Patents

Literature

93results about How to "Improve mixing ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

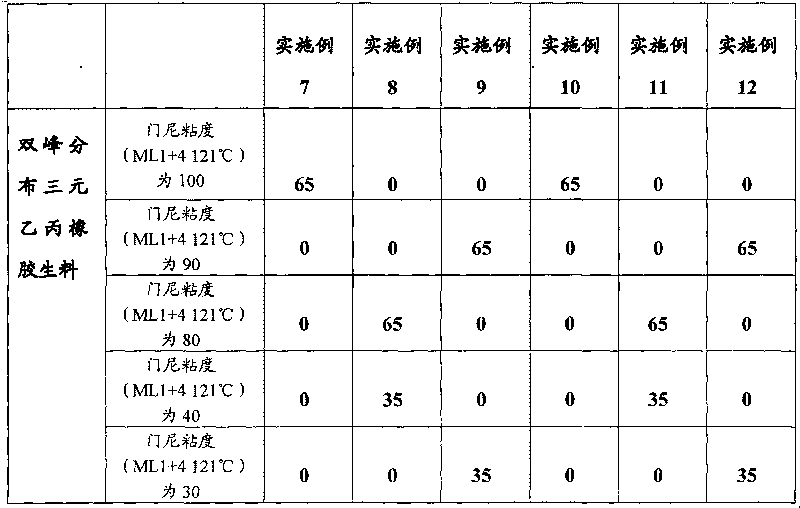

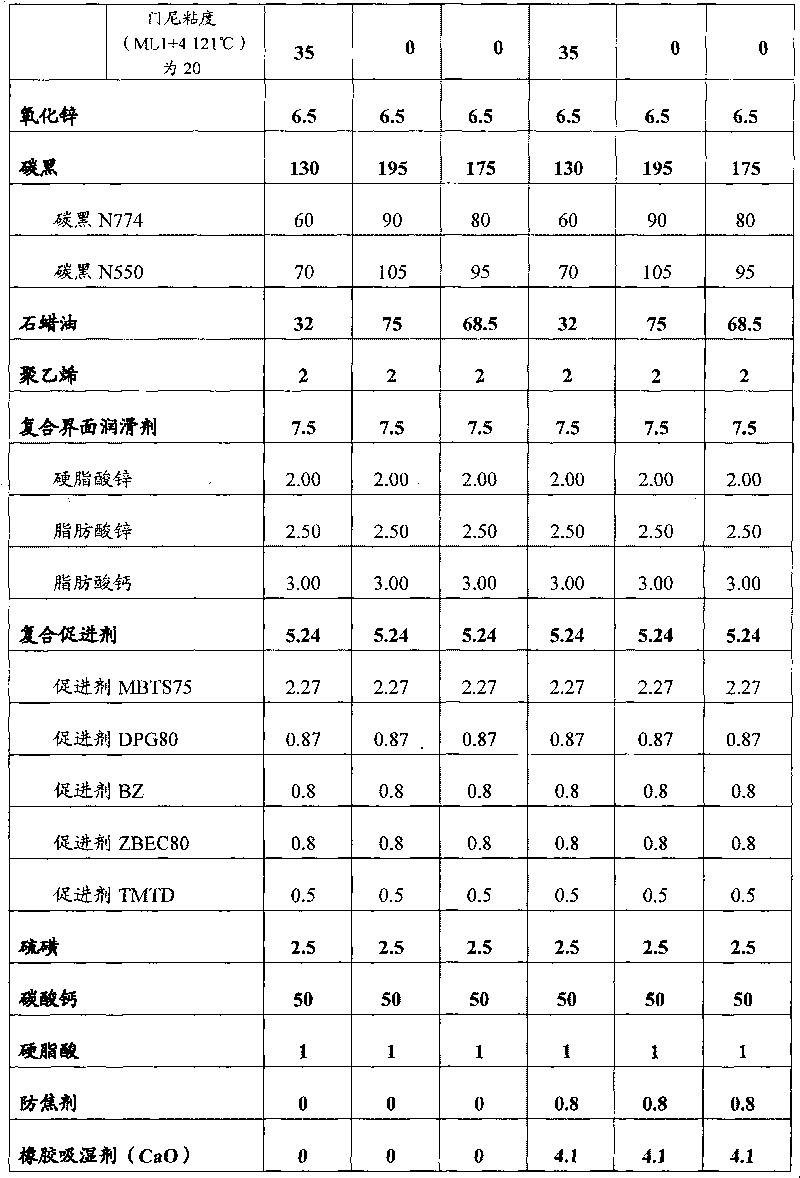

Rubber additive and ethylene propylene diene monomer containing same

The invention relates to a rubber additive and ethylene propylene diene monomer containing the same. The rubber additive is characterized by comprising the following components in part by weight: 6.5 parts of zinc oxide, 2.5 parts of sulfur, 1 part of stearic acid, 2 parts of polyethylene with the melting point of between 85 and 100 DEG C, 7.5 parts of composite interface lubricating agent, 130 to 195 parts of carbon black, 50 parts of carbonate, 32 to 75 parts of paraffin oil, and 5.24 pats of complex accelerant. The invention aims to solve the technical problems that the ethylene propylene diene monomer in the prior art has a high cost under the condition of the same hardness and the same Mooney viscosity, provides an additive which saves more cost and the ethylene propylene diene monomer using the additive, and further provides the ethylene propylene diene monomer with large tensile strength and elongation at break.

Owner:瀚德(中国)汽车密封系统有限公司

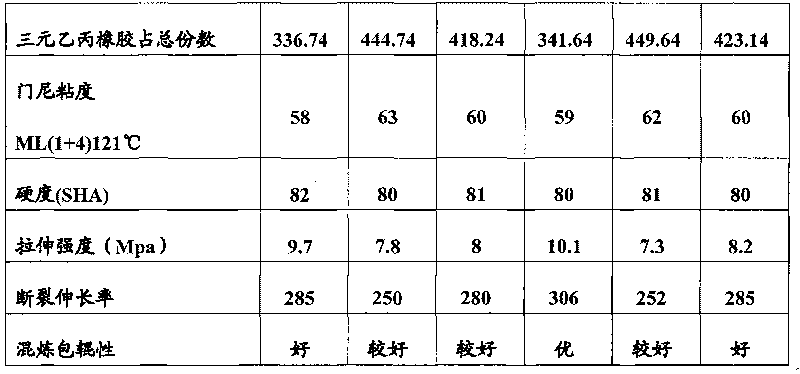

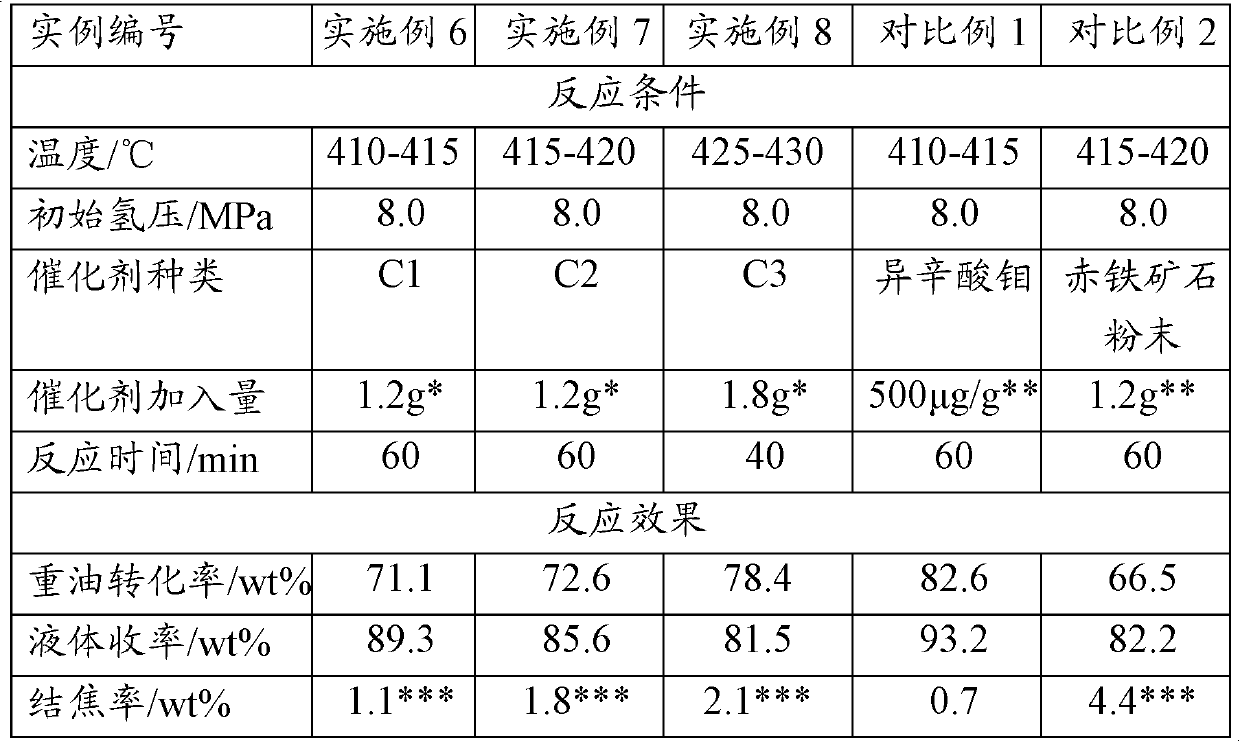

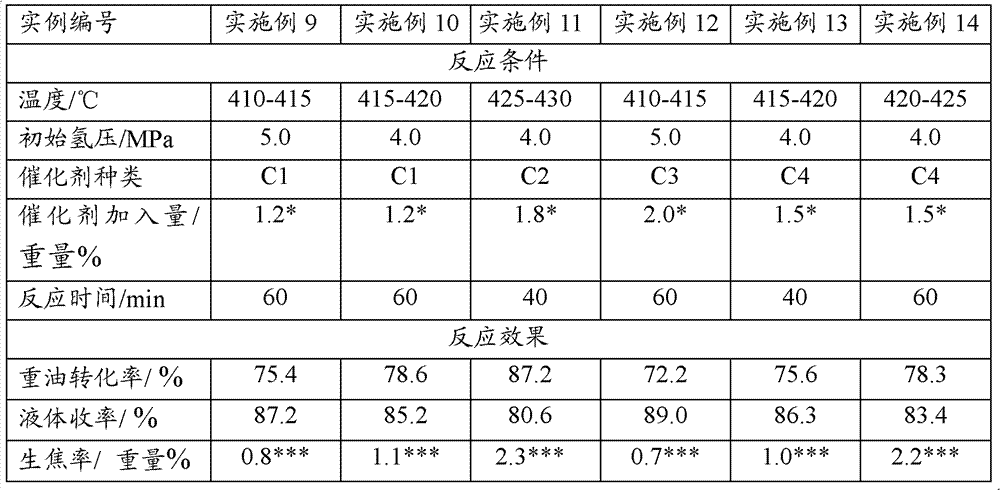

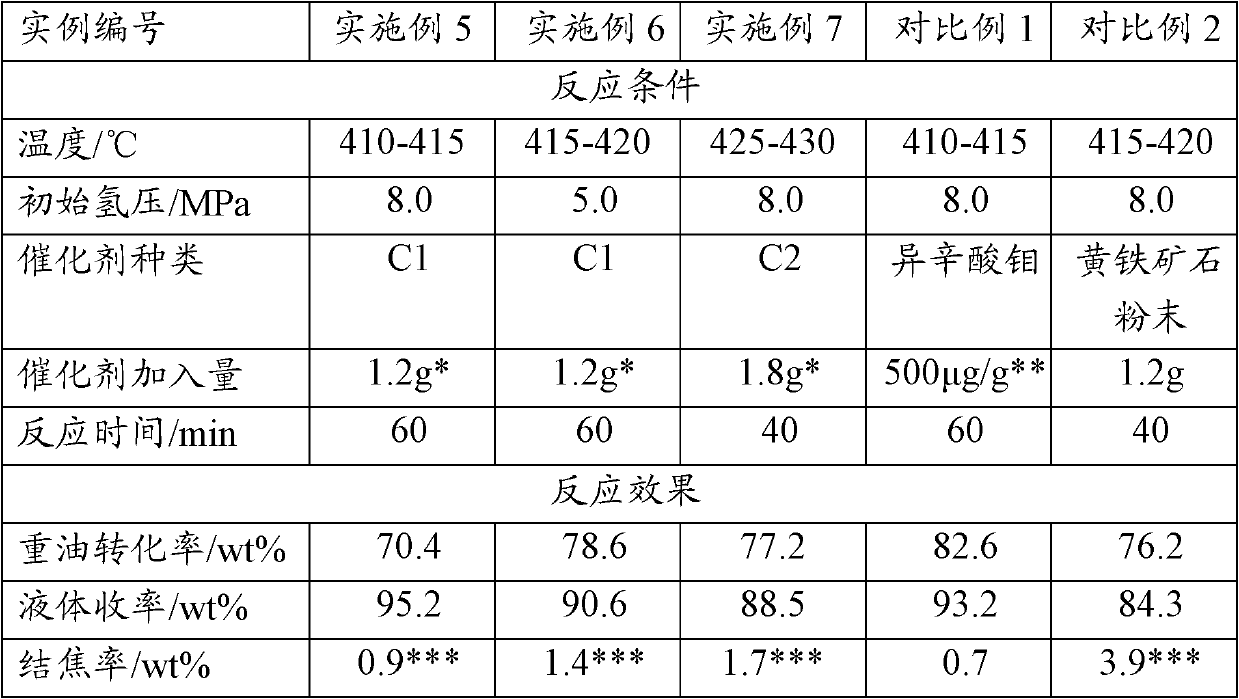

Bauxite-containing heavy oil hydrogenation catalyst, and preparation and application thereof

ActiveCN103285929AHigh catalytically active solids contentStrong mixing abilityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon oil crackingCatalytic effectFuel oil

The invention relates to a bauxite-containing heavy oil hydrogenation catalyst, and preparation and application thereof. The heavy oil hydrogenation catalyst is composed of bauxite powder and a dispersion medium, wherein the bauxite powder accounts for 5-70 wt% of the catalyst; and on the basis of the dispersion medium, the dispersion medium contains 80-99% of base oil, 0.05-10 wt% of surfactant, 0.05-10 wt% of solid thickening rheological agent, 0.5-2 wt% of oleic acid and 0.05-10 wt% of polar additive. The heavy oil hydrogenation catalyst provided by the invention has the advantages of high catalytic-activity solid content, favorable mixing capacity with heavy oil raw oil, and favorable catalytic effect in heavy oil hydrocracking or modification in a suspension bed or slurry-state bed.

