High-rigidity and high-precision spindle structure of spiral bevel gear grinding machine

A technology of spiral bevel gear and gear grinding machine, which is applied in the direction of belt/chain/gear, gear teeth, mechanical equipment, etc. It can solve the problems of affecting the rigidity and positioning accuracy of the grinding head, reducing the rigidity of the main shaft, and insufficient connection strength, etc., to achieve rigidity The effect of improving and improving the overall performance and stabilizing the machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

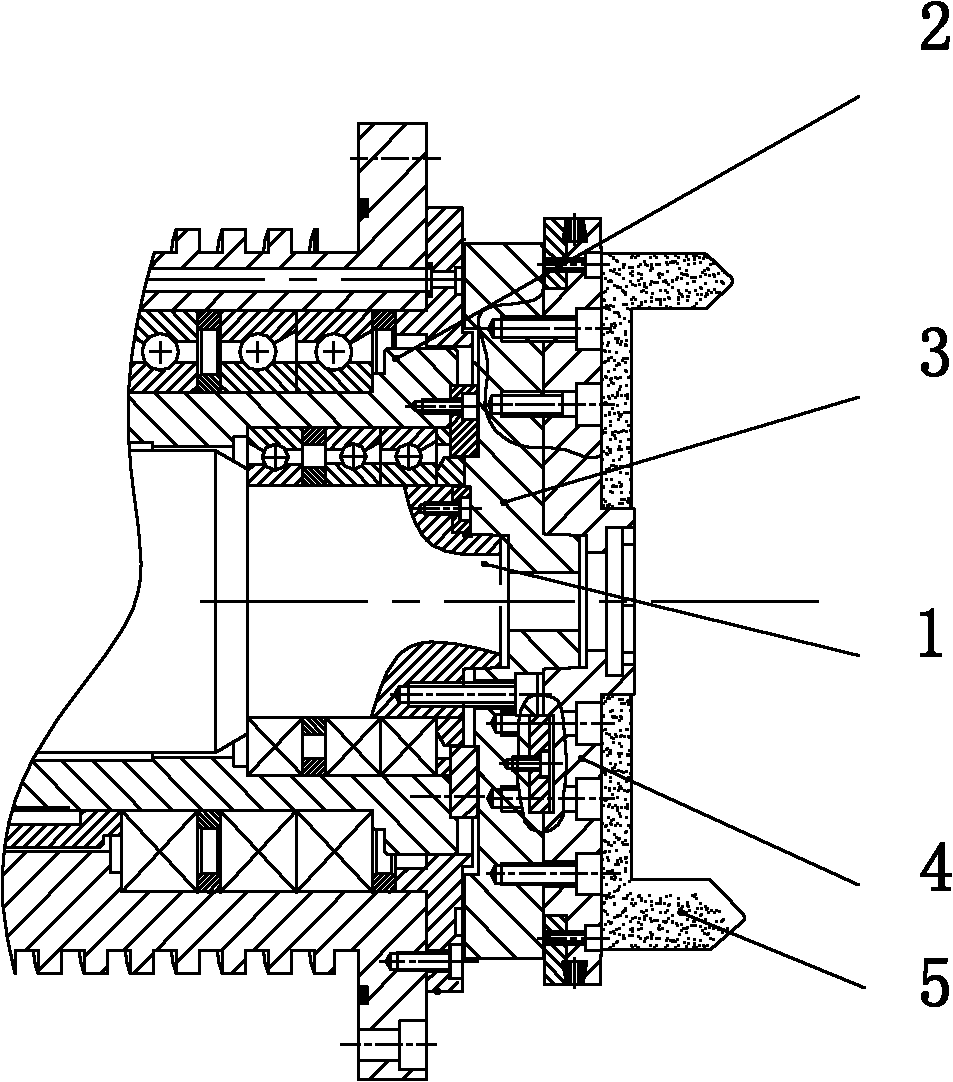

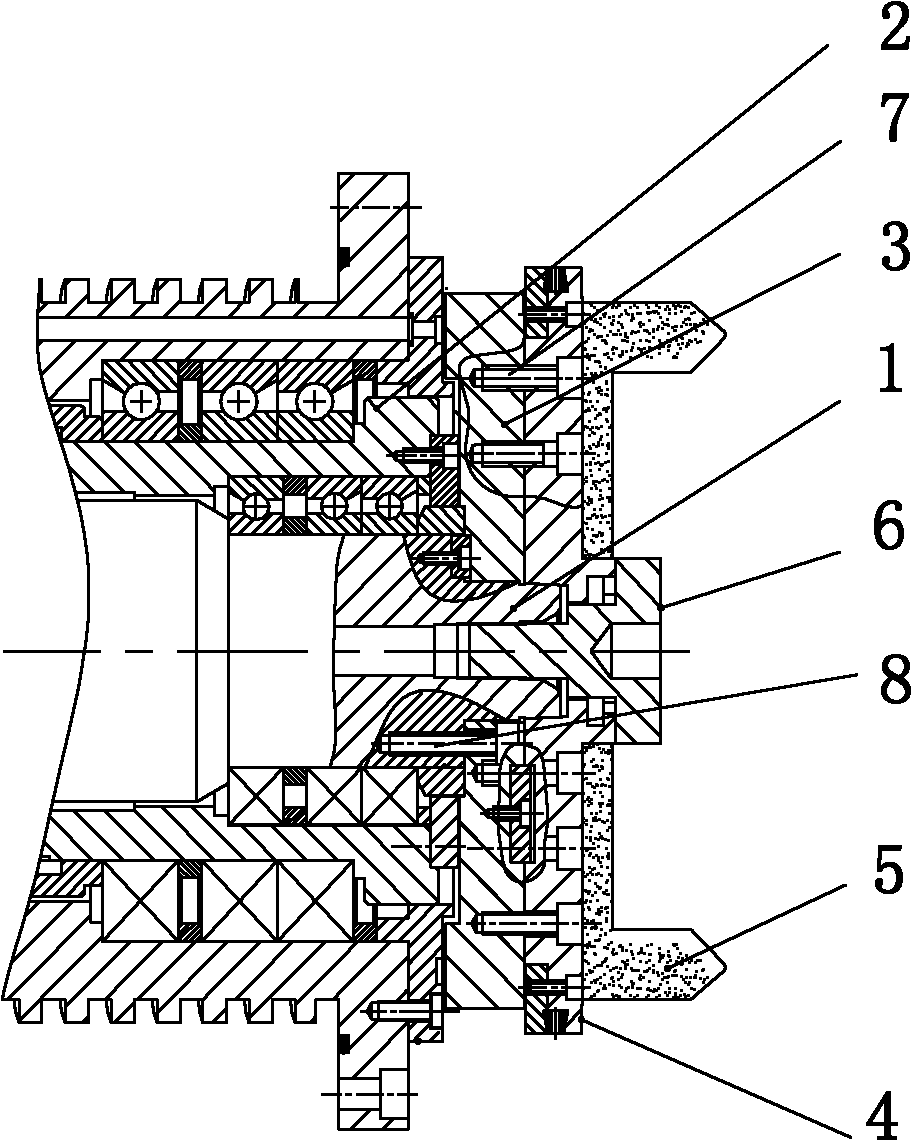

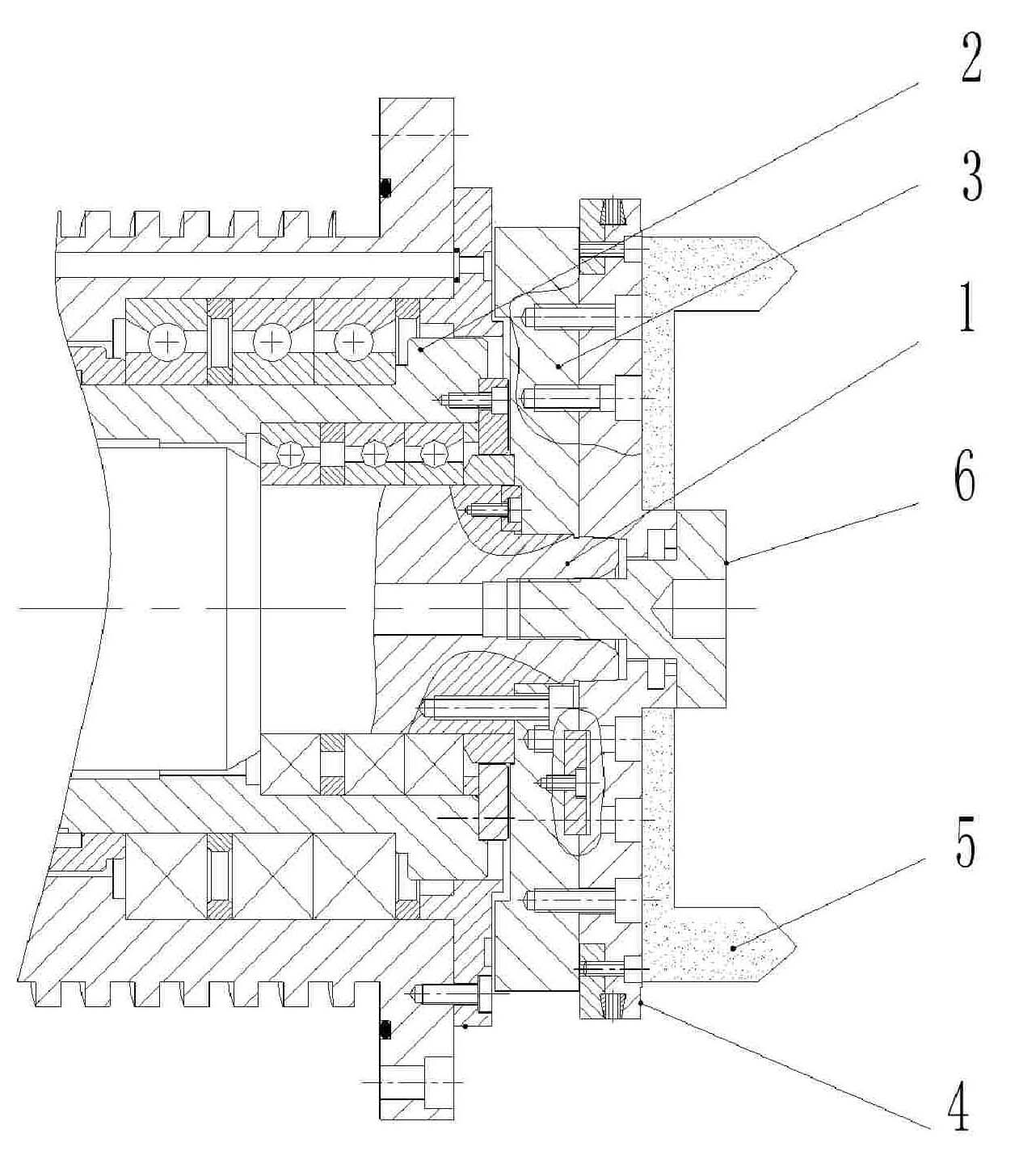

[0014] see figure 2 , the grinding wheel spindle 1 is supported on the eccentric shaft 2 by a high-precision spindle special bearing; the spindle flange 3 is positioned on the cylindrical surface of the grinding wheel spindle 1 instead of the original conical surface and is fastened on the grinding wheel spindle 1. The original 4 The fastening of one M10 screw is replaced by eight first screws 8 of M8; the grinding wheel transition plate assembly 4 is positioned through the conical surface of the grinding wheel main shaft 1 and fastened to the main shaft flange 3 by 12 second screws 7 of M8 Top: increase the fastening screw 6 to fasten the grinding wheel transition plate assembly 4 on the grinding wheel spindle 1; the grinding wheel 5 is positioned through the cylindrical surface and the end surface of the grinding wheel transition plate assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com