Patents

Literature

33results about How to "Improve axial positioning accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

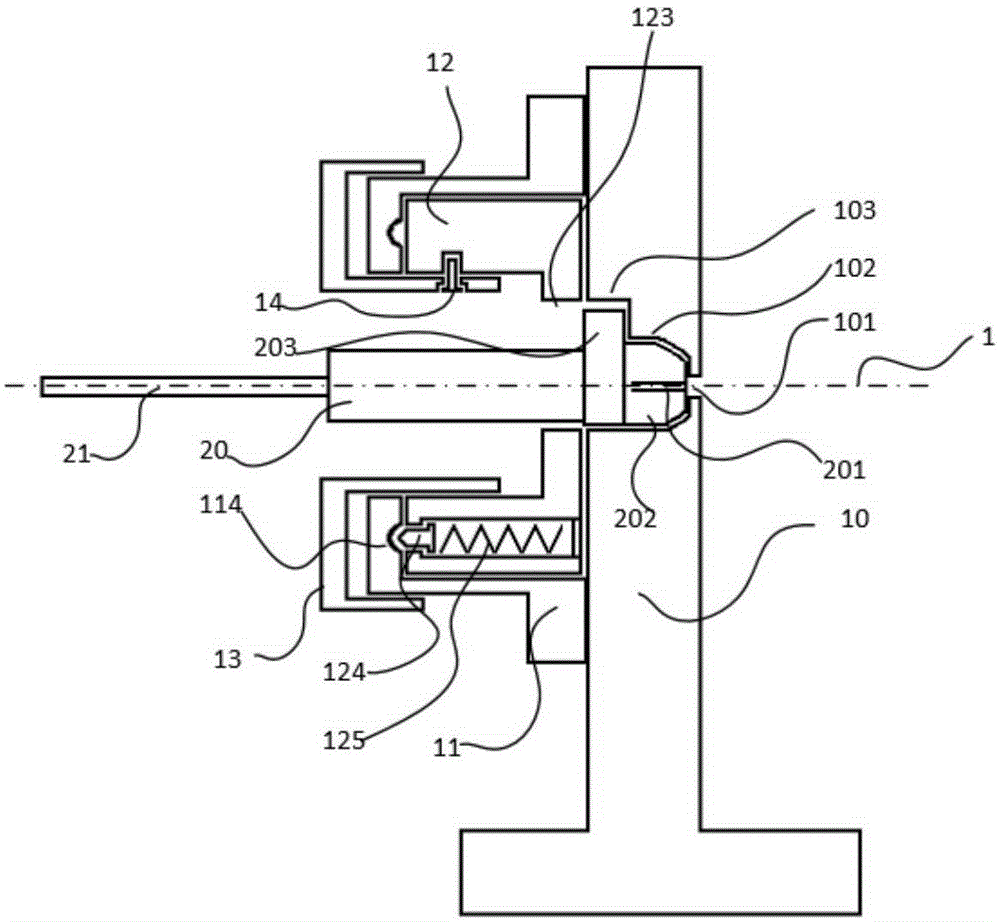

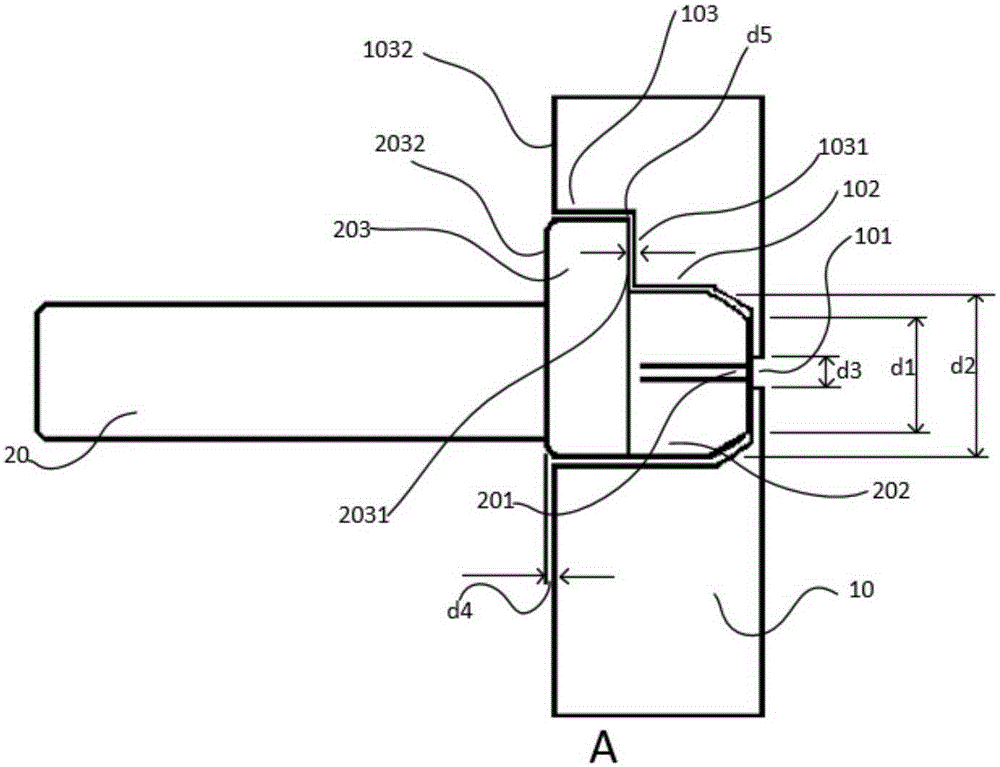

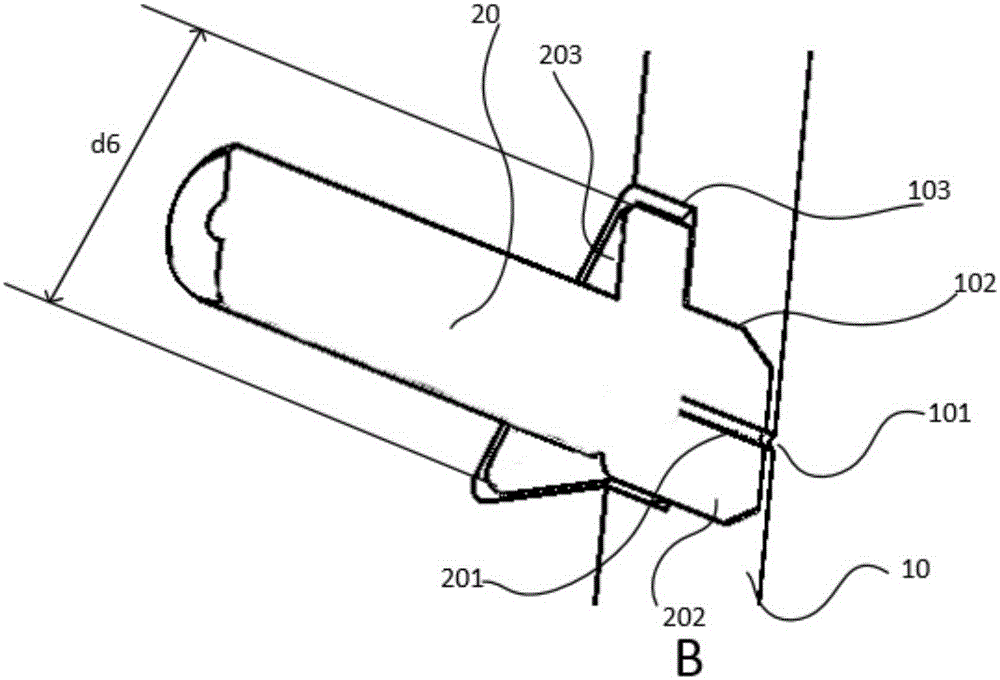

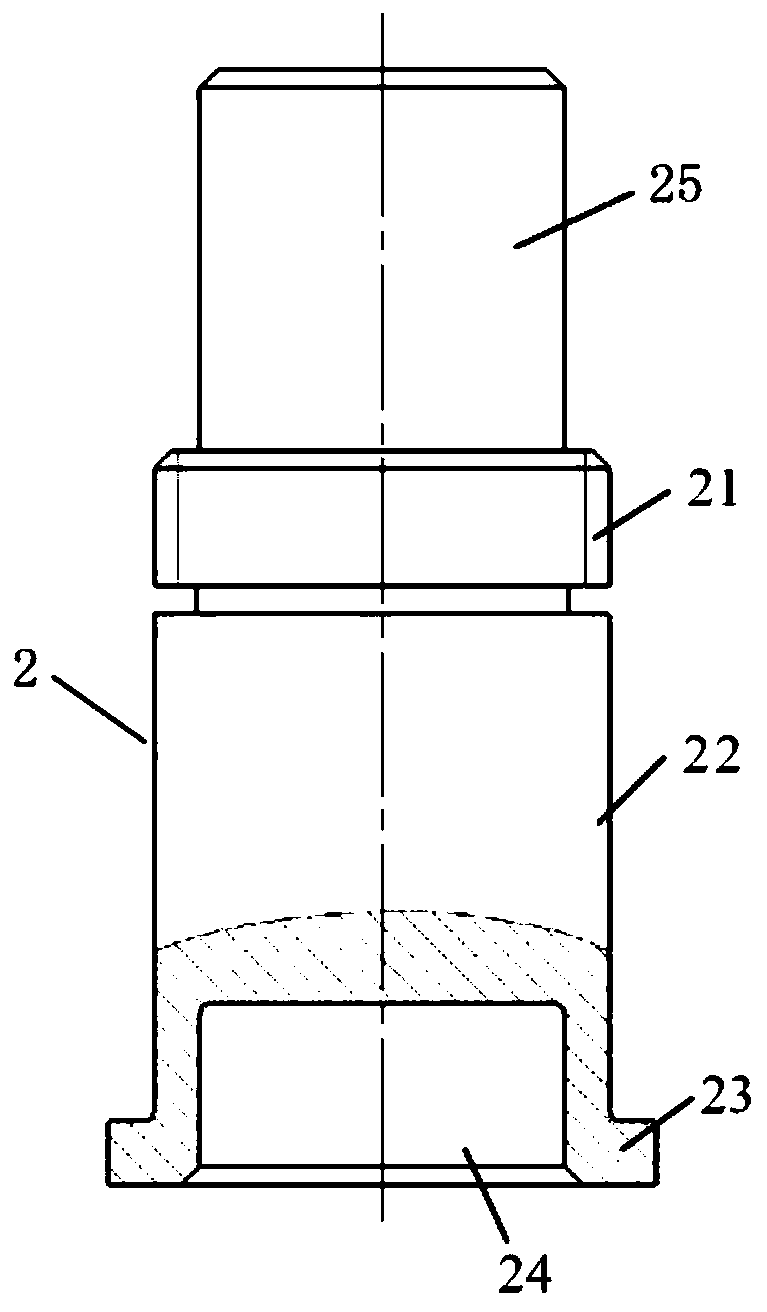

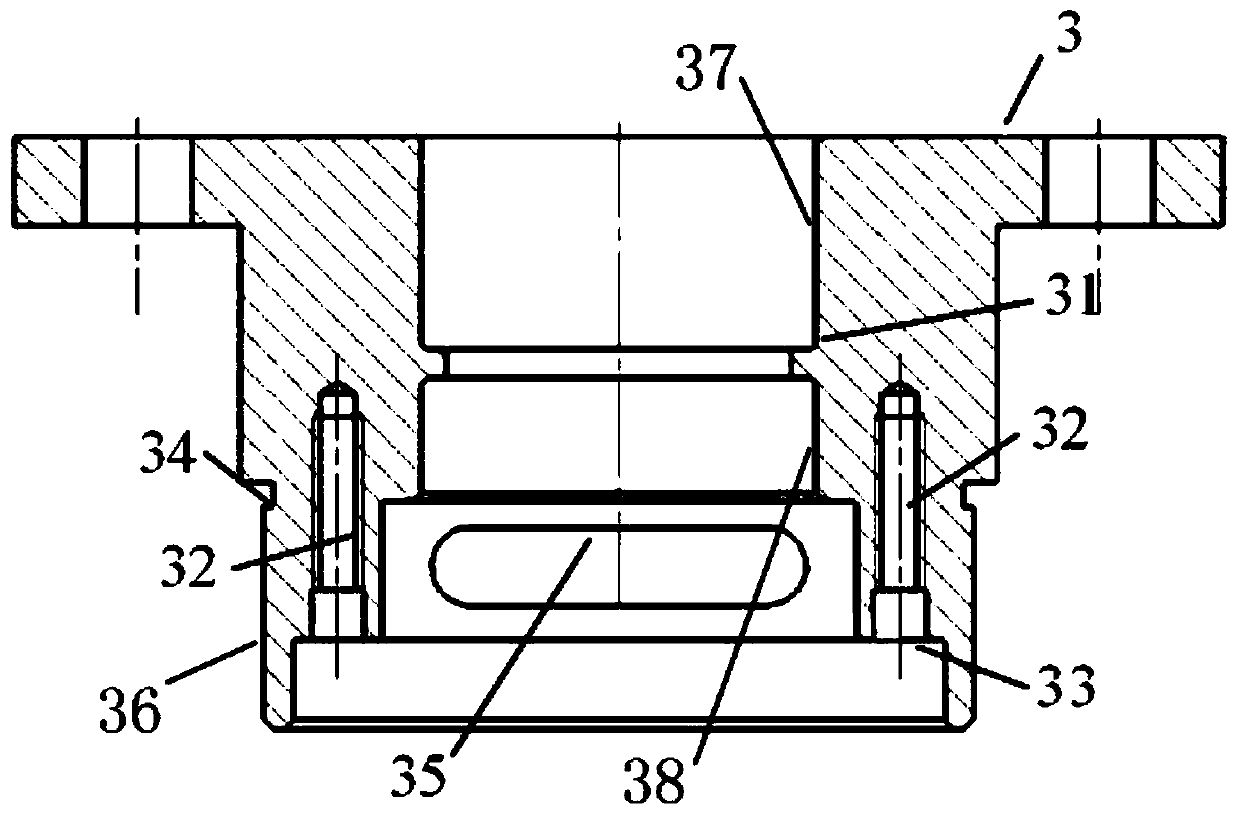

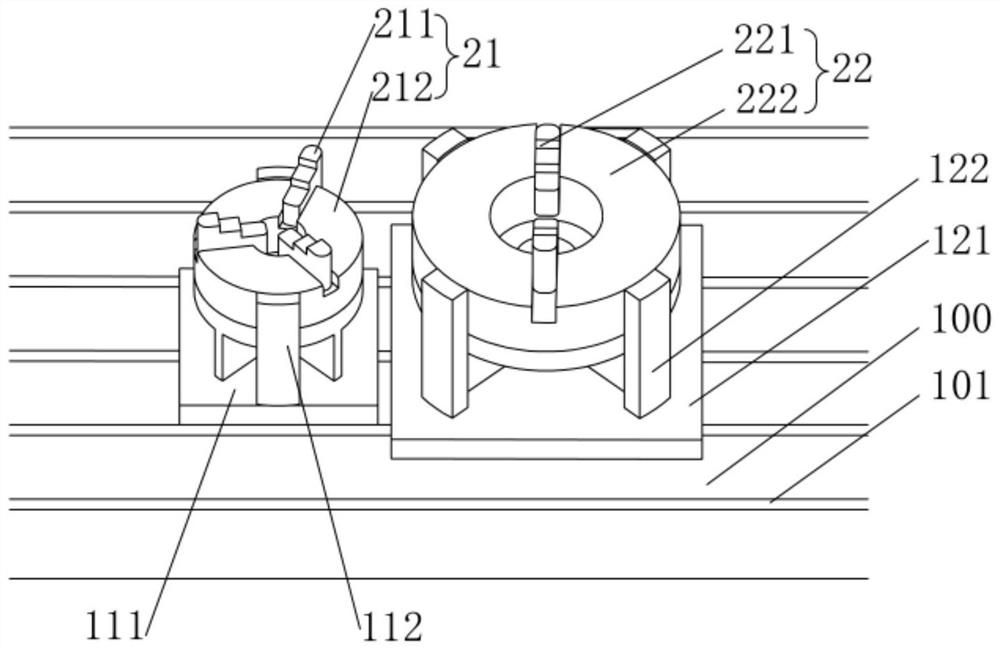

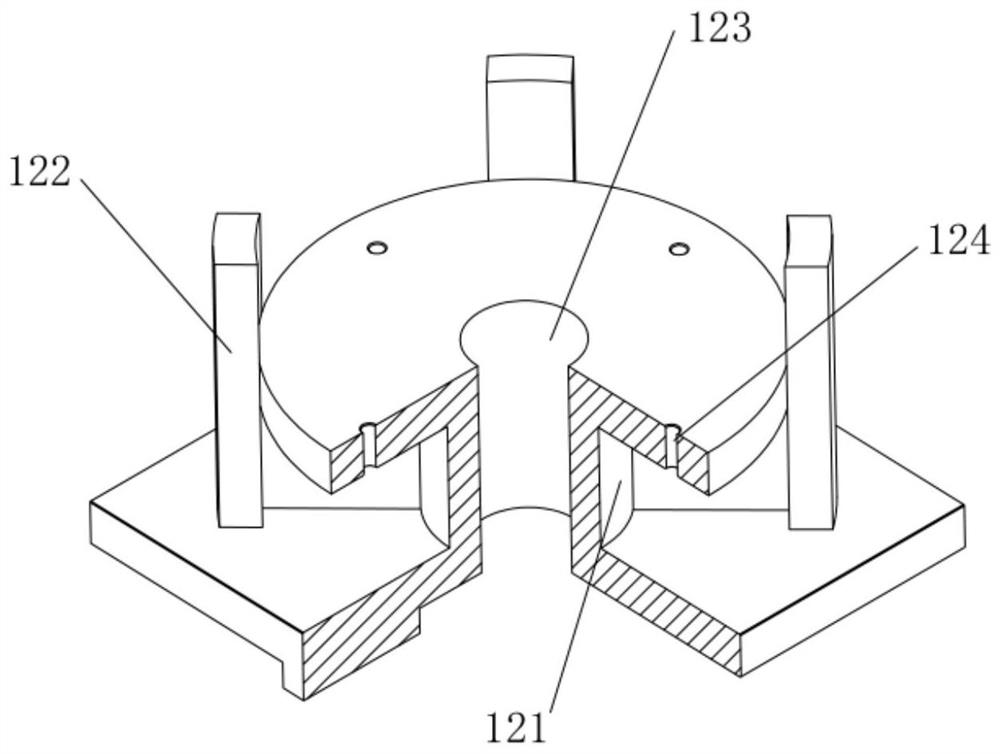

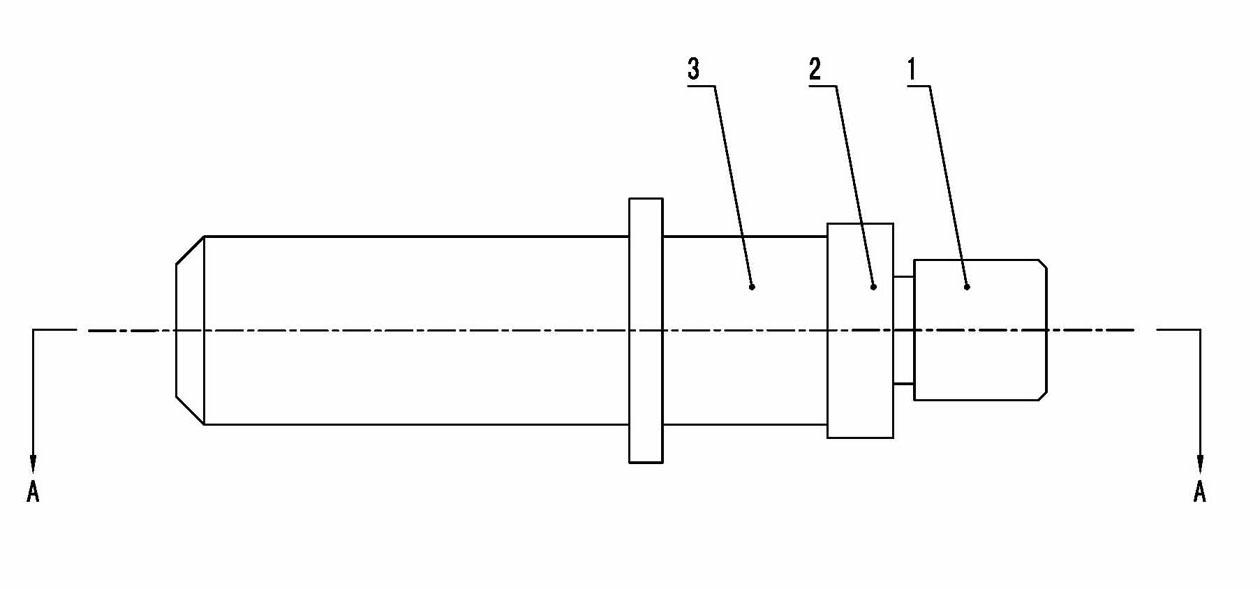

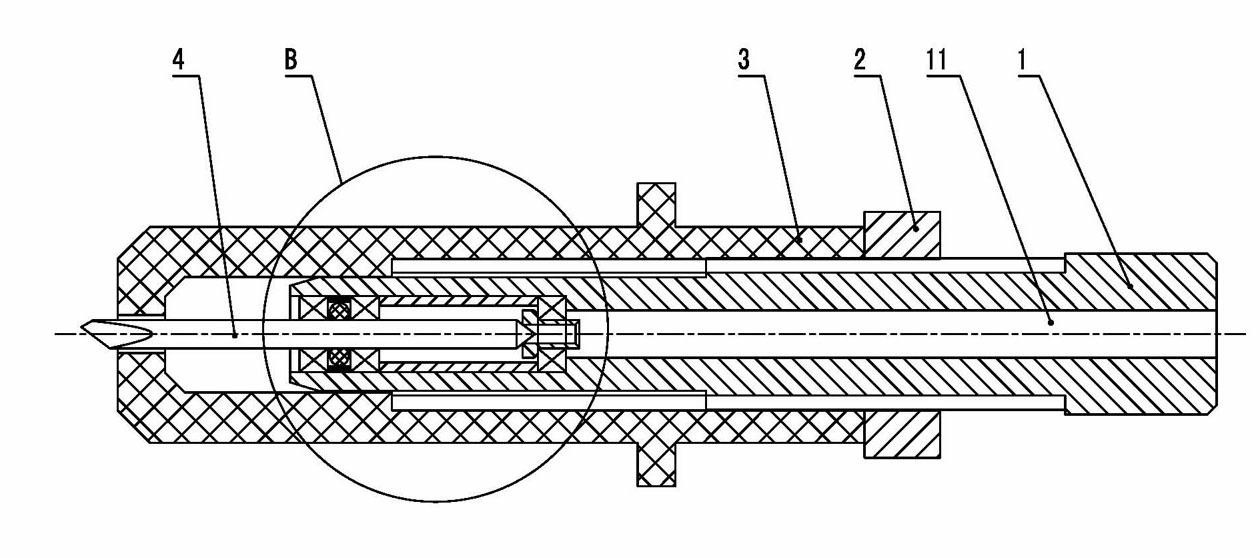

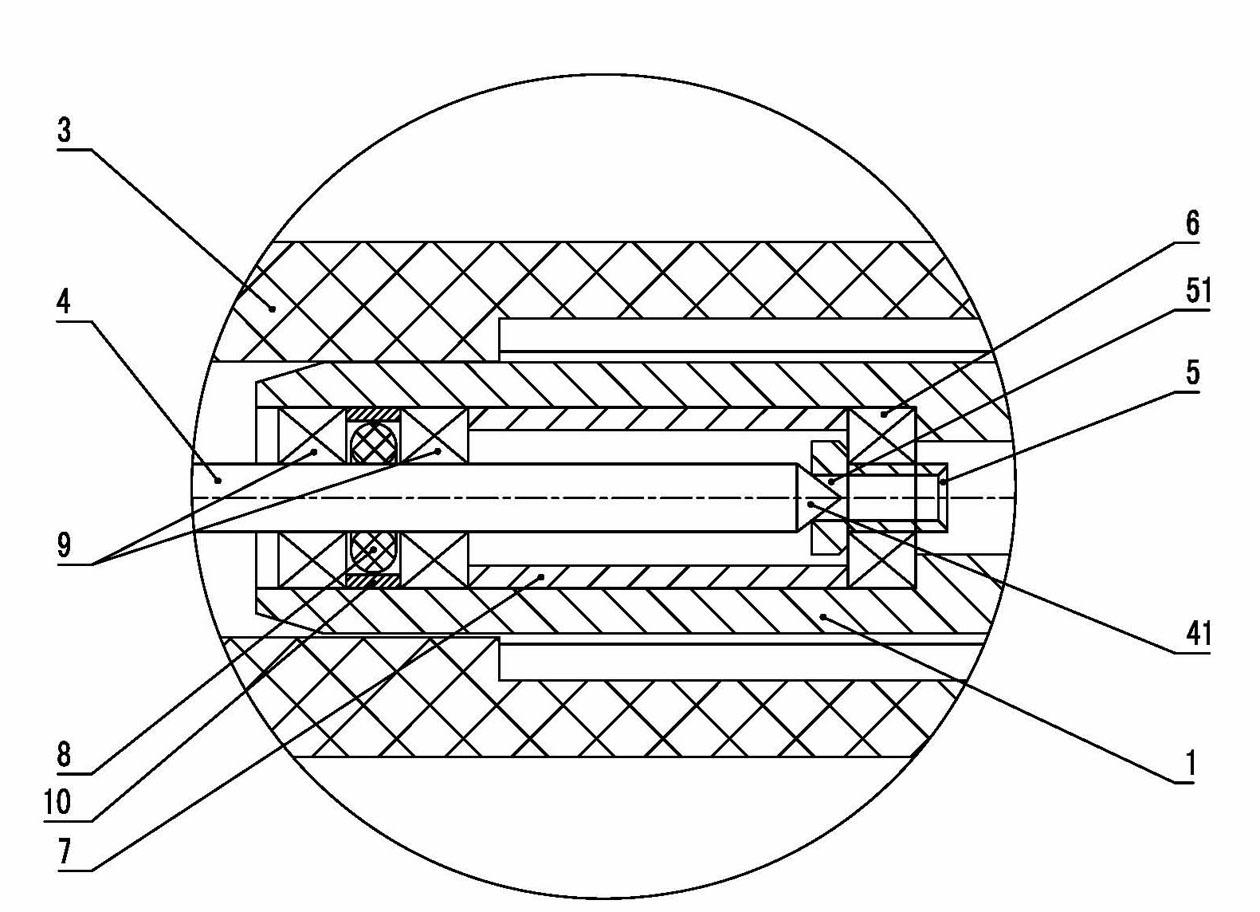

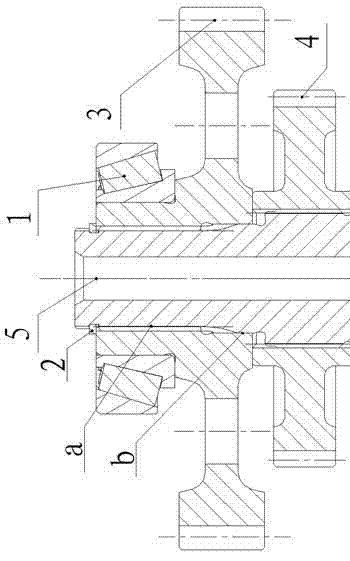

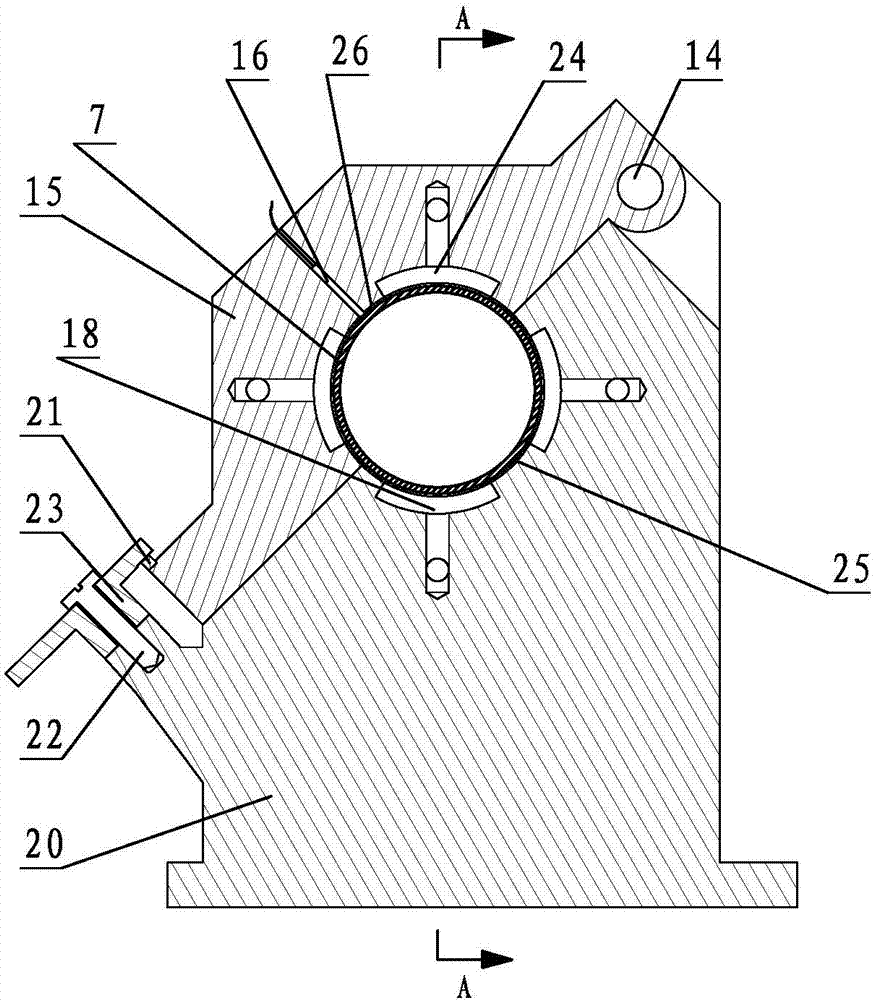

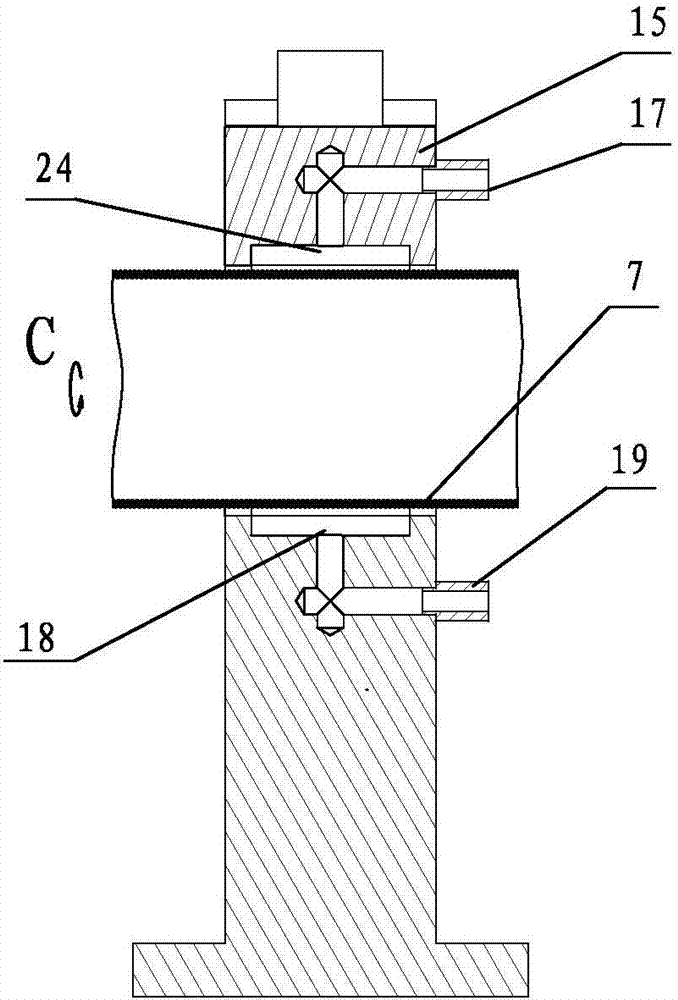

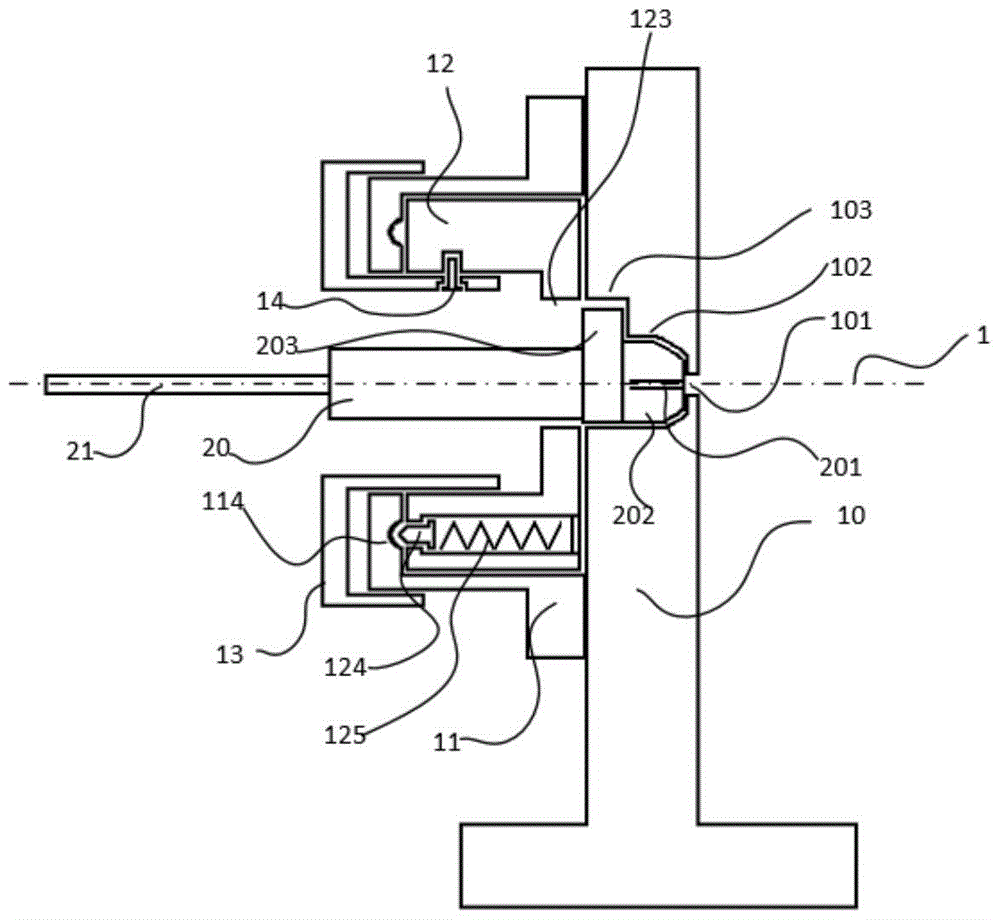

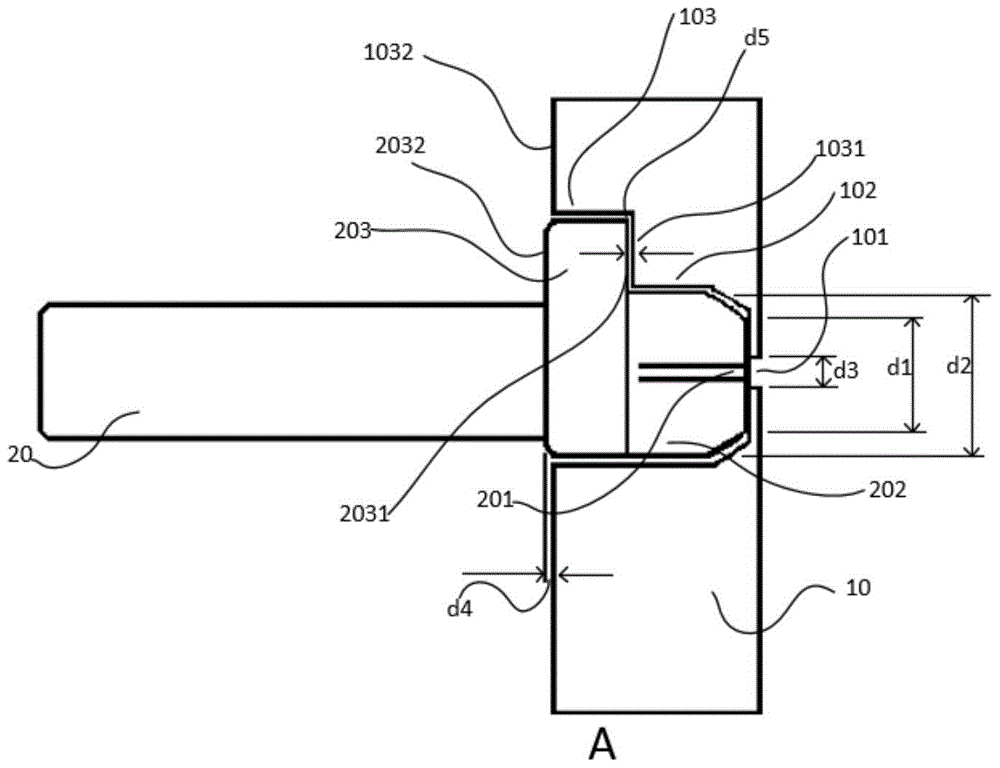

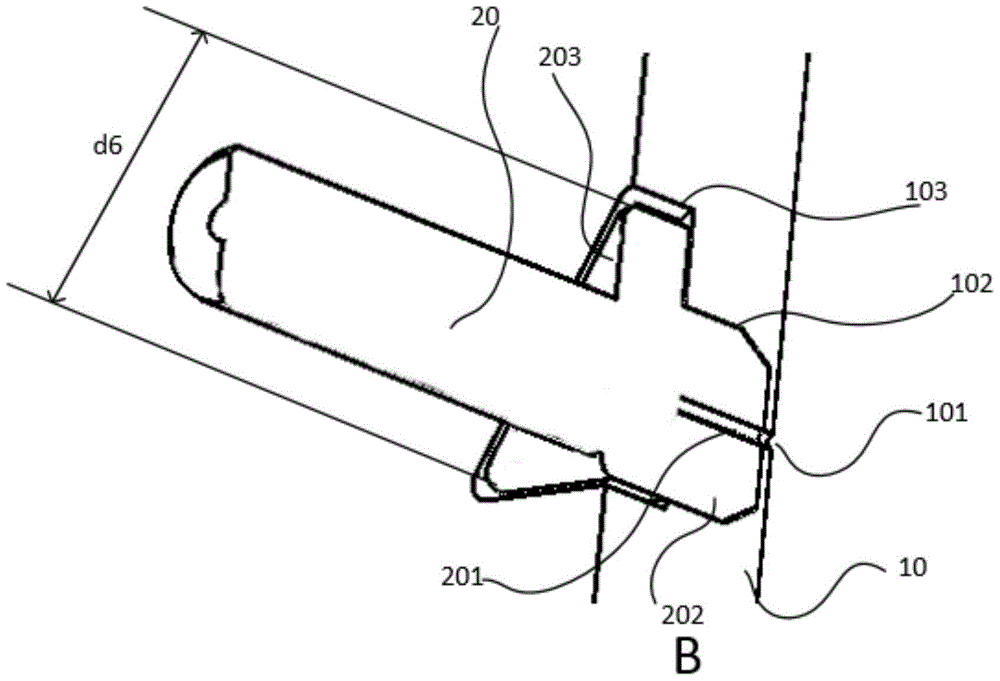

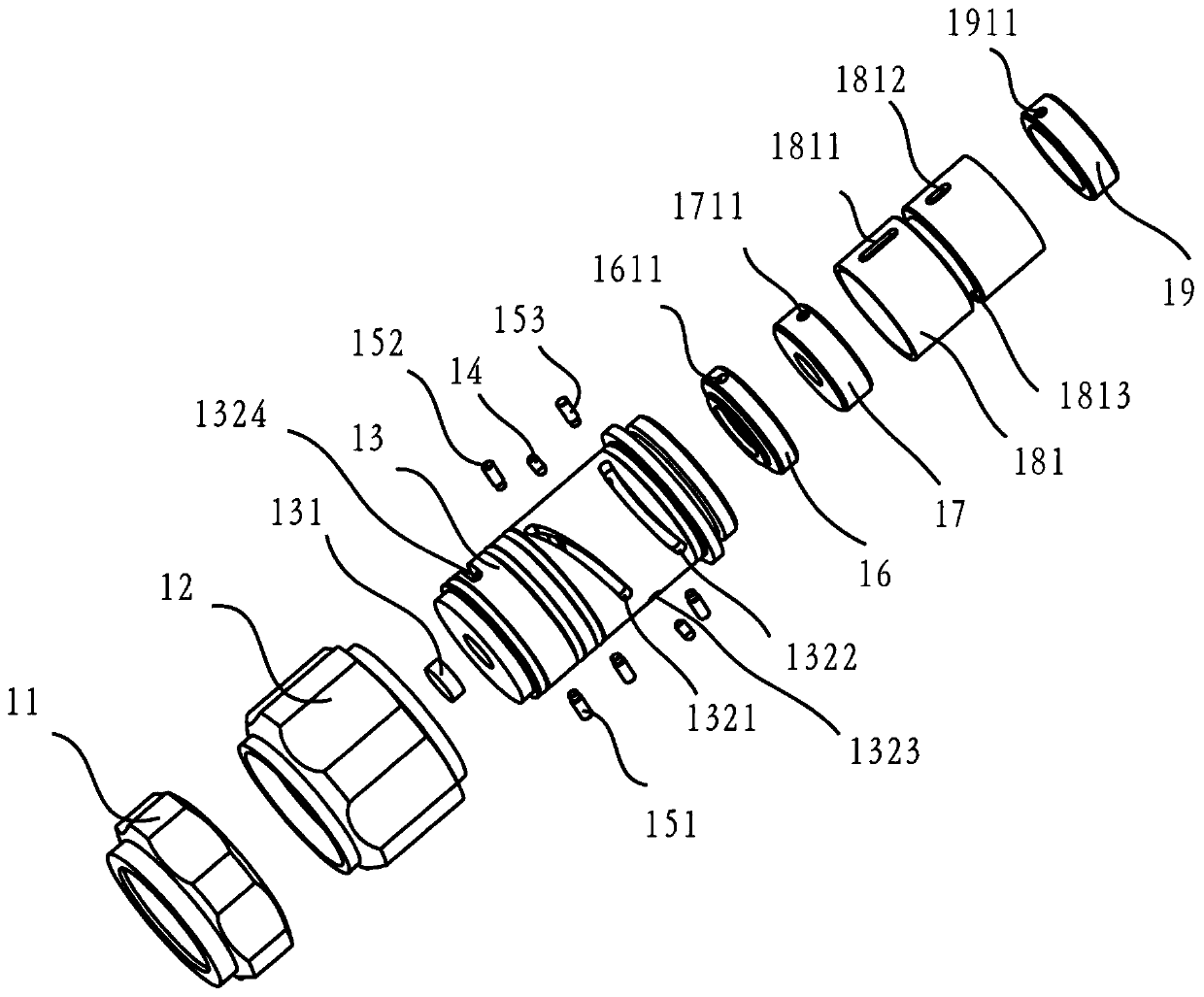

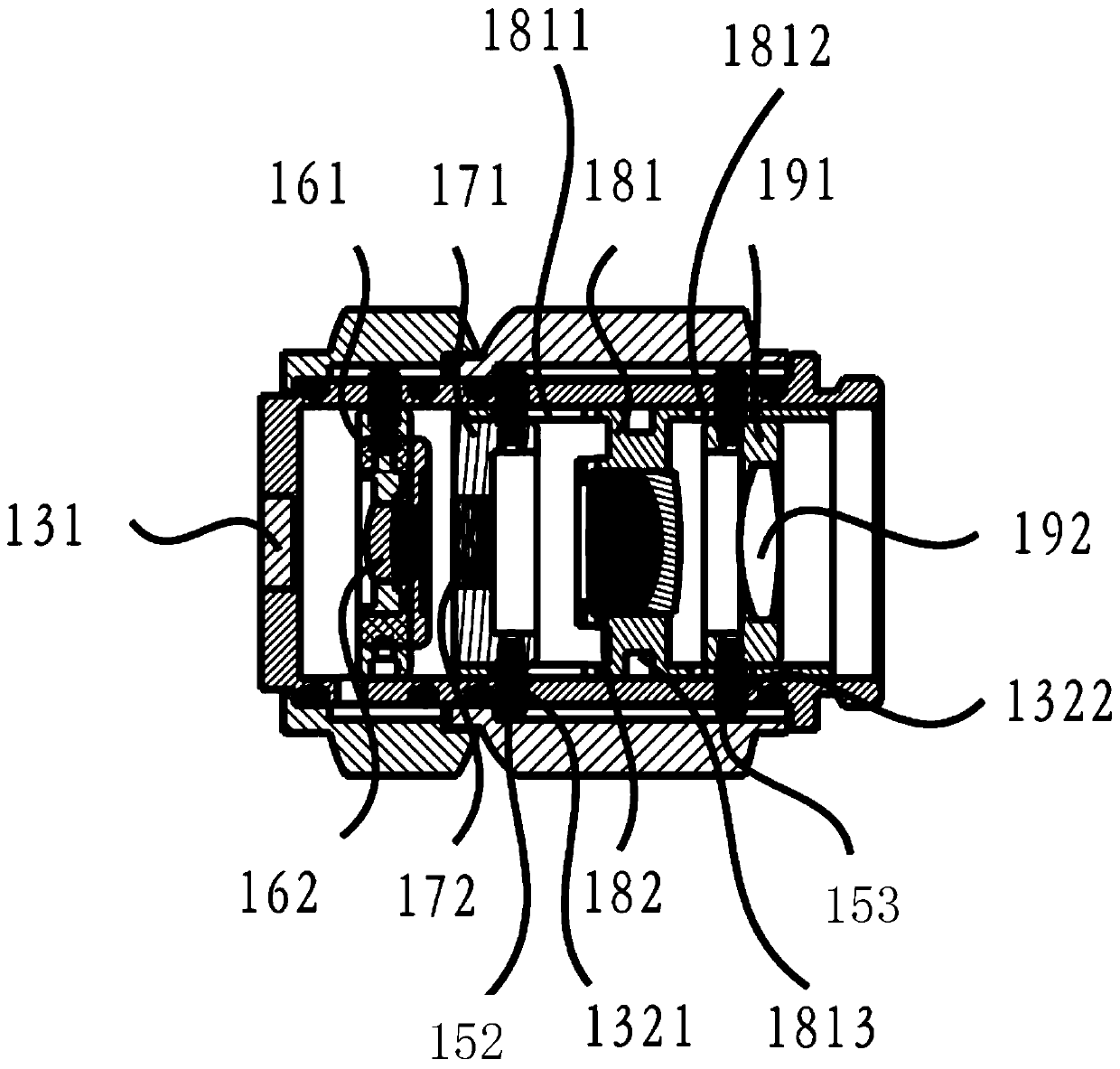

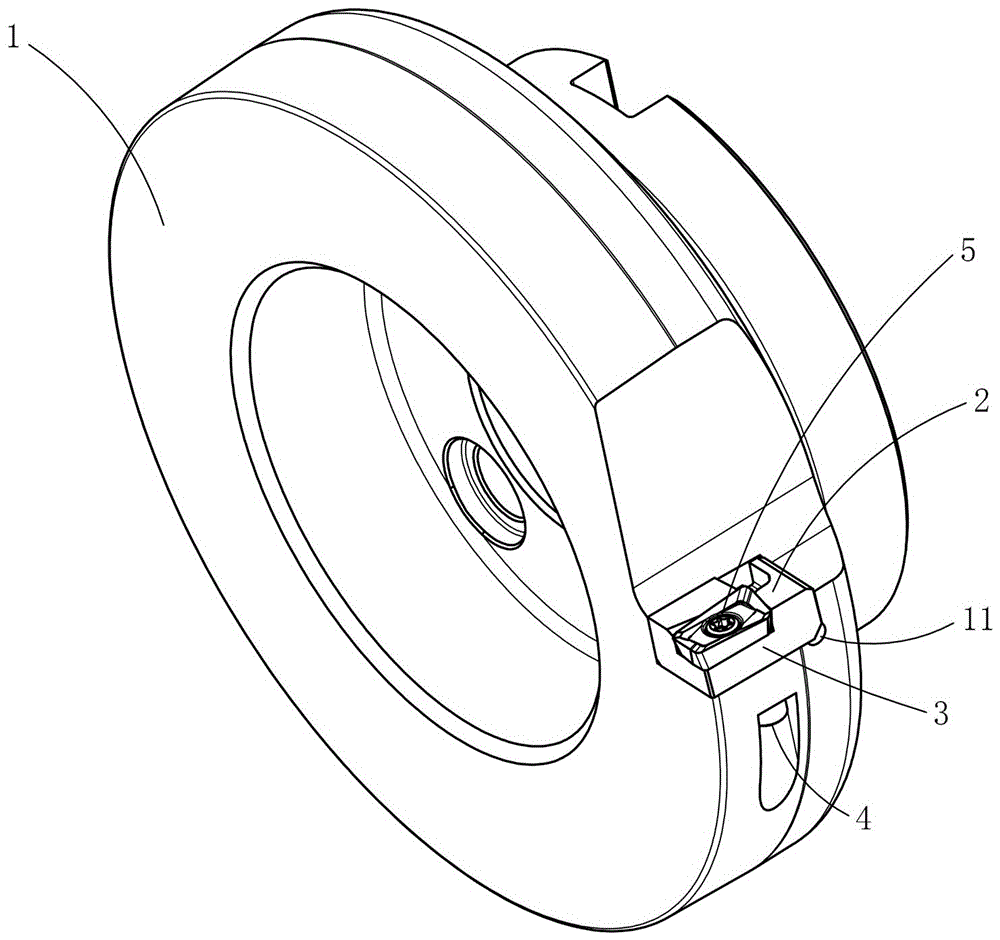

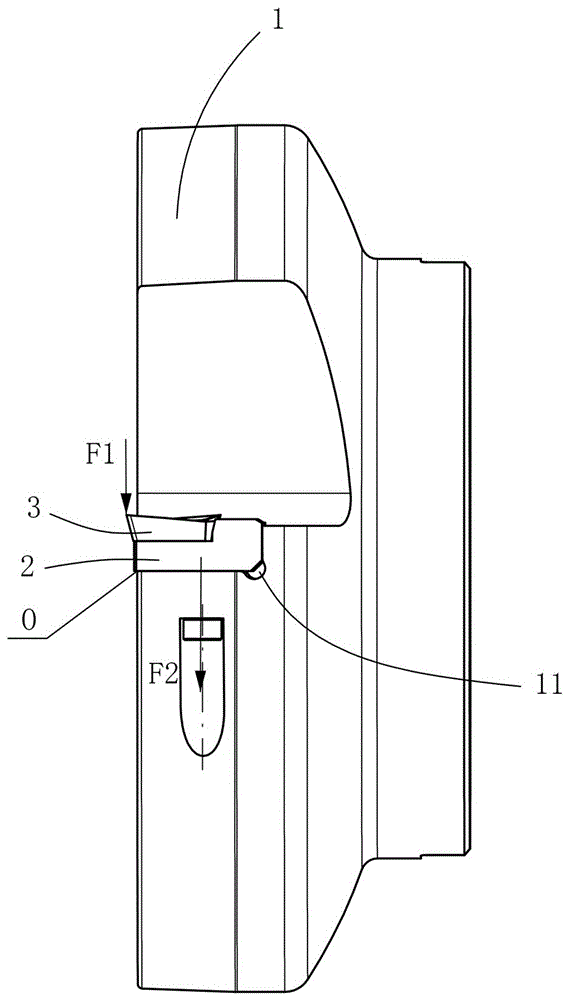

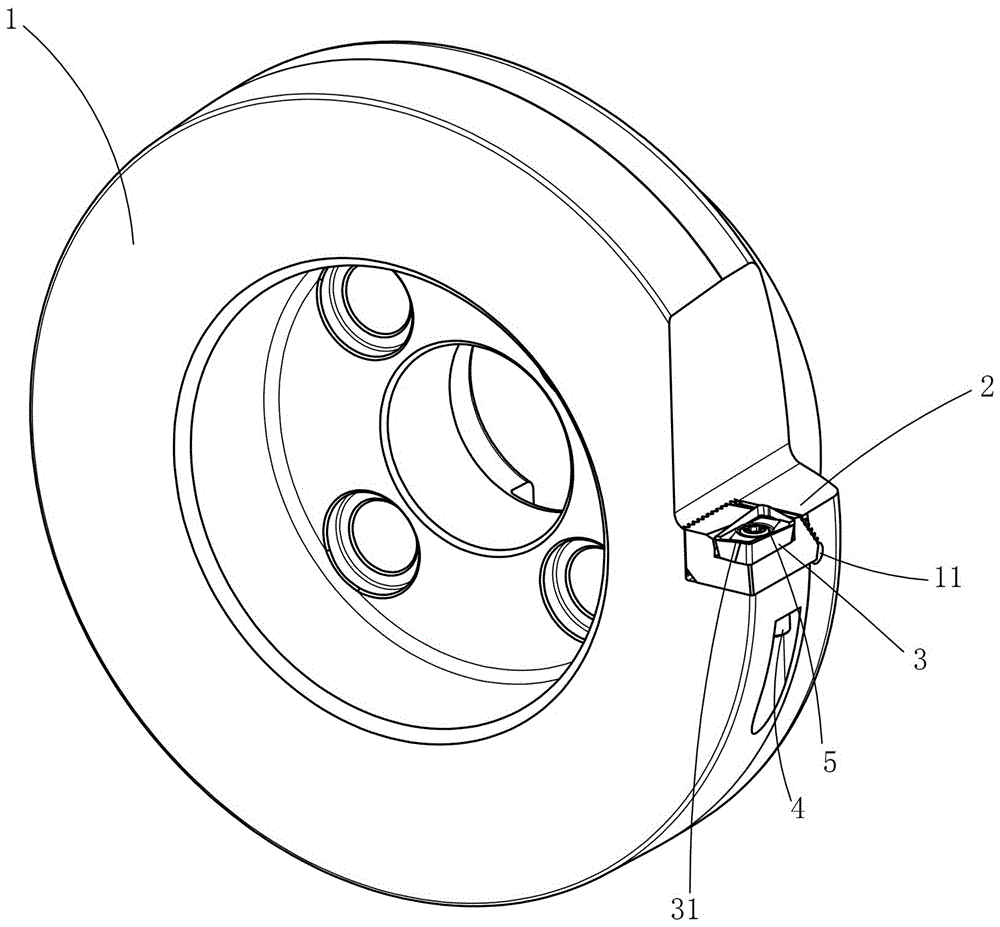