Owner:CHINA PETROLEUM & CHEM CORP +1

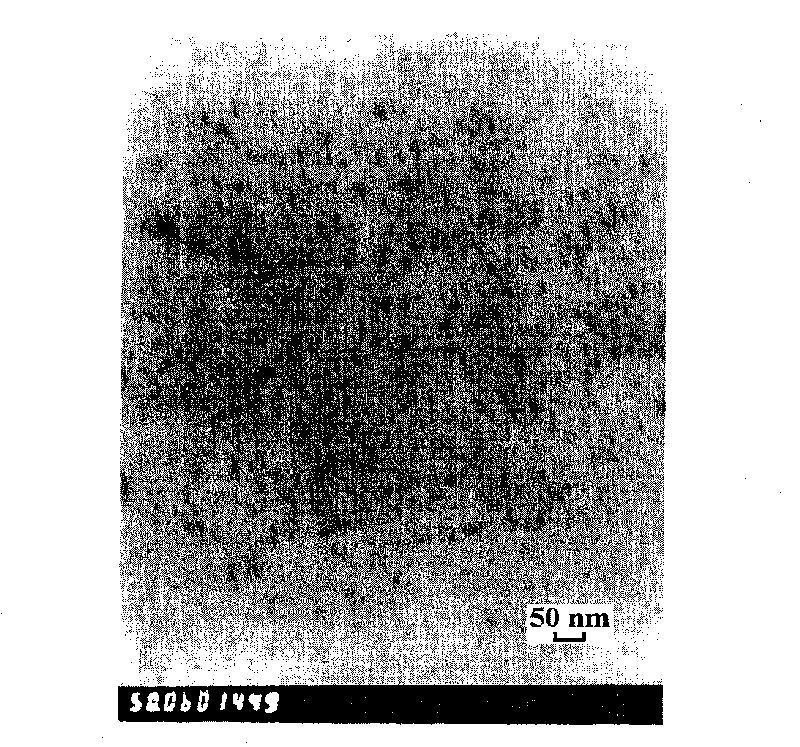

Modified rubber and preparation method thereof

The invention discloses a modified rubber and a preparation method thereof. The modified rubber is prepared by mixing rubber latex (1) and a nano-silica / poly(conjugated diene) composite emulsion (2) and carrying out coagulation and demulsification coprecipitation, wherein a mass ratio of the dry basis of the rubber latex to the dry basis of the nano-silica / poly(conjugated diene) composite emulsion is 100: (0.1 to 100); based on the dry basis of the nano-silica / poly(conjugated diene) composite emulsion, the nano-silica / poly(conjugated diene) composite emulsion comprises 0.1 to 5 parts of surface functionalization-modified nano-silica; the nano-silica / poly(conjugated diene) composite emulsion has granularity of 50 to 80nm, number-average molecular weight of 100000 to 120000 and molecular weight distribution of 2 to 3; and the rubber latex is a homopolymer or a copolymer containing a poly(conjugated diene) compound and is prepared by emulsion polymerization.

Owner:PETROCHINA CO LTD

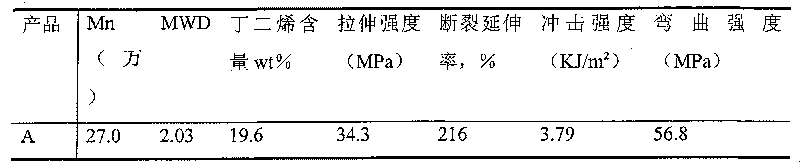

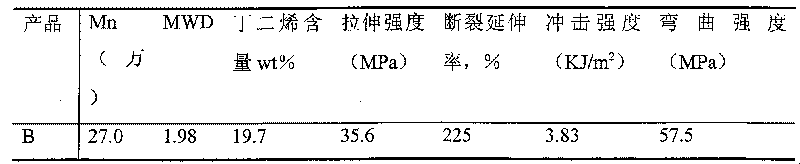

Styrene block copolymer reacting and extruding polymerization

A styrene block copolymer reacting extruding polymerizing method is carried out by: delivering styrene monomer, initiating agent, styrene / conjugated diene mixed monomer into screw extruder for polymerization, or delivering styrene monomer, mono-functional organic alkali metal or alkali earth metal initiating agent, styrene / conjugated diene mixed monomer, and coupler into screw extruder for polymerization, and obtaining styrene block copolymer. Its advantages include low cost and consumption, short production period, high output efficiency and no environmental pollution.

Owner:EAST CHINA UNIV OF SCI & TECH

Grafting-modified rubber and preparation method thereof

The invention discloses a grafting-modified rubber and a preparation method thereof. The grafting-modified rubber is prepared by graft polymerization of rubber latex (1) and a nano-silica / poly(conjugated diene) composite emulsion (2) in the presence of an initiator, wherein a mass ratio of the dry basis of the rubber latex to the dry basis of the nano-silica / poly(conjugated diene) composite emulsion is 100: (0.1 to 100); based on the dry basis of the nano-silica / poly(conjugated diene) composite emulsion, the nano-silica / poly(conjugated diene) composite emulsion comprises 0.1 to 5 parts of surface functionalization-modified nano-silica; the nano-silica / poly(conjugated diene) composite emulsion has granularity of 50 to 80nm, number-average molecular weight of 100000 to 120000 and molecular weight distribution of 2 to 3; and the rubber latex is a homopolymer or a copolymer containing a poly(conjugated diene) compound and is prepared by emulsion polymerization.

Owner:PETROCHINA CO LTD

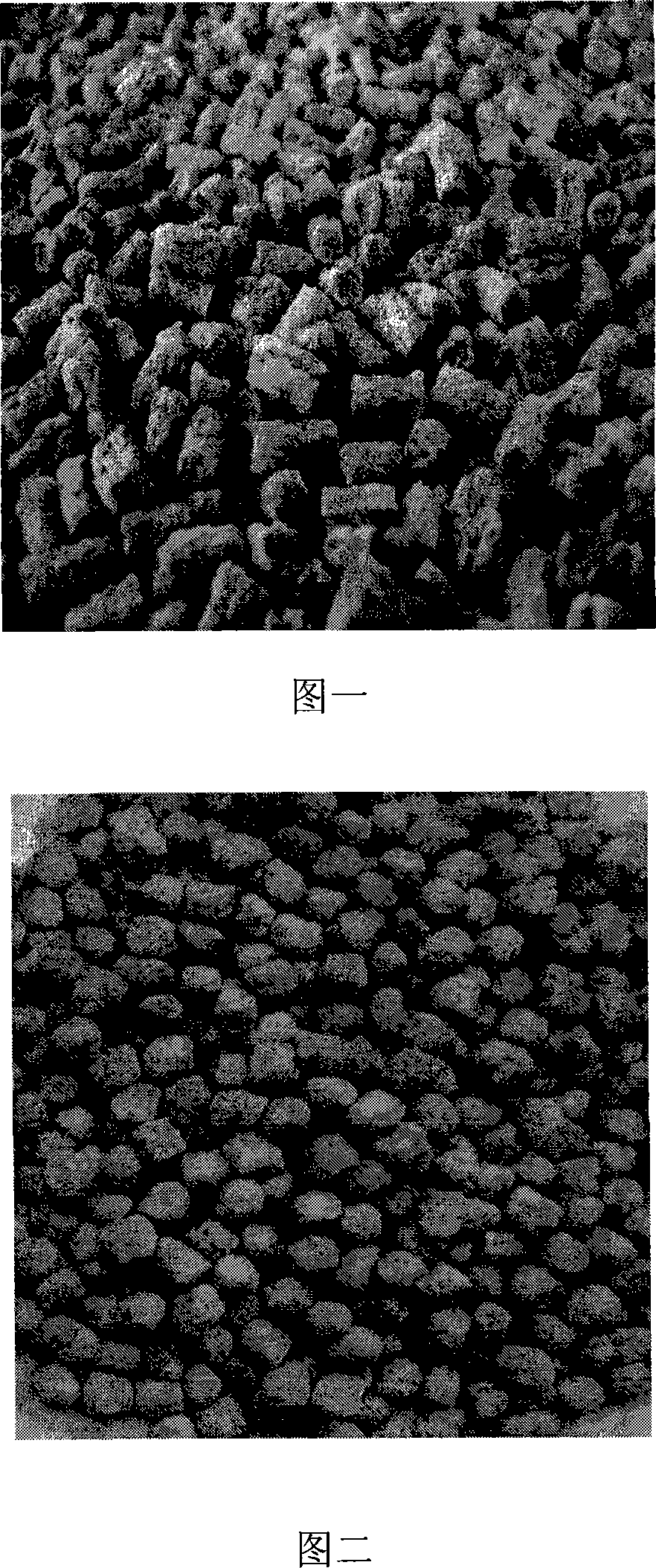

Spherical iron oxide and ultra-high density drilling fluid adopting spherical iron oxide as weighting agent

InactiveCN106753280AAcid solubleFeed speed controlFerric oxidesDrilling compositionHigh pressure oxygenVolumetric Mass Density

The invention provides spherical iron oxide. The spherical iron oxide is prepared from hematite by high-temperature flame melting, the hematite is conveyed by high-pressure oxygen to main combustion oxygen and natural gas combustion flame at a temperature being 2400 DEG C or higher, the hematite is molten by flames to form dispersed droplets, the droplets rapidly enter a cooling area under the action of negative pressure and are condensed into small spherical particles, and the spherical iron oxide is prepared accordingly. The feeding rate of the hematite is 10-40 Hz, the conveying amount of high-pressure oxygen is 110-190 m<3> / h, the amount of the main combustion oxygen is 550-660 m<3> / h, the consumption of the natural gas is 220-330 m<3> / h, and the oxygen enrichment coefficient is 1.0-1.3. According to ultra-high density drilling fluid adopting the spherical iron oxide as a weighting agent, the ultra-high density drilling fluid is prepared by taking the mixed spherical iron oxide as the weighting agent, and has good rheological property and settling stability, low water loss, high compressive strength and good cementing performance; the density of the drilling fluid is higher than 2.6 g / cm<3>.

Owner:天津泽希矿产加工有限公司

Iron-oxide-ore-containing heavy oil hydrogenation catalyst, and preparation and application thereof

ActiveCN103285928AStrong mixing abilityGood dispersion performanceOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon oil crackingChemistryBrown iron oxide

The invention relates to an iron-oxide-ore-containing heavy oil hydrogenation catalyst, and preparation and application thereof. The heavy oil hydrogenation catalyst is composed of iron oxide ore powder and a dispersion medium, wherein the iron oxide ore powder accounts for 5-70 wt% of the catalyst; and on the basis of the dispersion medium, the dispersion medium contains 80-99 wt% of base oil, 0.05-10 wt% of solid thickening rheological agent and 0.05-10 wt% of polar additive. The heavy oil hydrogenation catalyst provided by the invention has the advantages of high catalytic-activity solid content, favorable mixing capacity with heavy oil raw oil, and favorable catalytic effect in heavy oil hydrocracking or modification in a suspension bed or slurry-state bed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Barley powder food and production method thereof

InactiveCN101715923AStrong shearImprove mixing abilityFood preparationAdditive ingredientAqueous solution

The invention discloses barley powder food and a production method thereof. The barley powder food is prepared by the following method: extruding and puffing barley powder with a twin-screw extruder; and obtaining the barley powder food having regular shapes. In the method, only the barley powder is used as a raw material, and the barley powder can be shaped without adding other materials and can be made into a product having various regular shapes as required. The barley product prepared by the method is regular and uniform in shape and has a porous structure; the product is rich in special nutritional and functional health-care components of barley such as protein, VE and beta-glucan; the food has good brittleness in water solution; and the food can be solely eaten, can be added into beverage such as yogurt, milk, coffee and the like, or can be used as cooking raw materials of other food; and the food has storability and is a truly healthy and nutritious barley powder food.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI +1

Styrene block copolymer reaction extruding polymerizing method

The reaction and extrusion polymerizing process of styrene block copolymer includes the following steps: feeding styrene monomer, initiator and other monomer to be copolymerized to different sections of screw extruder successively to perform copolymerization; or, feeding styrene monomer, single functional group organic alkali or alkali earth metal initiator, other monomer to be copolymerized and coupler to different sections of screw extruder successively to perform copolymerization, so as to obtain the styrene block copolymer. The present invention adopts reaction and extrusion polymerizing technology to shorten the production period to several minutes, and the whole process has no solvent added and thus no need of complicated solvent separation and purification. Therefore, the present invention has high production efficiency, low power consumption, low cost, less pollution and other advantages.

