Clutch for rail vehicle

A rail vehicle and clutch technology, applied in the field of rail vehicle clutches, can solve the problems of type and mode control, insufficient accuracy, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

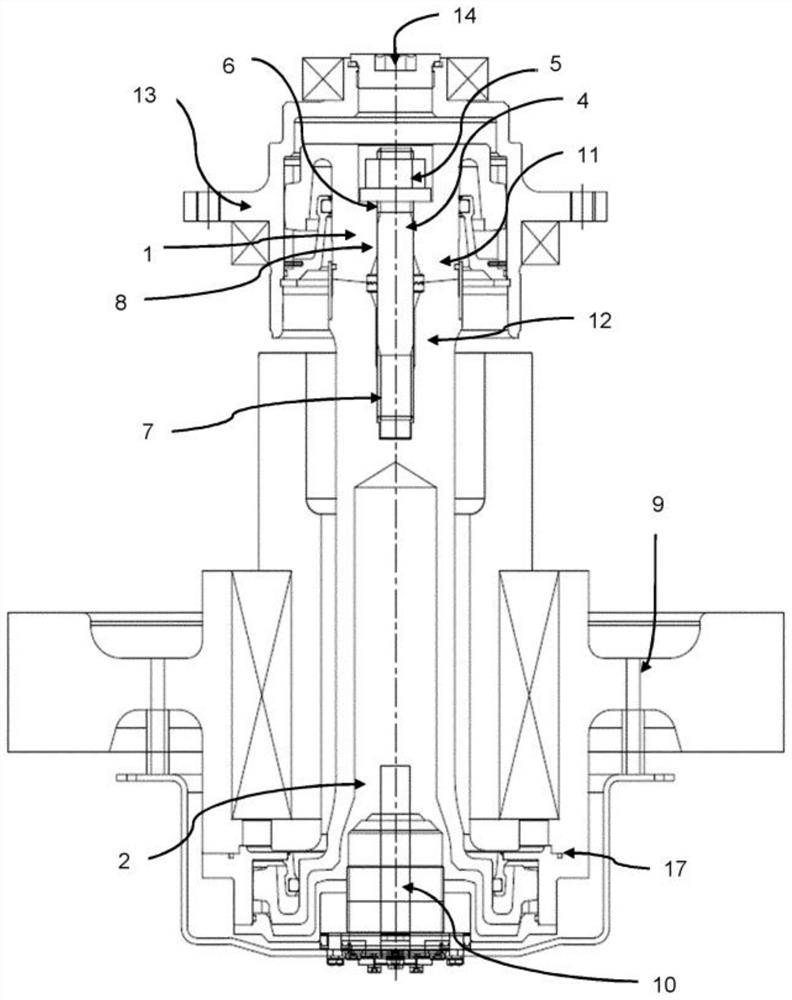

[0054] according to figure 1 A wheel drive with a two-piece clutch system for a rail vehicle is shown.

[0055] here, figure 1 The first clutch half 1 is shown, which is configured as a dog clutch and is connected to a gearbox (not shown) via the teeth of the drive-side sleeve 13 . The first clutch half 1 has a first clutch shaft 11 into which the through hole 8 is introduced centrally and axially. The first clutch shaft 11 is arranged in axial alignment with the second clutch shaft 12 . The second clutch shaft 12 is a component of the second clutch half 2 and has a central axially arranged set screw 4 on the end region side, which is screwed into the second clutch shaft 12 via the internal thread 7 of the set screw 4 . At the other end of the set screw 4 there is an external thread 6 onto which the nut 5 is screwed and thus the two clutch halves 1 and 2 are connected non-positively.

[0056] The grounding element 10 is connected not only to the second clutch half 2 but al...