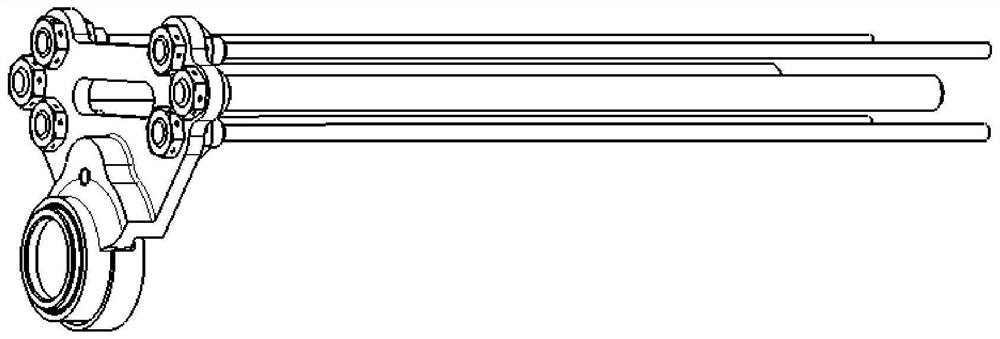

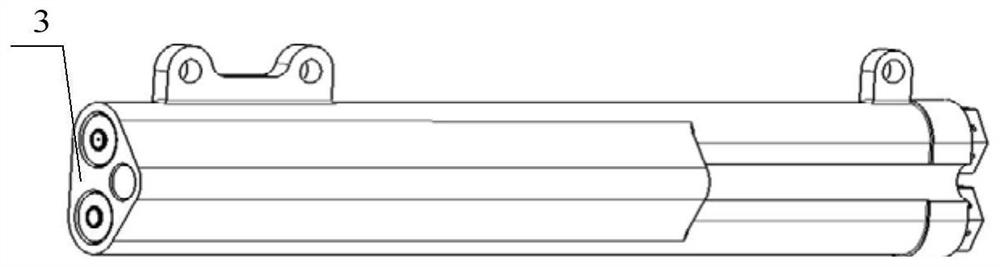

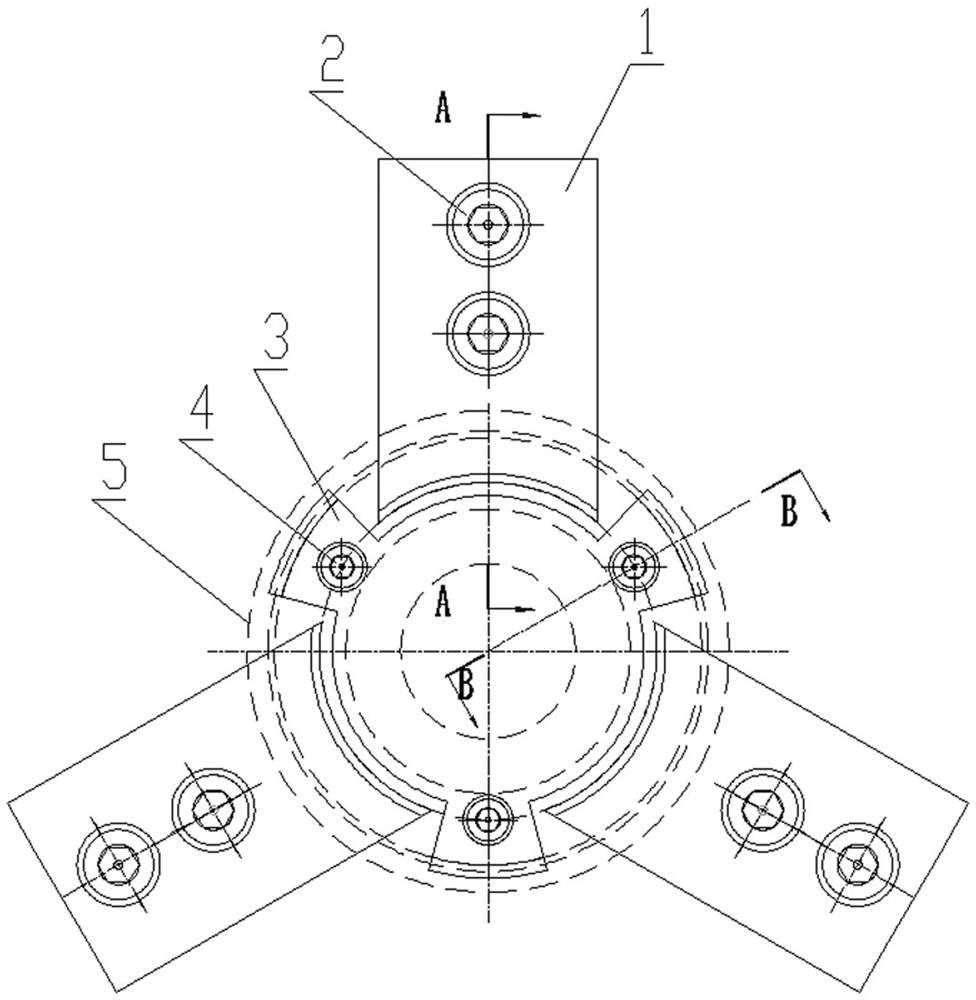

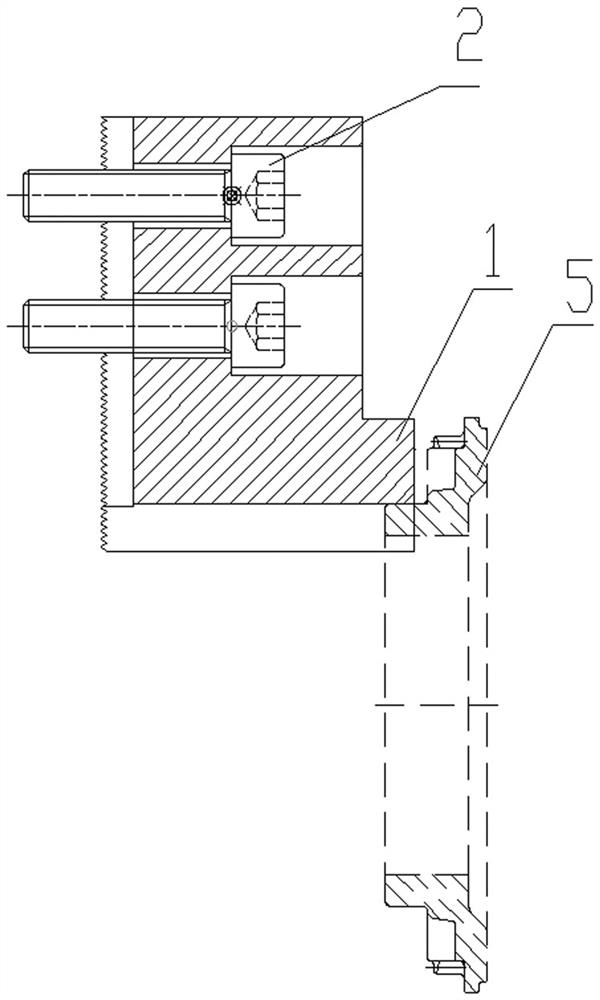

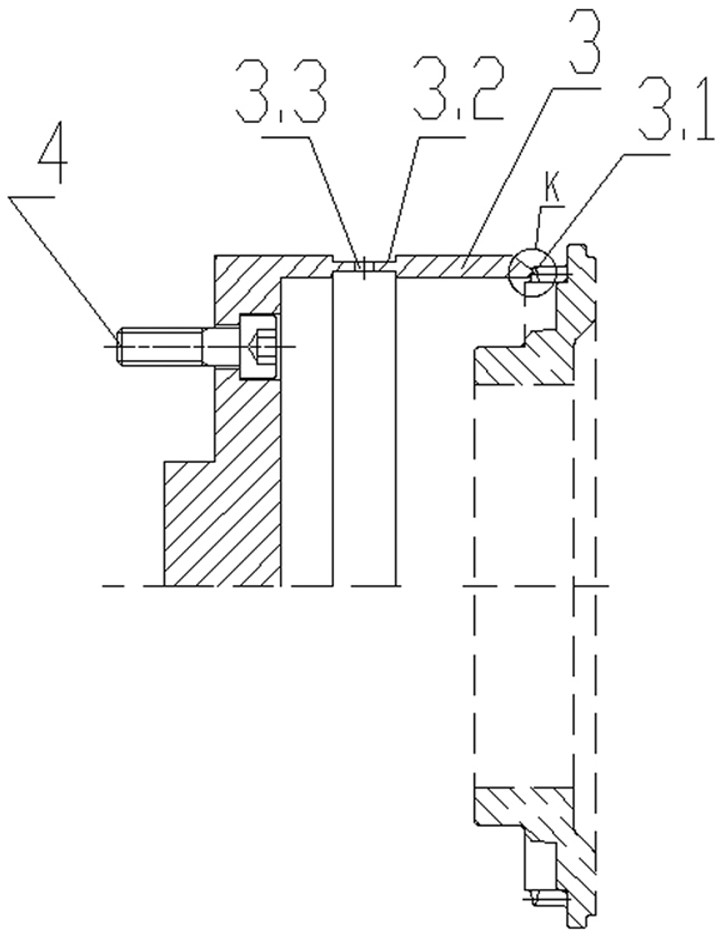

Optical fiber connector capable of accurate positioning

ActiveCN105242358AImprove axial positioning accuracyLimited rotationCoupling light guidesEngineeringConfocal imaging

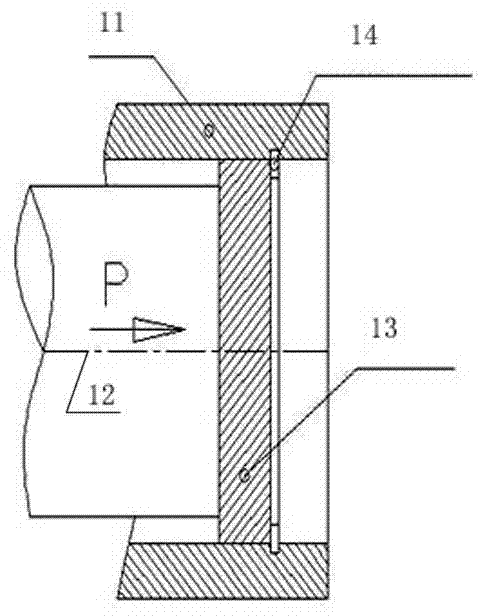

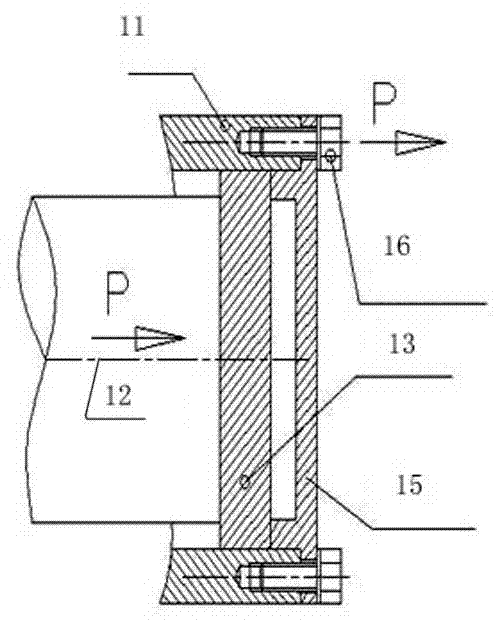

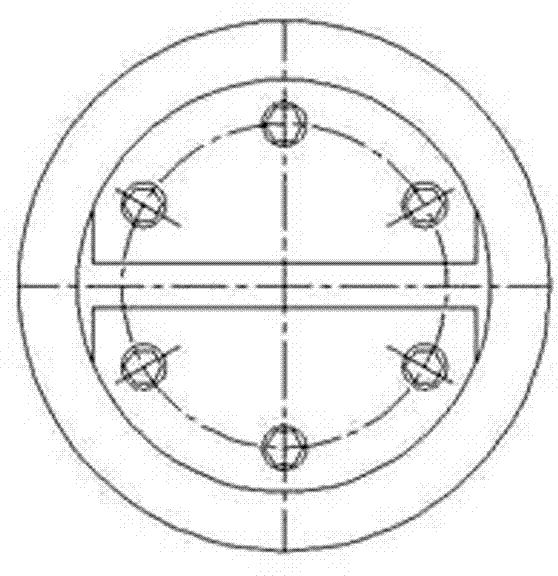

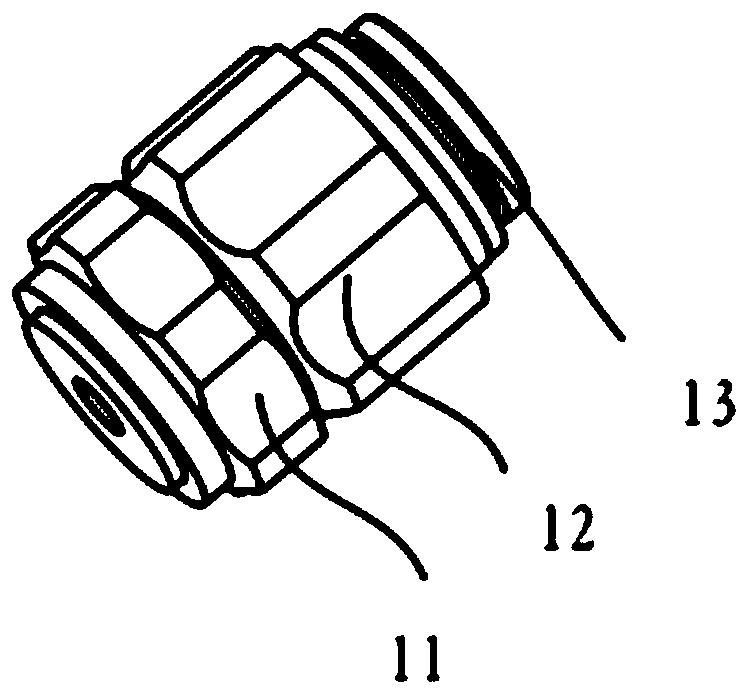

The invention discloses an optical fiber connector capable of accurate positioning, which comprises a connector socket and a connector plug, wherein the connector socket comprises a connector socket base, a locking wheel pressure ring, a locking wheel and an operating handle, and the connector socket base is fixed to an optical bottom plate of a confocal imaging system in a rigid manner; the locking wheel pressure ring, the locking wheel and the operating handle form a locking and limiting mechanism of the connector socket; the head part of the connector plug is provided with an axial positioning head, a rotary positioning head is arranged behind the axial positioning head, an optical fiber bundle passes through a hollow hole, and the optical fiber bundle and the connector plug are fixed to each other after being leveled; and the hollow hole faces just to a circular light passing hole when connector plug is inserted to the bottom part of a positioning groove of the connector socket base, and focused laser is injected into the optical fiber bundle through the circular light passing hole. The optical fiber connector adds a rotary positioning function, limits the optical fiber to rotate around the axis, achieves positioning in the rotational direction, applies a pressure on the connector through a spring, ensures stable and reliable locking of the connector, and can control the pressure.