Owner:EAST CHINA UNIV OF SCI & TECH

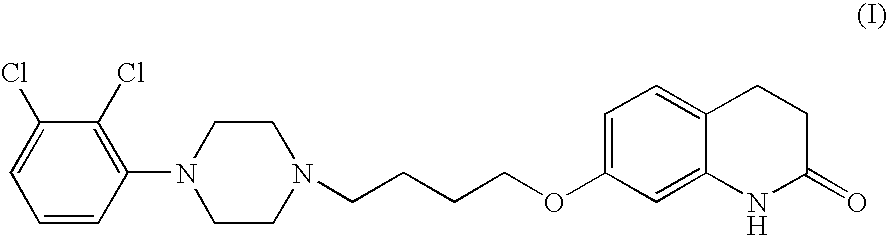

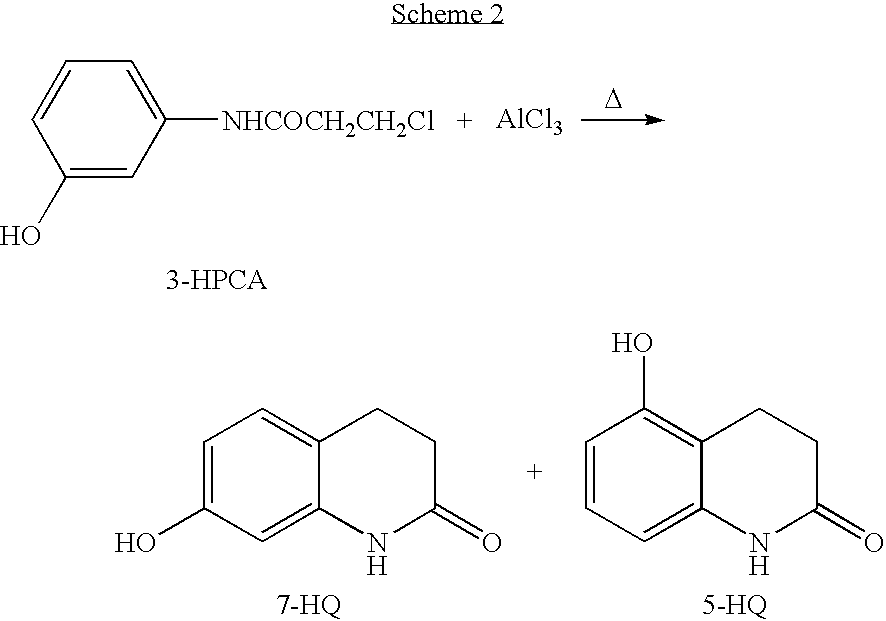

Processes for preparing 7-hydroxy-3,4-dihydro-2(1H)-quinolinone and the use in aripiprazole preparation thereof

InactiveUS20060079690A1Improve the mixing effectEnhance stirringNervous disorderOrganic chemistryCombinatorial chemistryAripiprazole

The present invention provides improved processes for preparing the intermediate 7-hydroxy-3,4-dihydro-2(1H)-quinolinone (7-HQ), which may be used in preparing the drug aripiprazole. Among these processes are included three efficient processes for preparing 7-hydroxy-3,4-dihydro-2(1H)-quinolinone comprising reacting N-(3-methoxyphenyl)-3-chloropropionamide with AlCl3 using novel reaction conditions thus obtaining a substantially pure product, which may be used in the subsequent steps for obtaining aripiprazole without further purification.

Owner:CHEMAGIS

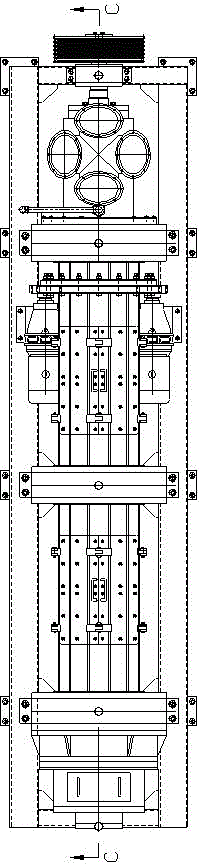

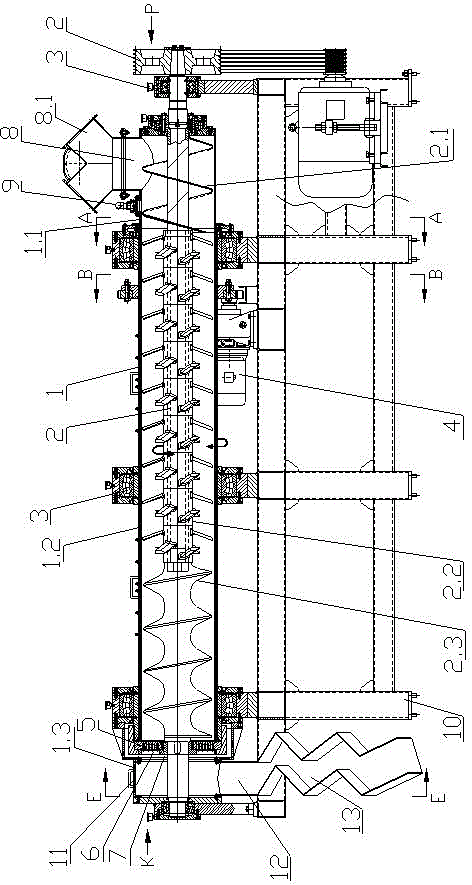

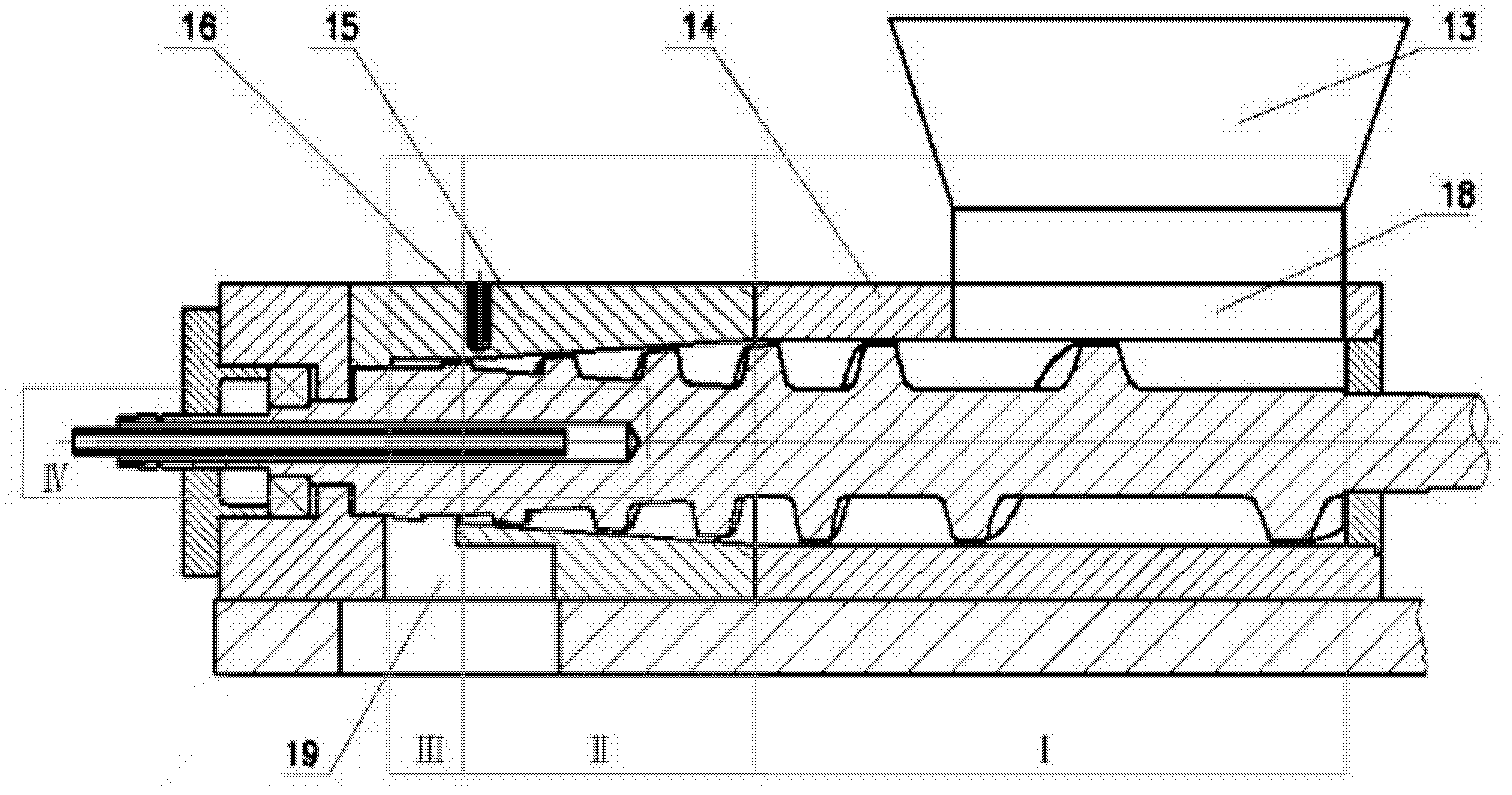

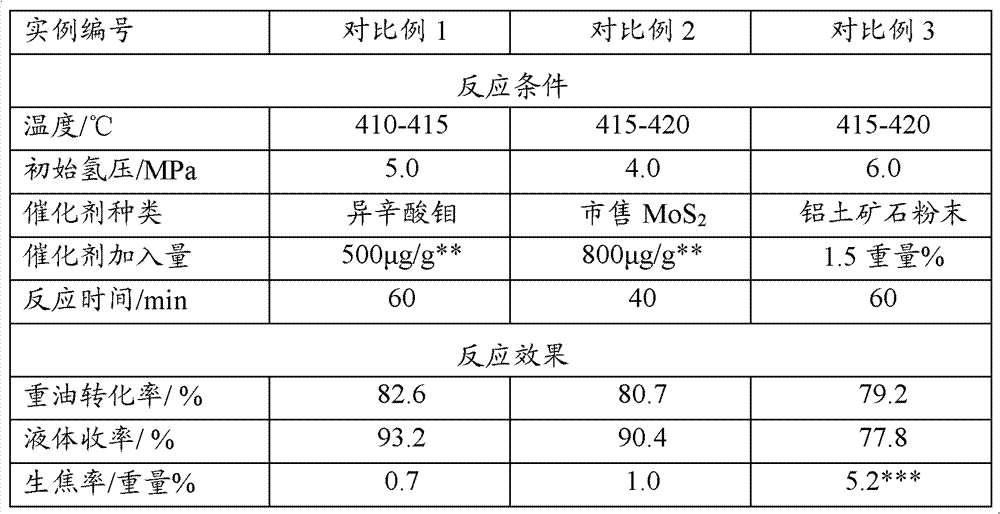

Horizontal type continuous intensive mixing pelletizer with double functions

InactiveCN104857892AImprove material mixing effectEnergy savingGranulation in rotating drumsGranulation by material expressionPelletizingEngineering

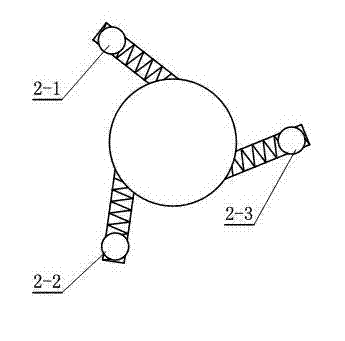

The invention relates to a horizontal type continuous intensive mixing pelletizer with double functions. The horizontal type continuous intensive mixing pelletizer comprises a cylinder (1) and a rotating shaft (2), wherein the cylinder (1) comprises a feeding cylinder (1.1) at the right end, a rotating cylinder (1.2) in the middle and a discharging cylinder (1.3) at the left end; the rotating shaft (2) is provided with a screw fin transverse feeding section (2.1), a three-dimensional rotor stirring and feeding section (2.2) and a screw pushing and extruding section (2.3) sequentially from right to left; the screw fin transverse feeding section (2.1) is located in the feeding cylinder (1.1); the three-dimensional rotor stirring and feeding section (2.2) and the screw pushing and extruding section (2.3) are located in the rotating cylinder (1.2); a perforated plate (5) and a scraper plate (6) are fixed leftwards at the left end of the rotating cylinder (1.2) sequentially. The horizontal type continuous intensive mixing pelletizer has the advantages of reasonable structure, high mixing and pelletizing capacity, high production efficiency, low driving energy consumption and low equipment investment.

