Multiple blade saw

A multi-blade saw and saw blade technology, which is applied in the field of multi-blade saws, can solve the problems of loose connection between the flywheel shaft and the saw blade main shaft, difficulty in disassembly and assembly, and infirmity, so as to facilitate disassembly or installation of saw blades and avoid loss Rotation, stable and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

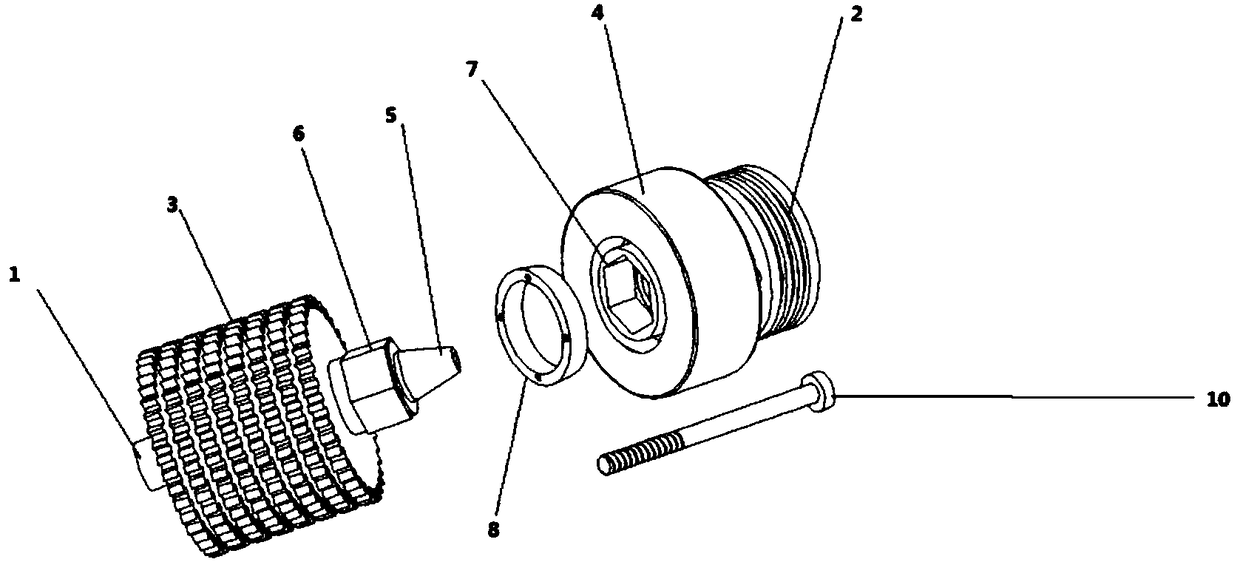

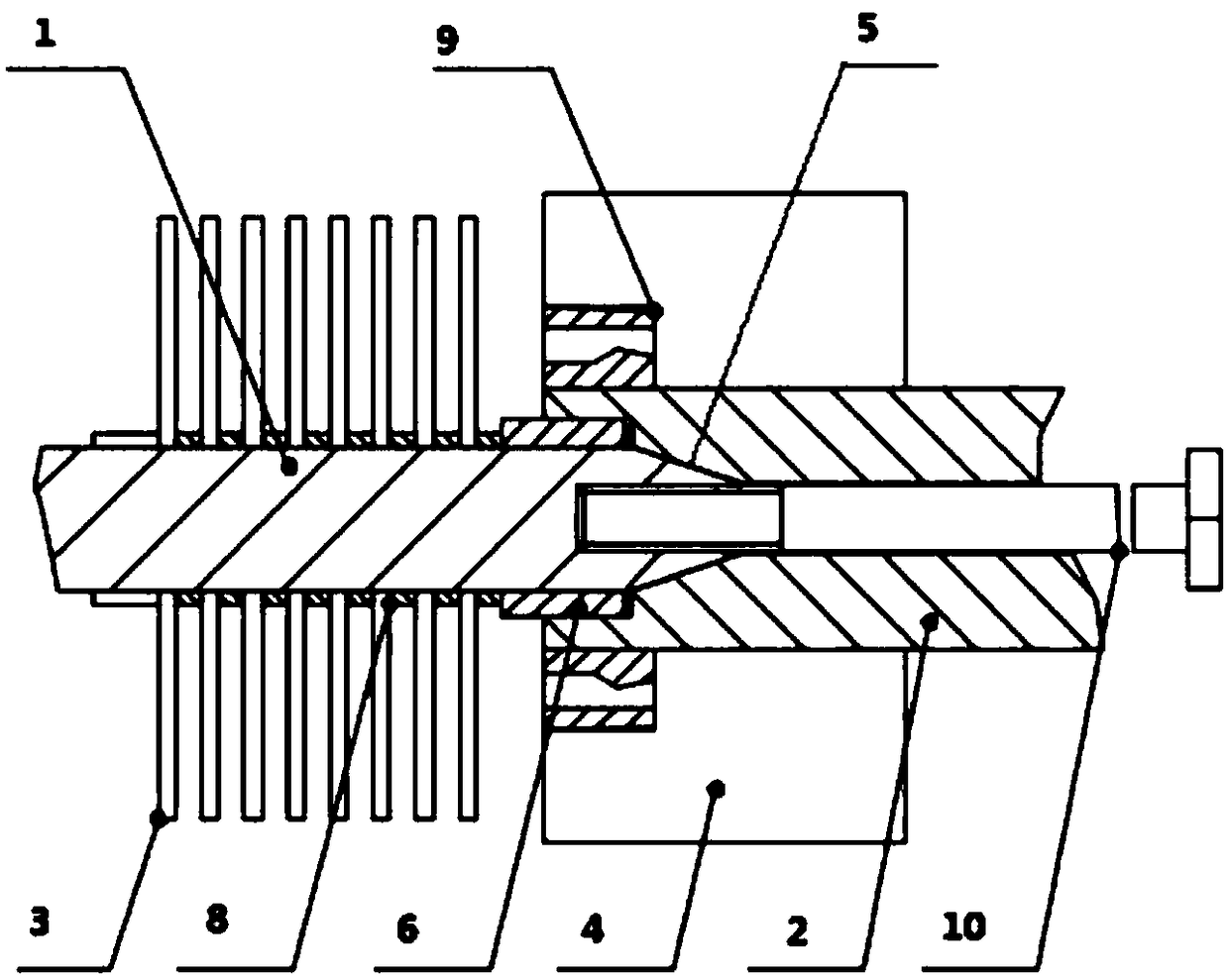

[0023] Such as Figure 1-2 As shown, a multi-blade saw includes a saw blade main shaft 1 and a flywheel shaft 2, wherein the saw blade 3 is arranged on the saw blade main shaft 1, and the flywheel 4 is fixed on the flywheel shaft 2. It is characterized in that the saw blade main shaft 1 The right end of the saw blade main shaft 1 is provided with a conical joint 5, which is connected with the inner taper of the flywheel shaft 2. The right end of the saw blade main shaft 1 is also provided with a limit nut 6, and the inside of the flywheel shaft 2 is provided with a limit hole 7 matched with the limit nut 6. The screw rod 10 inside the flywheel shaft 2 is provided with an external thread on the outer wall of the left end of the screw rod 10 , which can be screwed into the saw blade main shaft 1 from the right end of the flywheel shaft 2 .

[0024] Specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com