Radial positioning unit and positioning clamping device for internal grinding of thin-walled cylindrical workpieces

A clamping device and thin-walled tube technology, which is applied in the direction of grinding workpiece support, grinding/polishing equipment, and machine tools designed for grinding the rotating surface of workpieces, etc., can solve the problem of low positioning accuracy and difficulty in adapting to the automatic adjustment of the central axis of the workpiece , clamping deformation and other problems, to achieve the effect of improving positioning accuracy, not easy clamping deformation, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

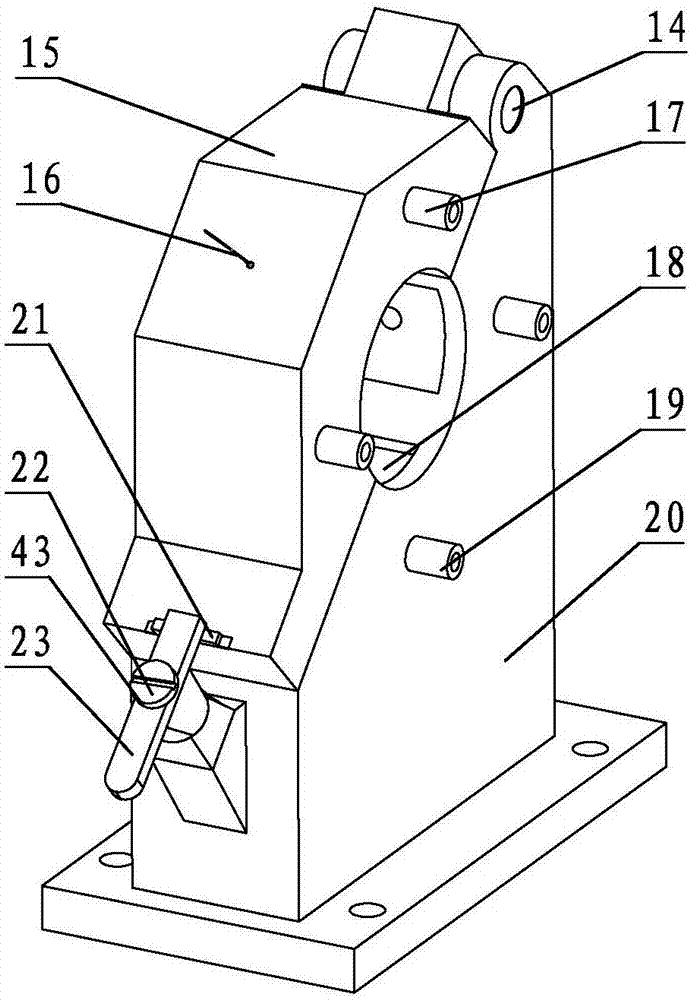

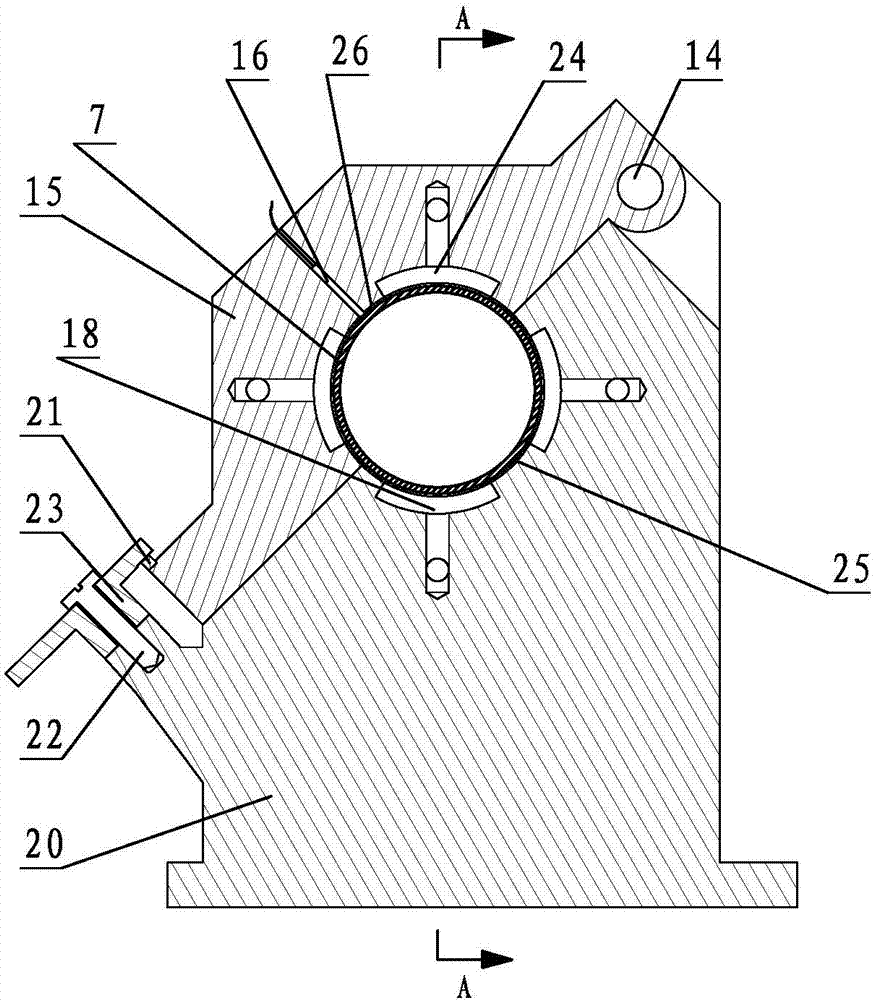

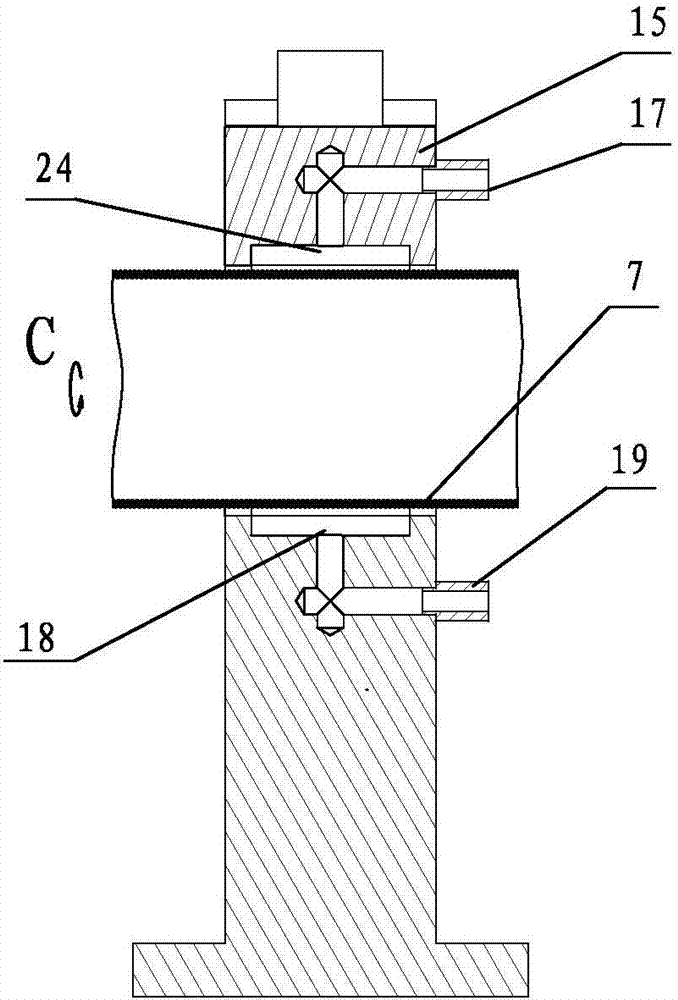

[0028] Such as Figure 1-Figure 3 As shown, a radial positioning unit for internal grinding of thin-walled cylindrical workpieces includes a support base 20 and a support cover 15, one end of the support cover 15 is pivotally connected to the support base 20, and the support cover 15 can be wound around the support base The pin shaft 14 on the 20 rotates, the support base 20 is provided with a clamping curved surface I25, and the support cover 15 is provided with a clamping curved surface II26, so that the support base 20 and the support cover 15 can align The workpiece is clamped, and the support cover 15 and the support base 20 are set to be hollow, allowing the workpiece 7 to pass through the middle. The support base 20 is provided with a support cover that can be fixed when the support cover 15 and the support base 20 are fastened. 15, the clamping curved surface I25 is provided with a concave structure to form a hydraulic chamber I18, and the clamping curved surface II26 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com