Owner:JIANGYIN KAIQIAN MACHINERY CO LTD

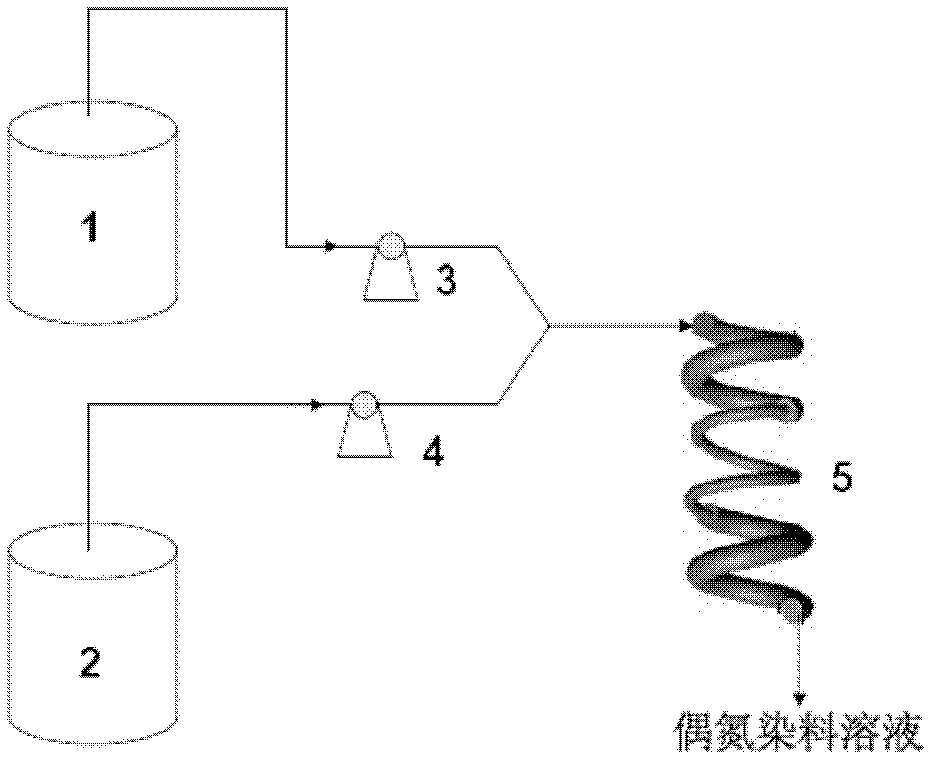

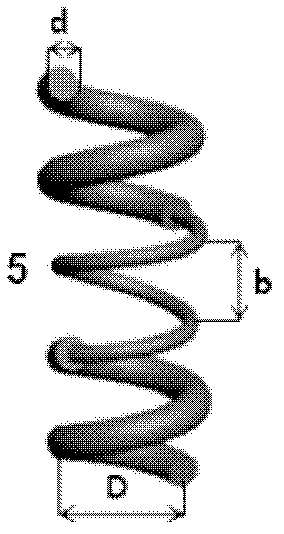

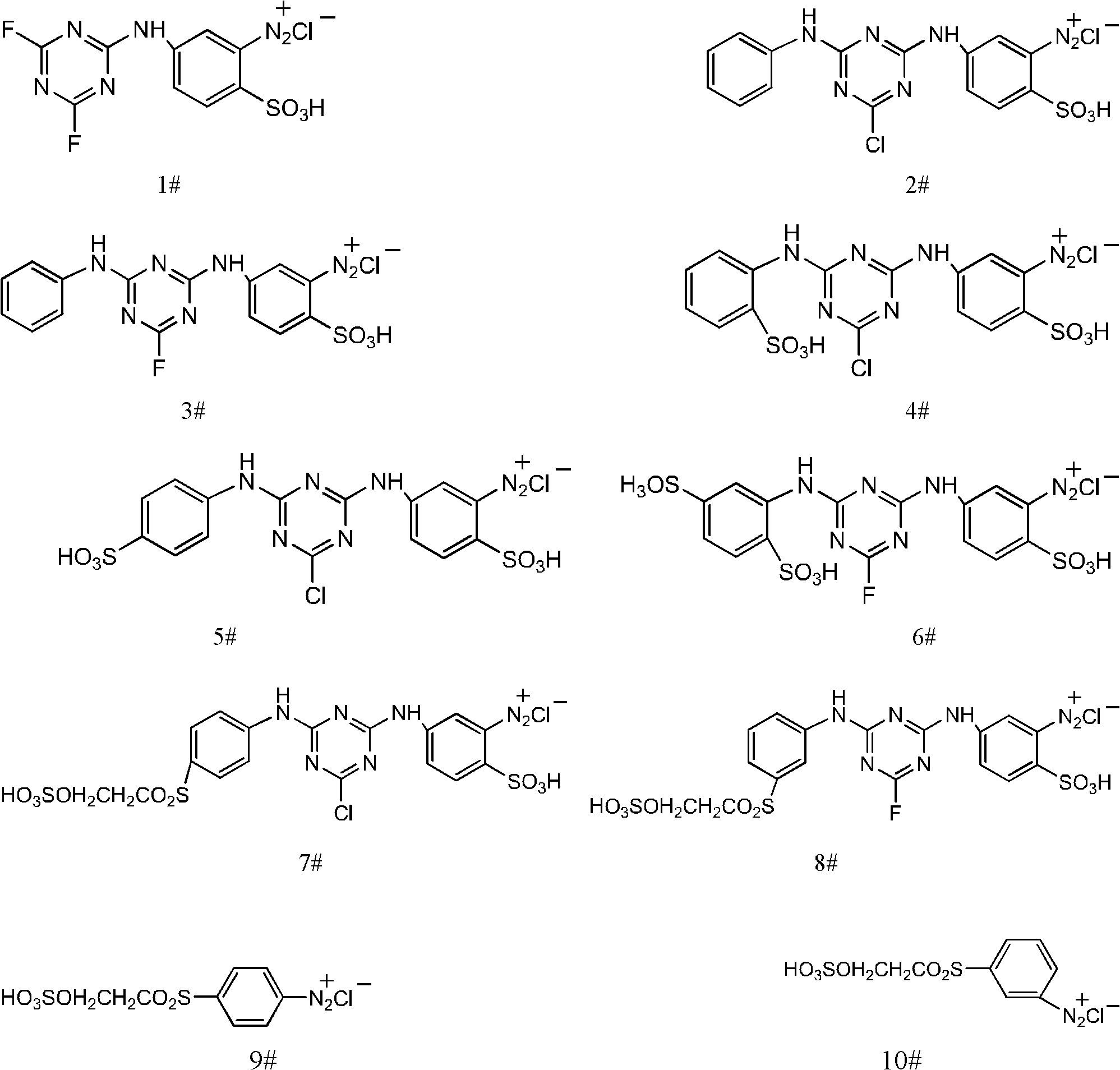

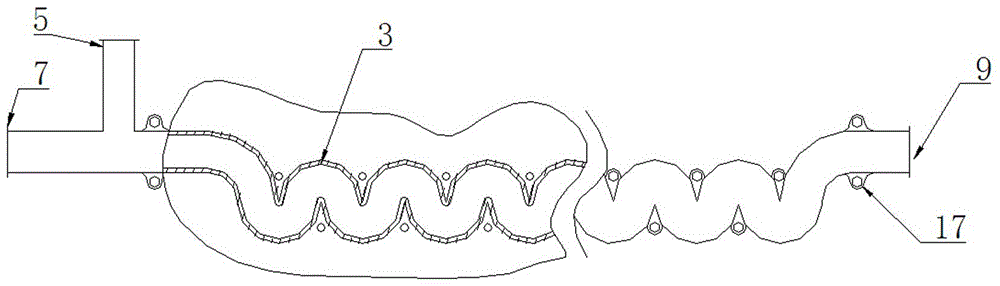

Method for preparing water-soluble azo dye continuously by chaos mixing of spiral tube

ActiveCN102618063BRapid serial productionFully contactedMonoazo dyesDisazo dyesMicroreactorStraight tube

The invention provides a method for preparing a water-soluble azo dye continuously by the chaos mixing of a spiral tube. The core is that a spiral tube sudden-expansion and sudden-contraction structure is adopted; compared with pure straight tube sudden-expansion and sudden-contraction mixed reaction, the method has the advantages that a mixed effect of a transverse secondary flow generated by fluid in a curved pipeline is far stronger than that of pure diffusion of a straight tube part; compared with the conventional spiral tube, the sudden-expansion and sudden-contraction part has the advantages that the motion trail of the fluid can be changed, the superficial area of a mixed interface can be increased and a chaos mixing effect can be enhanced; and the mixer has the advantages of quick and uniform mixing, stirring prevention, short retention time, high quality stability of the product, high speed of removing reaction heat by a tube wall and the like of a microreactor, and also overcomes the defects of small internal diameter and high possibility of blockage of the microreactor, so that the dye can be produced quickly and continuously, and the method is wide in industrial prospect.

Owner:DALIAN UNIV OF TECH

Oat whole powder foodstuff and method for manufacturing the same

The invention discloses a regular-shaped all powder oat foodstuff and a production method thereof. The method of producing the regular-shaped all powder oat foodstuff provided by the invention is that all powder oat is extruded and swelled by a twin screw extruder, thereby acquiring the regular-shaped all powder oat foodstuff. The method adopts only the oat as raw material, and can be formed without adding any additive, and various regular-shaped foodstuffs can be made according to specific requirements. The oat product acquired by adopting the method has rich nutrient, can be stored for a long time, and is a healthy and nutritious all powder oat foodstuff.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

