A Rotary Cutting Tool with Accurate Axial Positioning

A rotary cutting tool, axial positioning technology, applied in milling cutters, manufacturing tools, metal processing equipment, etc., can solve the loosening or displacement of the tool holder 2 and the cutting insert, reduce the machining accuracy of the cutting tool, and the deformation of the tool holder fastener 4. and other problems to achieve the effect of avoiding deformation or collapse, improving safety and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

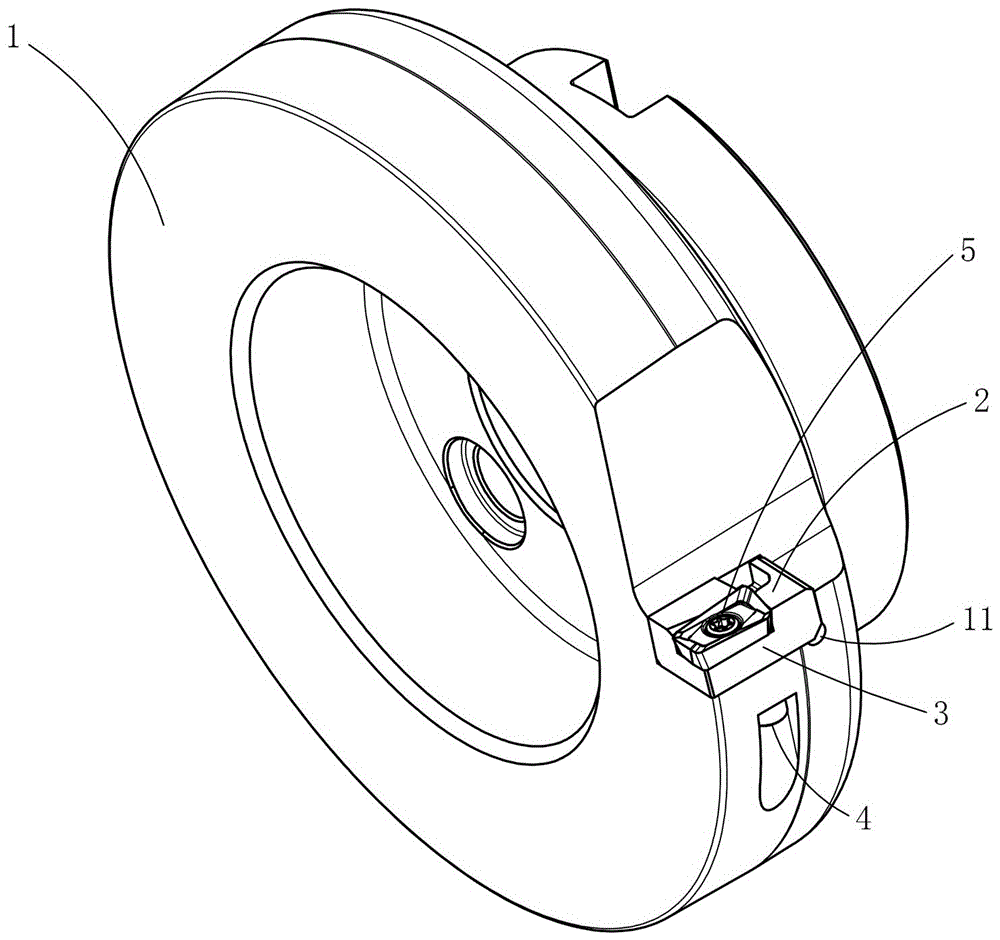

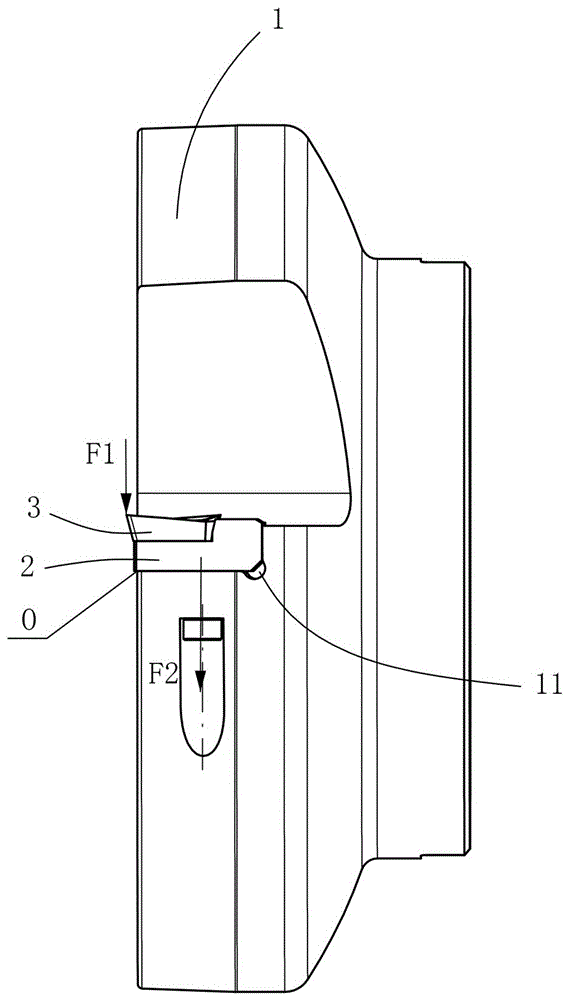

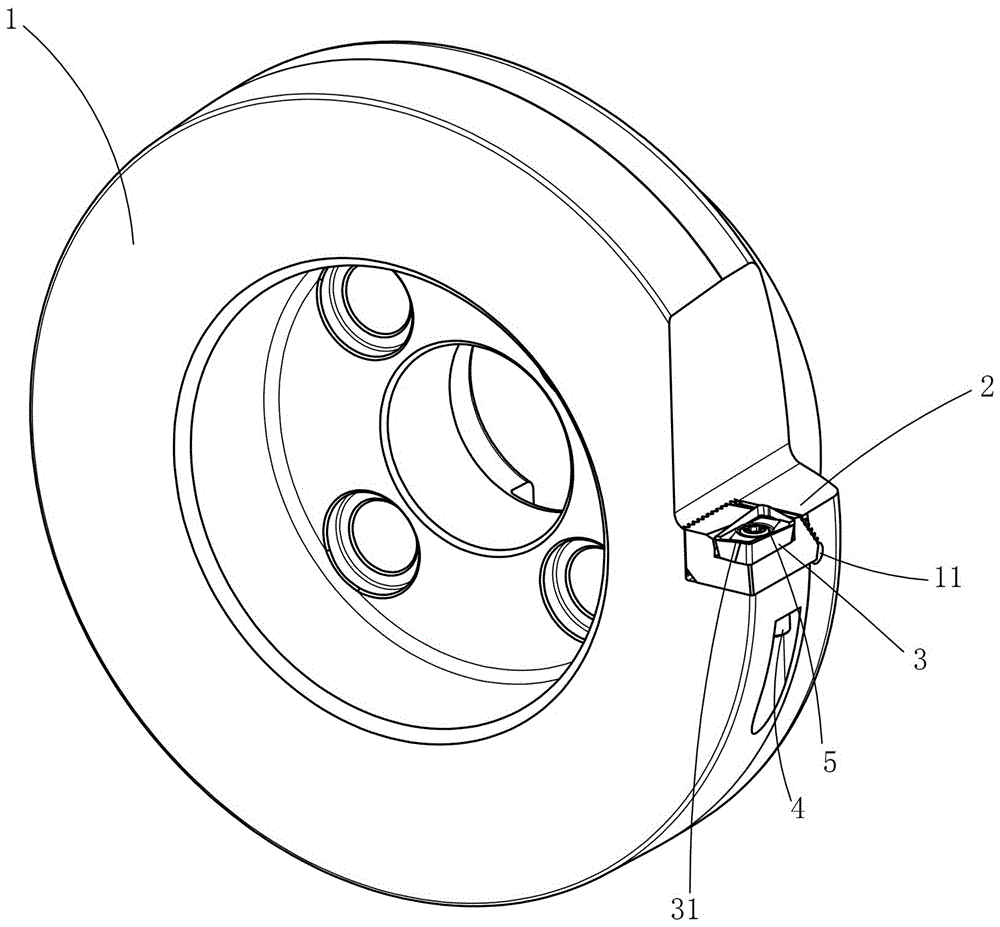

[0039] Figure 3 to Figure 6It shows the first embodiment of the rotary cutting tool with accurate axial positioning of the present invention, including a rotary cutter body 1, a tool holder 2, a cutting blade 3, a tool holder fastener 4 and a blade fastener 5, and the rotary cutter body 1 The top is provided with the sipe 11 surrounded by the bottom positioning surface 111, the first side positioning surface 112 and the second side positioning surface 113. The cutting blade 3 is fixed on the tool holder 2 by the blade fastener 5. The first side positioning surface 112 is the opposite surface of the knife groove 11 and the end cutting edge 31 of the cutting blade 3, the tool holder 2 is inserted into the knife groove 11 along the radial direction of the rotating cutter body 1, and the first side positioning surface 112 and the bottom positioning surface 111 are formed on the tool holder 2 Interference clamping and positioning, the tool holder fastener 4 is connected and fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com