Deepwater pipeline tie-back pose measuring device

A measuring device, a technology for position and attitude measurement, which is applied in the direction of measuring devices, electrical devices, instruments, etc., can solve problems such as unfavorable errors and uncertainties, corrosion of pipelines, inability to measure accurately, etc., to improve the accuracy of axial positioning, The effect of reducing the difficulty of operation and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

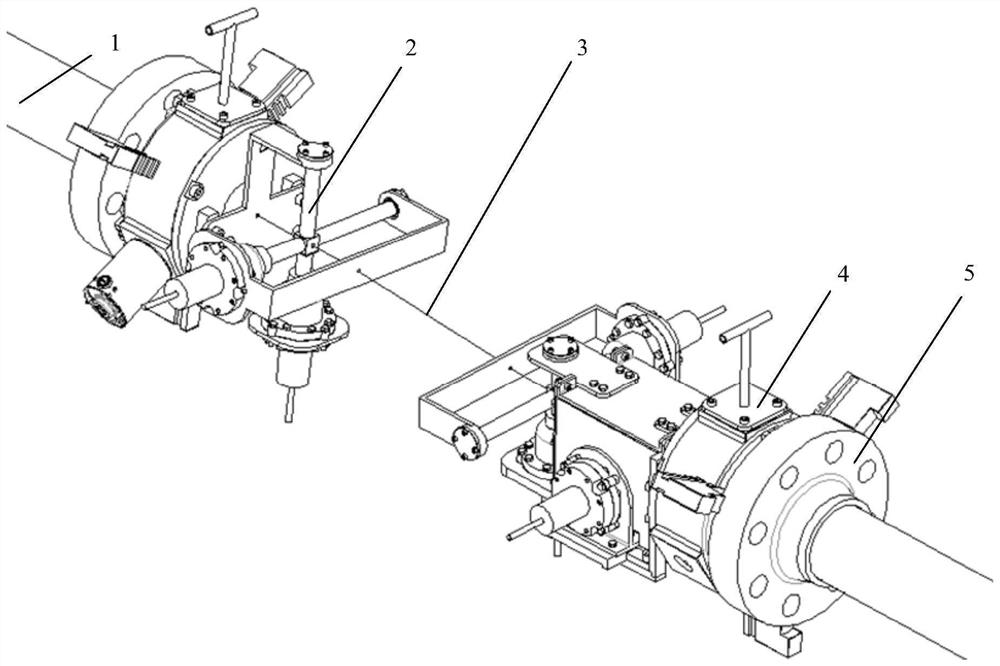

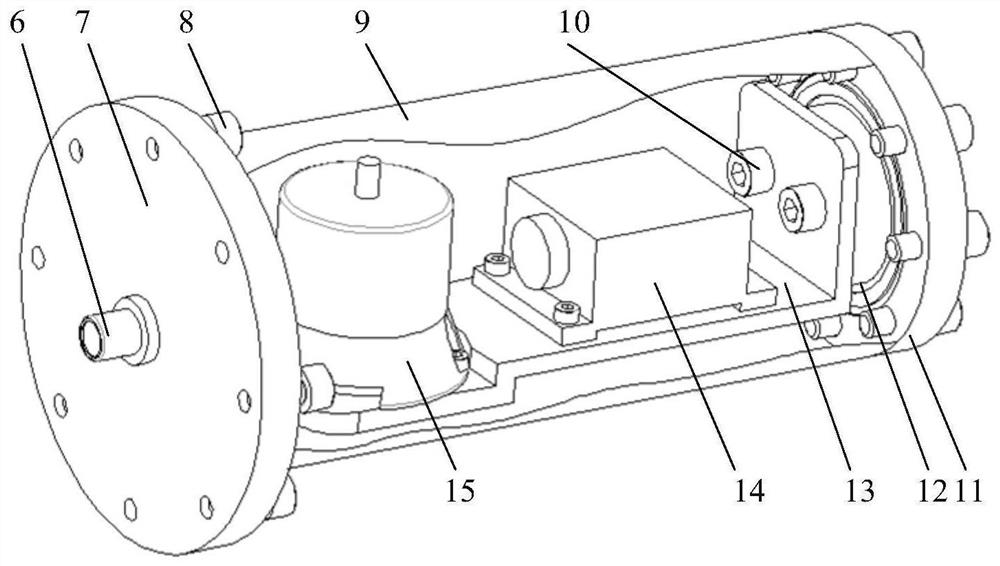

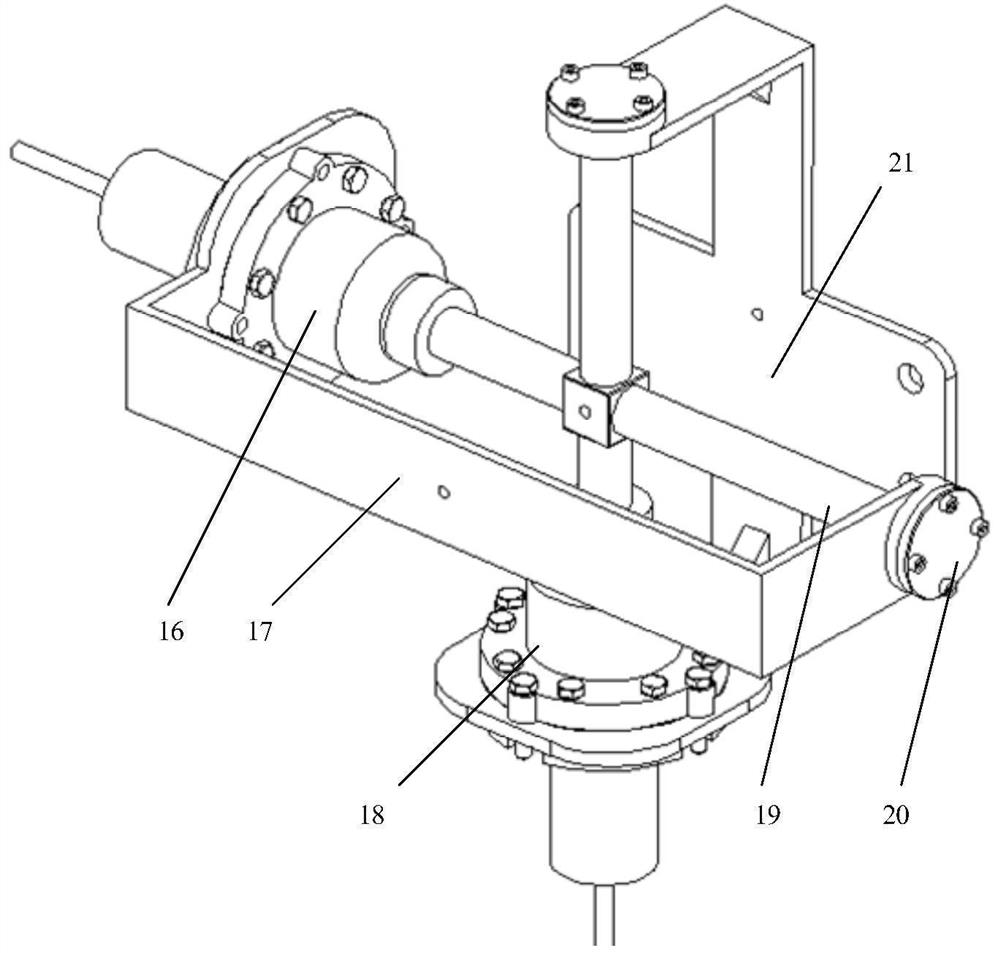

[0022] Combined with the working environment and operation mode of the device of the present invention, that is, during the actual measurement process, the ROV carries the measuring device to the designated operation area and completes the docking installation with the pipeline, and the corresponding docking mechanism is designed so that the measuring device is positioned and installed on the flange end face, ensuring The distance between the protruding point of the wire rope in the measuring device and the end face of the flange is a fixed value. In addition, a measuring device is designed based on the docking mechanism, including measuring device (I) and measuring device (II). Both are composed of an orthogonal inclination measuring mechanism, a horizontal and pitch swing angle measuring mechanism and a flange docking mechanism, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com