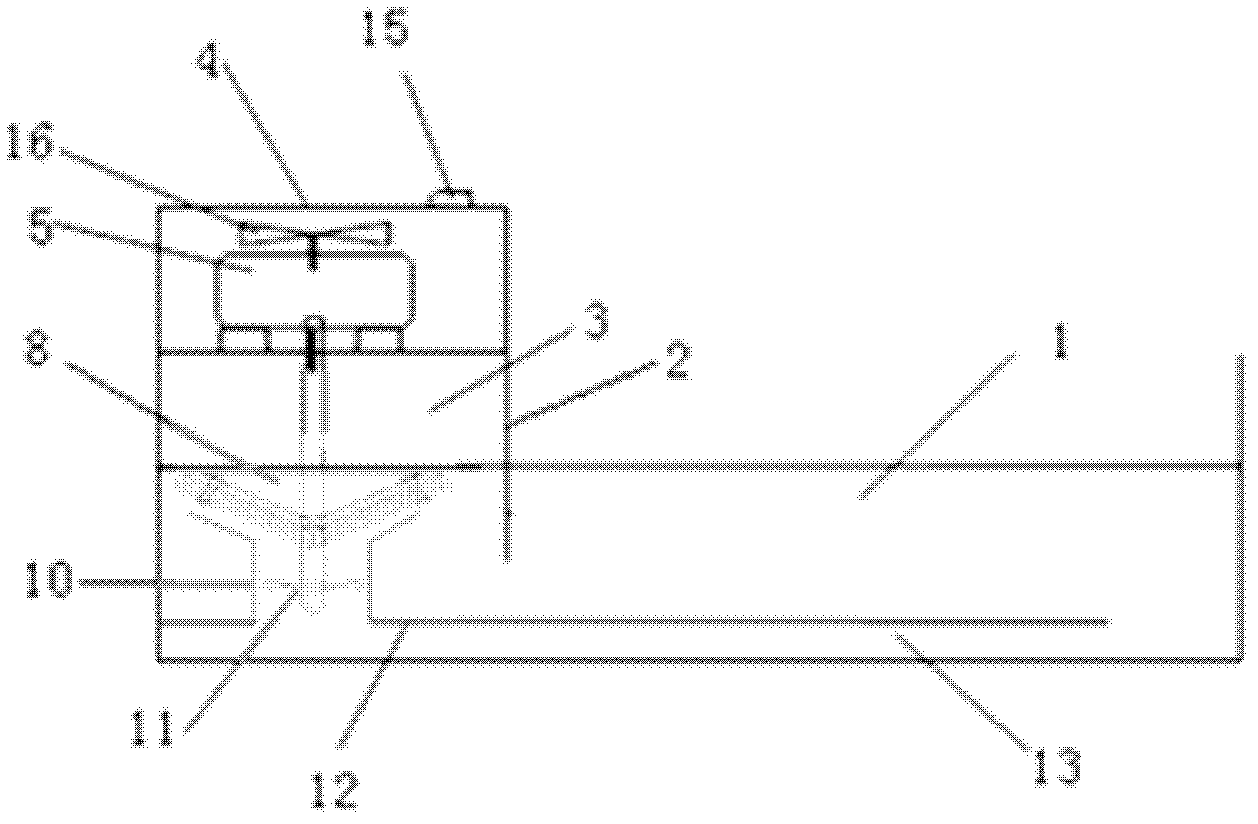

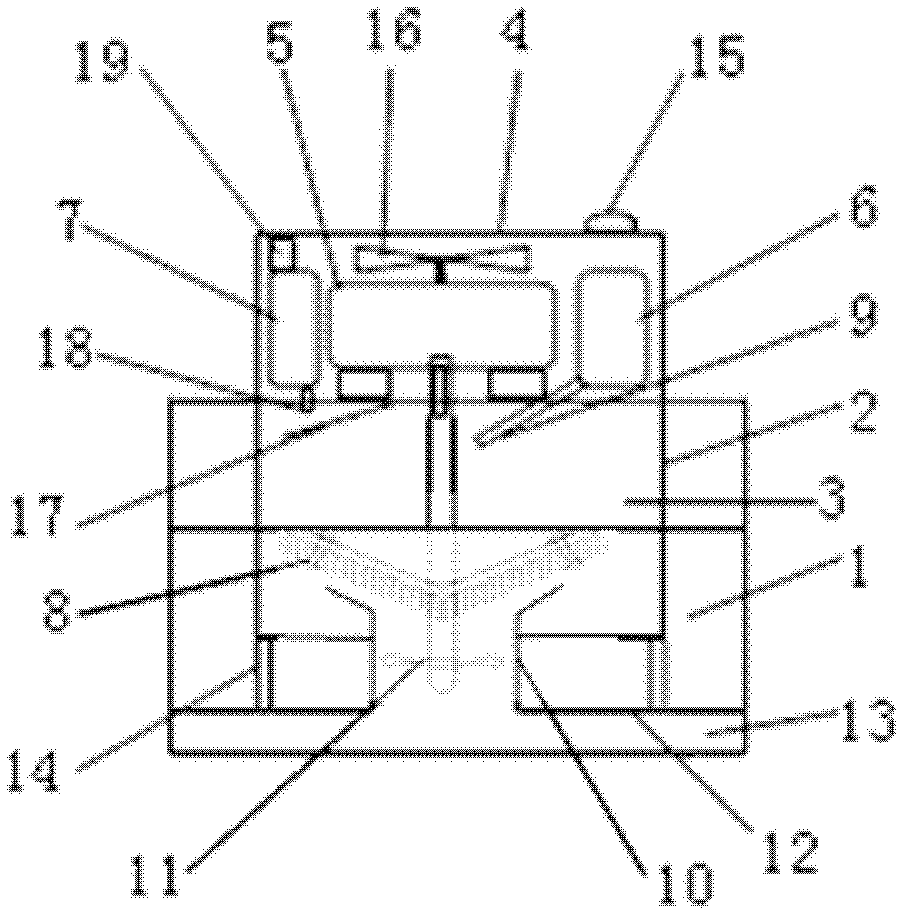

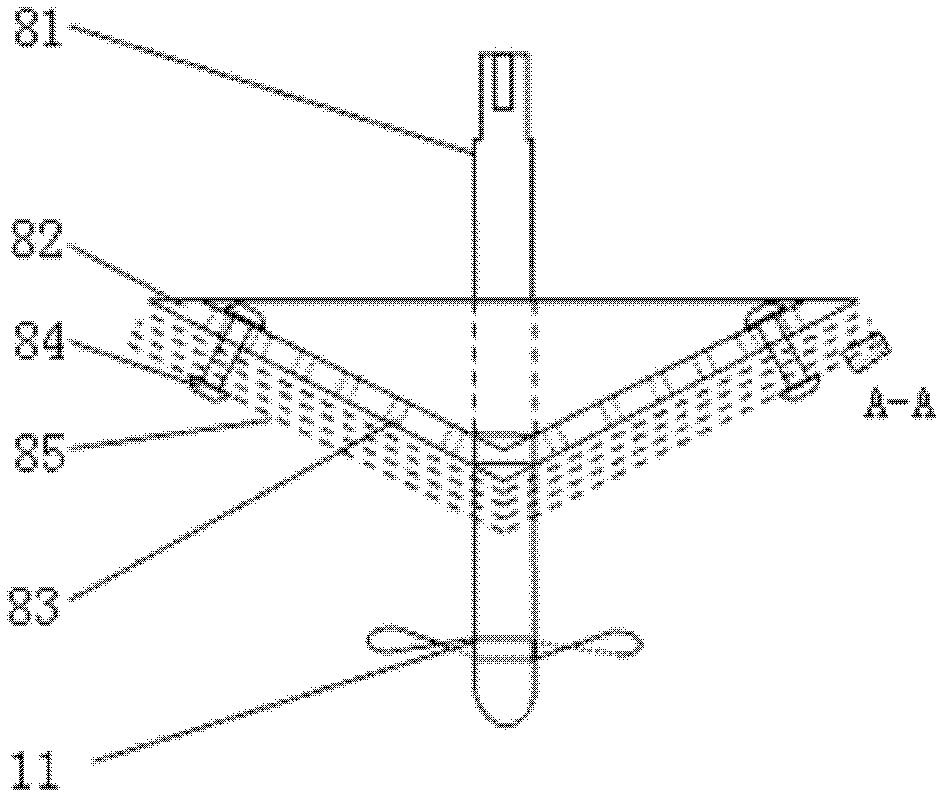

Multifunctional cold sterilization basin

ActiveCN103251500AGood purification effectTreatment of athlete's footBathing devicesKitchen equipmentExhaust gasDrive motor

The invention discloses a multifunctional cold sterilization basin comprising a water bin basin. An air bin formed by surrounding of an air bin barrel plate is arranged above one end of the water bin basin, the lower portion of the air bin barrel plate is immersed in the water bin basin, a gap is reserved between the lower portion of the air bin barrel plate and the bottom of the water bin basin, an electrical appliance bin is arranged on the top of the air bin, a driving motor, an ozone generating device and a tail gas absorbing and decomposing device are arranged in the electrical appliance bin, a porous inverted-umbrella shaped air-liquid delivering device with multiple nets covering on an umbrella top is arranged on the outer side of the bottom of the electrical appliance bin and connected with a rotating shaft of the driving motor, the umbrella top of the porous inverted-umbrella shaped air-liquid delivering device with the multiple nets covering on the umbrella top is arranged in the water bin basin, and the ozone generating device and the tail gas absorbing and decomposing device are respectively communicated with the air bin through pipelines. By the multifunctional cold sterilization basin, human feet suffering from foot diseases, polluted fabrics, vegetables or the like can be subjected to cold sterilization, high-concentration ozone dissolving in water is realized, and ozone gas harmful to respiratory systems of humans is prevented from leaking.

Owner:NINGBO HUISHIKANG HEALTH SCI & TECH

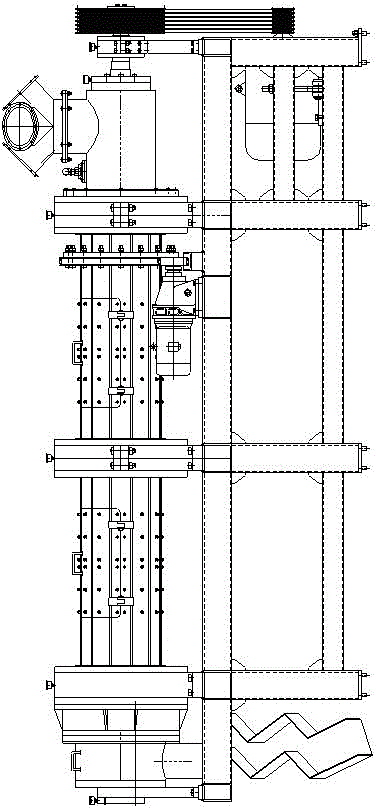

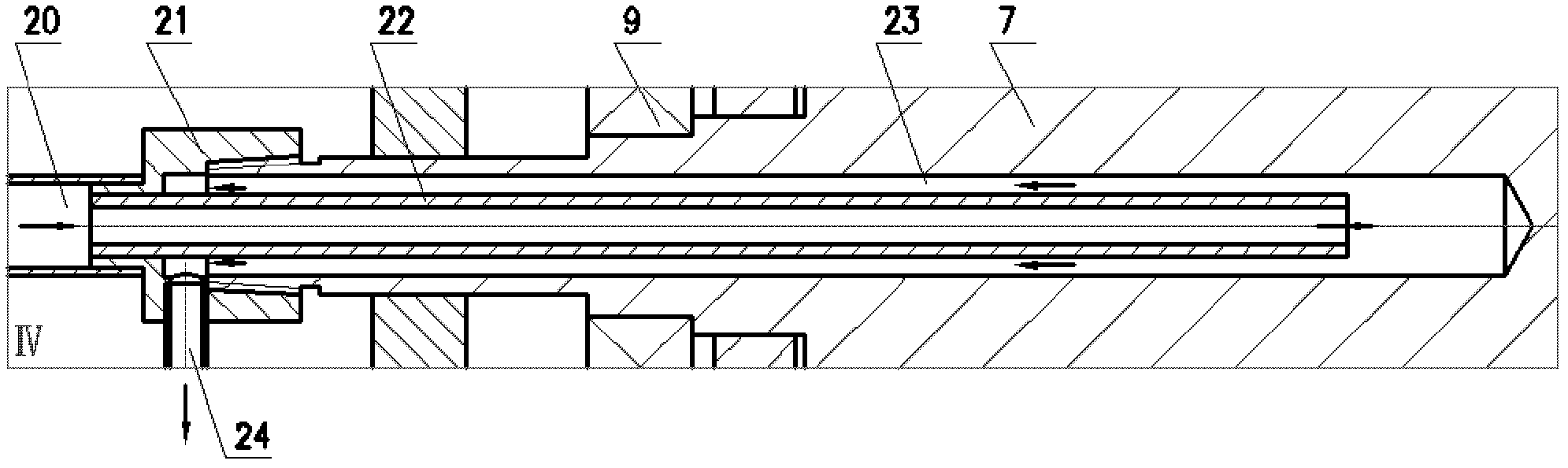

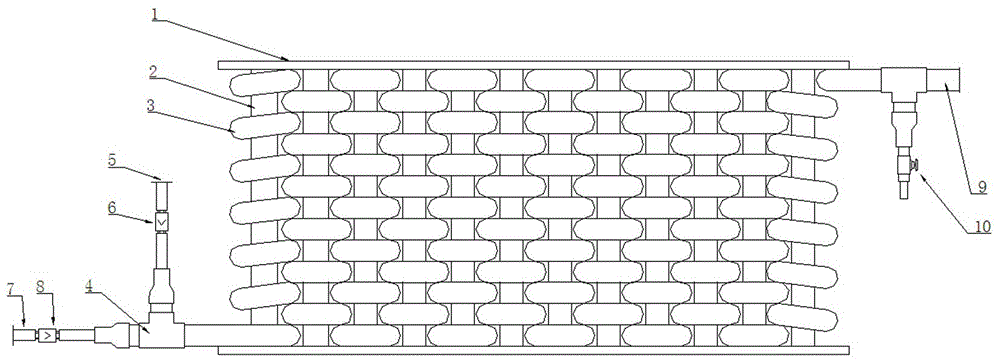

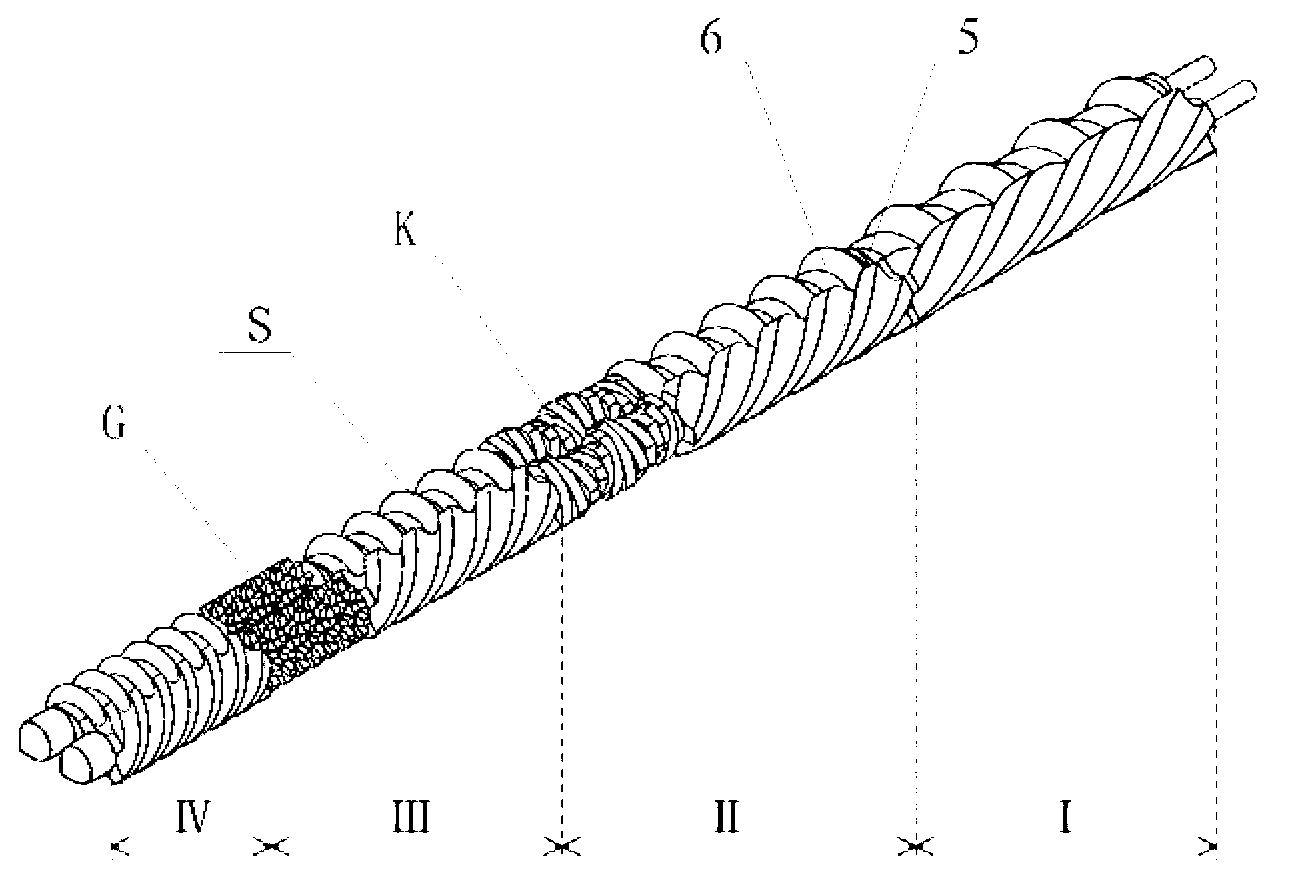

Continuous steam explosion device for plant fibers

ActiveCN102677502AStrong positive displacement conveying abilityStrong mixing abilityRaw material divisionProcess engineeringPlant fibre

The invention discloses a continuous steam explosion device for plant fibers. The continuous steam explosion device comprises a barrel, a transmission mechanism and a driving mechanism which are sequentially connected, a feed inlet and a discharge outlet are arranged on the barrel, three screws located on the same horizontal plane are disposed in the barrel, the adjacent screws are radially meshed mutually, the cross sectional area of the end, which is close to the feed inlet, of each screw is larger than that of the end, which is close to the discharge outlet, of the screw, and the driving mechanism is connected with the screws and drives each two adjacent screws to rotate in opposite directions. The continuous steam explosion device can realize continuous steam explosion for materials, and has the advantages of simple structure, low manufacturing cost, fine steam explosion effect and high yield.