Embodiment 2

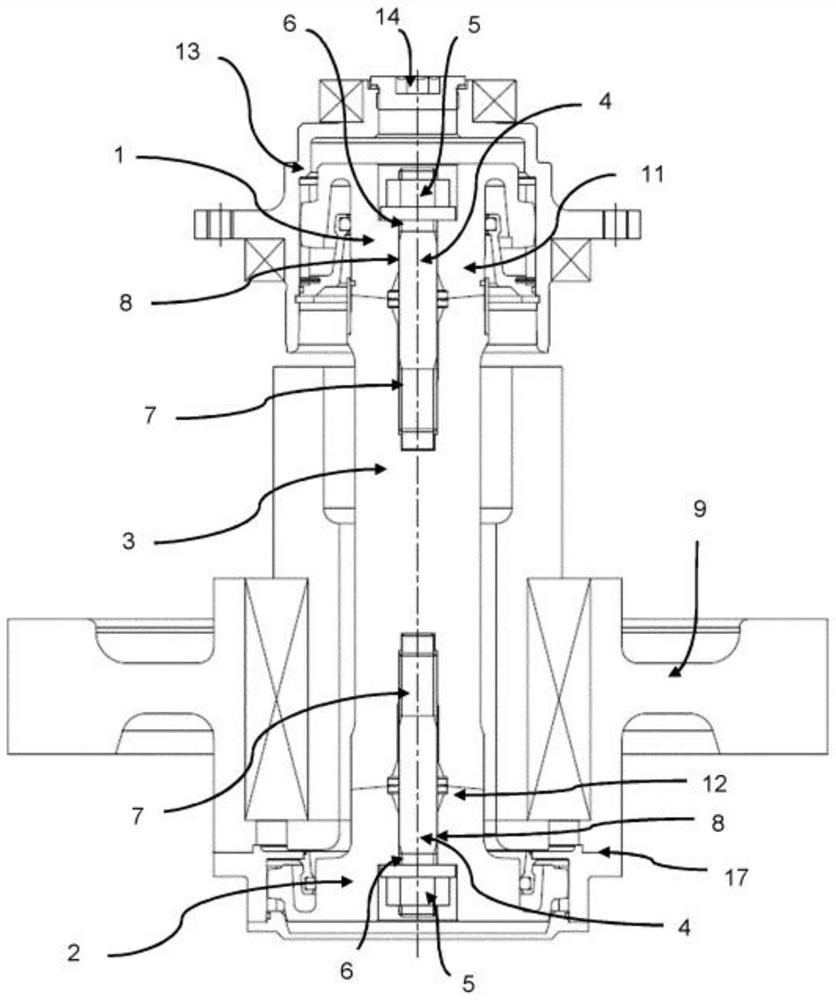

[0060] according to figure 2 , 3 and 4 show a wheel drive with a three-piece clutch system for rail vehicles.

[0061] here, figure 2 A clutch system with a clutch half 1 configured as a dog clutch is shown, wherein the dog clutch engages with a gearbox (not shown) and with the gears on the end side of the transmission shaft 3 . The first clutch half 1 has a first clutch shaft 11 into which the through hole 8 is introduced centrally and axially. The first clutch shaft 11 is arranged in axial alignment with the transmission shaft 3 and the second clutch shaft 12 .

[0062] At its left end, the transmission shaft 3 has a central axially arranged set screw 4 , which is screwed into the transmission shaft 3 via an internal thread 7 of the set screw 4 . At the other end of the set screw 4 there is an external thread 6 onto which the nut 5 is screwed and thus the transmission shaft 3 and the first clutch half 1 are connected in a non-positive manner.

[0063] At its right end...

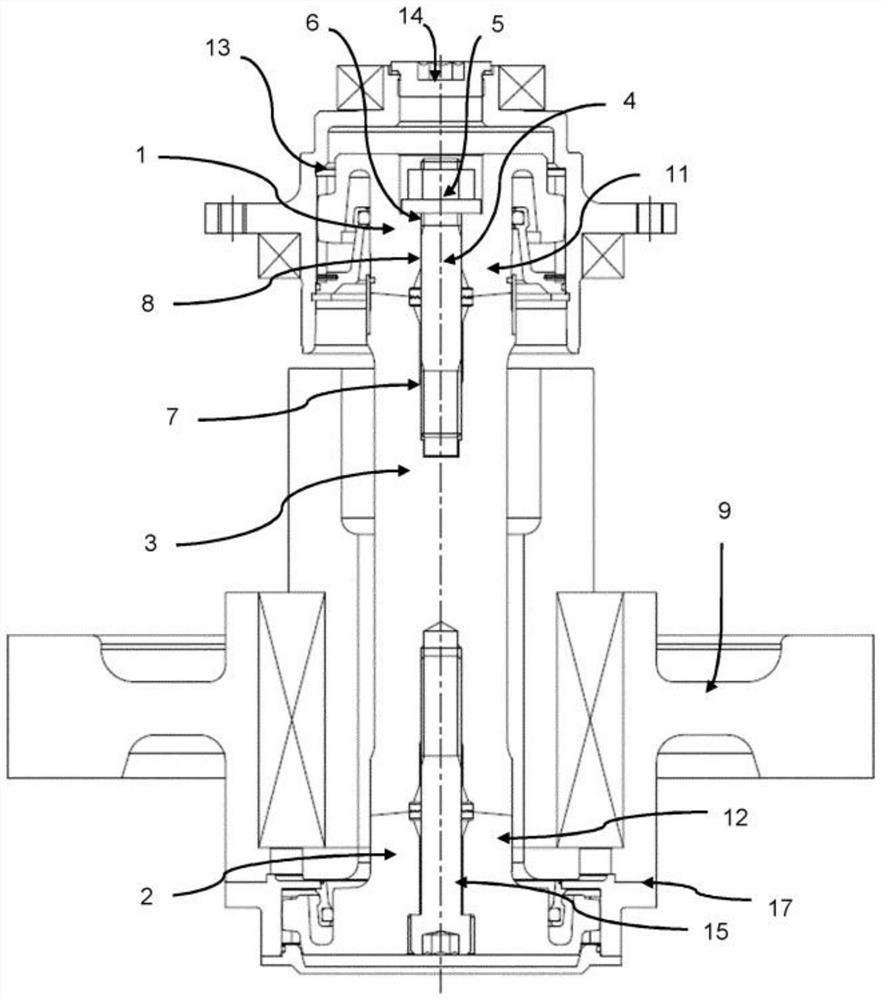

Embodiment 3

[0071] Figure 5 A three-part clutch system is shown in which the set bolt 4 is pre-assembled centrally and axially in the second clutch half 2 assigned to the wheel. In this case, the set screw 4 extends through the through hole 8 of the aligned transmission shaft 3 and further through the through hole 8 assigned to the first clutch half 1 of the drive. The end of the set screw protrudes from the first clutch half 1 , wherein the non-positive connection of the first clutch half 1 , the transmission shaft 3 and the second clutch half 2 is by means of a nut screwed on the external thread 6 of the set screw 4 5 to achieve.

[0072] Assembly of the clutch is carried out in such a way that the set screw 4 is pre-assembled into the clutch shaft 12 in the second clutch half 2 assigned to the wheel. The transmission shaft 3 with the through hole 8 is then pushed onto the set screw 4 and then the first clutch half 1 with the through hole 8 assigned to the drive is also pushed onto t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com