Owner:精微致远医疗科技(武汉)有限公司

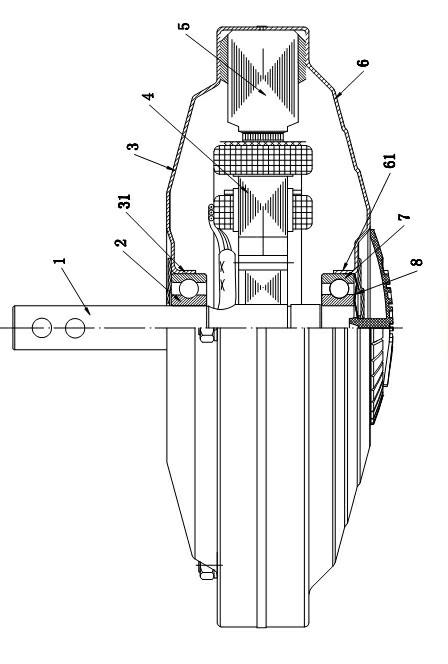

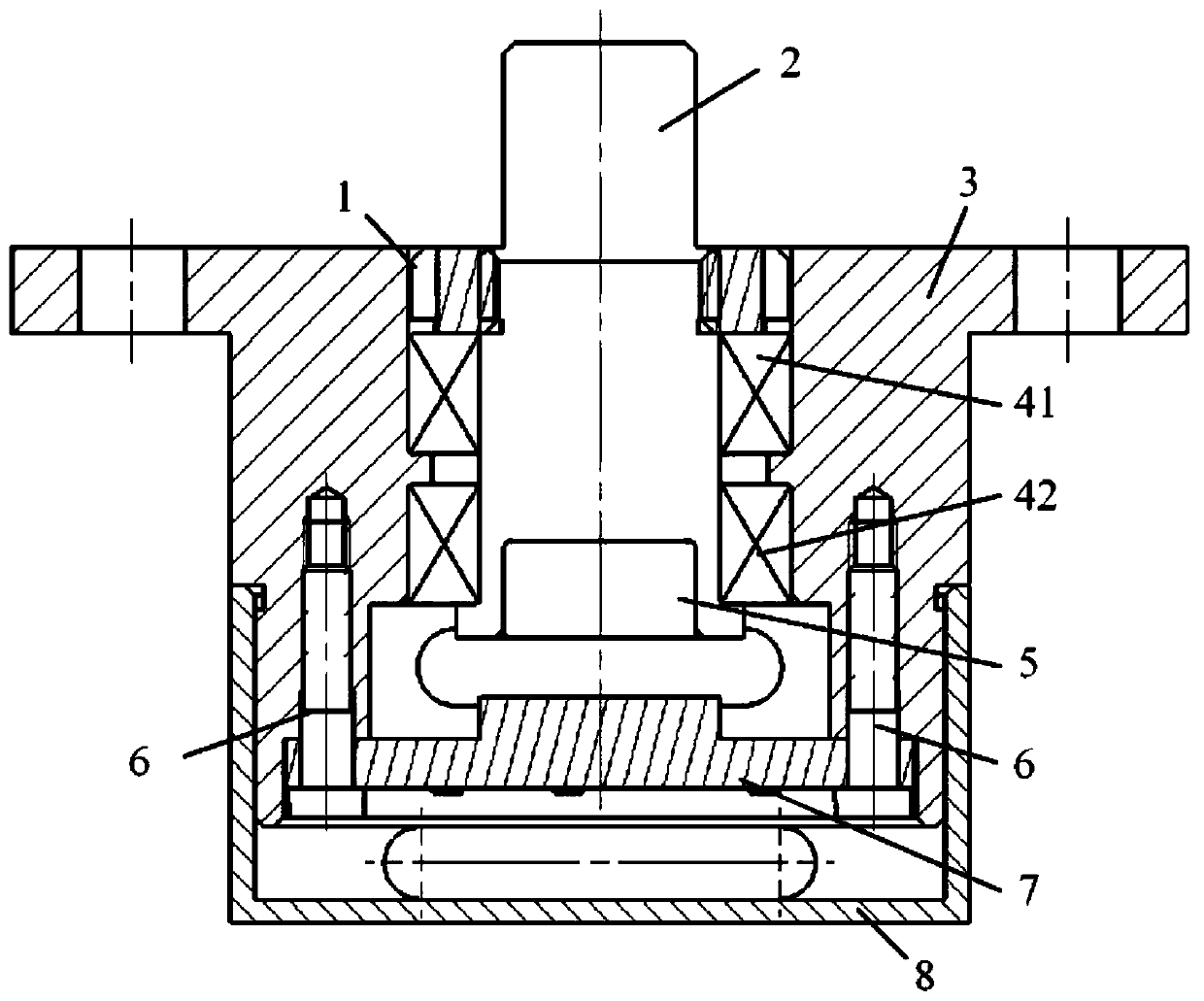

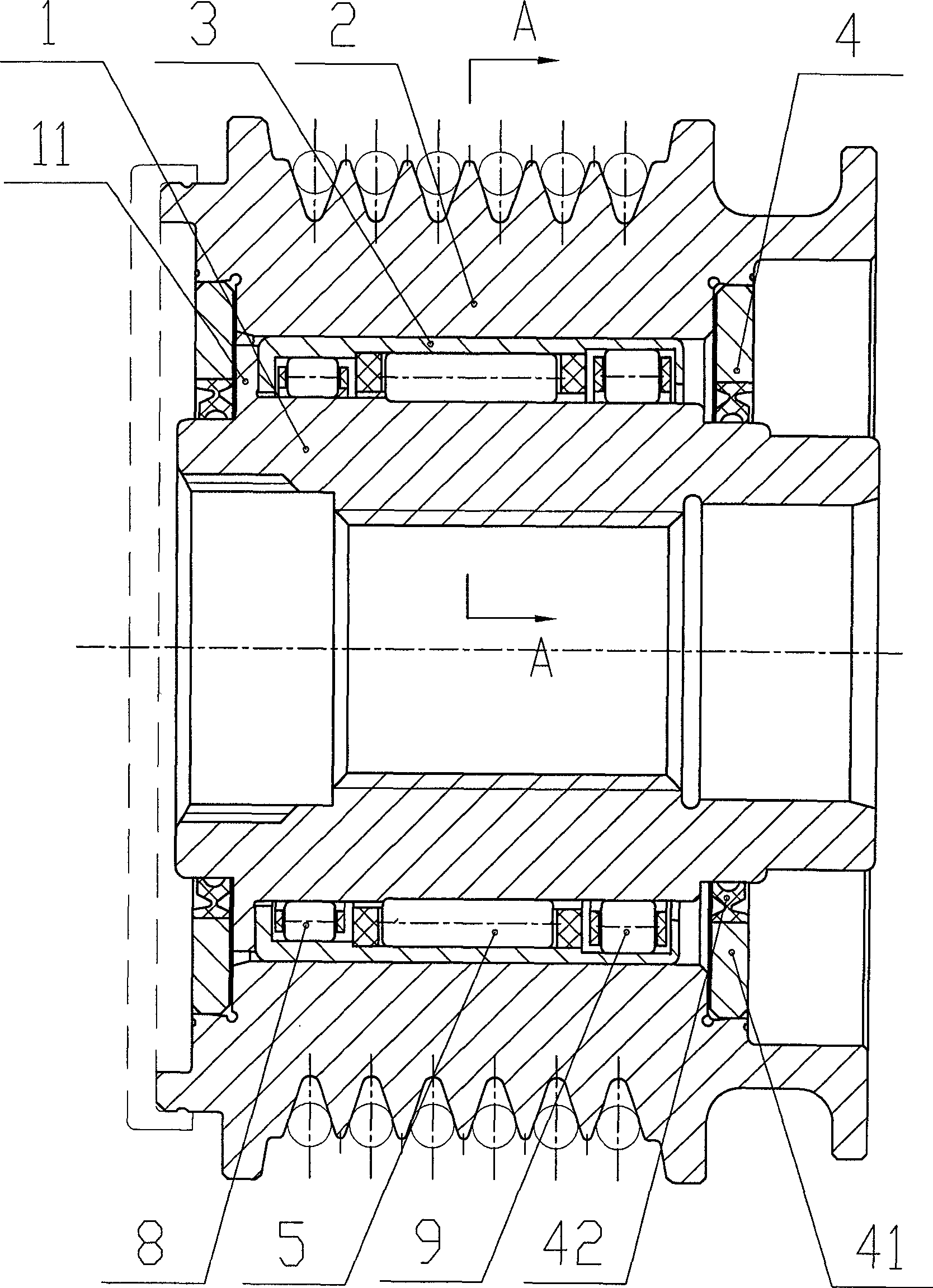

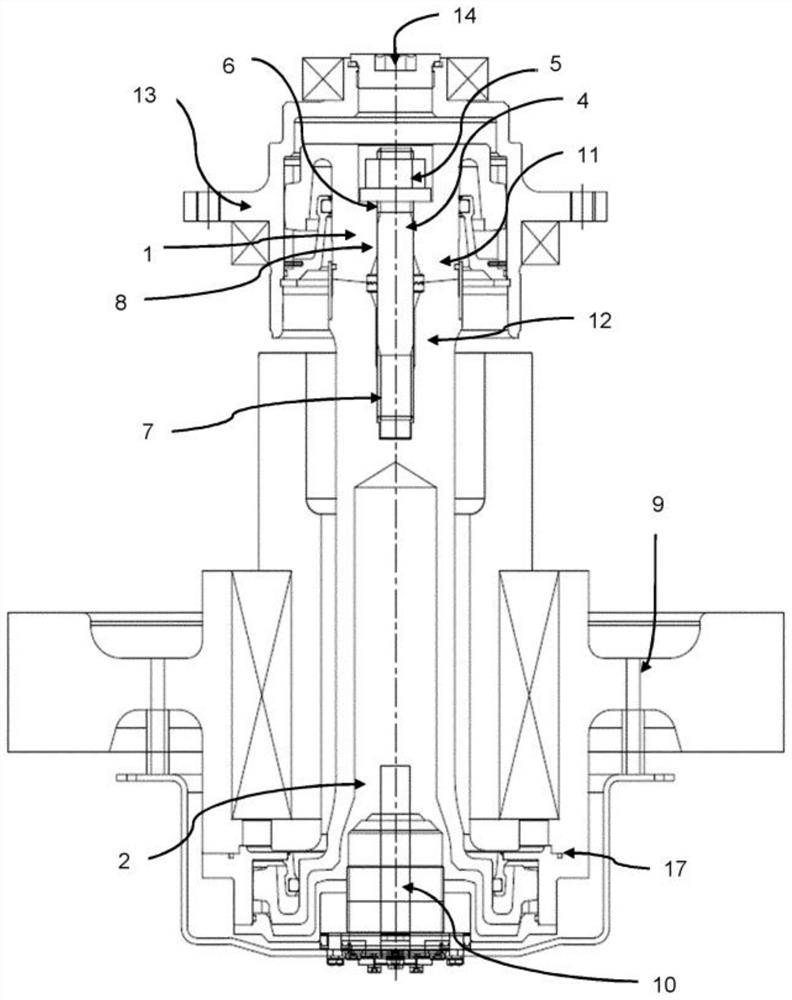

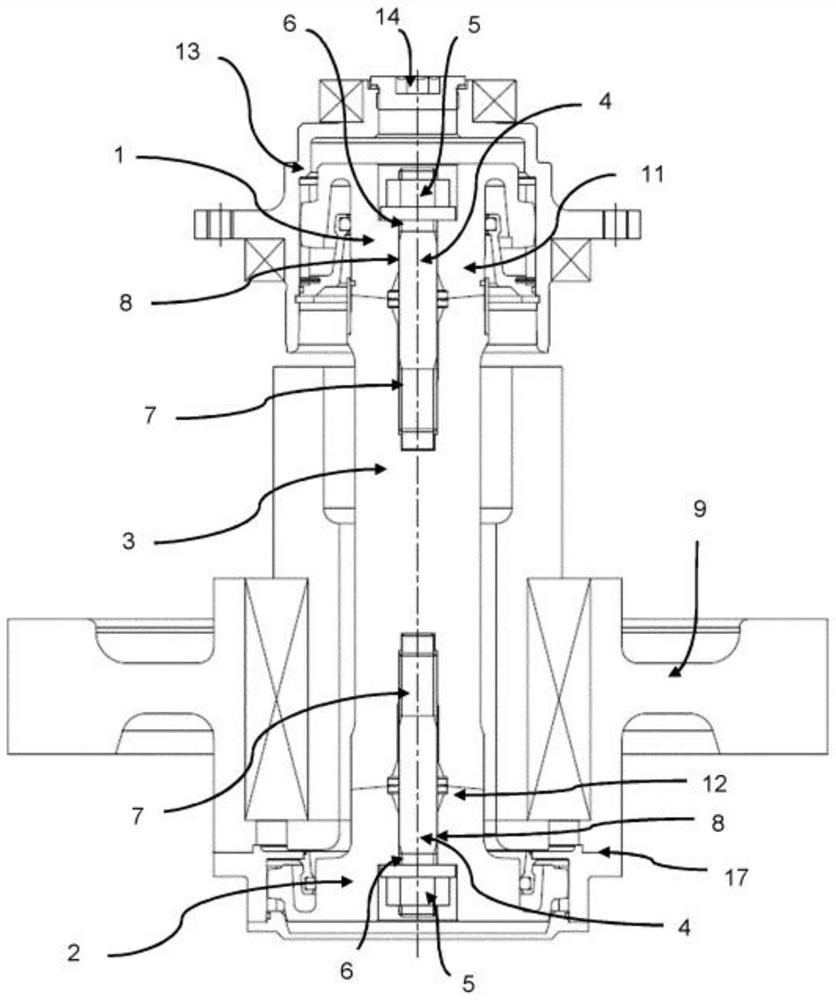

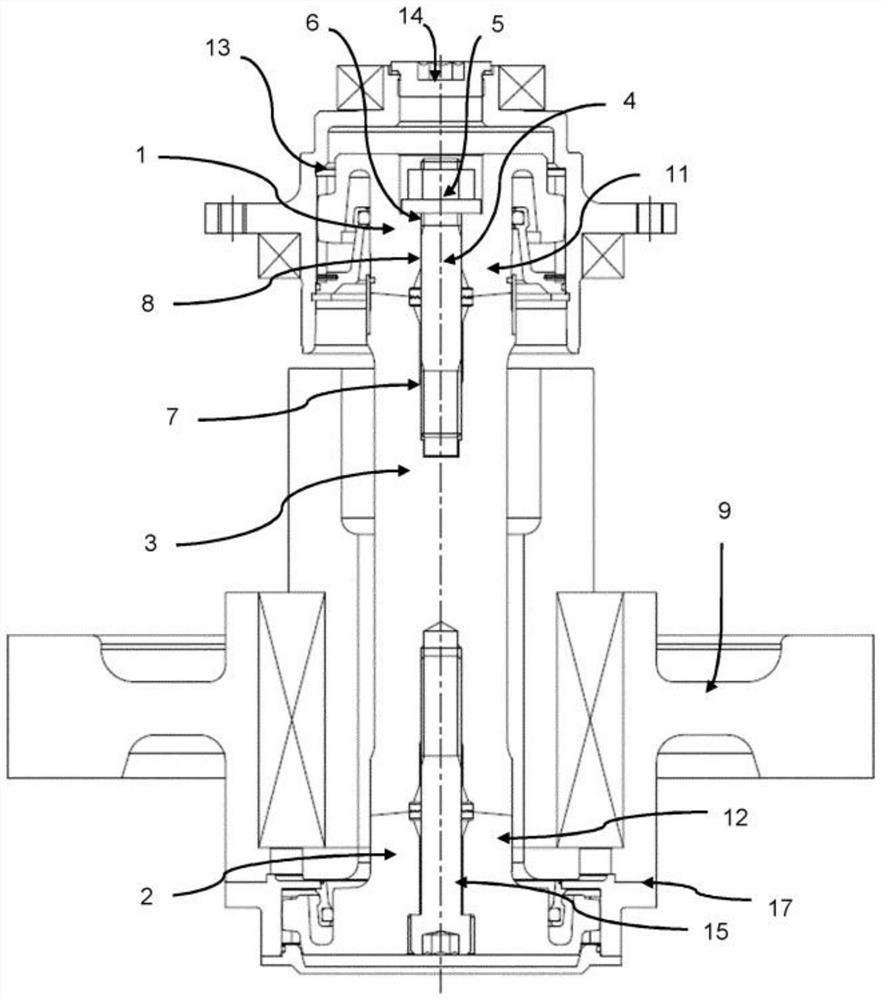

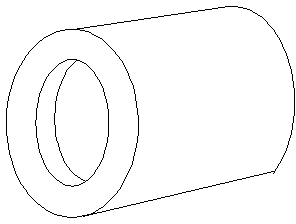

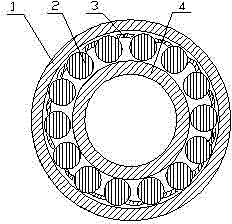

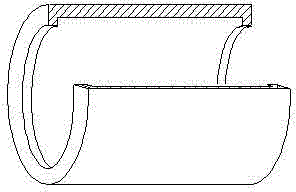

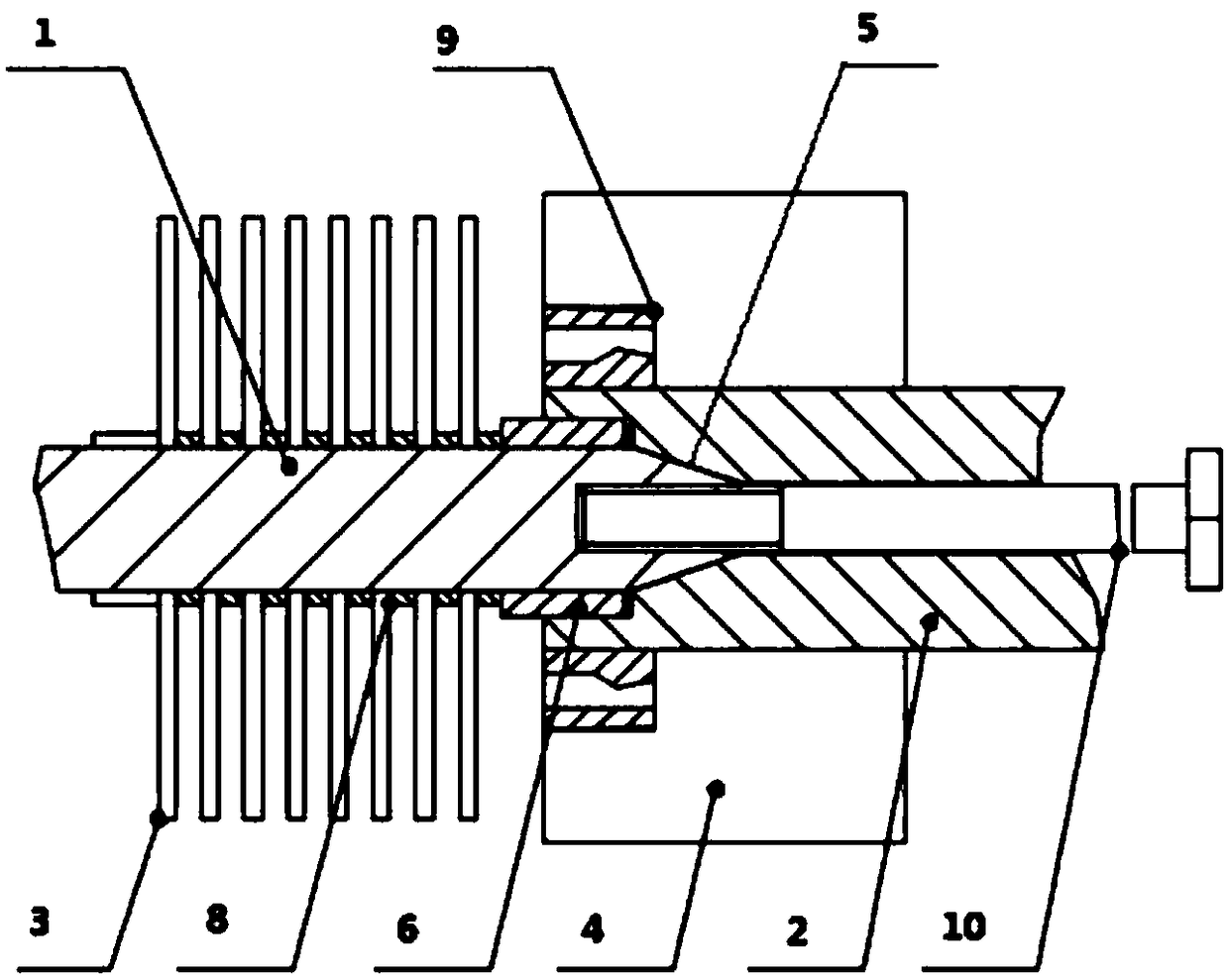

Ceiling-fan motor

The invention relates to a ceiling-fan motor, comprising a motor upper shell (3), a motor lower shell (6), a motor shaft (1), an upper bearing (2), a lower bearing (7), a motor stator (4) and a motor rotor (5), wherein the motor rotor (5) is arranged outside the motor stator in a matching mode; the center of the motor upper shell (3) is provided with an upper bearing chamber (31); the upper bearing (2) is positioned in the upper bearing chamber (31) and sleeved on the motor shaft (1); the center of the motor lower shell (6) is provided with a lower bearing chamber (61); the lower bearing (7) is arranged in the lower bearing chamber and sleeved on the motor shaft (1); and the motor rotor (5) is arranged in the inner circles of the motor upper shell (3) and the motor lower shell (6). The ceiling-fan motor is characterized by further comprising a wave-shaped spring gasket ring (8) which is arranged in the lower bearing chamber (61) and positioned at the bottom of the lower bearing (7); the upper bearing (2) is in clearance fit with the upper bearing chamber (31); and the lower bearing (7) is in clearance fit with the lower bearing chamber (61). The upper bearing, the lower bearing and the motor rotor are maintained at proper positions; the radial and axial positioning precision of the upper bearing and the lower bearing is improved; the rotary precision is improved; the vibration is reduced; and the bearing noise caused by resonance is avoided.

Owner:MIDEA GRP CO LTD

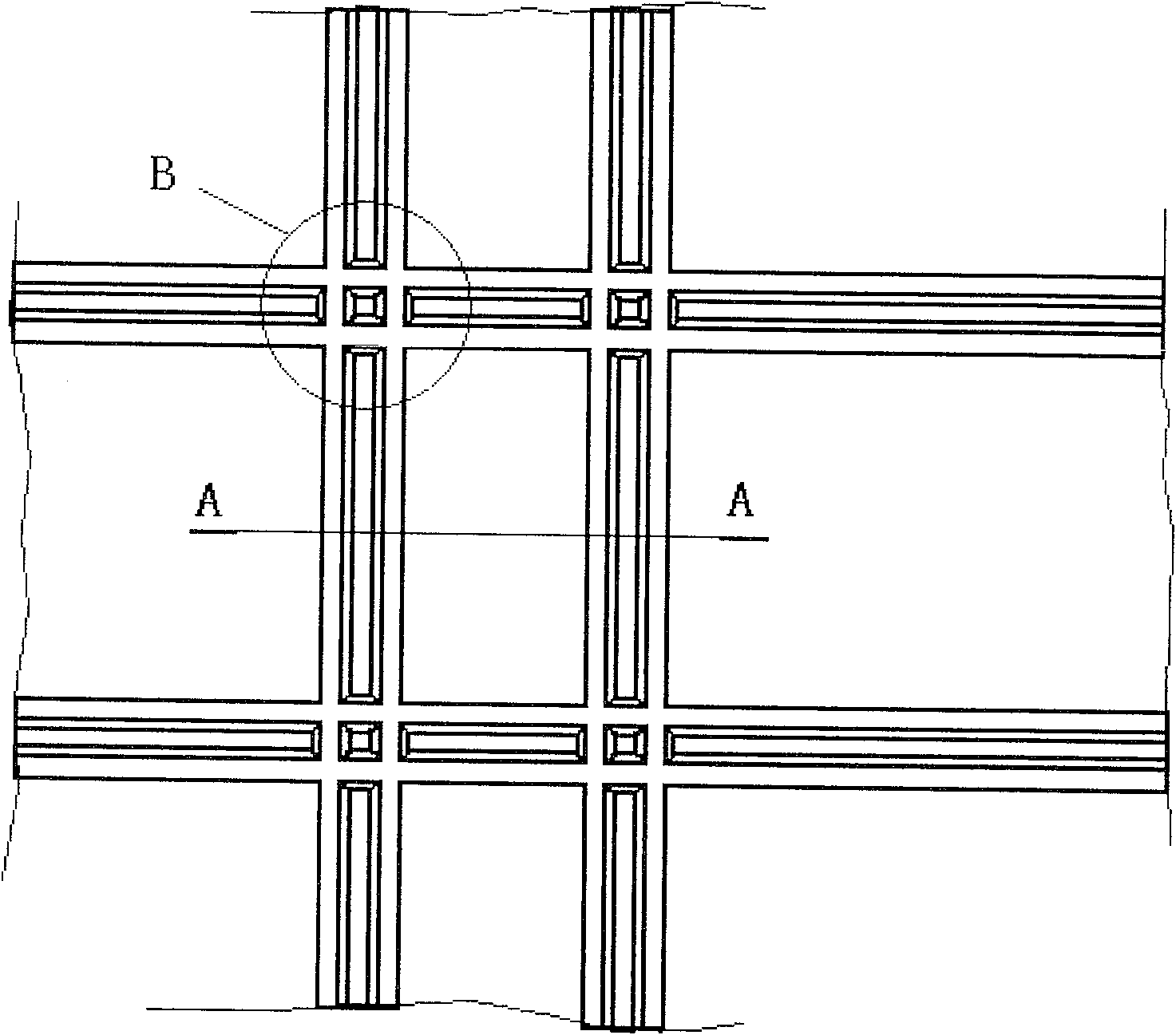

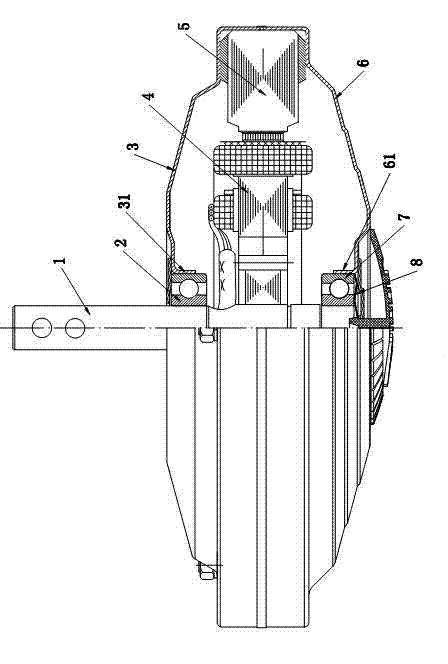

Double crossed vehicle running track

InactiveCN100554582CNo sliding frictionReduce frictional resistanceRailsRail switchesAxial displacementEngineering

The invention discloses a "well" shaped intersecting vehicle running track, which comprises a bearing surface for carrying the weight of the vehicle and a limiting surface for limiting the axial displacement of wheels. The bearing surface and the limiting surface are bilaterally symmetrical, and the section is in the shape of "convex". The invention solves the defects of the existing "I"-shaped track that the bearing surface cannot be continuous at the vertical and horizontal intersections, the vehicle is not running smoothly, and the limit surface and the wheel edge have high friction. The vehicle running track of the invention runs smoothly at the intersection, has small friction, and the force on the bearing surface is symmetrical and even.

Owner:NORTHWEST A & F UNIV

Small high-dynamic and high-precision digital output magneto-electricity encoder and mounting control method thereof

InactiveCN110006336AImprove performanceHigh rotation accuracyProgramme controlComputer controlElectricityMicrocontroller

The invention discloses a small high-dynamic and high-precision digital output magneto-electricity encoder and a mounting control method thereof. The digital output magneto-electricity encoder comprises a main shaft, a main body, a signal processing circuit board and a shell; the main shaft and the main body are in dual-bearing support mechanism; a radial magnetizing circular magnet is arranged ina main shaft counter bore; the signal processing circuit board is a wafer shape, and a Hall sensor chip is arranged at the center of the front, and a microcontroller and a CAN bus interface circuit are arranged at the back, and the signal processing circuit board is fixed on a step surface of the main body through bolts; a magnetic field signal is tested by adopting a diameter differential way, and a closed-loop tracking segmentation algorithm is used for quickly converge a measurement angle to input two orthogonal cosine signal corresponding angle values. Through the small high-dynamic and high-precision digital output magneto-electricity encoder and the mounting control method thereof disclosed by the invention, the interference resistance is improved, and the measurement angle precision and the response speed are improved.