Owner:SOUTH CHINA UNIV OF TECH +1

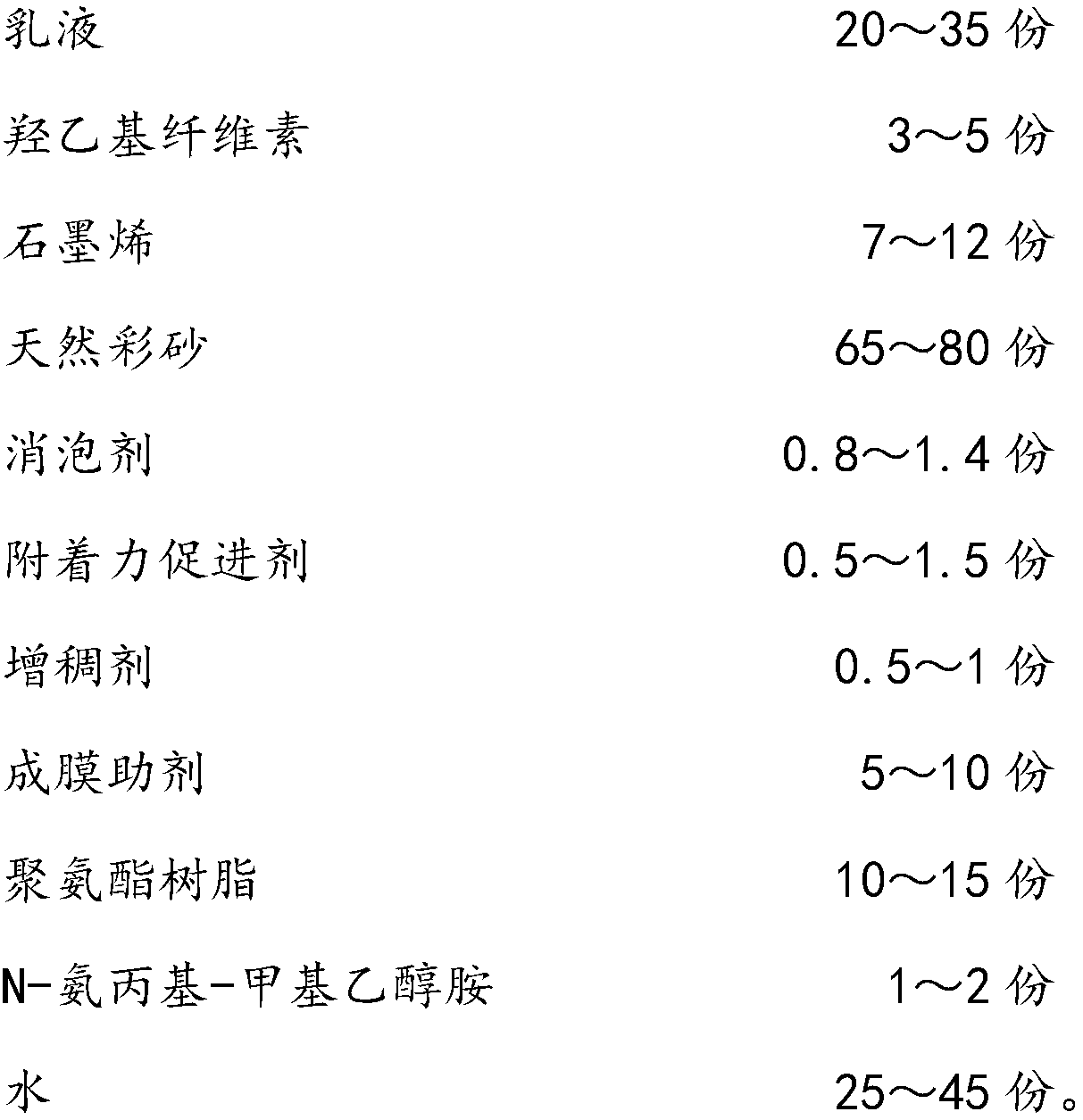

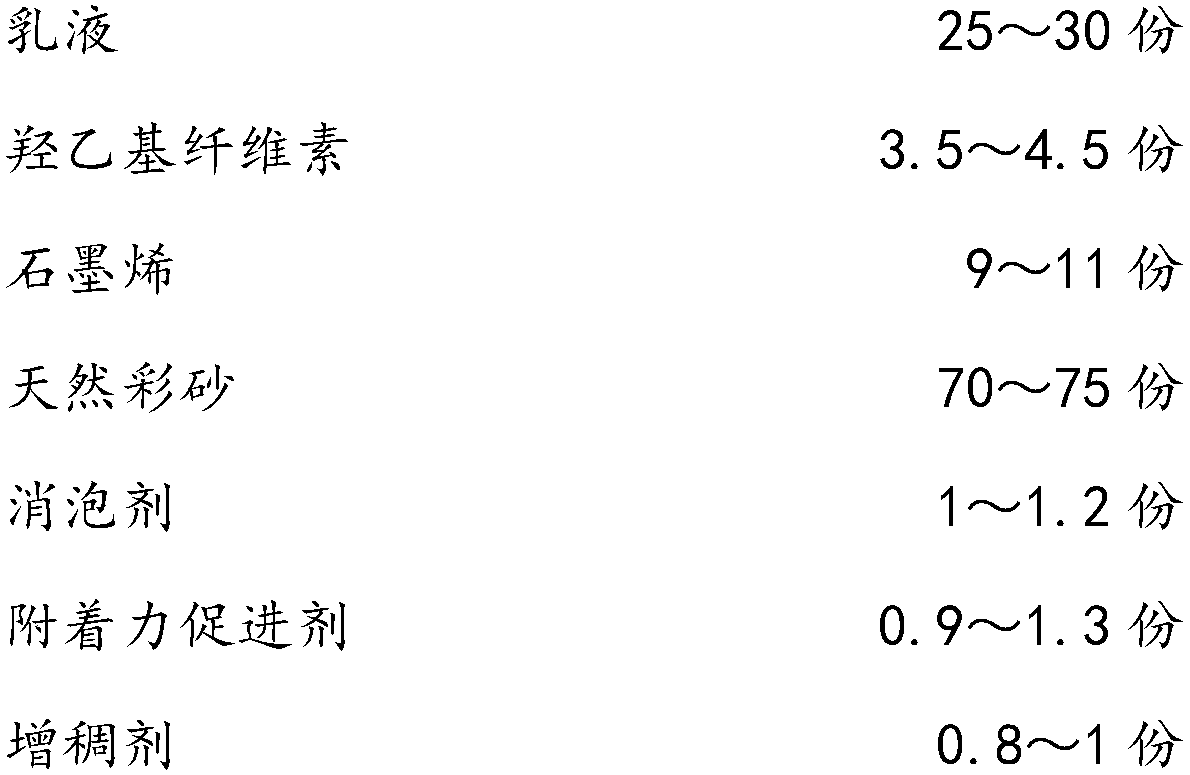

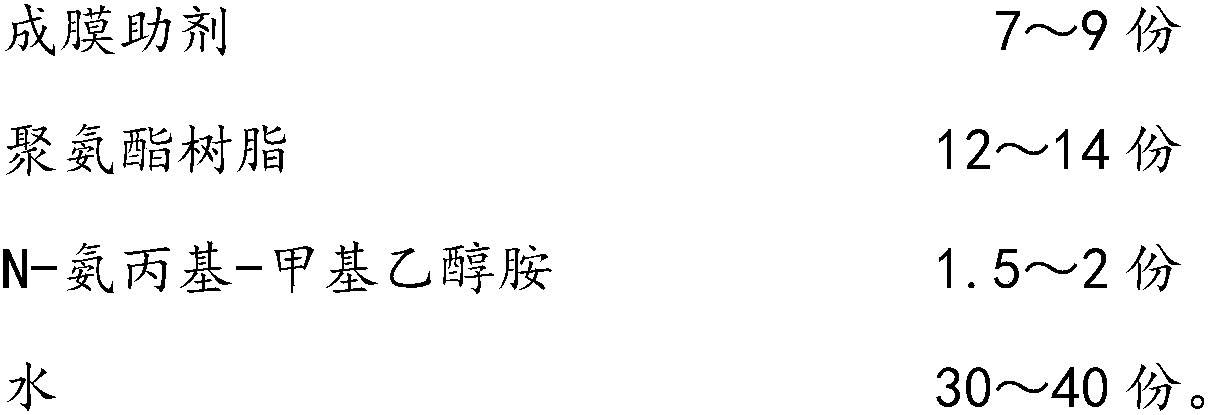

Anti-fall graphene lacquer and preparing method thereof

The invention provides an anti-fall graphene lacquer and a preparing method thereof. The anti-fall graphene lacquer is prepared from, by weight, 20-35 parts of emulsion, 3-5 parts of hydroxyethyl cellulose, 7-12 parts of graphene, 65-80 parts of natural colorful sand, 0.8-1.4 parts of antifoaming agent, 0.5-1.5 parts of adhesion promoter, 0.5-1 part of thickening agent, 5-10 parts of coalescing agent, 1-2 parts of N-aminopropyl-methylethanolamine and 25-45 parts of water. By adding graphene in the composition, hydroxyethyl cellulose is compounded with graphene, the softness and adhesion of thelacquer are improved while the agglomeration problem of graphene is solved, and the compactness of the lacquer coating is improved, so that after the lacquer is used for a long time, the phenomena like stripping and bubbling are not generated.

Owner:XIAMEN GULIKE ENERGY SAVING TECH CO LTD

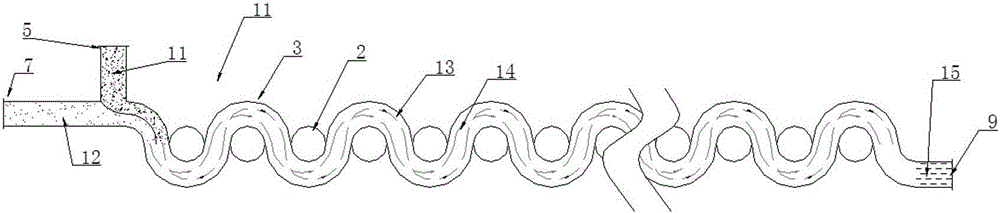

Fluid static mixing device with corrugated pipeline

InactiveCN105749777AImprove mixing abilityIncrease flow rateFlow mixersTransportation and packagingEngineeringMixed materials

The invention discloses a fluid static mixing device with a corrugated pipeline.The device comprises the mixing pipeline, a main material inlet pipe, an auxiliary material inlet pipe and a mixed material outlet pipe, wherein the main material inlet pipe and the auxiliary material inlet pipe are arranged at one end of the mixed pipeline, the mixed material outlet pipe is arranged at the other end of the mixed pipeline, and the mixed pipeline is a corrugated pipe body.By means of the corrugated pipeline, fluids which have different densities and conduct one-way movement are automatically mixed in the corrugated pipeline, and the mixing capacity is high, an appropriate number of semicircular pipelines and the flow velocity of the mixed fluid can be set according to the mixed objects and aims and demands.By means of the fluid static mixing device with the corrugated pipeline, the flow velocity is increased, and the mixing capacity, produced from centrifugal force, of the fluids with different densities can be improved and exceeds the gravity finally or even is improved in multiples.

Owner:NANYANG NORMAL UNIV

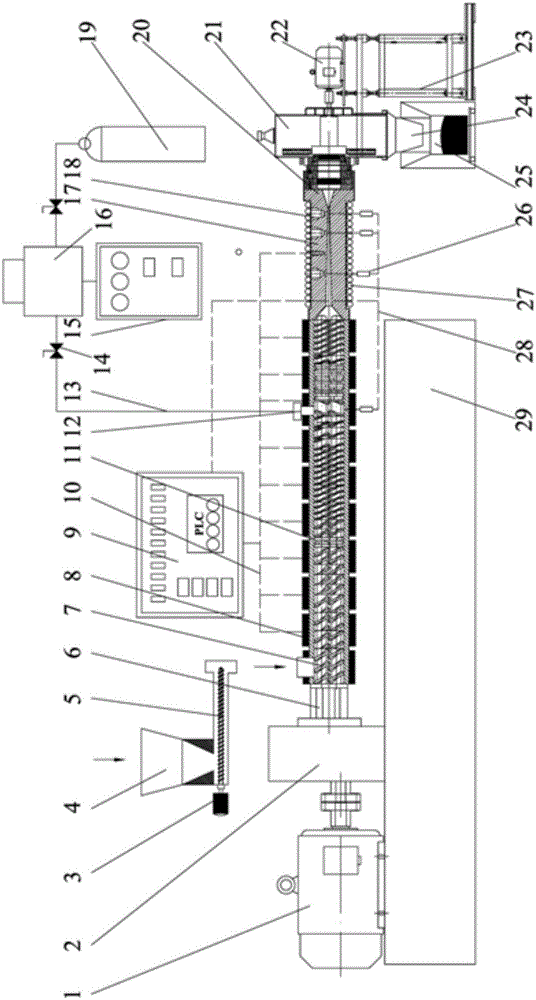

Green devulcanizing and reclaiming apparatus with supercritical CO2 and microwave assisted multi-segment twin-screw extrusion

The invention discloses a green devulcanizing and reclaiming apparatus with supercritical CO2 and microwave assisted multi-segment twin-screw extrusion, comprising a horizontal barrel; a twin-screw is rotationally mounted in the barrel; the barrel is provided with a feed port at the left upper end of the twin-screw, and the upper end of the barrel is fitted ith a microwave heating device; the middle of the barrel is provided with a gas injection end for supplying supercritical CO2; the rear end of the barrel is provided with a cooling extruder, the tail end of the cooling extruder is fitted with a dicing device, and a discharge port of the dicing device is provided with a product packaging device. The apparatus of the invention has simple structure, uses small floor area, is full-automatically controllable, low in production process energy consumption and green, and the defect that traditional reclaimed rubber production process has high contamination, high energy consumption, intermittence, high labor intensity and unstable product properties is effectively solved.

