Asymmetric section steel rail straightening and preheating device

A preheating device and asymmetric technology, applied in the field of rail adjustment and adjustment manufacturing, can solve the problems of slow process progress and low processing efficiency, and achieve the effects of reducing environmental noise, improving processing efficiency and reducing labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Attached below Figure 1-12 Specific examples of the present invention are described.

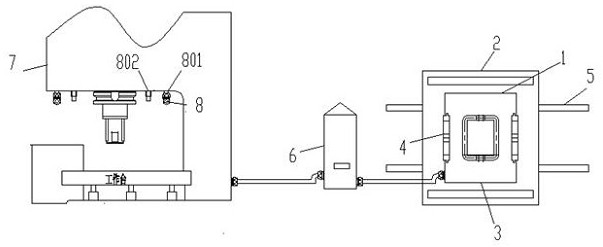

[0035] (Such as figure 1 As shown) the rail straightening and adjusting preheating device with asymmetric cross section includes a rail preheating device 1 and rail straightening and adjusting equipment 7 .

[0036] The rail preheating device 1 is used for heating the rail, and the rail straightening equipment 7 is used for straightening after the rail is preheated. When the preheating temperature of the rail on the rail preheating device 1 reaches the required value, after the rail is hoisted from the rail preheating device 1 to the rail straightening equipment 7, the preheated rail is carried out on the rail straightening equipment 7 Adjustment operation.

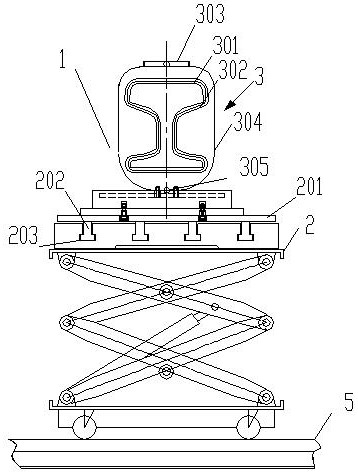

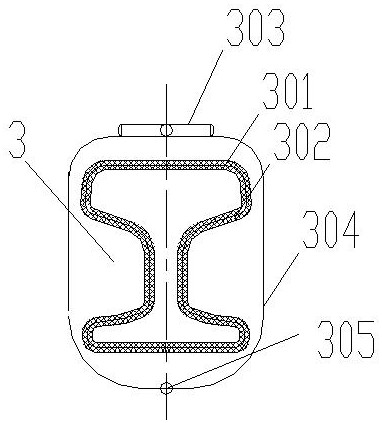

[0037] (combined with figure 2 ) The rail preheating device 1 is installed on the top of the lifting platform 2 that lifts in the Z direction. The lifting platform 2 adjusts the Z-direction height of the lifting platform a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com