Owner:CHINA AIR TO AIR MISSILE INST

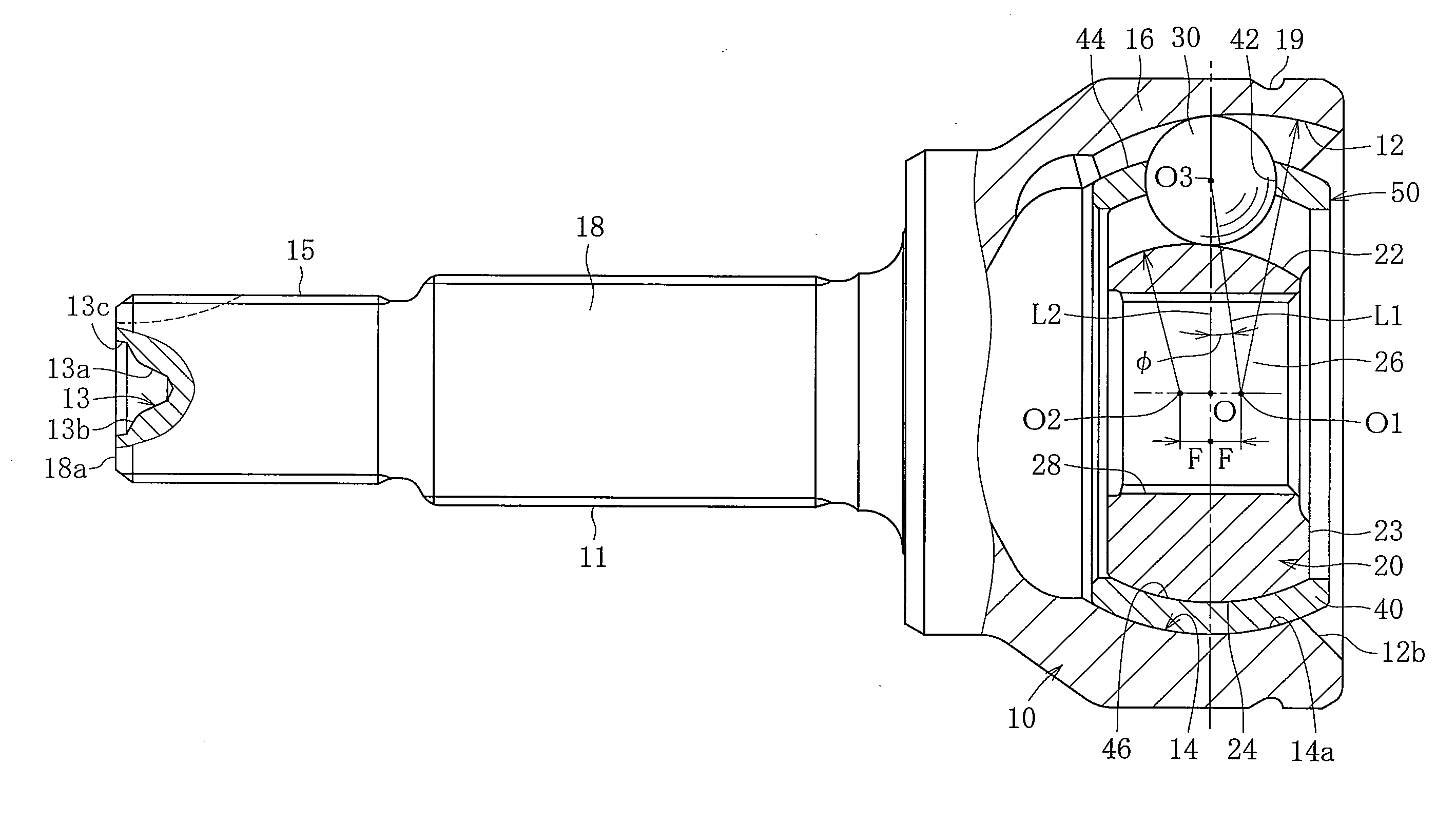

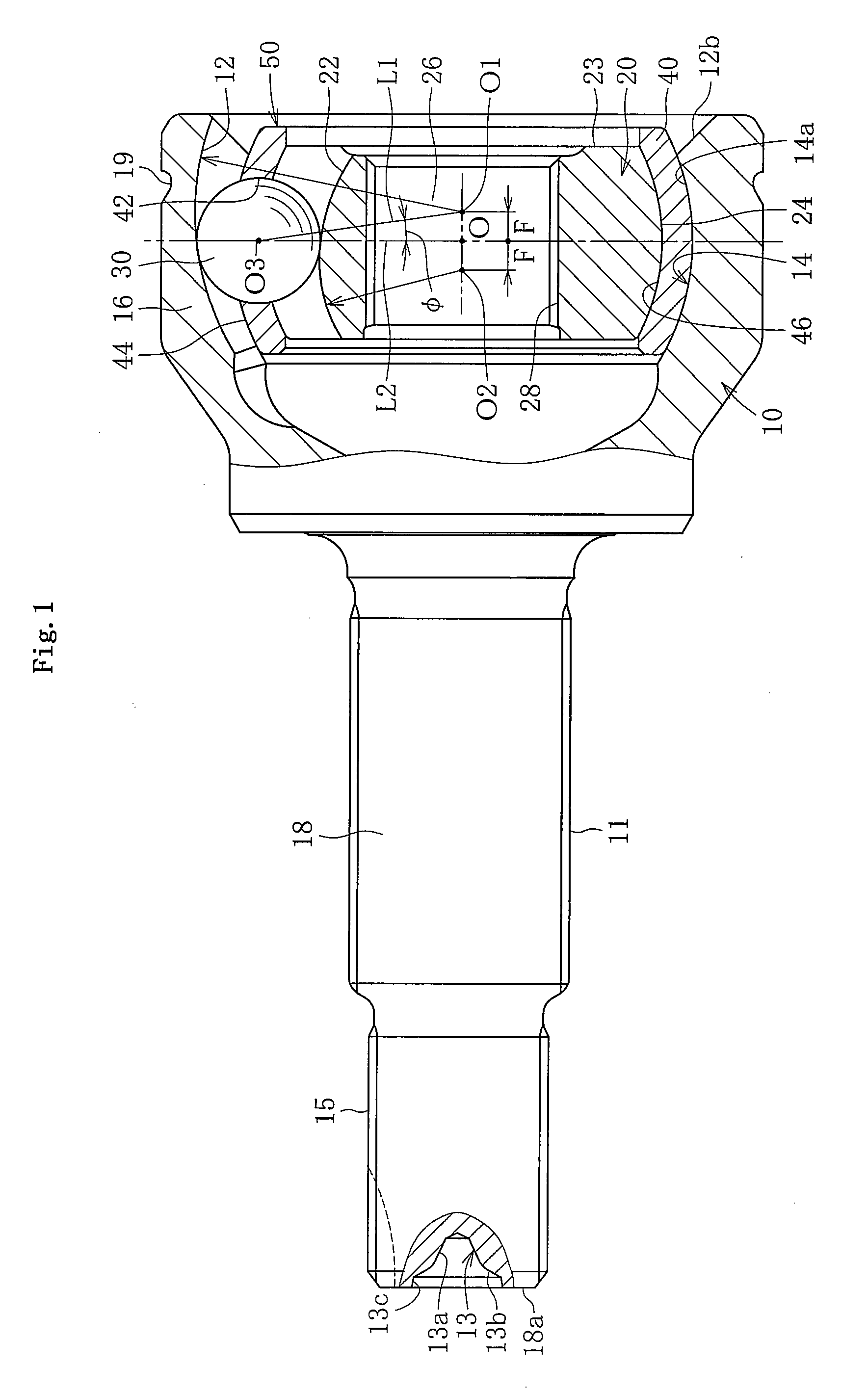

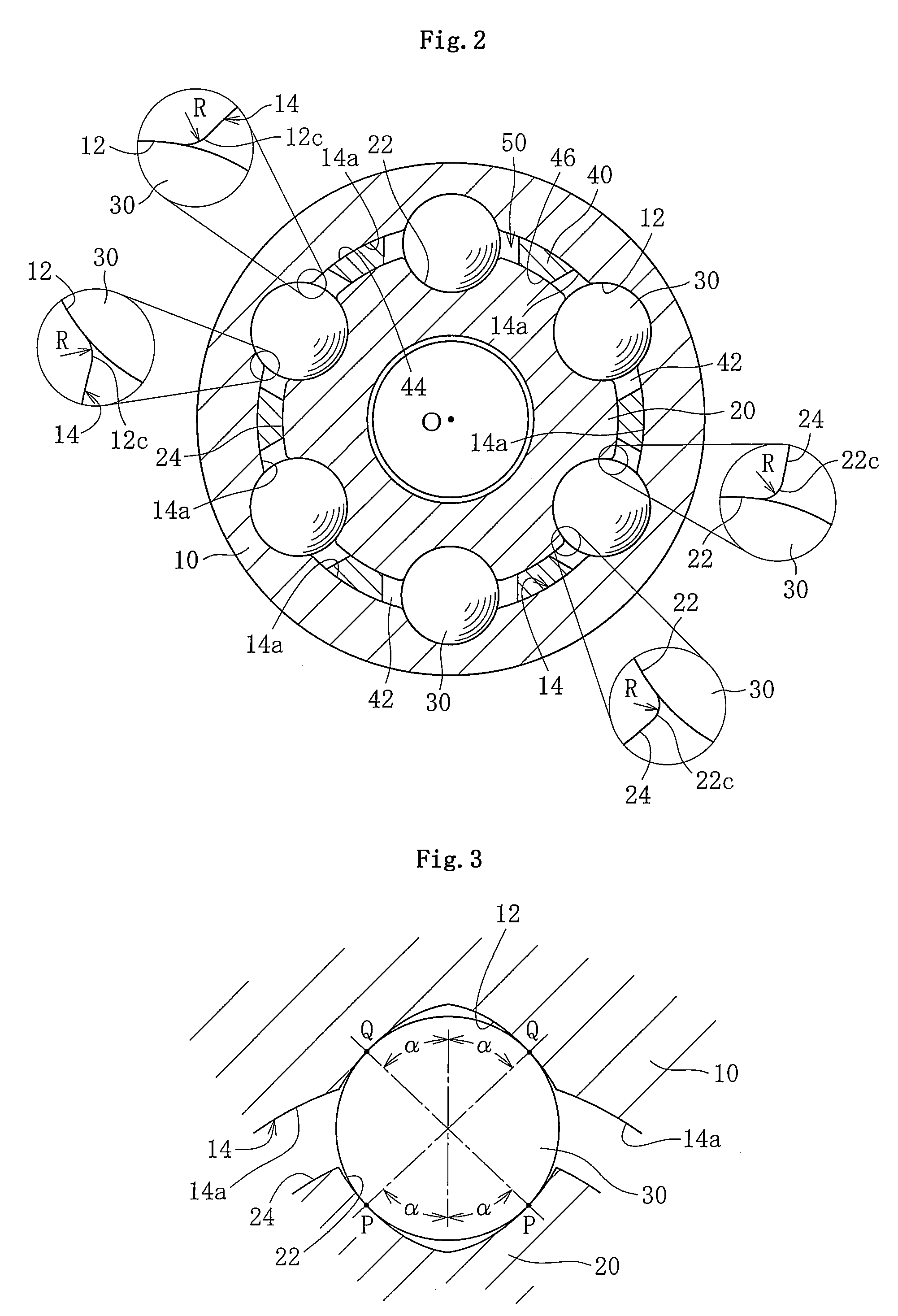

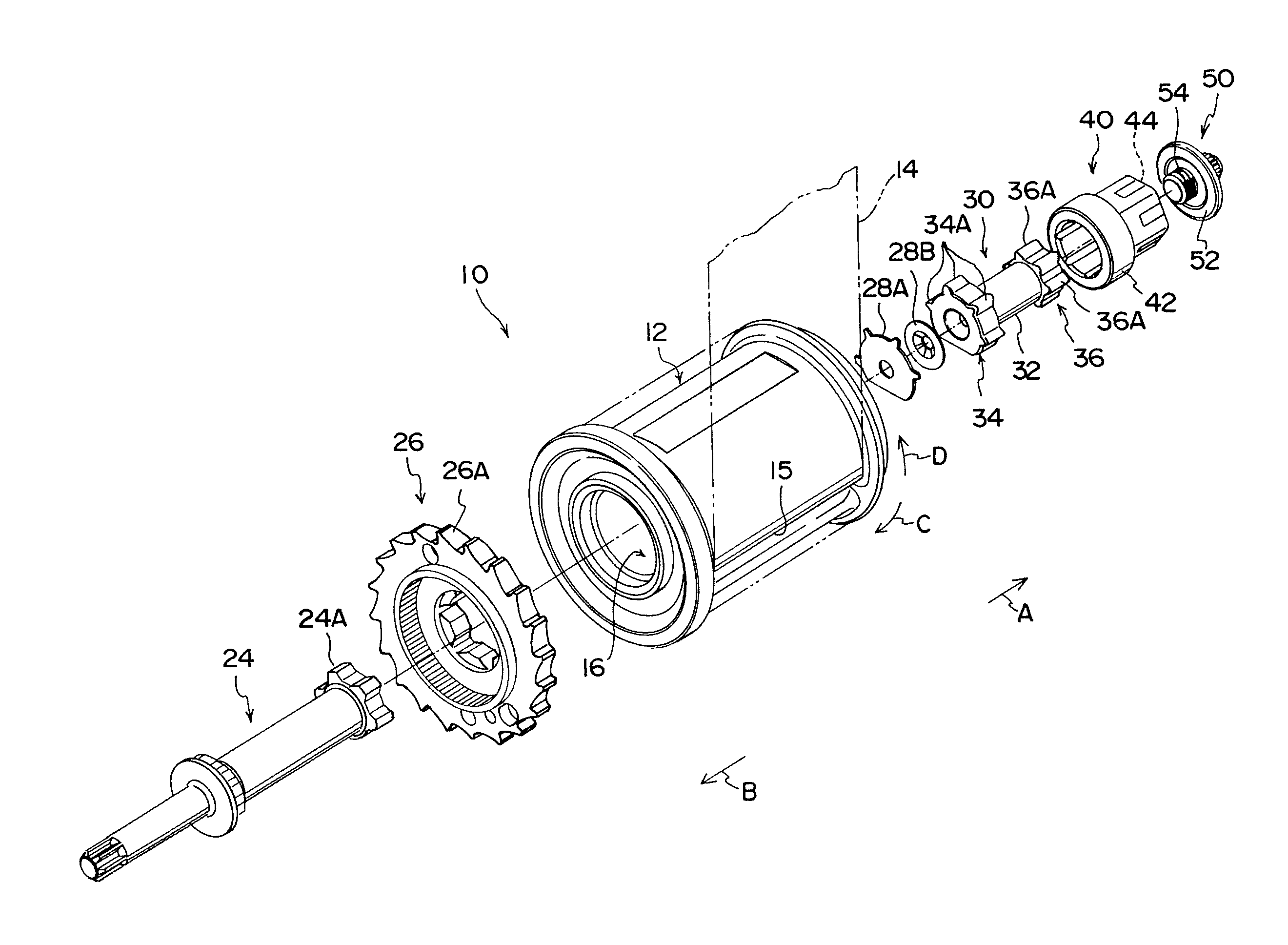

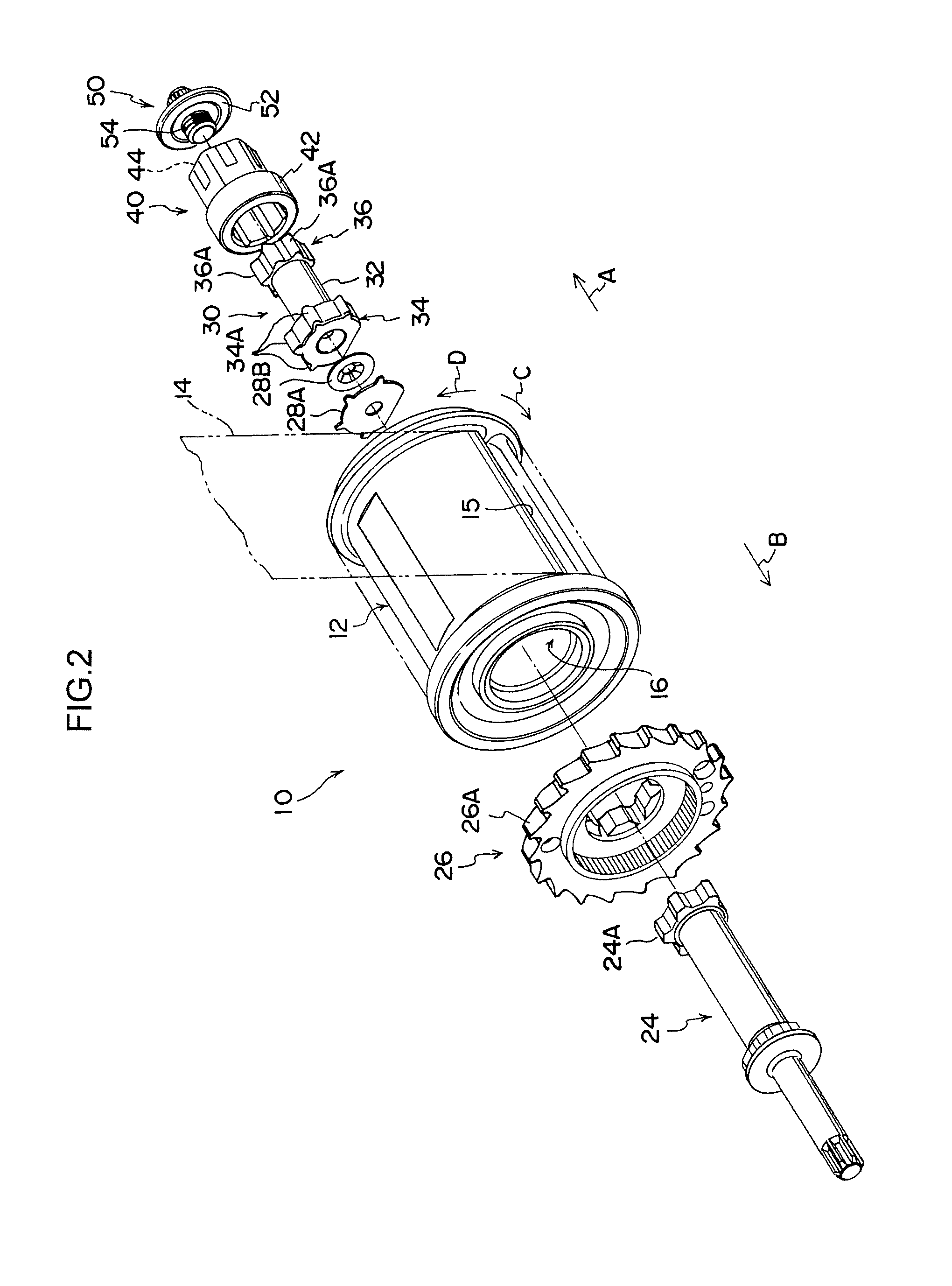

Outer joint member for fixed constant velocity universal joint

ActiveUS20110269556A1Increase productionCost of manufactureYielding couplingEngine componentsManufacturing cost reductionJoint component

Provided is an outer joint member for a fixed type constant velocity universal joint, the outer joint member contributing to reduction of the number of man-hours through reduction of the number of post processes after a forging process, and to an increase in yield, and reduction of manufacturing cost. The outer joint member for a fixed type constant velocity universal joint includes a cup section (16) and a shaft section (18) extending in an axial direction from a bottom portion of the cup section (16). The outer joint member is made of machine-structural carbon steel. The following portions of the outer joint member are finished by cold forging: track grooves (12); radially inner spherical-surface portions (14a); a cup-inlet chamfer (12b); track chamfers (12c); track-inlet chamfers (12a); a part except for a boot fixing portion (19) on a radially outer surface of the cup section (16); and a center hole (13) at an end surface (18a) of the shaft section (18).

Owner:NTN CORP

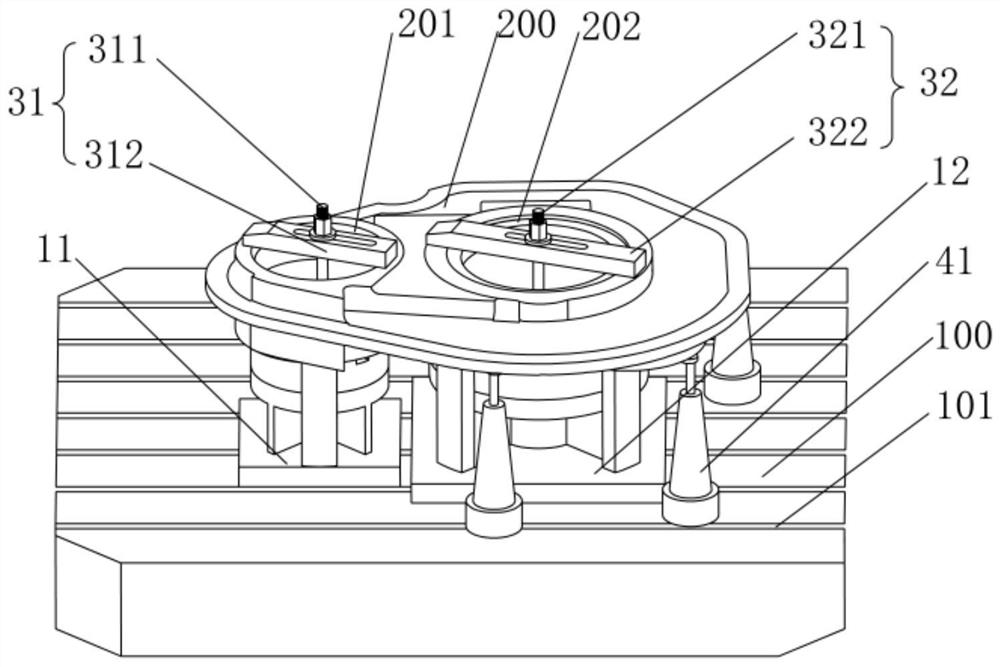

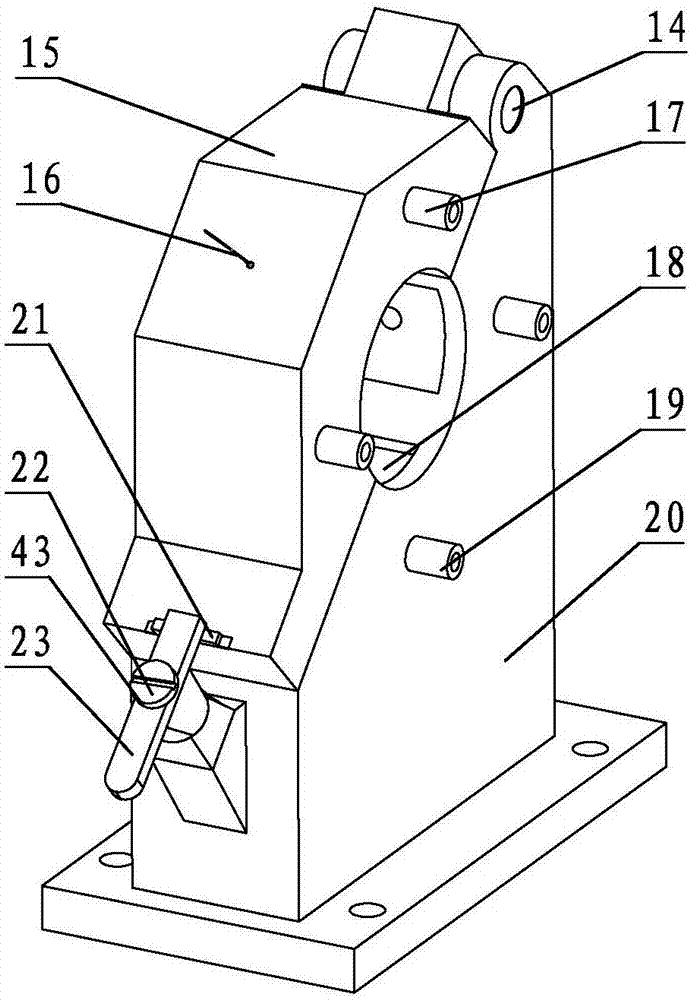

Clamping device for cover of wind power gear box

PendingCN111890086AImprove stabilityGuaranteed radial positioning accuracyPositioning apparatusMetal-working holdersWind powerMachining

The invention discloses a clamping device for a cover of a wind power gear box, and belongs to the technical field of machining. The clamping device for the cover of the wind power gear box comprisesa first base, a second base, a first clamping unit, a second clamping unit, a first pressing unit, a second pressing unit and an adjustment unit, wherein the first base and the second base are slidably connected with a worktable separately and can support the cover; the first clamping unit and the second clamping unit are arranged on the first base and the second base respectively and used for positioning of a first bearing hole and a second bearing hole respectively; the first pressing unit and the second pressing unit are slidably connected with the worktable and used for pressing the upperend faces of the first bearing hole and the second bearing hole respectively; and the adjustment unit is arranged on the worktable and can abut upon the edge of the bottom surface of the cover to support and adjust the height of the cover. The clamping device for the cover of the wind power gear box is high in universality, improves the production efficiency and reduces the production cost.

Owner:NANJING HIGH SPEED GEAR MFG

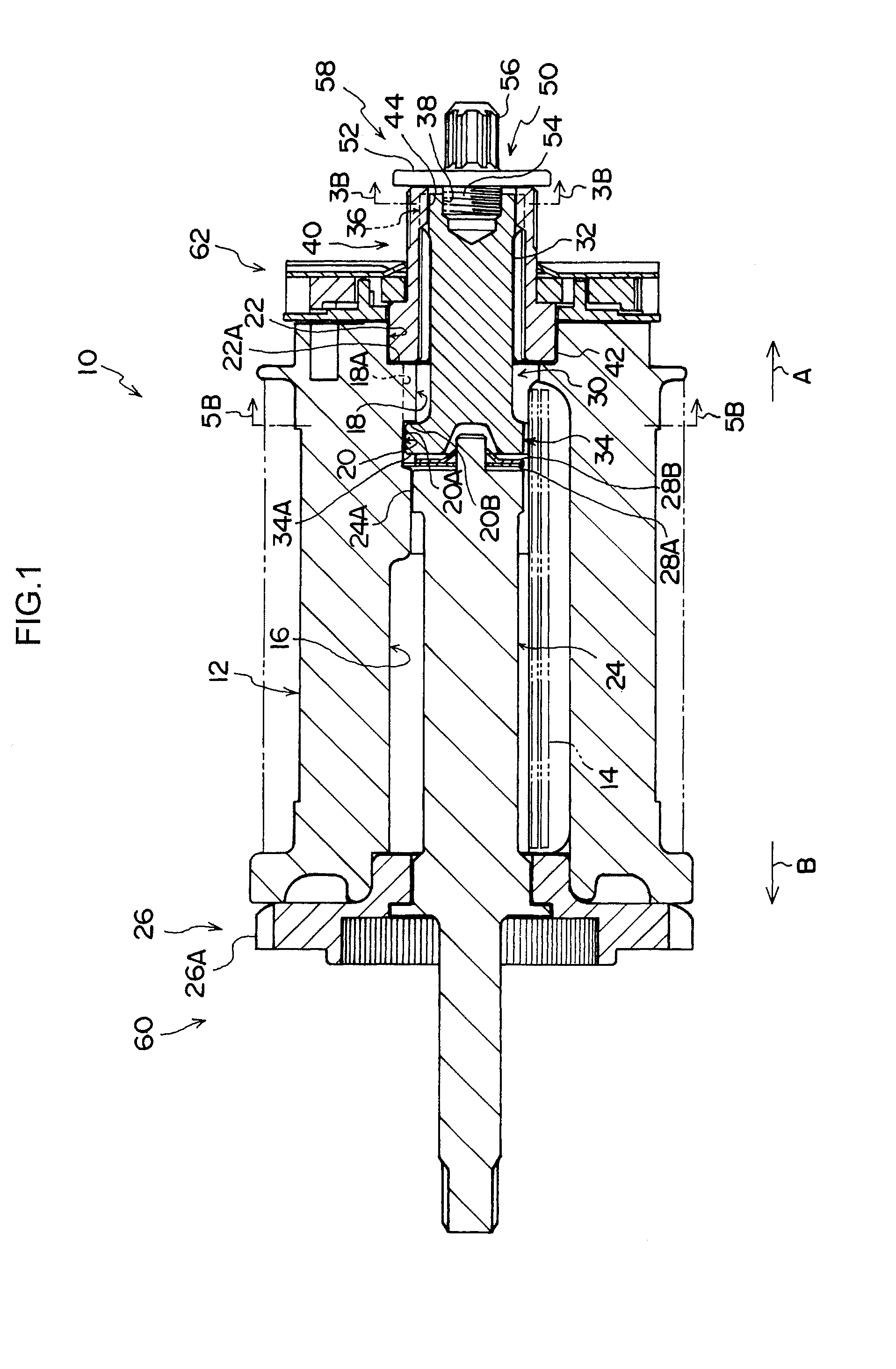

Webbing take-up device

InactiveUS20110303780A1Improve axial positioning accuracyGood effectBelt retractorsEnergy-absorbing device incorporationEngineeringMechanical engineering

A sleeve is fitted in a spool so as to be arranged coaxially with the spool. A fit-insertion hole including plural female splines is formed on a cylindrical inner side of the sleeve coaxially with an axial line of the sleeve. A fit-insertion portion, which is fit-inserted in the fit-insertion hole, of a sub torsion shaft is coaxial with an axial line of the sub torsion shaft and provided with plural male splines formed on an outer peripheral side of the fit-insertion portion. As a result of rotational displacement of the sleeve about the axial line thereof and regulation of rotation of the sub torsion shaft, so an axial center of the fit-insertion portion is made to coincide with an axial center of the fit-insertion hole, a fit-insertion portion side of the sub torsion shaft is fixed by a fixing mechanism with respect to the sleeve.

Owner:KK TOKAI RIKA DENKI SEISAKUSHO

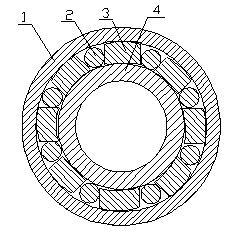

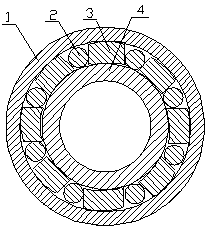

Rolling and sliding bearing with outer ring as sleeve

InactiveCN102434577AEasy to installExtended service lifeRolling contact bearingsBearing componentsEngineeringFlange

Owner:EAST CHINA JIAOTONG UNIVERSITY

Tool sleeve group of scribing machine and scribing machine

InactiveCN102673282AImprove axial positioning accuracyPrevent falling outEngravingEngineeringMechanical engineering

The invention relates to a tool sleeve group of a scribing machine and the scribing machine. The tool sleeve group of the scribing machine comprises a scribing tool, a tool sleeve and a tool bar sleeved into the tool sleeve, wherein a locking part for locking the tool sleeve and the tool bar is arranged on the tool bar, the tool bar is provided with an installation inner hole overlapped with the axis of the tool bar, and an elastic friction ring and a tool tail sleeve which are axially and fixedly connected with the installation inner hole are arranged on the installation inner hole. The scribing tool is arranged on the installation inner hole of the tool bar and disposed on the elastic friction ring in penetrating mode, the internal diameter of the elastic friction ring is smaller than the diameter of the scribing tool, and the tail portion of the scribing tool is axially fixedly connected with and peripherally movably connected with the tool tail sleeve. The invention further provides the scribing machine. The tool sleeve group of the scribing machine and the scribing machine have the advantages that the axial positioning accuracy of the scribing tool is improved, and the scribing tool is prevented from falling off the tool sleeve and is convenient to mount, demount and replace.

Owner:深圳市创造机电有限公司

Electric vehicle reducer gear shaft assembly structure

InactiveCN104265840AImprove machining accuracyGood processing consistencyToothed gearingsAssembly machinesNoise, vibration, and harshnessGear wheel

An electric vehicle reducer gear shaft assembly structure comprises an input shaft assembly, an output shaft and a differential mechanism assembly and is characterized in that a ratchet wheel and an output gear which is meshed with the input shaft assembly are sequentially installed on the output shaft in a press fitting mode; a cone bearing is installed on a shaft shoulder of the output gear in a press fitting mode; an output shaft shoulder which is close to a meshed position of the output shaft and the differential mechanism assembly is provided with a cone bearing; a graded snap spring is arranged on the press fitting external side portion of the output shaft and the output gear. The electric vehicle reducer gear shaft assembly structure is impact and light. According to the electric vehicle reducer gear shaft assembly structure, the length of a gear shaft string is shortened, the axial length, the size and the weight of a reducer is reduced, and the gear accuracy is improved due to a gear structure design; the gear machining and assembling error caused by spline is avoided and accordingly the gear accuracy is improved due to a gear machining and assembling scheme; meanwhile the NVH (Noise Vibration and Harshness) performance, the gear intensity service life and the cone bearing service life are improved.