Owner:ANHUI GVG NEW MATERIAL CO LTD

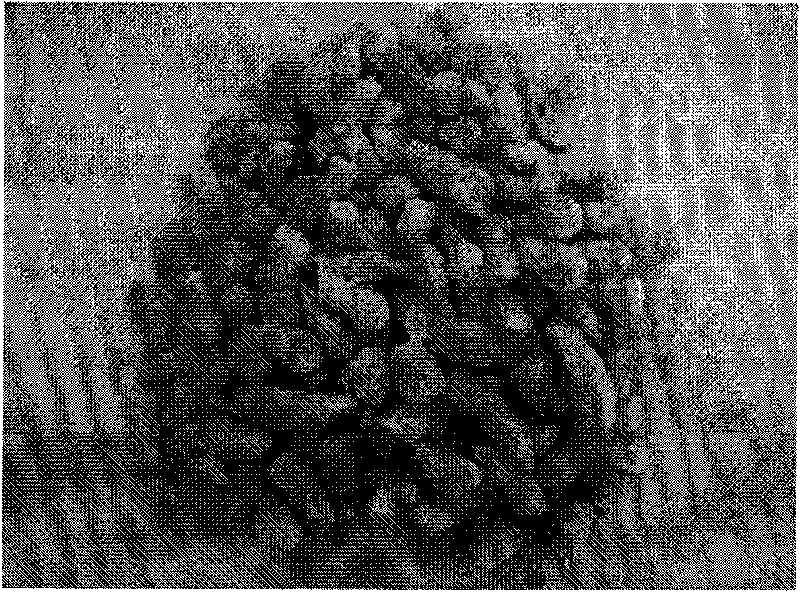

Iron ore-containing heavy oil hydrogenation catalyst, and preparation method and application thereof

ActiveCN103240126AHigh catalytically active solids contentStrong mixing abilityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon oils treatmentBoiling pointSlurry

The invention relates to an iron ore-containing heavy oil hydrogenation catalyst, and a preparation method and an application thereof. The heavy oil hydrogenation catalyst is composed by iron ore-containing powder and a dispersion medium. Based on the catalyst, the mass percentage of the iron ore-containing superfine powder is 5-70%; and the dispersion medium comprises the following components of, based on the dispersion medium, 80-99 wt% of a base oil, 0.05-10 wt% of a surfactant and 0.05-10 wt% of a solid thickening rheological agent, wherein the base oil is a distillate oil with a boiling point ranging from 220 DEG C to 550 DEG C. The heavy oil hydrogenation catalyst obtained by the invention has not only high catalytically active solid content but also good mixed ability with a raw oil of the heavy oil, and has good catalytic effect in heavy oil hydrocracking or hydro-upgrading of a suspended bed or a slurry bed.

Owner:CHINA PETROLEUM & CHEM CORP +1

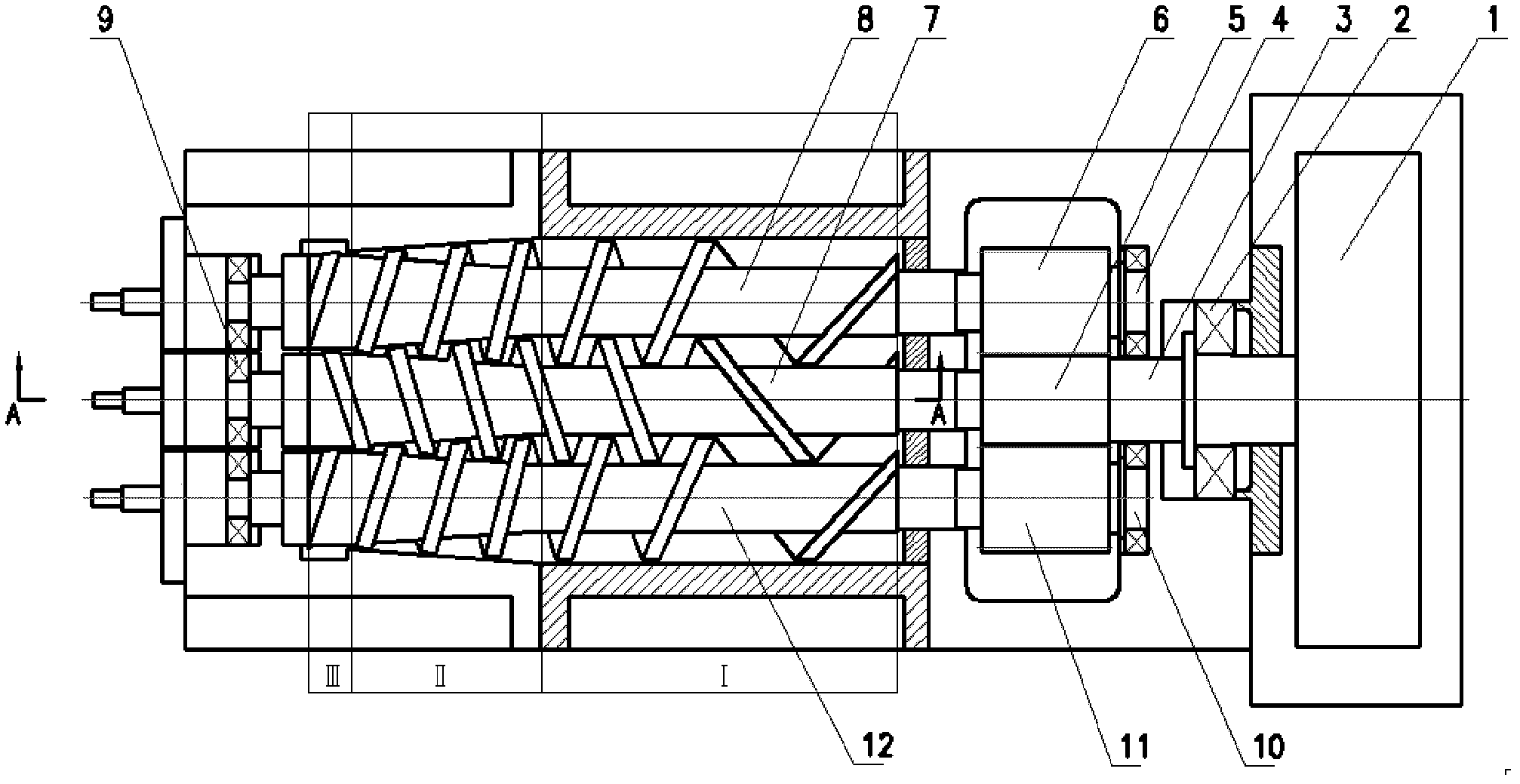

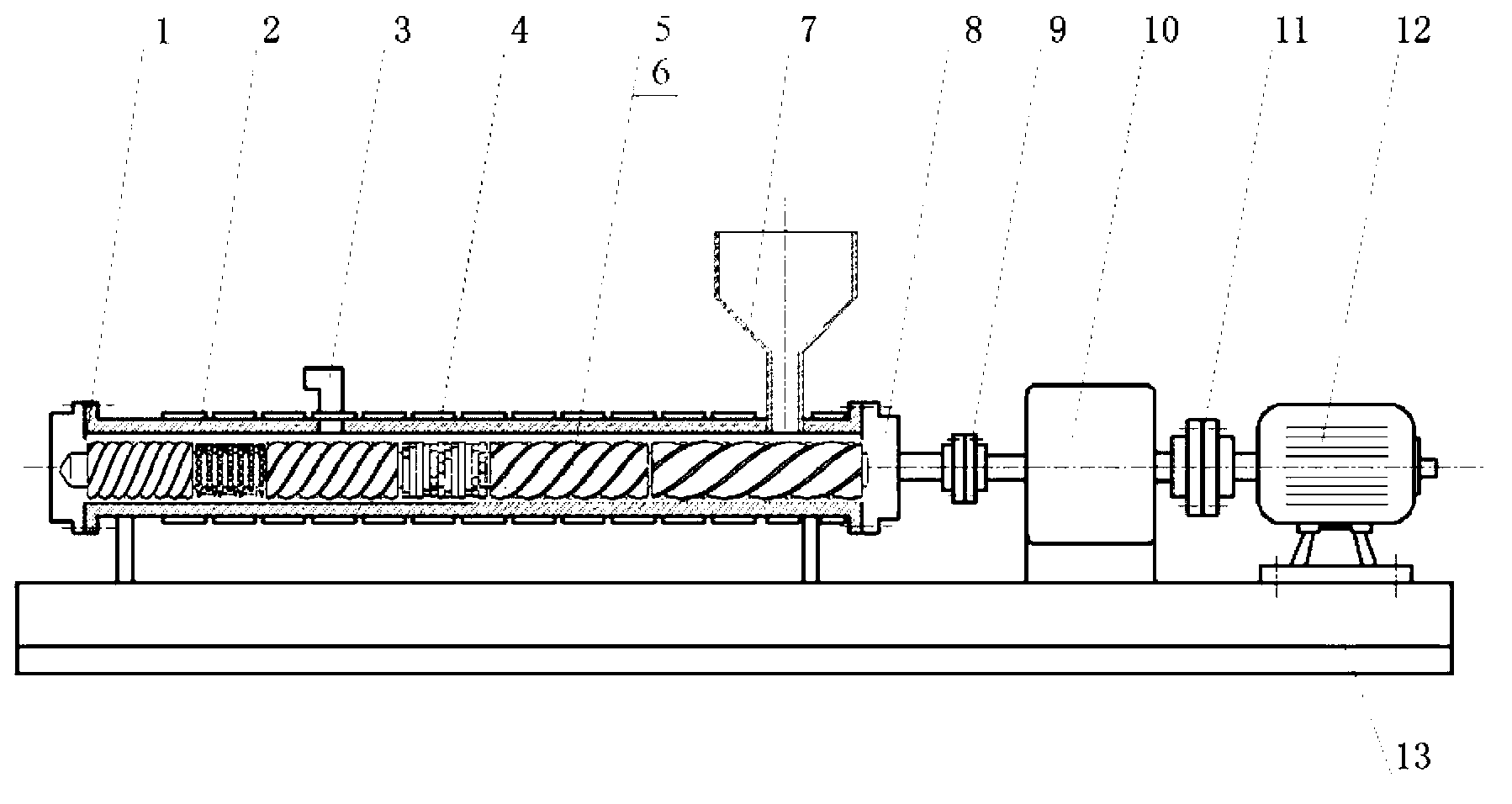

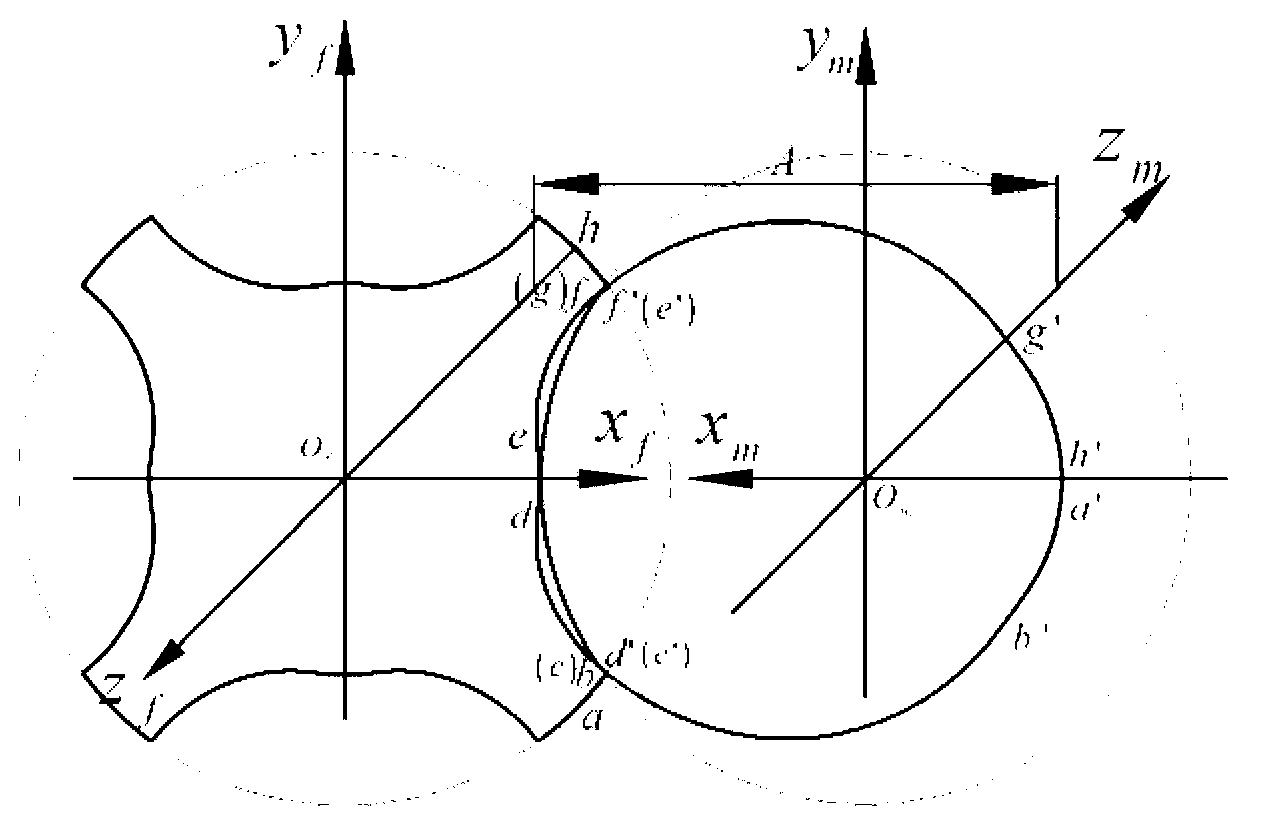

Twin-screw extruder with specially crafted yin and yang rotor profiles

InactiveCN103057089AStrong plasticizing mixing uniformityEnhanced distribution and mixing capabilitiesShear capacityEngineering

The invention discloses a twin-screw extruder with specially crafted yin and yang rotor profiles. The invention belongs to the field of twin-screw extruder, and especially relates to a twin-screw extruder with specially crafted yin and yang rotor profiles. The extruder is an extrusion device used for carrying out mixing and extrusion upon particle raw materials. An extruder main body arranged on a frame is composed of a machine head, a cylinder, a gas discharge port, a heating and cooling device, a yin rotor, a yang rotor, a feeding device, and an end cap. The gas discharge port is arranged on the cylinder on a place corresponding to a gas discharge section. The feeding device is arranged on the cylinder on a place corresponding to a melting section. The heating and cooling device is covered on the outer wall of the cylinder. The yin and yang rotors with a feeding section, the melting section, the gas discharge section, and a measuring section are composed of thread sections, kneading disc elements, and toothed disc elements. When the extruder operates, large mixing capacity, shearing capacity, plasticizing and kneading uniformity, and the like can be provided. The device can be widely applied in processing and molding of various materials such as plastic, rubber, food, and medicine preparation.

