Wet spinning solution premixing and delivery device

A wet spinning and conveying device technology, which is applied in the direction of spinning solution preparation, wet spinning, filament forming treatment, etc., can solve the problems of slow flow rate, difficult mixing, poor material compatibility, etc., and achieve simple equipment structure, Strong mixing ability, easy to operate and control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

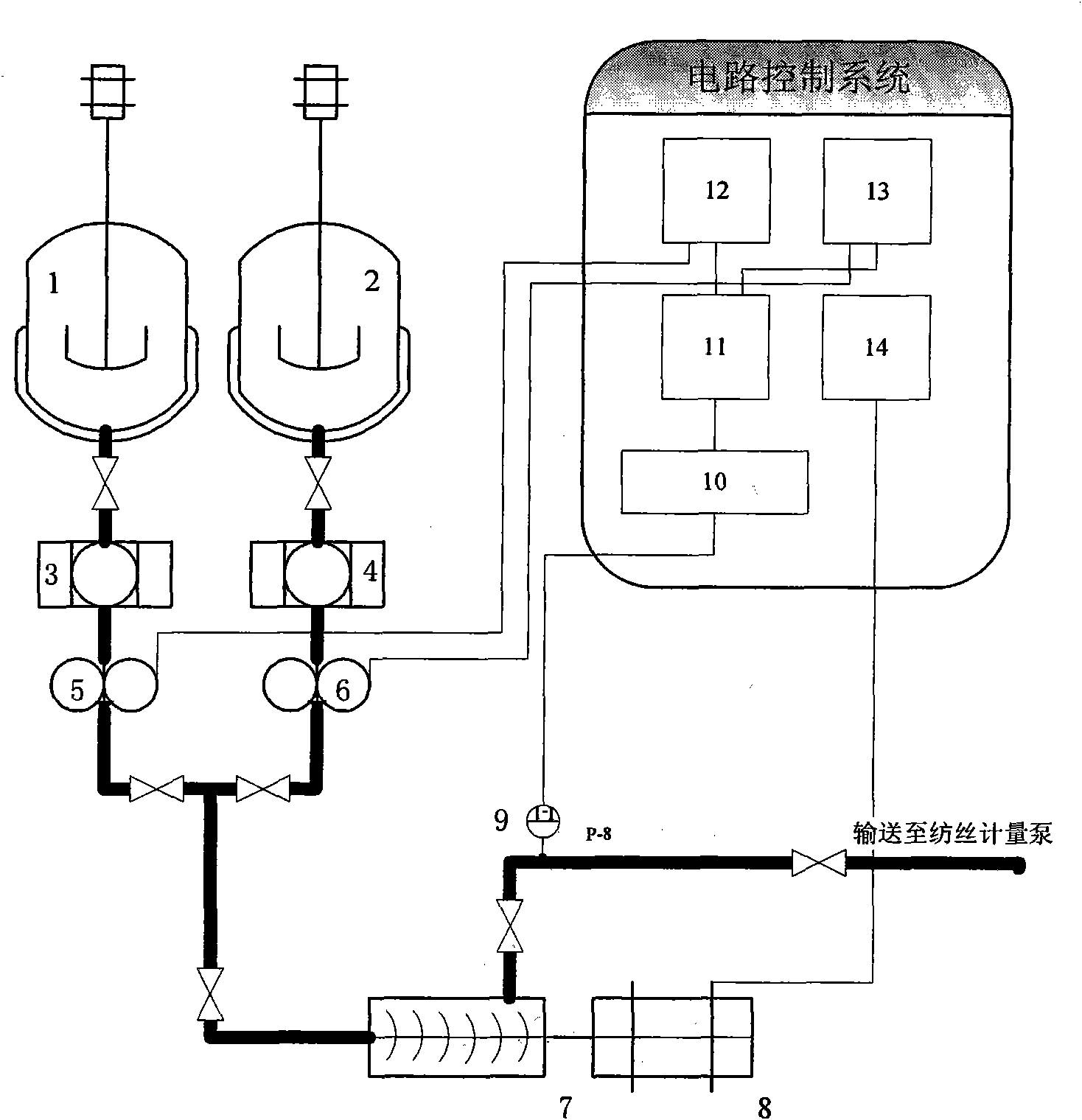

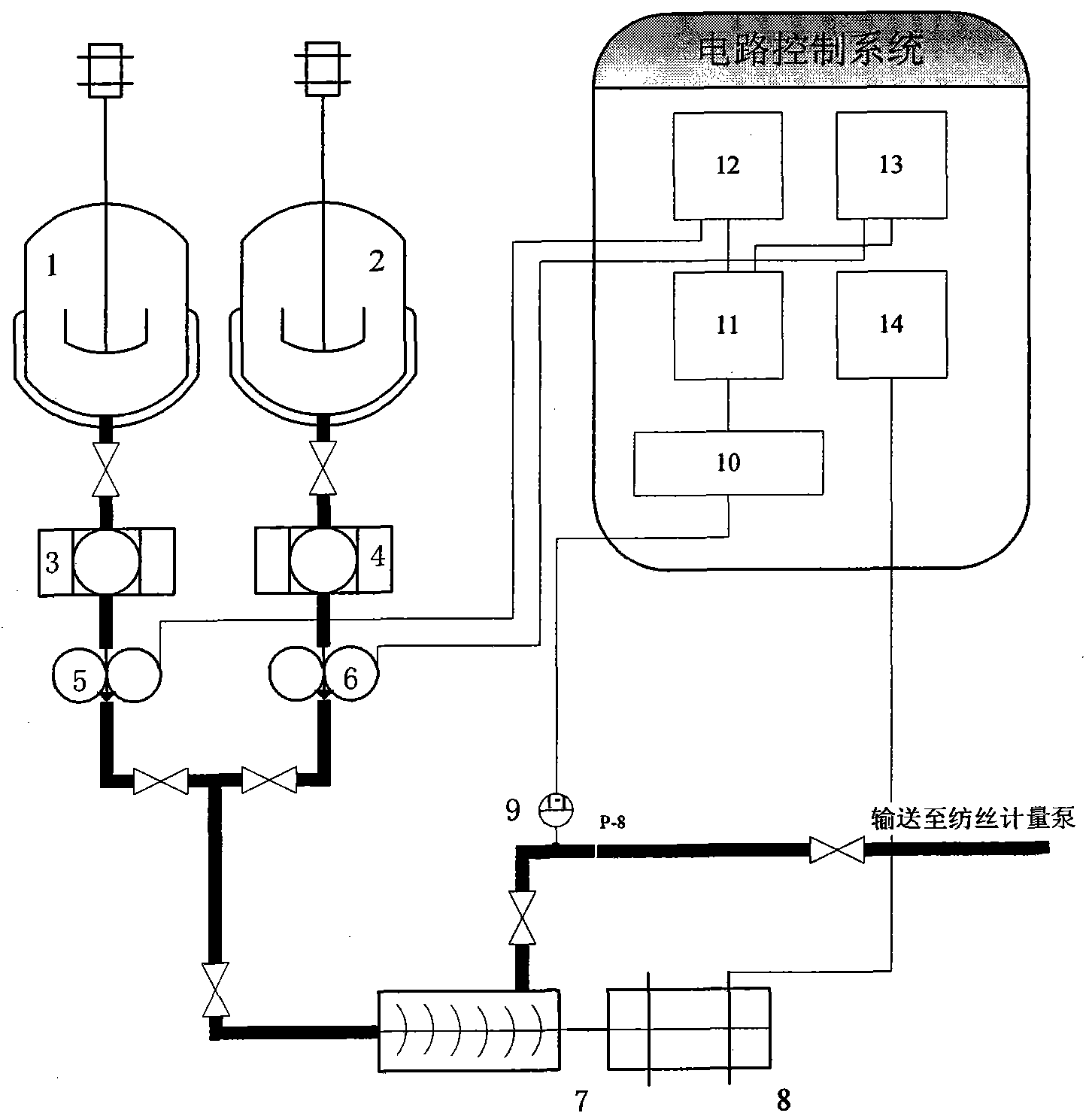

[0022] The pre-spinning mixing and conveying device of the method spinning stock solution consists of the first barrel 1 and the second barrel 2 respectively passing through the first metering pump 3, the first filter 5 and the second metering pump 4, the second filter 6 and the second metering pump respectively. The inlet end of the dynamic mixer is connected, and the outlet end of the dynamic mixer is connected to the spinning metering pump for spinning through pipelines; the motor 8 of the dynamic mixer is connected to the third frequency converter 14; the pipeline passes through valves, pressure transmitters 9, multiple The function controller 10 and the synchronous controller 11 are connected to the first frequency converter 12 and the second frequency converter 13 respectively, and the first frequency converter and the second frequency converter are connected to the first filter 5 and the second filter 6 respectively.

[0023] The present invention is achieved like this: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com