Owner:BRILLIANCE AUTO

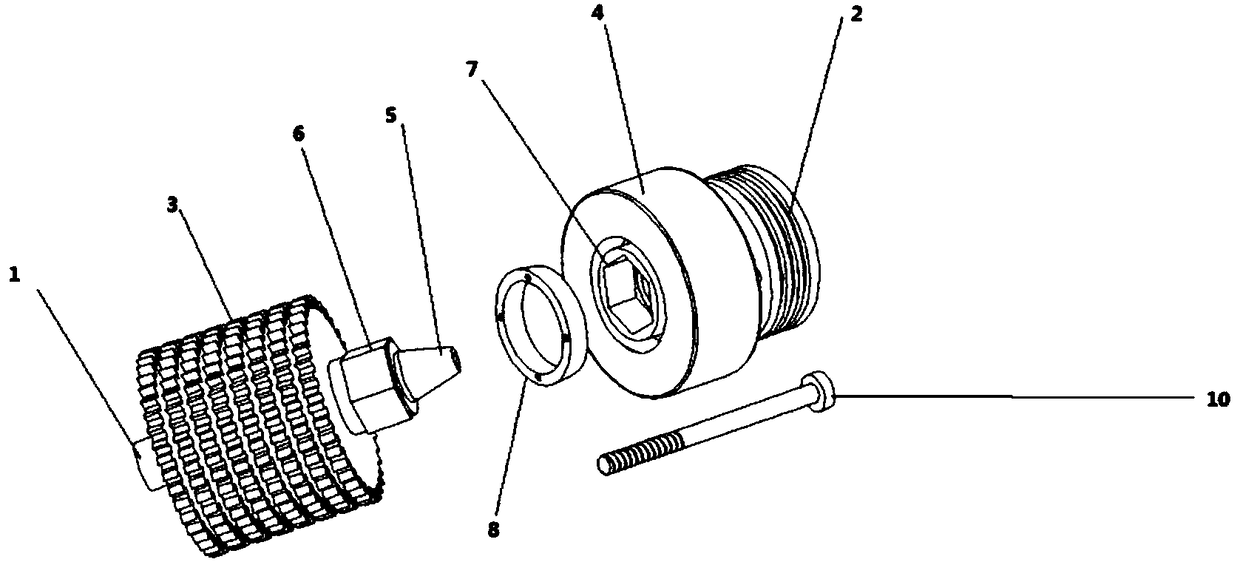

Automobile alternator integral pulley assembly

ActiveCN100468917CPrevent slippingImprove axial positioning accuracyRoller bearingsBearing assemblyAlternatorEngineering

This invention relates to one airmobile alternating motor integral slides bus with imbed single clutch, which is fixed on end of rotation axis and to drive automobile alternating moor through hook wireless joint band between the drive band wheels of the axis end. This invention is one integration structure outer ring composed of clutch outer ring, front supportive ring and back supportive ring.

Owner:JIANG SU NAN FANG BEARING CO LTD

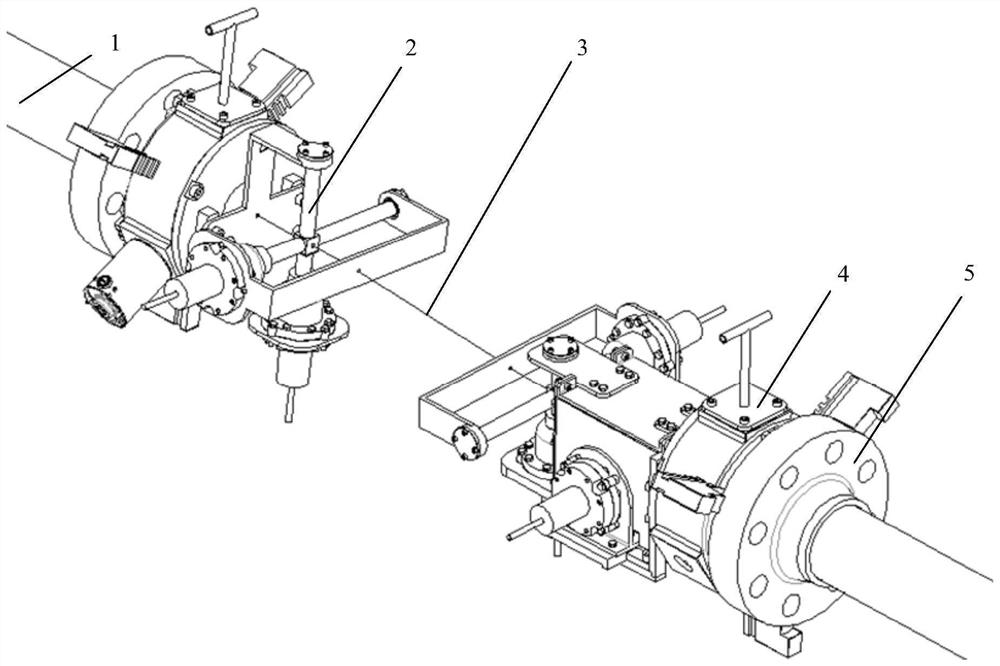

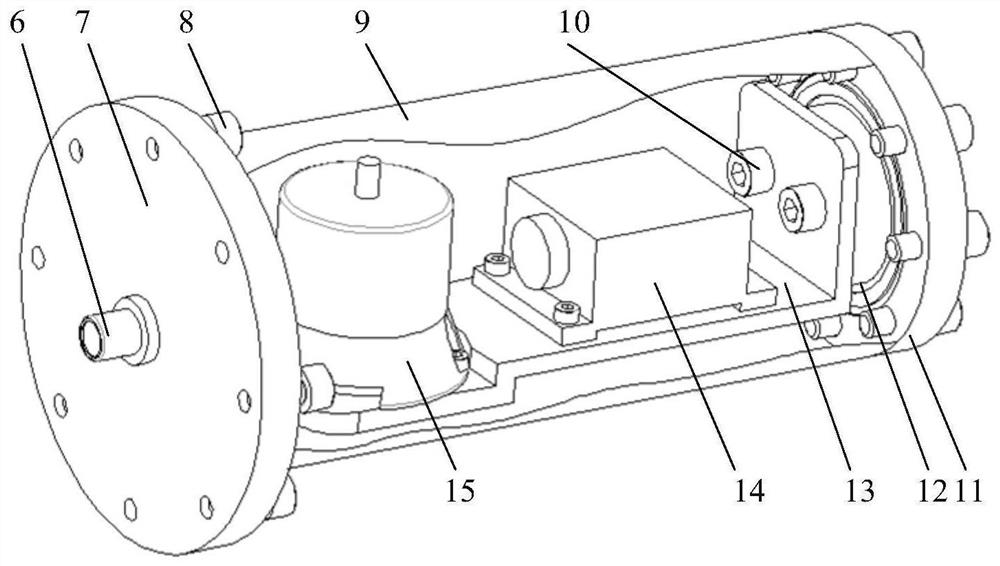

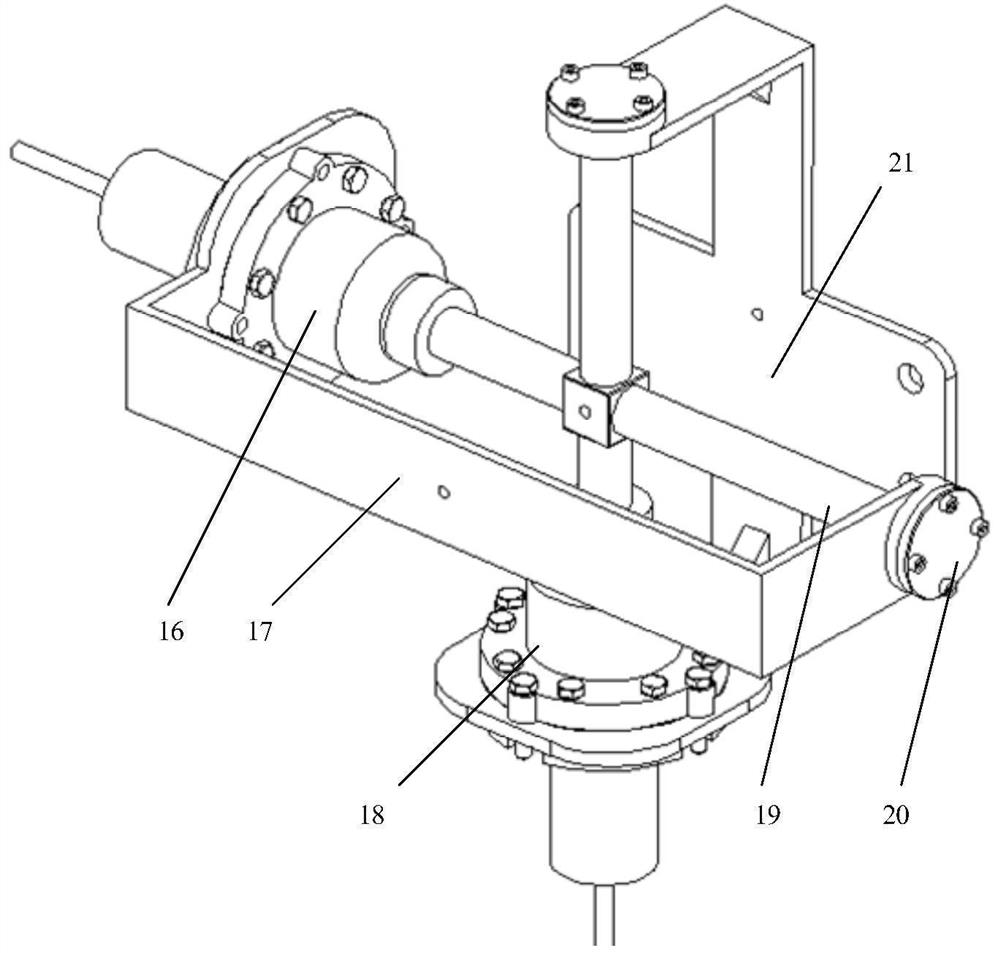

Deepwater pipeline tie-back pose measuring device

InactiveCN112629396AEasy to installImprove axial positioning accuracyUsing electrical meansMeasurement deviceClassical mechanics

The invention provides a deepwater pipeline tie-back pose measuring device. The deepwater pipeline tie-back pose measuring device is composed of a measuring device (I), a measuring device (II) and an auxiliary measuring steel wire rope (3). The structure of the measuring device (I) mainly comprises an orthogonal inclination angle measuring mechanism, a flange butt joint mechanism and a pitching and horizontal swing angle measuring mechanism. The structure of the measuring device (II) mainly comprises an orthogonal inclination angle measuring mechanism, a flange butt joint mechanism, a rope length detecting mechanism and a pitching and horizontal swing angle measuring mechanism. By designing the corresponding butt joint mechanism, flange end face positioning and flange outer circle clamping are fully utilized, the axial positioning precision is improved, and therefore the distance between the flange end face and the stretching-out position point of the measuring rope is changed into a fixed value from an unknown quantity. According to the invention, the leading-out site of the steel wire rope in the measuring device is adjusted to the extension line of the central axis of the corresponding measured pipeline, so that the solving process is simplified on the basis of the transition matrix algorithm.

Owner:HARBIN ENG UNIV

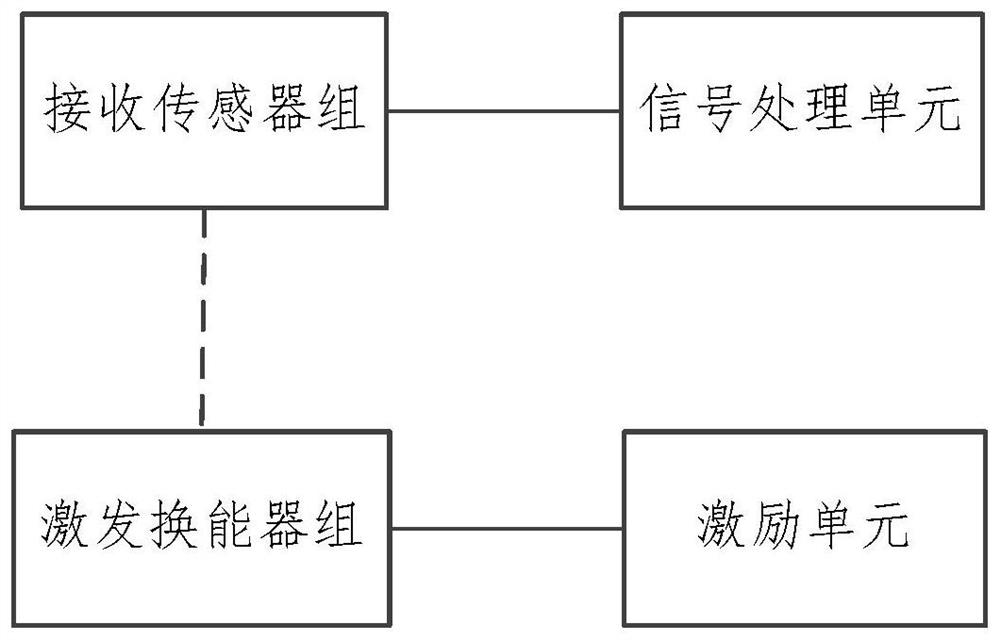

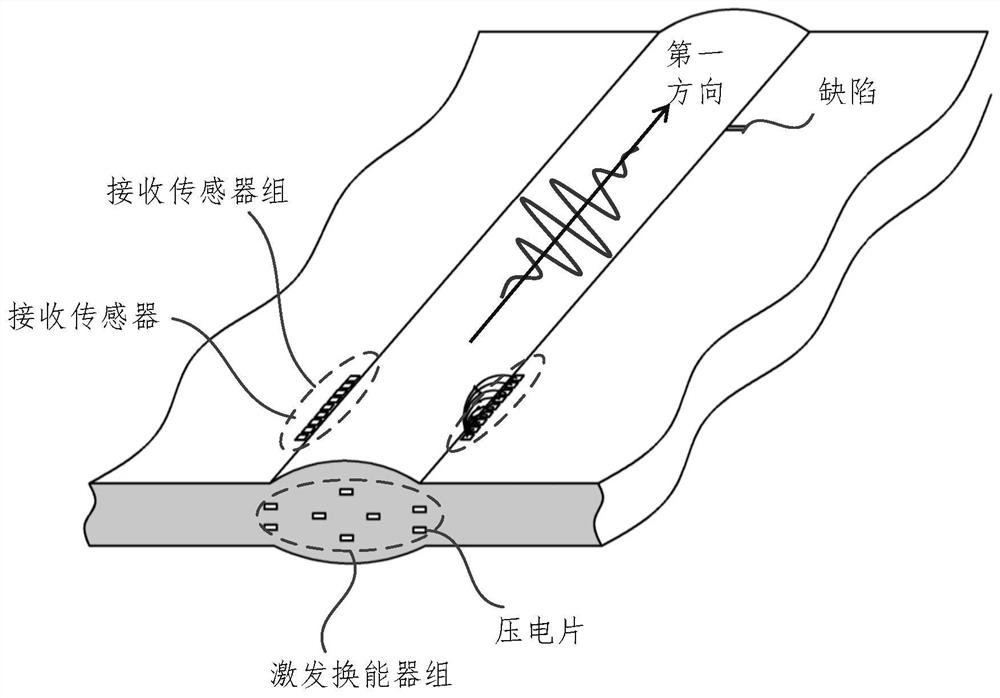

Weld defect detection method and device, electronic equipment and storage medium

ActiveCN113466336ANo dead angle detectionImprove efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesWeld seamEngineering

The invention relates to a weld defect detection method and device, electronic equipment and a storage medium. The method comprises the steps of determining a first vibration signal corresponding to a target sensor based on a detection signal of the target sensor; determining a first vibration signal corresponding to each non-target sensor based on the detection signal of each non-target sensor; based on the first vibration signals corresponding to the non-target sensors, determining second vibration signals of reference waves corresponding to the non-target sensors at target sensor setting positions; superposing the first vibration signal corresponding to the target sensor and the second vibration signal of each reference wave at the setting position of the target sensor to obtain a superposed third vibration signal; and determining weld defect data in the to-be-detected component based on the superposed third vibration signal. The device can be used for detecting local defects in a long welding seam structure with high transverse resolution capability and high axial positioning precision, and can realize remote in-service quality monitoring.

