Green devulcanizing and reclaiming apparatus with supercritical CO2 and microwave assisted multi-segment twin-screw extrusion

A twin-screw extrusion and microwave-assisted technology, which is applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems of unstable product performance, high labor intensity, high energy consumption, etc., and achieve excellent self-cleaning performance, The effect of small footprint and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

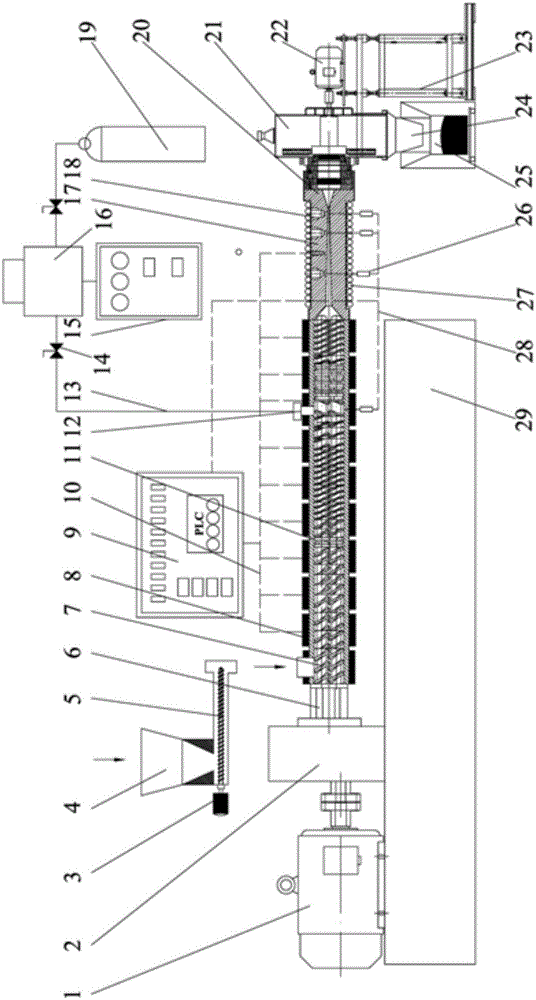

[0025] See attached picture:

[0026] Supercritical CO 2 Microwave-assisted multi-stage twin-screw extrusion green sulfur break regeneration equipment, including a barrel 11 along the center line in the horizontal direction, and a multi-stage twin-screw 7 is installed inside the barrel 11 coaxially rotating, and the front end of the barrel 11 and the multi-stage twin-screw 7 is connected by a shaft The device 6 is connected with the reduction box 2, and the front end of the reduction box 2 is connected with a multi-stage twin-screw drive motor 1, and the upper end of the machine barrel 11 is provided with a microwave heating device 8, and is also connected with the PLC control cabinet 9 through the temperature measurement signal line 10, and the machine barrel 11 The feed port at the upper left end is connected with the screw feeder, the screw feeder is composed of the feeder drive motor 3, the hopper 4, the screw 5, etc., the upper end of the reverse twin screw of the multi-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com