Skylight frame reinforcing assembly

A technology for strengthening components and skylight frames, applied in vehicle parts, roofs, transportation and packaging, etc., and can solve problems such as large roof surface differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

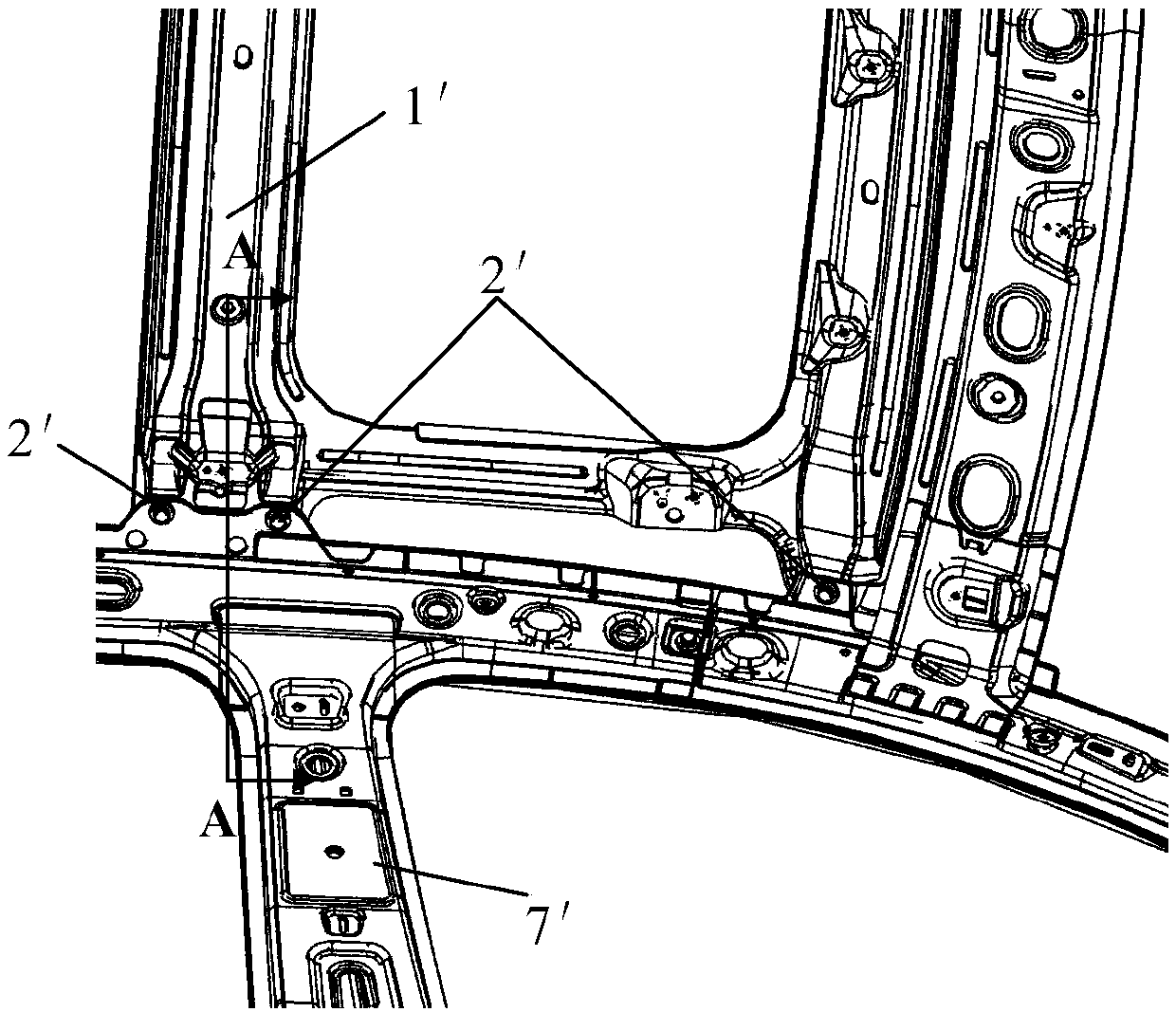

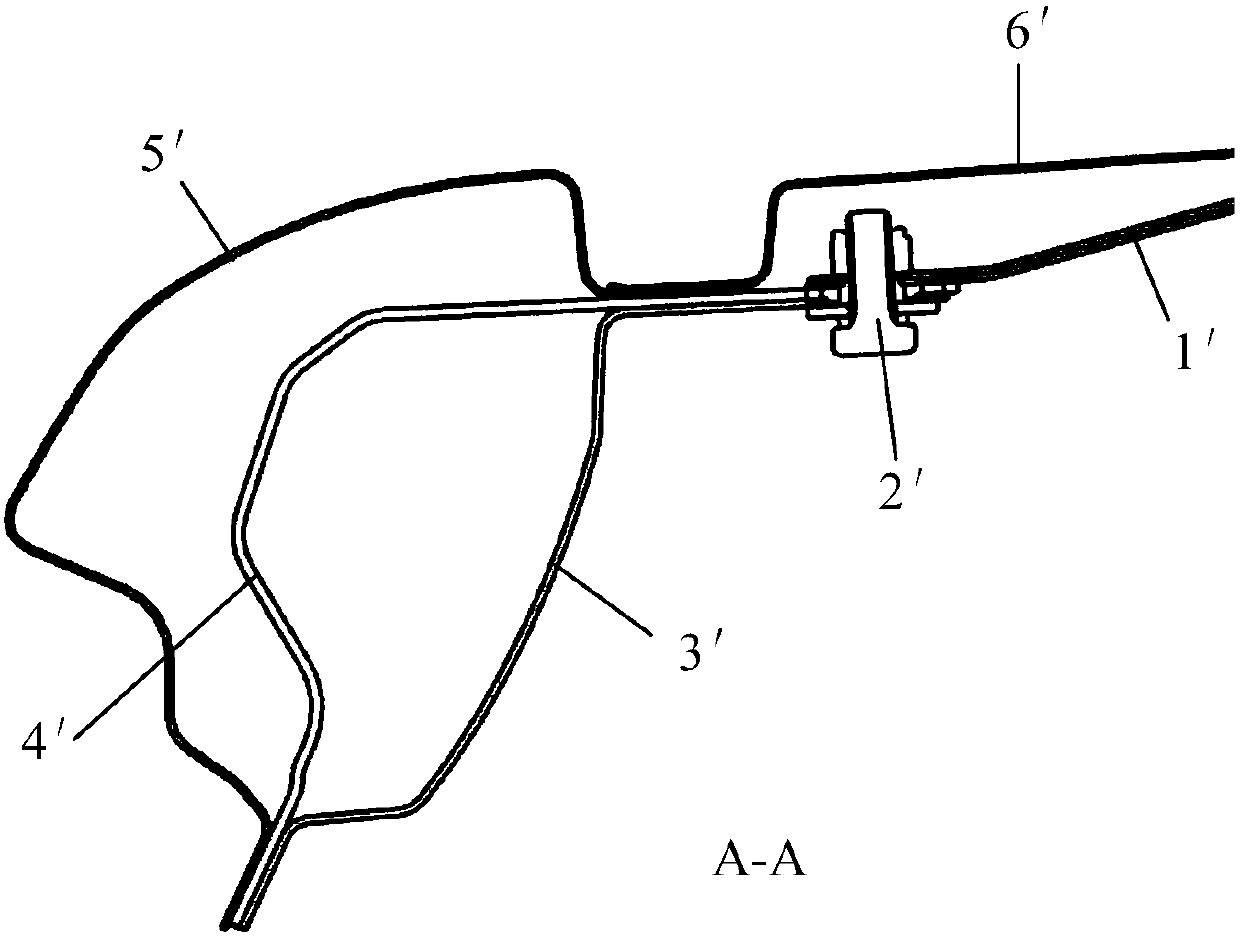

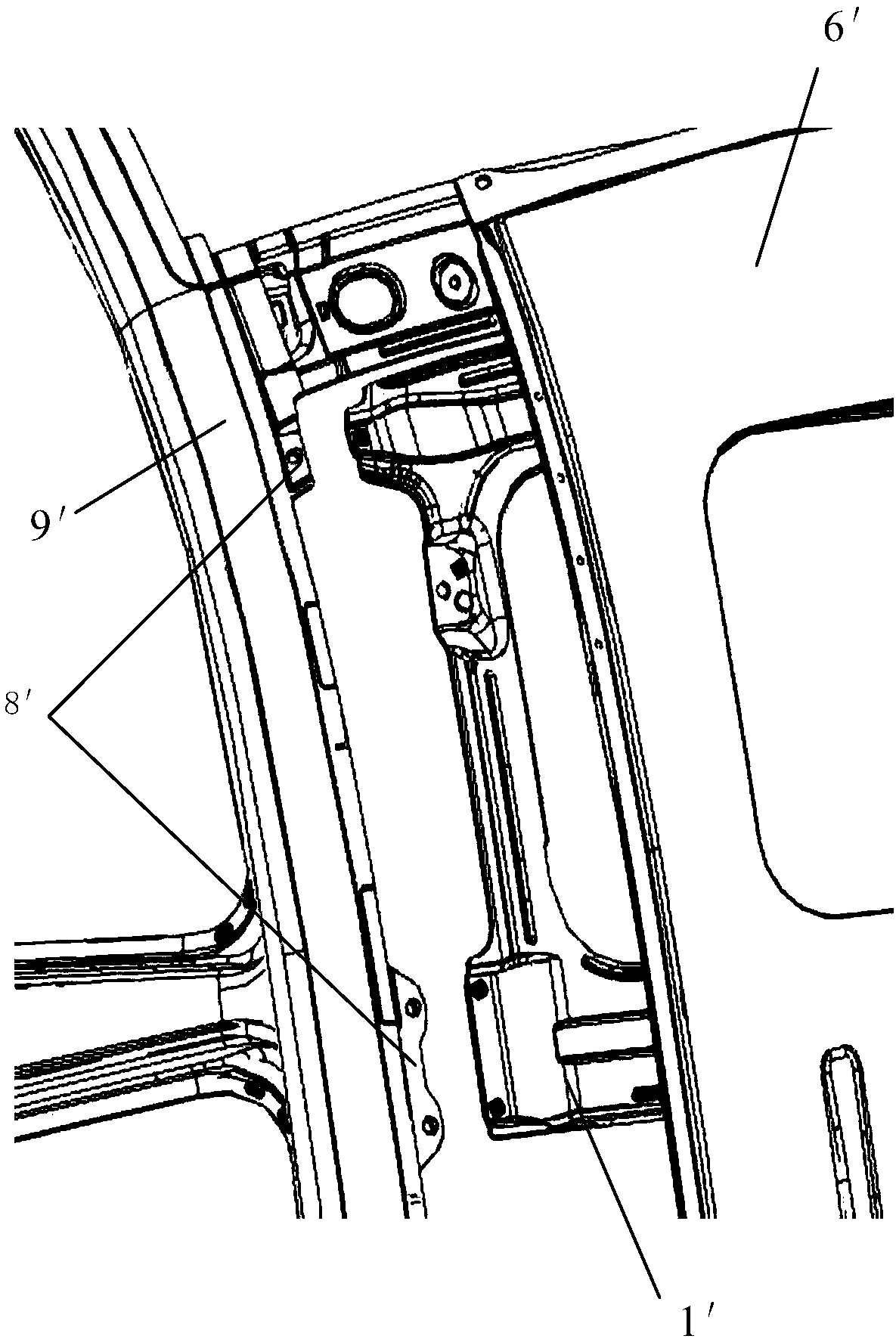

[0046] The following with attached Figure 6 to Figure 14 A sunroof frame reinforcement assembly of the present invention is further described in detail.

[0047] A sunroof frame reinforcement assembly of the present invention, please refer to Figure 6 to Figure 14As shown, the sunroof reinforcement frame 1 is included, and the sunroof reinforcement frame 1 is fixed between the vehicle roof 7 and the vehicle body top lining 8, and the upper and lower sides of the sunroof reinforcement frame 1 are provided with fixed laps 10, and the sunroof reinforcement The upper and lower sides of the frame 1 are respectively fixed between the corresponding upper side sill inner panel 2 and the upper reinforcement panel 6 of the A-pillar by fixed laps 10, and the upper side sill inner panel 2 is provided with a first fixing point 19 and a first avoidance Notch 20, the A-pillar upper reinforcement plate 6 is provided with a second fixed point and a second avoidance notch, the first avoidanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com