Owner:BEIHANG UNIV

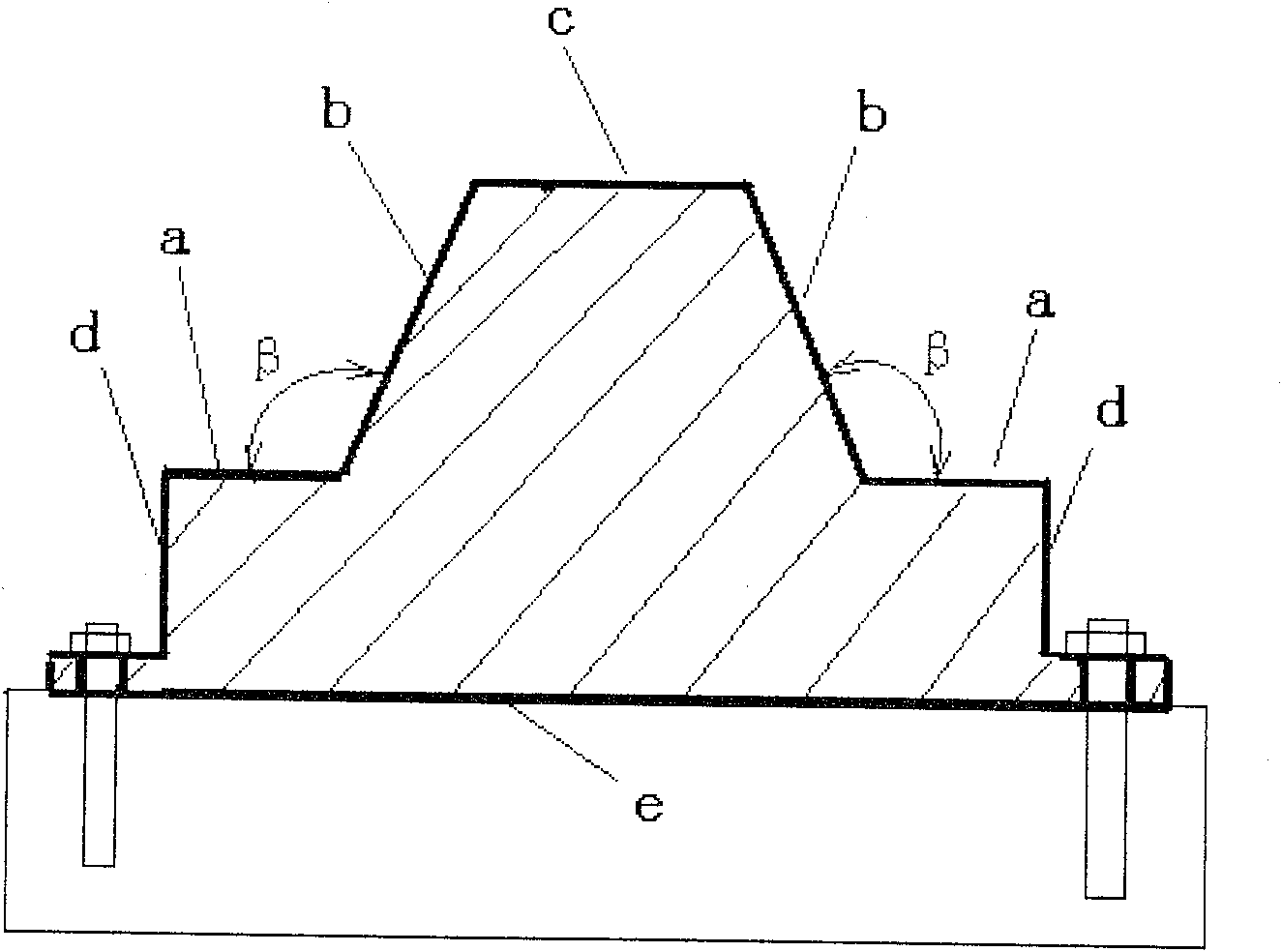

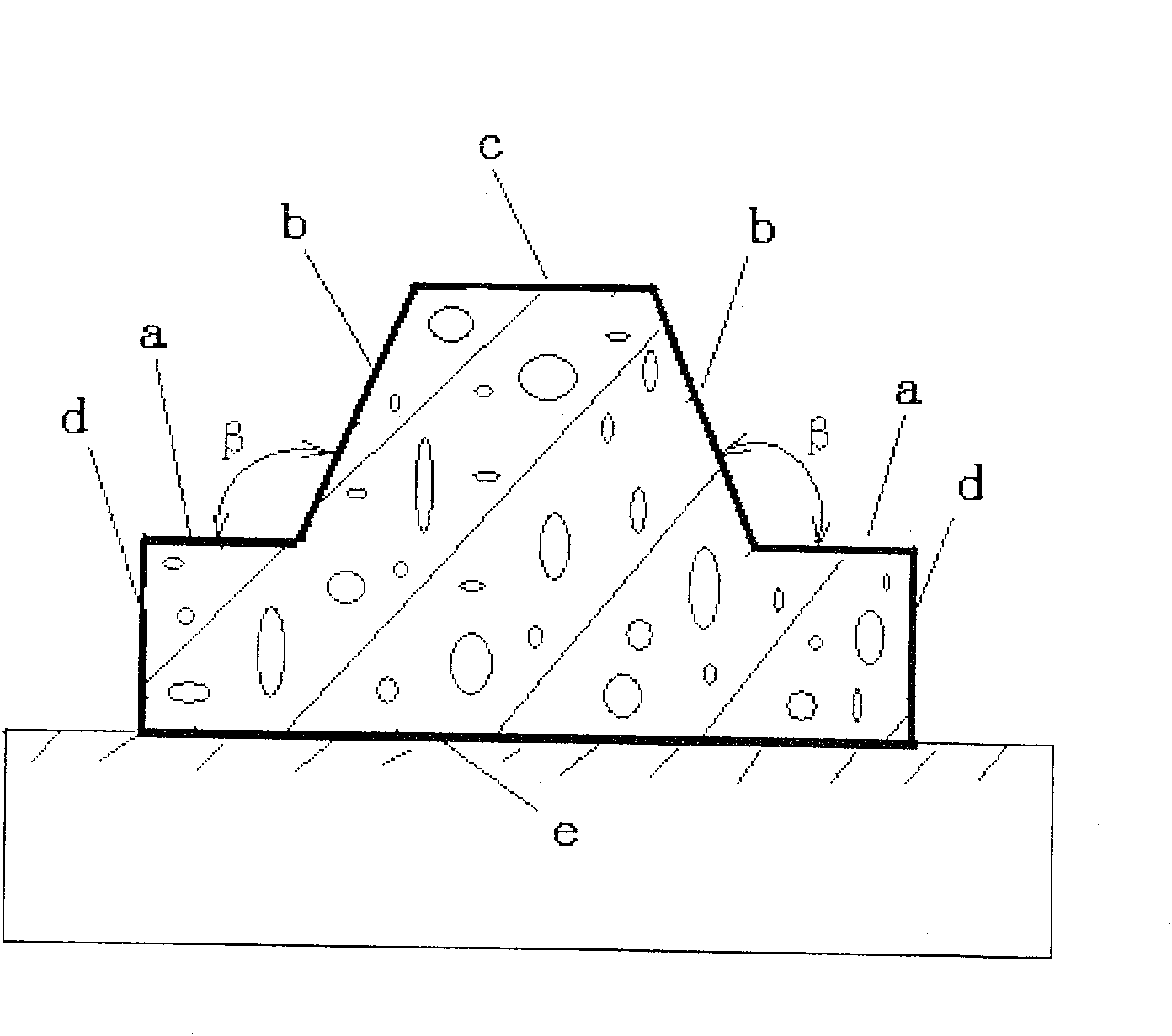

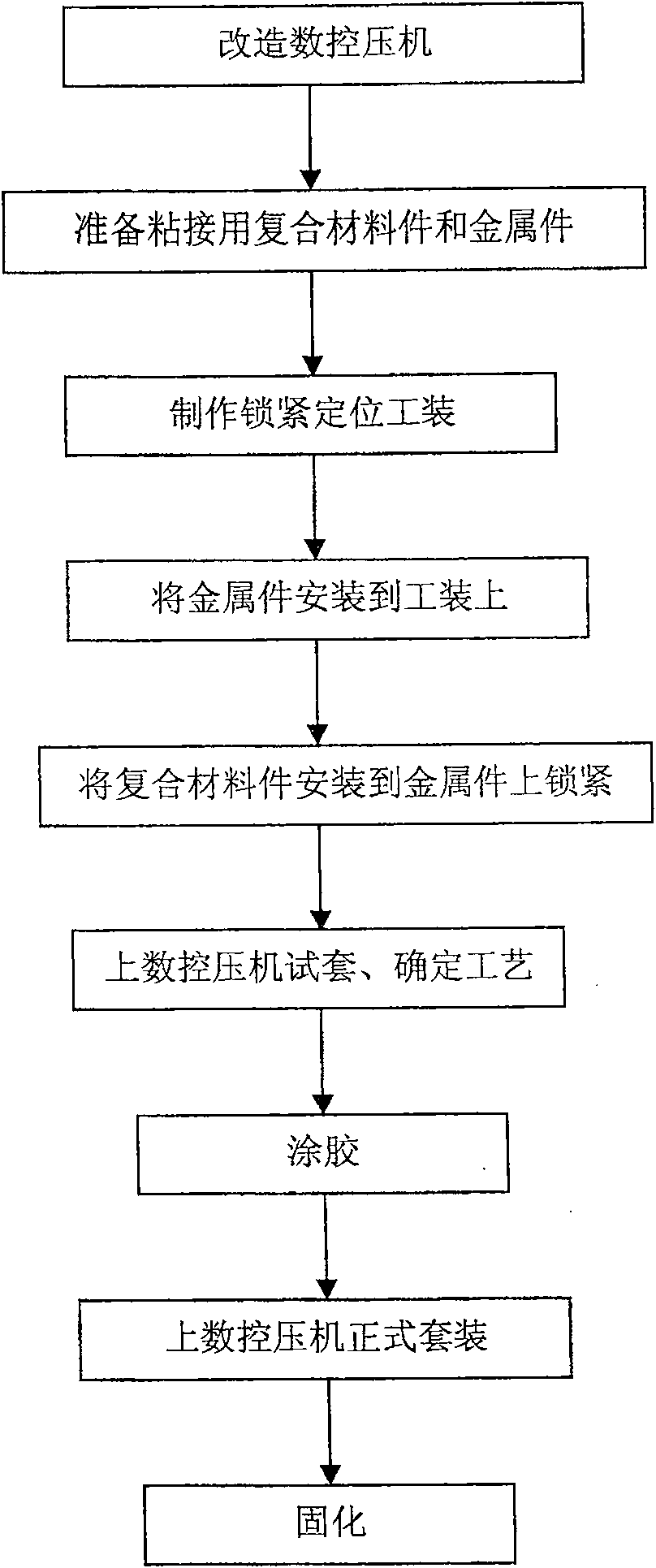

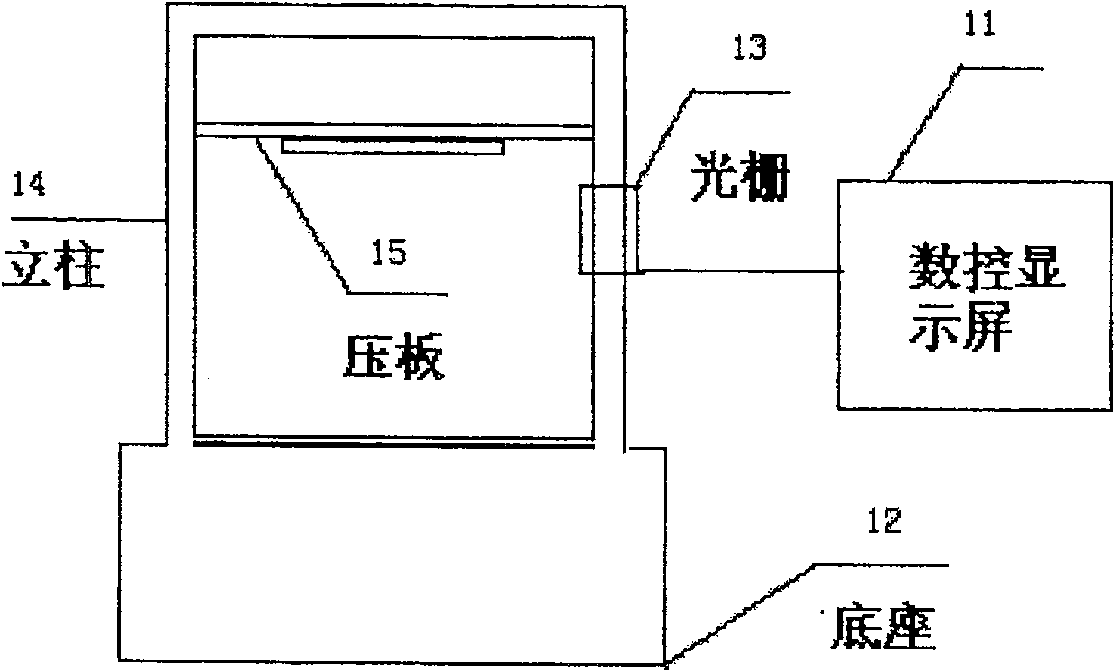

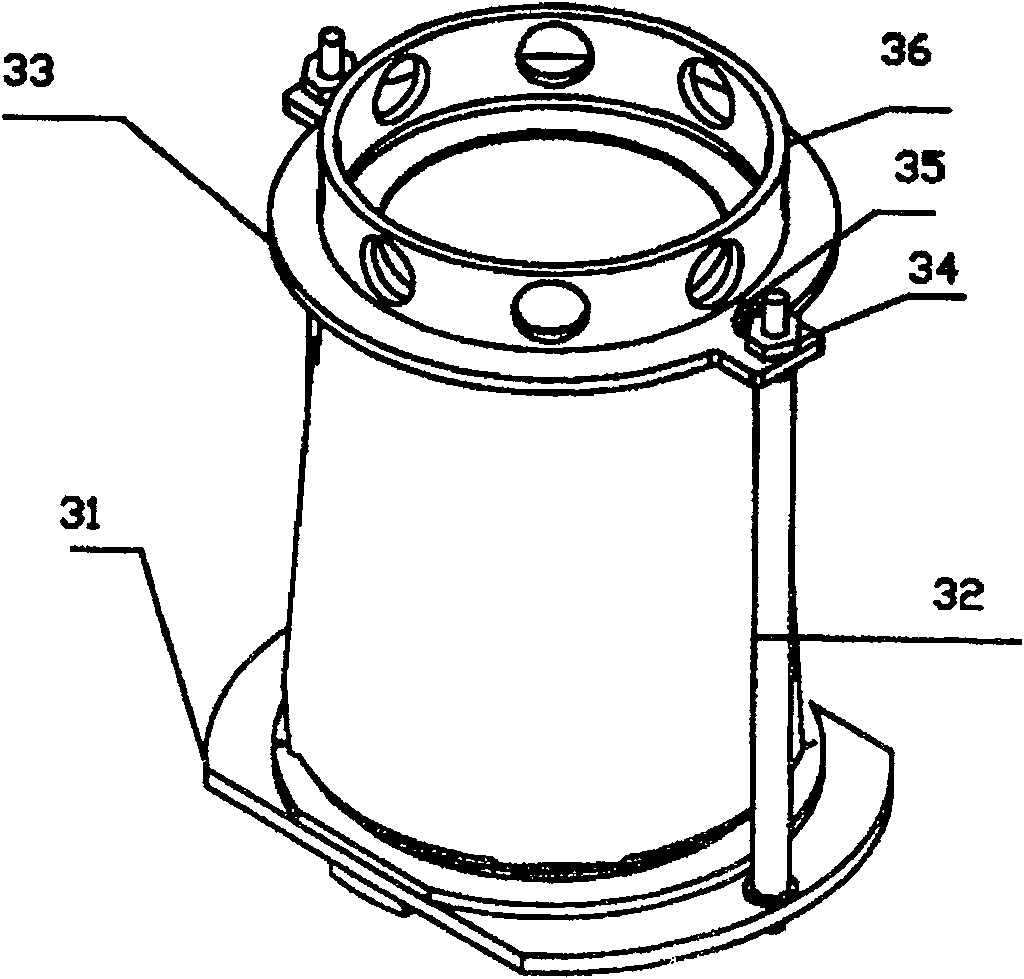

Truncated platform composite material member and metal member positioning adhesion process

ActiveCN100585196CSave raw materialsSolve the technical problems of precision positioningAdhesive processesFastening meansAxial displacementNumerical control

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

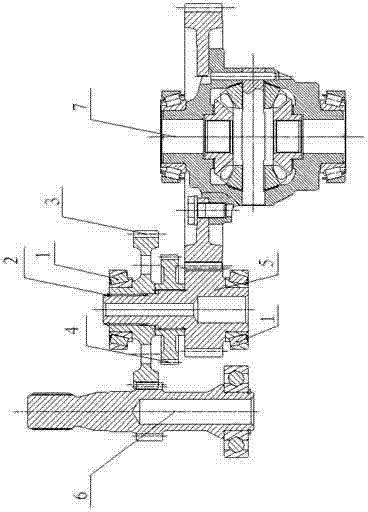

Clutch for rail vehicle

PendingCN114728665ASet Bolt InsertionEasy to insertElectric motor propulsion transmissionControl theoryClutch

The invention relates to the field of rail vehicles, and relates to a dual-joint-acting clutch for compensating for axial, radial and angular offsets between a gearbox and a wheel. The aim of the invention is to provide an at least two-part clutch for a rail vehicle, which clutch is simple and safe during assembly, largely avoids damage during assembly of the clutch, and has a high-precision positioning of the engaged clutch halves. According to the invention, a clutch for a rail vehicle is provided, which clutch is a two-part and / or three-part clutch system, according to the invention, a pre-assembled positioning bolt, which is arranged axially centrally in the second clutch shaft, is present at least for aligning, centering, guiding and checking the second clutch half relative to the first clutch half, the positioning bolt protrudes from the first clutch half on the side facing away from the end face of the first clutch shaft by a region, by means of which at least one force-fitting connection of the first clutch half and the second clutch half is achieved.

Owner:KWD KUPPLUNGSWERK DRESDEN

Radial positioning unit and positioning clamping device for internal grinding of thin-walled cylindrical workpieces

ActiveCN105397636BGuaranteed automaticImprove radial positioning accuracyRevolution surface grinding machinesGrinding work supportsEngineeringMachining process

Owner:DALIAN UNIV OF TECH

An optical fiber connector that can be precisely positioned

ActiveCN105242358BImprove axial positioning accuracyLimited rotationCoupling light guidesFiberEngineering

The invention discloses an optical fiber connector capable of accurate positioning, which comprises a connector socket and a connector plug, wherein the connector socket comprises a connector socket base, a locking wheel pressure ring, a locking wheel and an operating handle, and the connector socket base is fixed to an optical bottom plate of a confocal imaging system in a rigid manner; the locking wheel pressure ring, the locking wheel and the operating handle form a locking and limiting mechanism of the connector socket; the head part of the connector plug is provided with an axial positioning head, a rotary positioning head is arranged behind the axial positioning head, an optical fiber bundle passes through a hollow hole, and the optical fiber bundle and the connector plug are fixed to each other after being leveled; and the hollow hole faces just to a circular light passing hole when connector plug is inserted to the bottom part of a positioning groove of the connector socket base, and focused laser is injected into the optical fiber bundle through the circular light passing hole. The optical fiber connector adds a rotary positioning function, limits the optical fiber to rotate around the axis, achieves positioning in the rotational direction, applies a pressure on the connector through a spring, ensures stable and reliable locking of the connector, and can control the pressure.

Owner:BIOPSEE (ZHIYUAN) MEDICAL TECH CO LTD

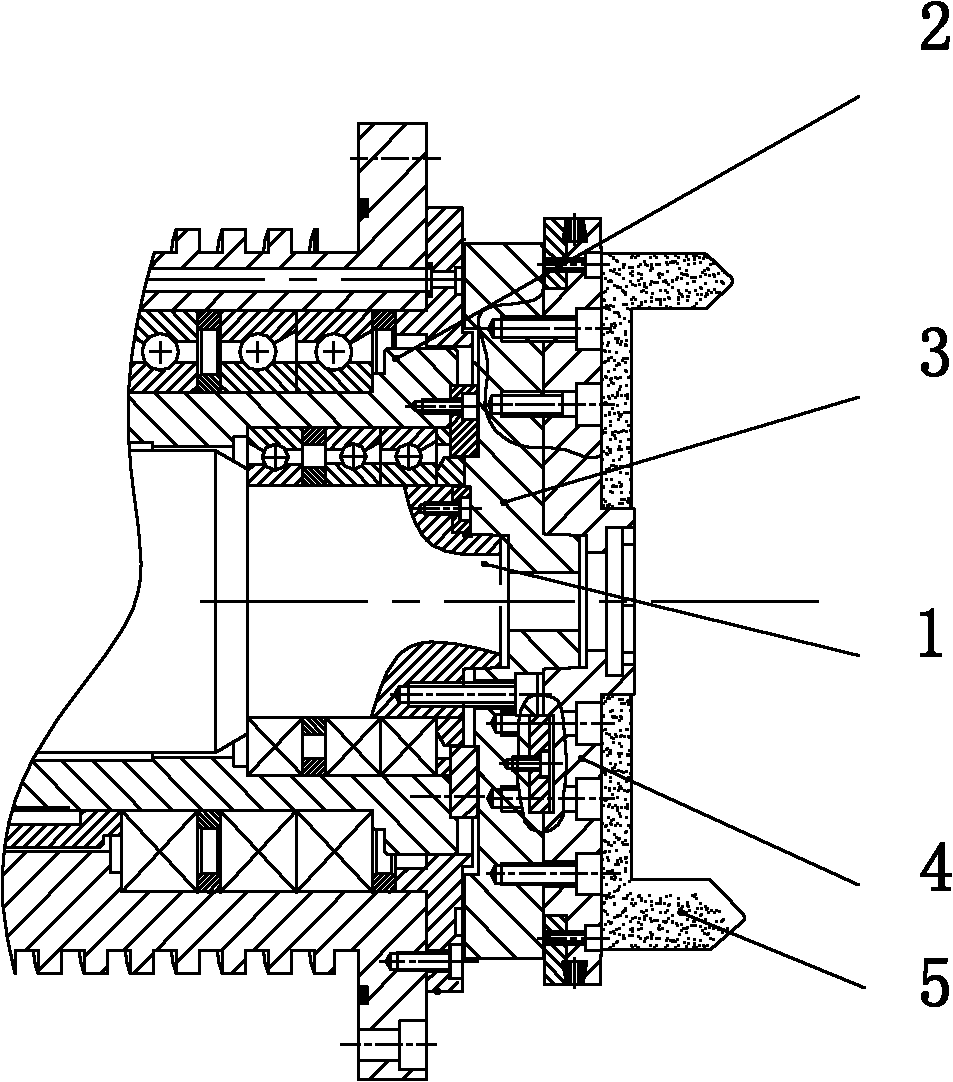

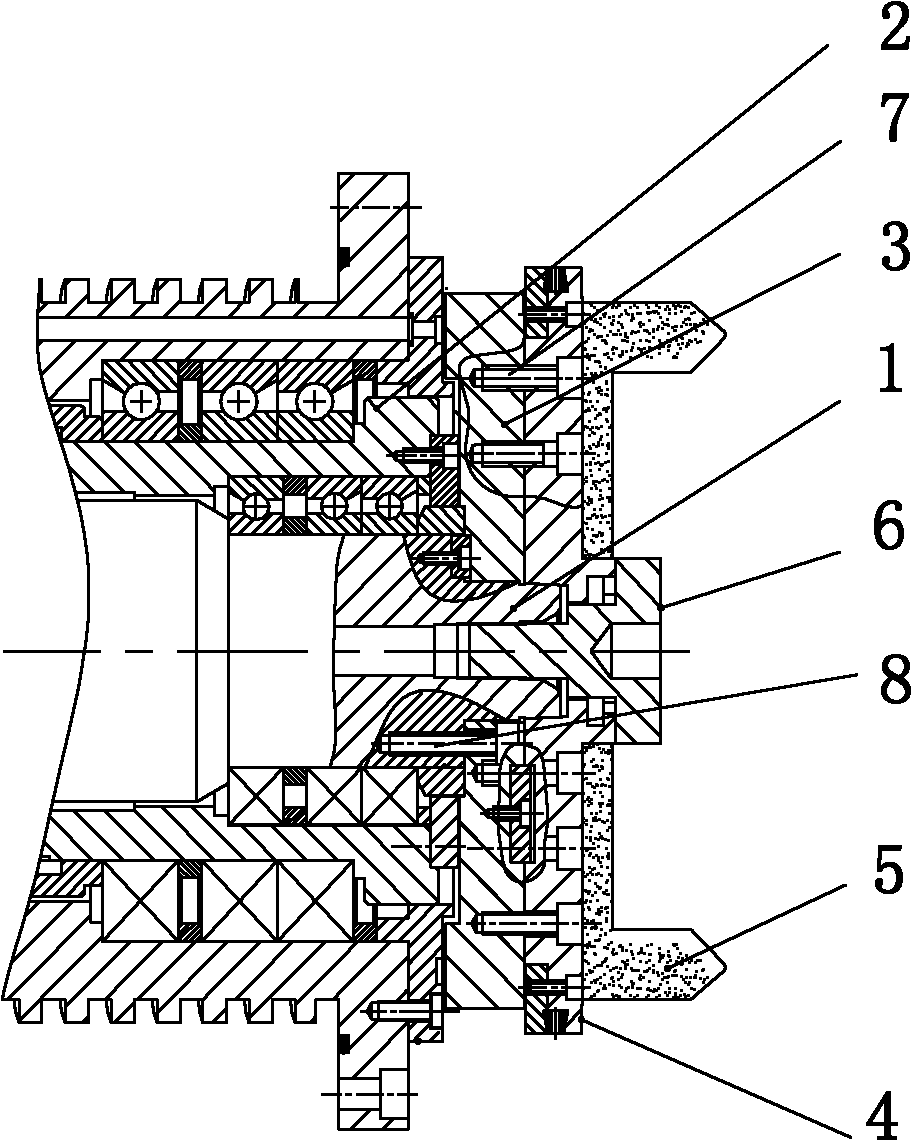

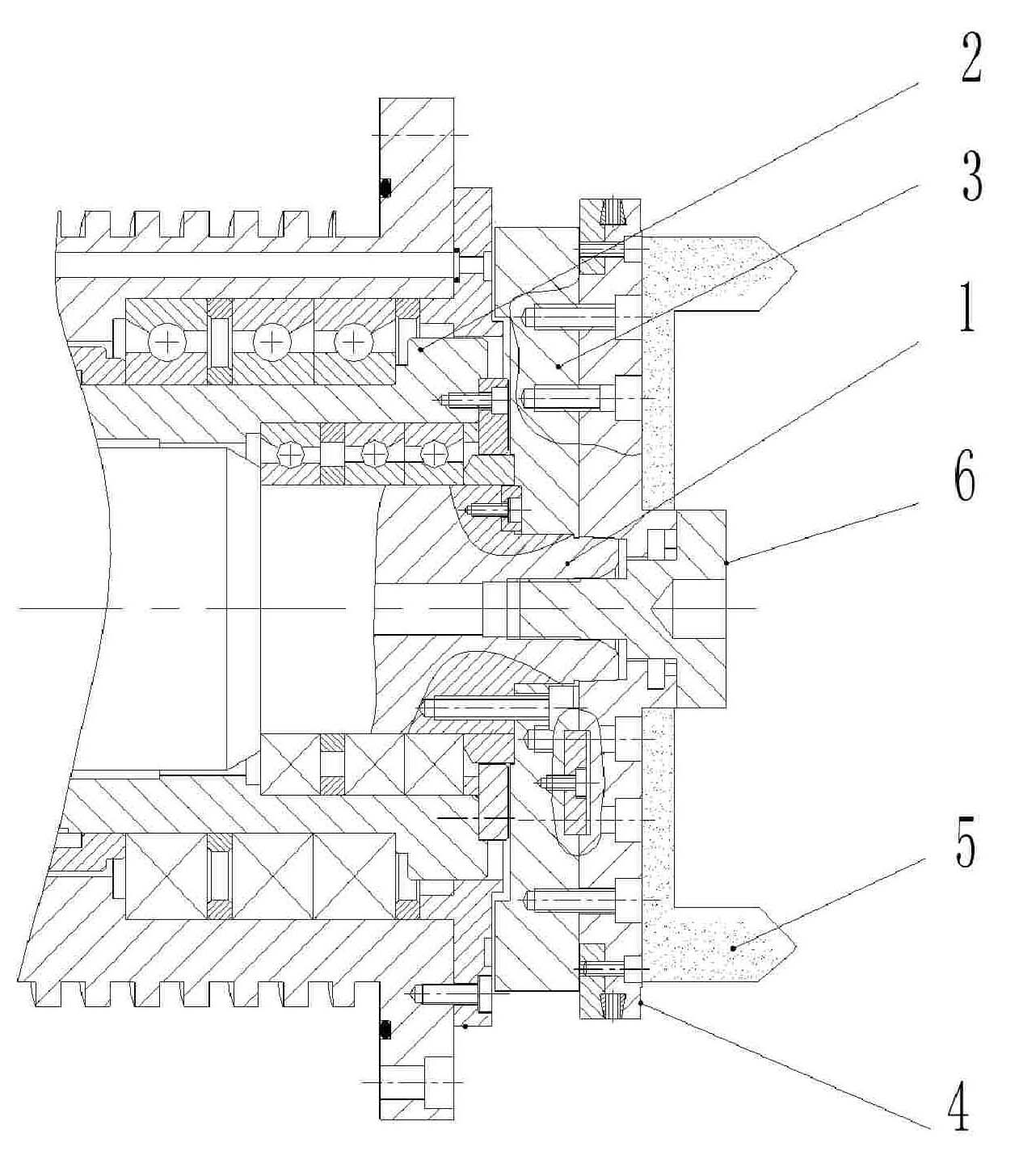

High-rigidity and high-precision spindle structure of spiral bevel gear grinding machine

The invention discloses a high-rigidity and high-precision spindle structure of a spiral bevel gear grinding machine. A spindle flange (3) is in interference fit and location with a grinding wheel spindle (1) by adopting a cylindrical surface and is fastened on the grinding wheel spindle (1) by eight M8 bolts. A grinding wheel transitional plate component (4) is interference fit and location withthe grinding wheel spindle (1) by adopting a cone surface and is fastened on the spindle flange (3). The grinding wheel transitional plate component (4) is mounted on the grinding wheel spindle (1) through a fastening screw (6) and twelve M8 bolts. The invention is the high-rigidity and high-precision spindle structure of a spiral bevel gear grinding machine with enough connection intensity and ahigh-rigidity and high-location precision grinding head when grinding, thus improving the rigidity of the grinding wheel spindle, making the machining accuracy more stable and improving the overall performance of a machine tool.

Owner:HUNAN ZDCY (ZHONGDA CHUANG YUAN) CNC EQUIP CO LTD

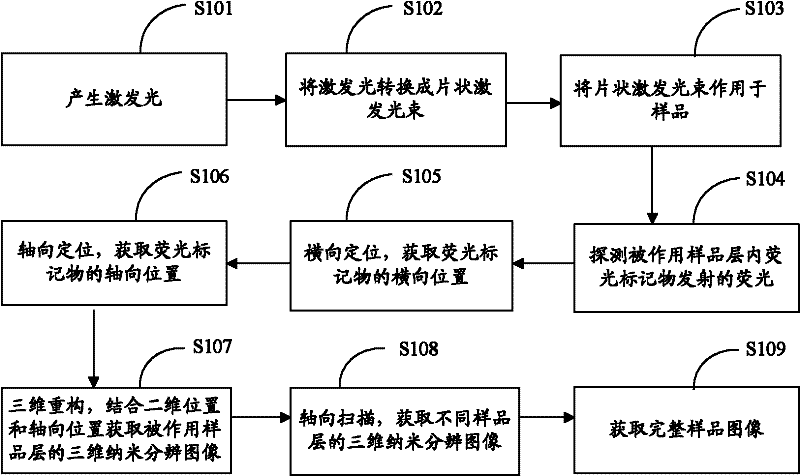

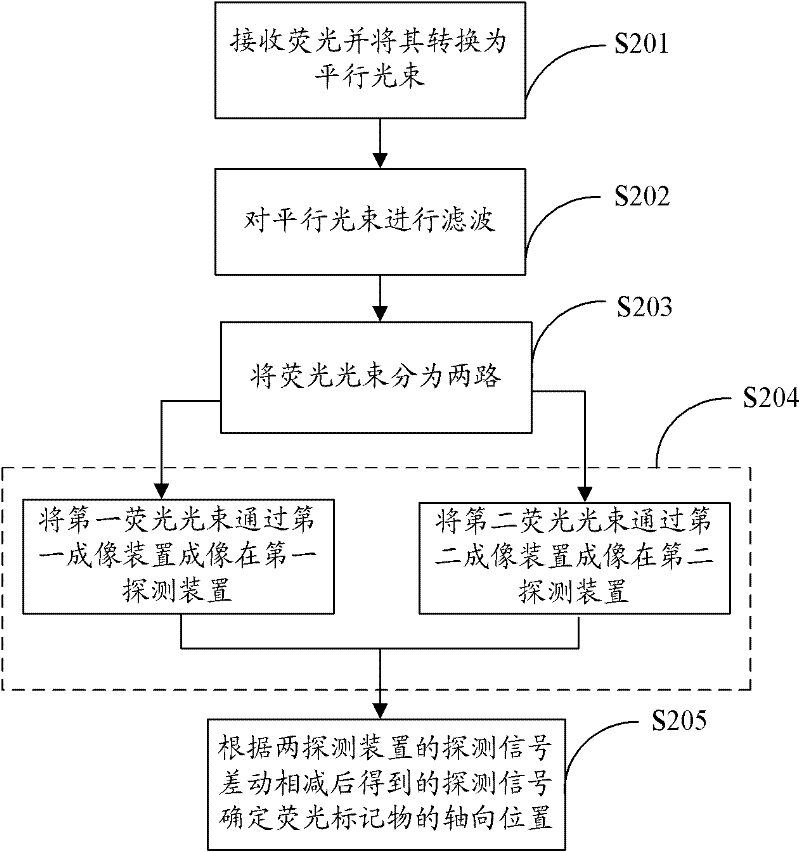

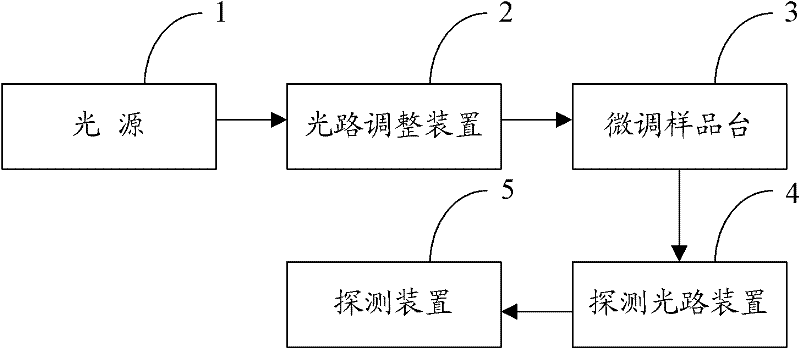

Three-dimensional fluorescence nano microscope imaging method and system, and image equipment

ActiveCN101963582BAvoid crosstalkReduce out-of-focus background noiseFluorescence/phosphorescenceMicro imagingLight beam

The invention is suitable for the field of microscope imaging, and provides a three-dimensional fluorescence nano microscope imaging method and a three-dimensional fluorescence nano microscope imaging system, and image equipment. The method comprises the following steps of: producing exciting light; converting the exciting light into a laminar exciting beam; making the laminar exciting beam act on a sample; detecting a fluorescent light emitted by a fluorescent label in the sample layer on which the laminar exciting beam acts; transversely positioning to acquire the two-dimensional position of the fluorescent label; axially positioning to acquire the axial position of the fluorescent label; three-dimensionally reconstructing, combining the two-dimensional position with the axial position to acquire a three-dimensional nano resolution image of the sample layer on which the laminar exciting beam acts; axially scanning to acquire the three-dimensional nano resolution images of different sample layers; and acquiring the three-dimensional nano resolution image of the complete sample. Through the three-dimensional fluorescence nano microscope imaging method and the three-dimensional fluorescence nano microscope imaging system, and the image equipment, the high-precision three-dimensional nano microscope imaging is realized by taking the laminar light beam as the exciting light, and combining with axial scanning, and the method, system and equipment are suitable for three-dimensional microscope imaging of the thick sample, such as cells in the biological field and the like, and solve the problems that the positioning accuracy of molecules in the thick sample is low and the sample is difficult to observe.

