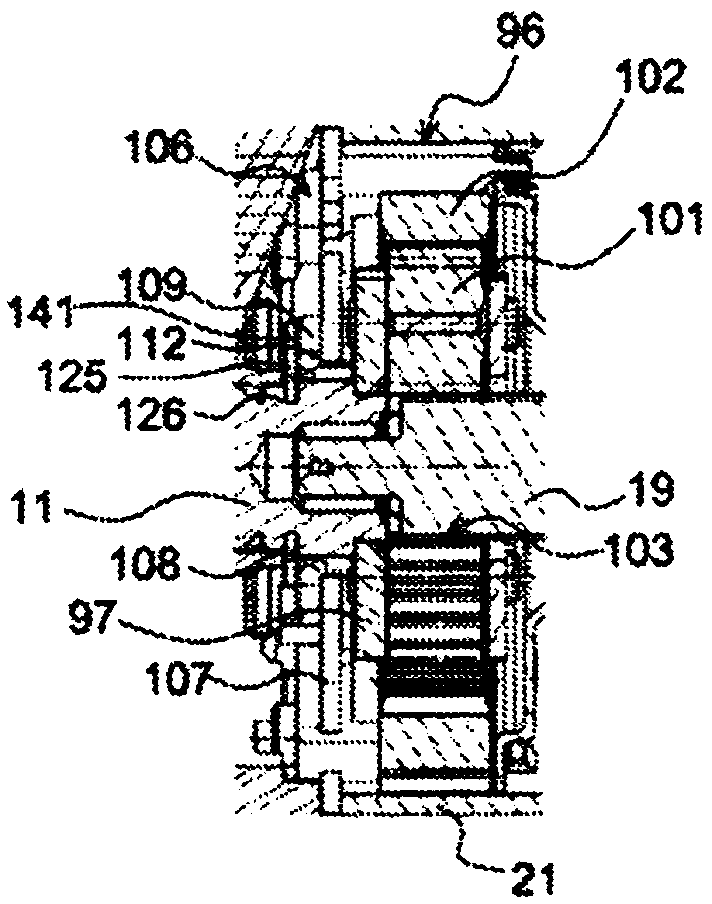

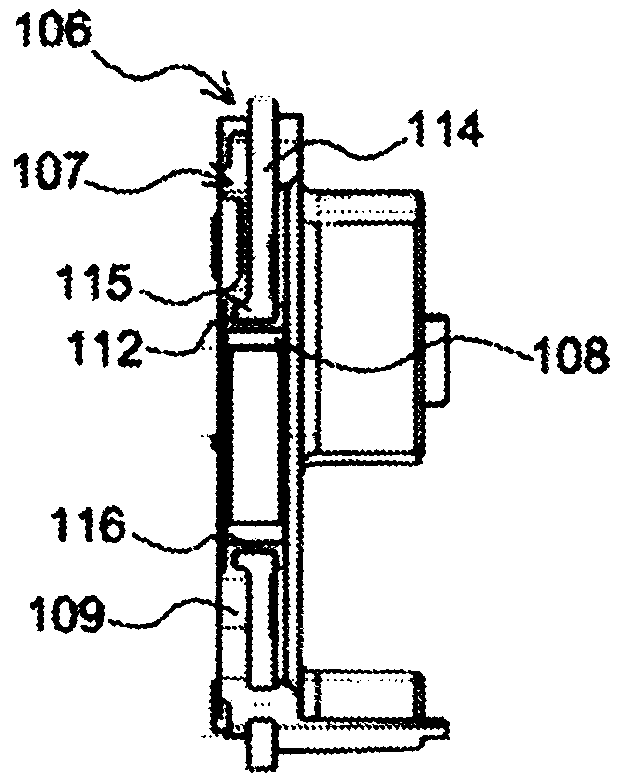

[0043] In the various figures, identical, similar or analogous elements keep the same reference numerals. In the description below, the axial direction will be used from back to front, corresponding to figure 1 in the right-to-left direction. In other words, the front element is located on the side of the drive pinion 15 and the rear element is located on the opposite side, ie on the side of the rear flange 39 .

[0044] refer to figure 1 , The starter 10 according to the present invention includes a drive shaft 11 and a starter 12 mounted on the drive shaft 11 and including a drive pinion 15 . Furthermore, the electric motor 16 includes an inductor stator 17 and a coaxially mounted induction rotor 18 . The stator 17 surrounds a rotor 18 mounted on a shaft 19 of the electric motor 16 . The rotor 18 is rotatable about an axis X inside the yoke 21 . The latter is integral with the metal support 23 of the starter 10 , which is designed to be fixed on a stationary part of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com