Owner:SHENZHEN UNIV

Rolling and sliding bearing with outer ring as sleeve

InactiveCN102434577BRestrict relative movementImprove axial positioning accuracyRolling contact bearingsBearing componentsEngineeringFlange

Owner:EAST CHINA JIAOTONG UNIVERSITY

Ceiling-fan motor

The invention relates to a ceiling-fan motor, comprising a motor upper shell (3), a motor lower shell (6), a motor shaft (1), an upper bearing (2), a lower bearing (7), a motor stator (4) and a motor rotor (5), wherein the motor rotor (5) is arranged outside the motor stator in a matching mode; the center of the motor upper shell (3) is provided with an upper bearing chamber (31); the upper bearing (2) is positioned in the upper bearing chamber (31) and sleeved on the motor shaft (1); the center of the motor lower shell (6) is provided with a lower bearing chamber (61); the lower bearing (7) is arranged in the lower bearing chamber and sleeved on the motor shaft (1); and the motor rotor (5) is arranged in the inner circles of the motor upper shell (3) and the motor lower shell (6). The ceiling-fan motor is characterized by further comprising a wave-shaped spring gasket ring (8) which is arranged in the lower bearing chamber (61) and positioned at the bottom of the lower bearing (7); the upper bearing (2) is in clearance fit with the upper bearing chamber (31); and the lower bearing (7) is in clearance fit with the lower bearing chamber (61). The upper bearing, the lower bearing and the motor rotor are maintained at proper positions; the radial and axial positioning precision of the upper bearing and the lower bearing is improved; the rotary precision is improved; the vibrationis reduced; and the bearing noise caused by resonance is avoided.

Owner:MIDEA GRP CO LTD

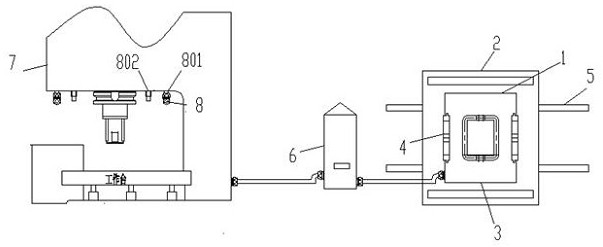

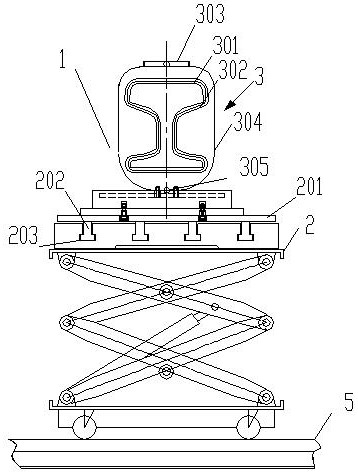

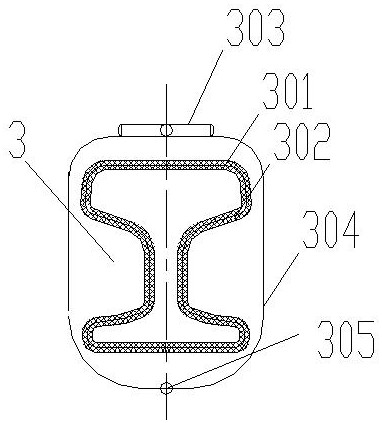

Asymmetric section steel rail straightening and preheating device

PendingCN113245411AWarm up evenlyImprove heating efficiencyMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention provides an asymmetric section steel rail straightening and preheating device which comprises a steel rail preheating device. The steel rail preheating device is mounted at the top of a lifting platform. The lifting platform does translation along X-direction trolley rails. The steel rail preheating device comprises a steel rail preheating tool. The steel rail preheating tool is of an I-shaped structure in bilateral symmetry. Steel rail outline lateral auxiliary positioning devices are detachably mounted on the left side and the right side of the steel rail preheating tool. By means of the asymmetric section steel rail straightening and preheating device, the problem about rapid local preheating of an asymmetric section steel rail is solved, the preheating process progress is accelerated, the preheating operation difficulty is reduced, use is convenient, the number of times of clamping is reduced, the machining efficiency is improved, and the machining quality is guaranteed.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

Heavy loading shaft push device for hole

ActiveCN102141071BEasy to installImprove axial positioning accuracyFastening meansClassical mechanicsEngineering

Owner:HANGZHOU ADVANCE GEARBOX GRP

Medical endoscope optical parfocal lens

PendingCN111221092AImprove axial positioning accuracyImprove coaxialitySurgeryEndoscopesParfocal lensOphthalmology

The invention relates to a medical endoscope optical parfocal lens. According to the technical scheme, the medical endoscope optical parfocal lens is characterized in that the medical endoscope optical parfocal lens comprises a cam groove sleeve, a focusing lens group assembled in the cam groove sleeve, a fixed base rotationally assembled in the cam groove sleeve, a fixed lens assembled in the fixed base, a plurality of zoom lens assemblies assembled in the fixed base, a focusing driving assembly assembled on the cam groove sleeve and used for driving the focusing lens group to move along theoptical axis; and a zoom driving assembly assembled on the cam groove sleeve, used for driving the plurality of zoom lens assemblies to move along the optical axis, and synchronously rotating around the optical axis with the fixed lens in the fixed base. Therefore, the coaxiality, the inclination and the axial positioning precision between the zoom lens assembly and the fixed lens are improved, and the problems of image bounce and image blurring caused by position errors between the zoom lens assembly and the fixed lens assembly in the zoom process are effectively solved.

Owner:深圳英术生命科技有限公司

Bearing with inner ring serving as sleeve piece

InactiveCN102494017BRestrict relative movementImprove axial positioning accuracyRoller bearingsBearing componentsArchitectural engineeringFlange

Owner:EAST CHINA JIAOTONG UNIVERSITY

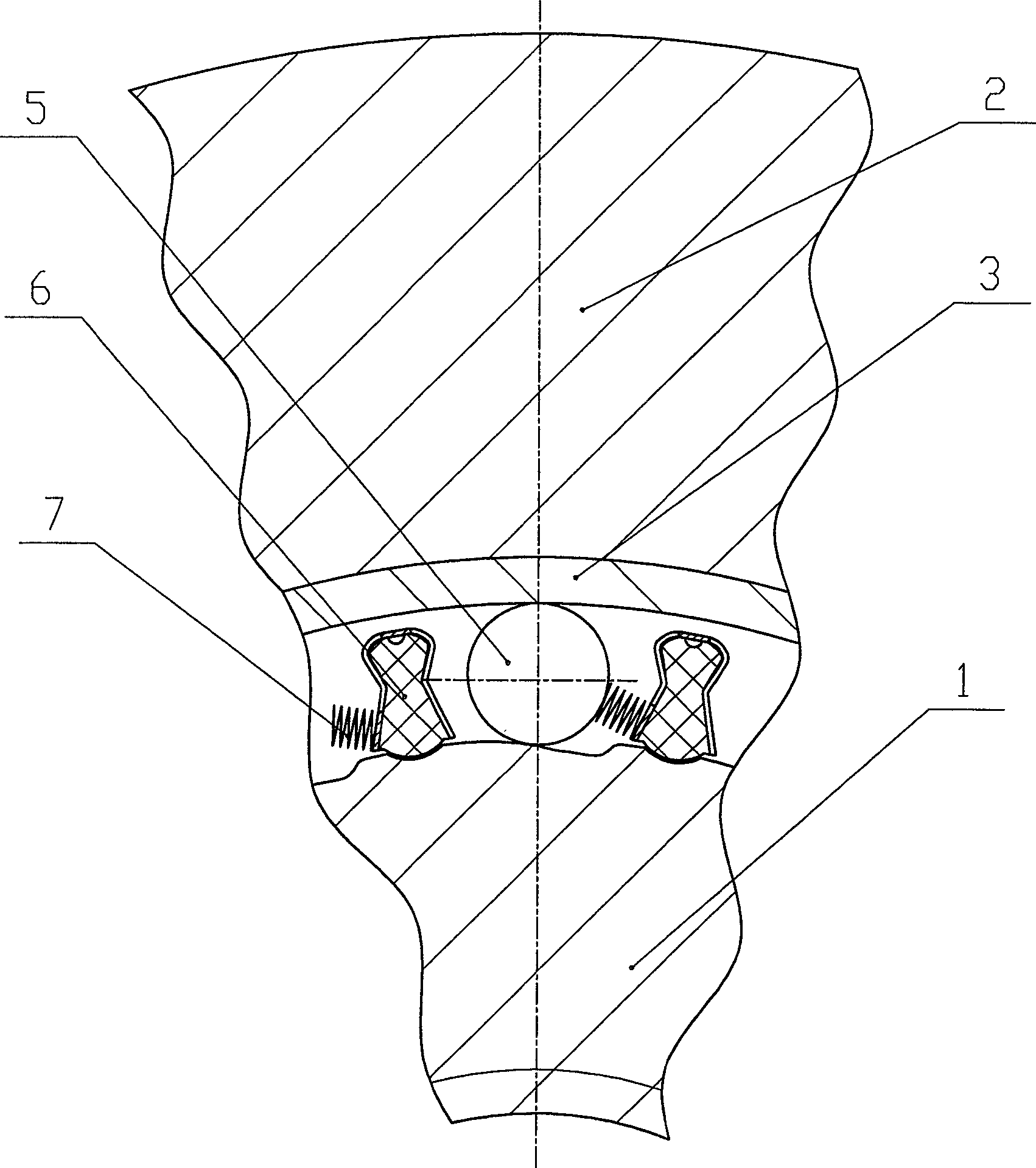

A Rotary Cutting Tool with Accurate Axial Positioning

ActiveCN103894663BImprove impact resistanceImprove axial positioning accuracyMilling cuttersEngineeringFastener

The invention discloses a rotary cutting tool capable of axially and accurately locating. The rotary cutting tool comprises a rotary cutter body, a cutter holder, a cutting blade, a cutter holder fastening part and a cutting blade fastening part, wherein a cutter slot defined by a bottom locating surface, a first side locating surface and a second side locating surface is formed in the rotary cutter body, the cutting blade is fixed on the cutter holder by the cutting blade fastening part, the first side locating surface is a surface at which the cutter slot is opposite to an end cutting edge of the cutting blade, the cutter holder is radically inserted in the cutter slot along the rotary cutter body, the first side locating surface and the bottom locating surface form interference clamping locating to the cutter holder, and the cutter holder and the rotary cutter body are fixedly connected with each other by the cutter holder fastening part. The rotary cutting tool capable of axially and accurately locating has the advantages of high axial anti-shock capability, high locating precision, good safety and long service life.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

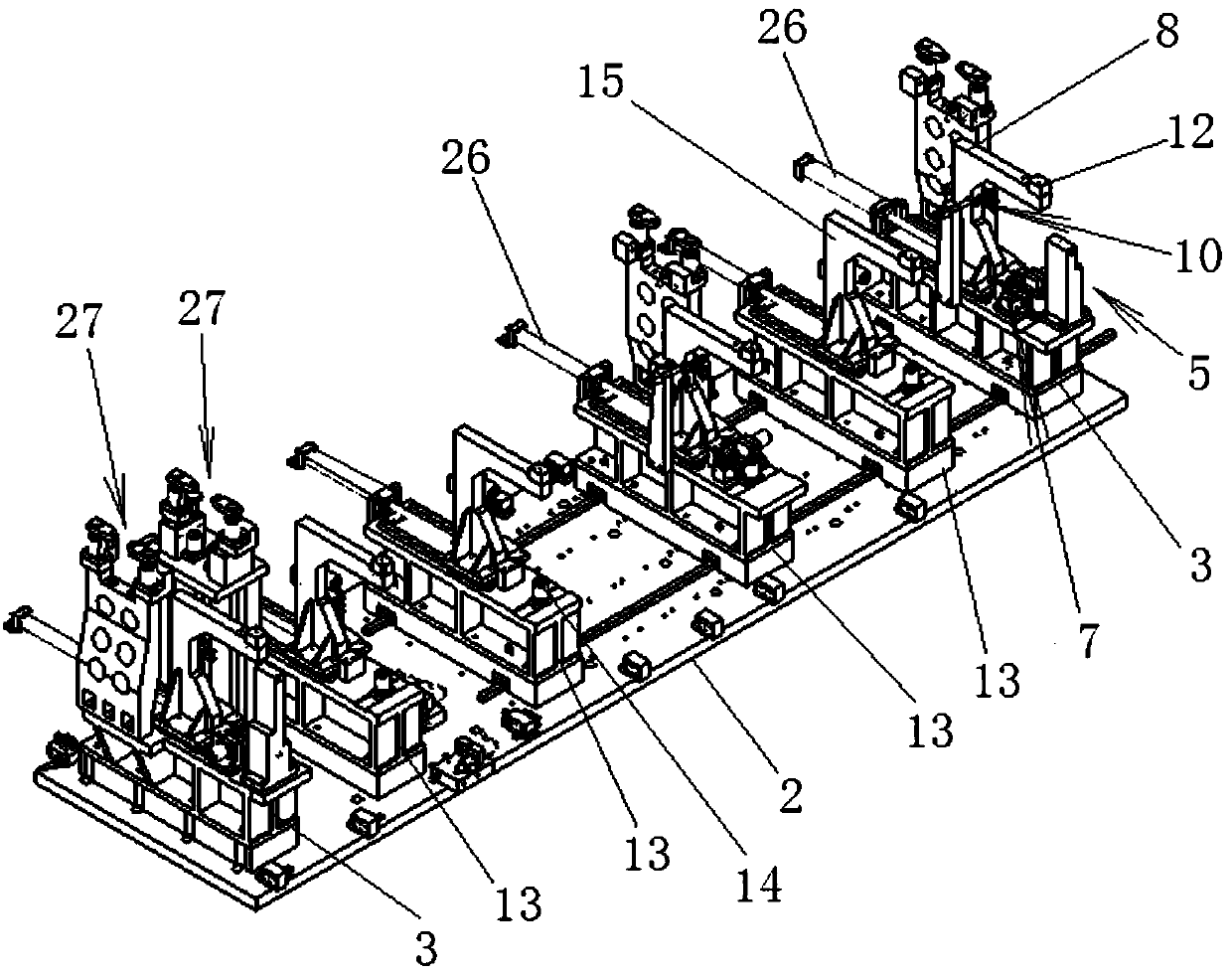

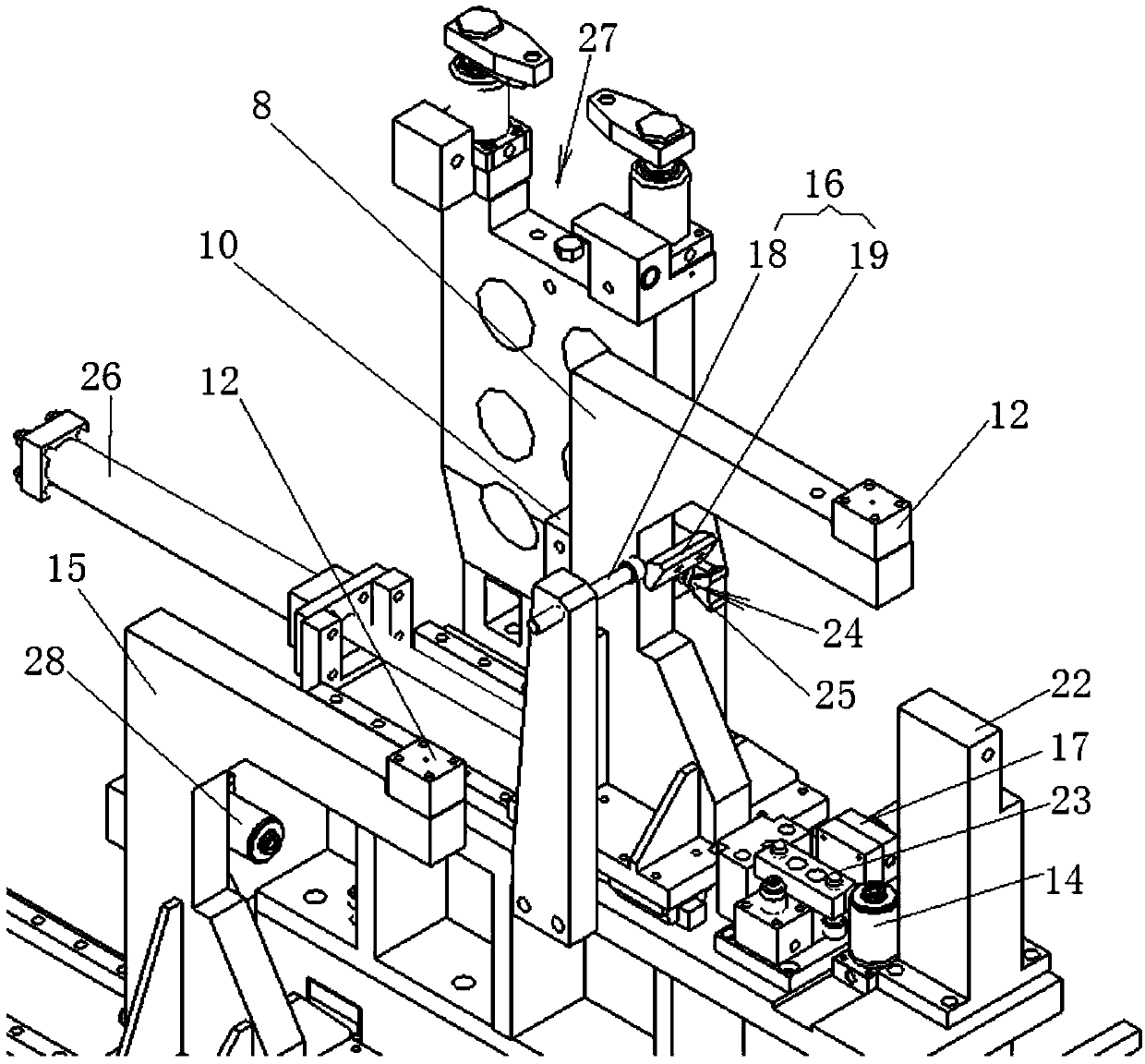

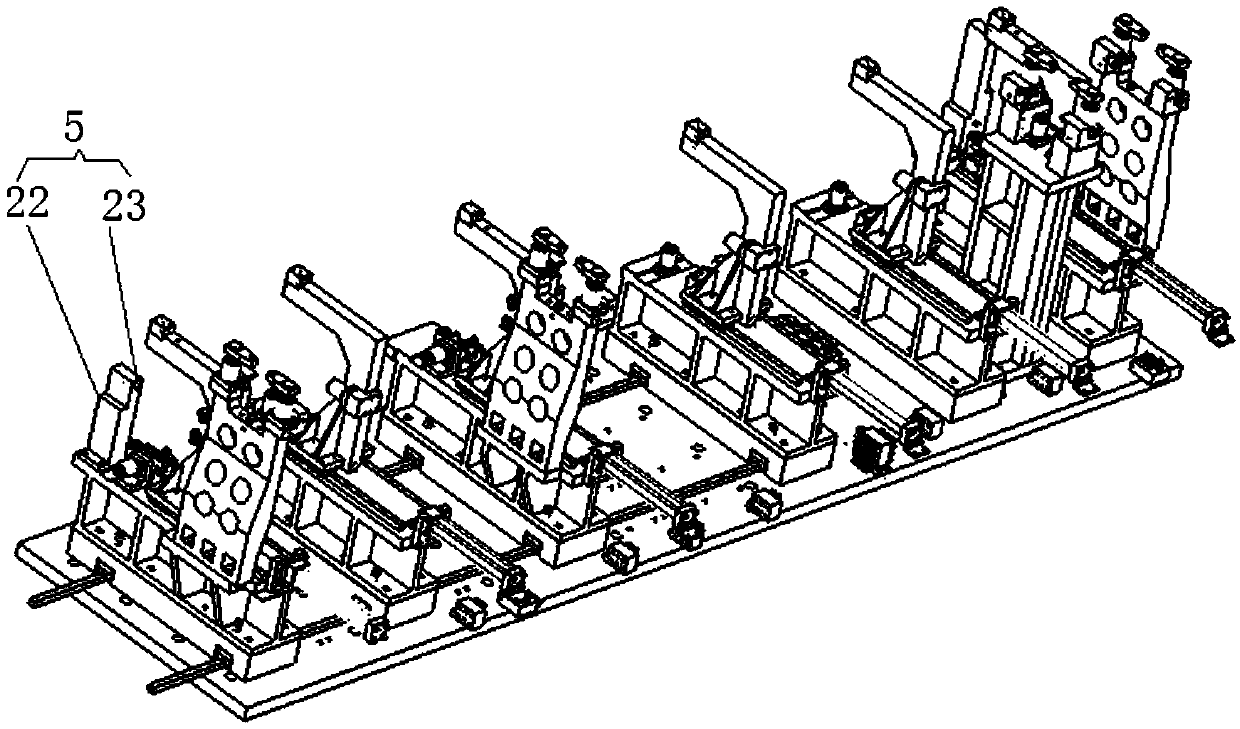

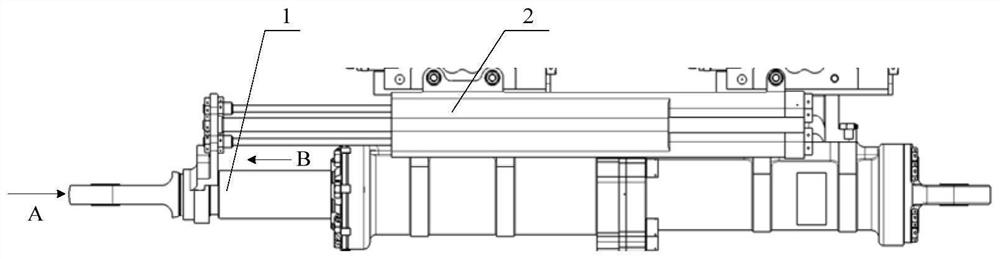

Clamping and positioning method and tool for special-shaped transverse beam

ActiveCN109623452AImprove rigidityImprove efficiencyPositioning apparatusMetal-working holdersEngineeringMachining process

The invention relates to the technical field of machining process equipment, and discloses a clamping and positioning method and tool for a special-shaped transverse beam. The clamping and positioningmethod comprises the steps of arranging of the clamping and positioning tool, arranging of a hydraulic system, adjusting of the clamping and positioning tool, arranging of a hoisting space of a transverse beam, hoisting and positioning of the transverse beam, and clamping of the transverse beam. The clamping and positioning tool comprises a bottom plate and main bases arranged on the left end upper plane and the right end upper plane of the bottom plate correspondingly, and the front upper plane of each main base is provided with a front side face positioning element used for positioning thefront side face of the transverse beam, and a bottom end face positioning element used for positioning the bottom end face of the transverse beam; a main moving frame capable of moving in the front-rear direction is arranged on the rear part of each main base; and each main moving frame is provided with a lateral jacking element used for jacking the rear side face of the transverse beam, and a vertical compressing element used for compressing the upper end face of the transverse beam. According to the clamping and positioning method and tool for the special-shaped transverse beam, the convenience and stability of clamping and positioning operation of the transverse beam are improved.

Owner:江阴市惠尔信精密装备股份有限公司

External linear displacement sensor anti-torsion structure with rotatable actuator piston rod

PendingCN114136254AImprove axial positioning accuracyImprove servo control accuracyMeasurement devicesClassical mechanicsActuator

The invention provides an external linear displacement sensor anti-torsion structure with a rotatable actuator piston rod. The external linear displacement sensor anti-torsion structure comprises an axial positioning pin, a positioning pin bush, a positioning pin anti-falling ring, a support, an axial guide rod and a metal shell. The support is installed on an actuator piston rod through the axial positioning pin, the positioning pin bush and the positioning pin anti-disengaging ring, and the axial guide rod is installed on the support and is in coaxial clearance fit with a guide hole in the metal shell. Wherein the positioning pin bushing is fixedly installed on the actuator piston rod, the support is connected to the positioning pin bushing in a sleeving mode, fixed through the axial positioning pin and used for preventing the support from moving in the axial direction of the actuator piston rod but allowing radial rotation, and the metal shell is fixedly installed on the actuator shell and used for fixing the support to the actuator piston rod. Axial movement of the axial guide rod and the bracket along the actuator piston rod is allowed, but radial rotation is limited.

Owner:QINGAN GRP

Gear ring turning clamp with axial positioning structure

PendingCN112809102ASimple structureEasy to manufactureGear-cutting machinesGear teethBlade plateGear wheel

The invention discloses a gear ring turning clamp with an axial positioning structure. The gear ring turning clamp comprises a pressing block, a first bolt, a three-blade plate and a second bolt, wherein the pressing block is directly attached to a matching three-jaw chuck jaw and locked through the first bolt, a self-centering clamping structure that the pressing block moves in the radial direction along with the three-jaw chuck jaw is formed, the three-blade plate is positioned and installed in the middle of the end face, provided with clamping jaws, of the three-jaw chuck, the three-blade plate and the three-jaw chuck are connected in a locked mode through the second bolt, the three-blade plate is provided with three fan-shaped blades which extend out in the radial direction and are staggered with the clamping jaws of the three-jaw chuck, the radial outer edge of each fan-shaped blade is bent inwards in an angular mode according to the combination of the size of the gear tooth tips uniformly arranged in the gear ring, and an axial positioning structure in combination with the built-in gear tooth tip of the gear ring for limiting is formed. The radial clamping structure and the axial positioning structure adopt a discrete mode, so that a positioning component does not bear clamping force structurally, and the gear ring is axially positioned after being installed in place.

Owner:JIANGSU PACIFIC GEAR DRIVE CO LTD +1

Multiple blade saw

The invention provides a multiple blade saw. The multiple blade saw comprises a saw blade main shaft and a flywheel shaft, wherein saw blades are arranged on the saw blade main shaft and flywheels arefixed to the flywheel shaft. The multiple blade saw is characterized in that a cone-shaped joint is arranged at the right end of the saw blade main shaft and is in tapered connection into the flywheel shaft, a limiting nut is also arranged at the right end of the saw blade main shaft, and a limiting hole matched with the limiting nut is formed in the flywheel shaft. The multiple blade saw provided with a stable connecting shaft is stable and reliable in performance.

Owner:林灵

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com