Owner:DALIAN UNIV OF TECH

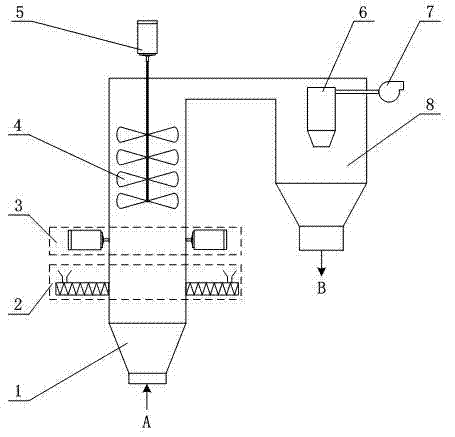

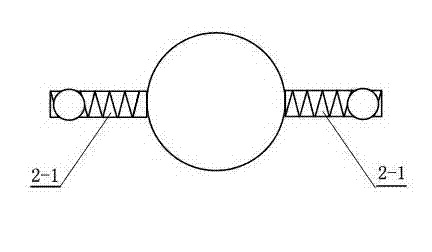

Mixing device for lithium battery positive electrode or negative electrode preparation materials

ActiveCN102513015AAvoid Purity LossOmit stop feedingCombination devicesCell electrodesFluidized bedBaghouse

The invention relates to a mixing device for lithium battery positive electrode or negative electrode preparation materials. The device is mainly composed of a fluidized bed, spiral feeders, vibration motors, spiral agitating blades, a spiral agitating motor and a settling chamber. Specifically, the spiral feeders are arranged at the lower parts of the fluidized bed; the middle part of the fluidized bed is provided with the vibration motors; the upper part inside the fluidized bed is equipped with the spiral agitating blades, the top of which is in connection with the spiral agitating motor; the top of the fluidized bed is connected to the settling chamber, the inside of which is provided with a cyclone separator and bag-type dust collector that is connected to a fan outside the settling chamber; the lower end of the fluidized bed is provided with an air vent, by which fluidized air that does not react with the lithium battery positive electrode or negative electrode preparation materials is introduced, and the lower end of the settling chamber is provided with a material outlet. The device of the invention is characterized by strong mixing ability, fast speed, low energy consumption, high degree of automation, and ability of sealing operation, so that it can better adapt to the requirements of large-scale industrial production.

Owner:济宁市无界科技有限公司

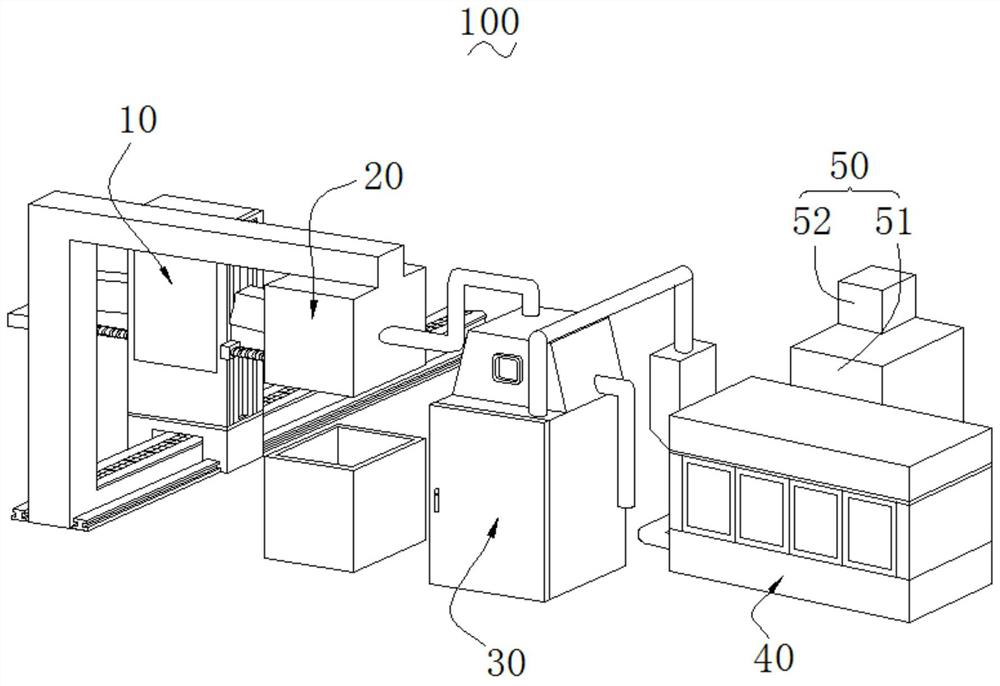

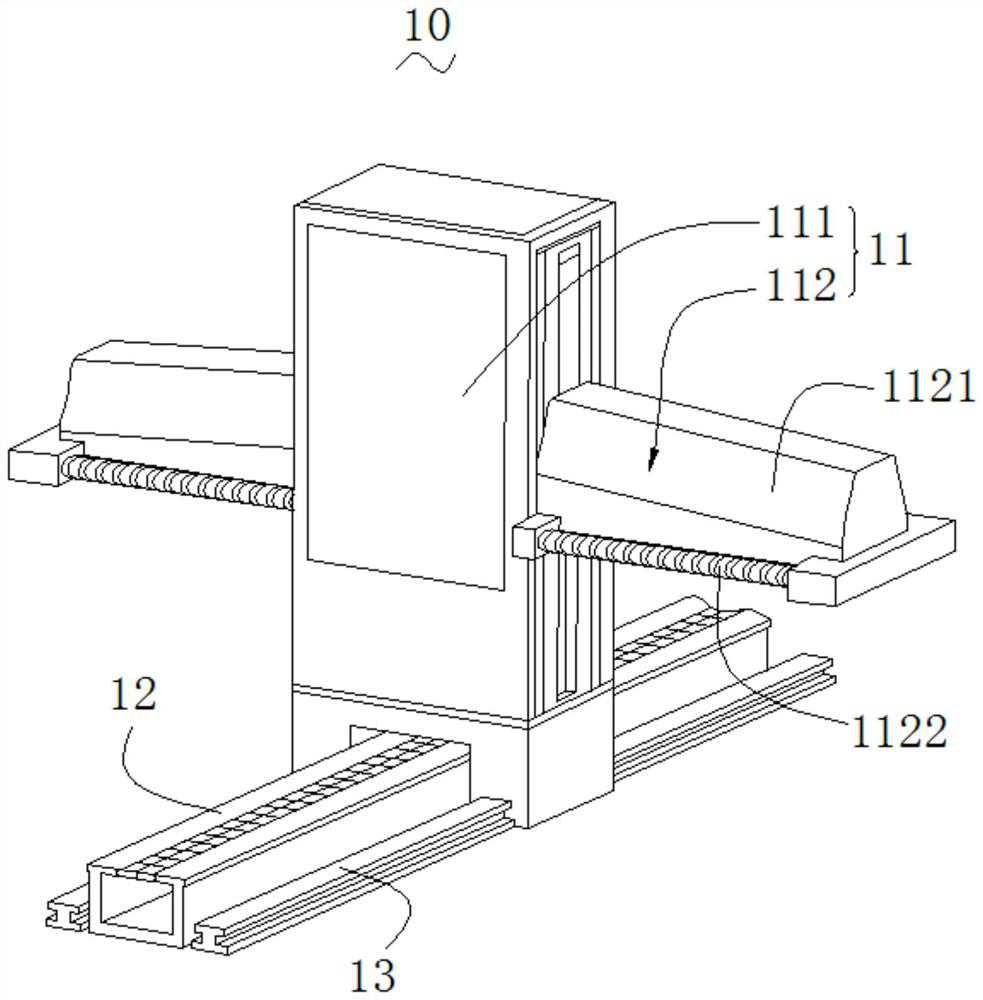

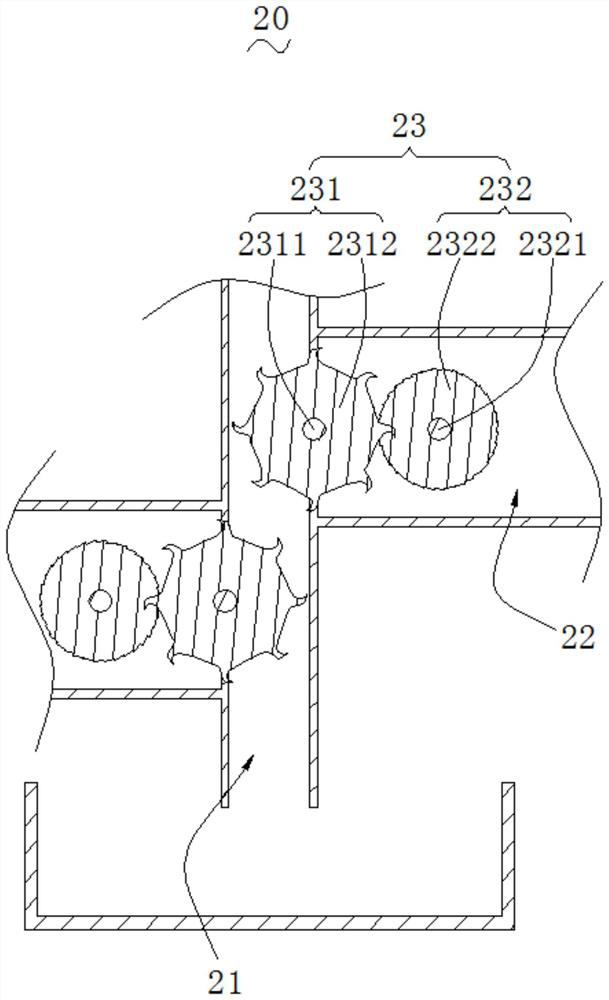

Intelligent blowing-carding production line and production method thereof

ActiveCN111850744ASave space in the workshopImprove economic efficiencyFibre mixingContinuous processingProcess engineeringManufacturing engineering

The invention discloses an intelligent blowing-carding production line. The intelligent blowing-carding production line comprises a cotton plucking device, a weight separation device, a fine cotton opening device, a multiple-bin cotton blending device and a cotton carding device, wherein the fine cotton opening device comprises mutually communicating dust removal bins and a first cotton storage bin communicating with the dust removal bins; the dust removal bins are used for initially opening raw cotton and strongly removing dust, and the first cotton storage bin is used for finely opening thecotton; the multiple-bin cotton blending device is used for blending the raw cotton and comprises a second cotton storage bin and a cotton blending bin, the second cotton storage bin is provided withmultiple parallel sub bin bodies, and the raw cotton enters the cotton blending bin through the multiple sub bin bodies; the cotton carding device comprises a cotton carding device body and a vacuum pumping device, the cotton carding device body communicates with the cotton blending bin, and the cotton carding device is used for carding the raw cotton; and the blended raw cotton is introduced intothe cotton carding device body under the action of the pressure difference between the cotton blending bin and the cotton carding device body. Compared with the prior art, the intelligent blowing-carding production line has the advantages of more reasonable structural design, high safety performance, stronger continuity in production and easiness in repair and replacement of parts. The inventionfurther provides a production method of the intelligent blowing-carding production line.

Owner:湖南科创纺织股份有限公司

Pyrite-containing heavy oil hydrogenation catalyst, and preparation and application thereof

ActiveCN103285930AStrong mixing abilityGood dispersion performanceOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon oil crackingFuel oilPyrite

The invention relates to a pyrite-containing heavy oil hydrogenation catalyst, and preparation and application thereof. The heavy oil hydrogenation catalyst is composed of pyrite powder and a dispersion medium, wherein the pyrite powder accounts for 5-70 wt% of the catalyst; and on the basis of the dispersion medium, the dispersion medium contains 80-99% of base oil, 0.05-10 wt% of surfactant, 0.05-10 wt% of solid thickening rheological agent and 0.5-2 wt% of oleic acid. The heavy oil hydrogenation catalyst provided by the invention has the advantages of high catalytic-activity solid content, favorable mixing capacity with heavy oil raw oil, and favorable catalytic effect in heavy oil hydrocracking or modification in a suspension bed or slurry-state bed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Reaction and extruding polymerizing method for nano size dispersion phase phenylethylene multiple block copolymer

The reaction and extrusion polymerizing process of linear styrene / conjugated diolefin block copolymer with nanometer level dispersed phase of special structure and performance includes the following steps: feeding styrene monomer and conjugated diolefin monomer in certain ratio to the first section of screw extruder, feeding polymerization initiator to the second section, and adding antioxidant and other modifiers to the screw extruder from one side and extruding out. The styrene block copolymer has outstanding percentage elongation at rupture and excellent mechanical performance. The presentinvention combines polymerization reaction and extrusion to shorten the production period to several minutes, and the whole process has no solvent added and thus no need of complicated solvent separation and purification. Therefore, the present invention has high production efficiency, low power consumption, low cost and less pollution.

Owner:EAST CHINA UNIV OF SCI & TECH

Modified rubber and preparation method thereof

Owner:PETROCHINA CO LTD

Reaction and extruding polymerizing method for nano size dispersion phase phenylethylene multiple block copolymer

InactiveCN1587292AElongation at breakThe mechanical properties are not inferiorPolymer scienceSolvent

The reaction and extrusion polymerizing process of linear styrene / conjugated diolefin block copolymer with nanometer level dispersed phase of special structure and performance includes the following steps: feeding styrene monomer and conjugated diolefin monomer in certain ratio to the first section of screw extruder, feeding polymerization initiator to the second section, and adding antioxidant and other modifiers to the screw extruder from one side and extruding out. The styrene block copolymer has outstanding percentage elongation at rupture and excellent mechanical performance. The present invention combines polymerization reaction and extrusion to shorten the production period to several minutes, and the whole process has no solvent added and thus no need of complicated solvent separation and purification. Therefore, the present invention has high production efficiency, low power consumption, low cost and less pollution.

Owner:EAST CHINA UNIV OF SCI & TECH

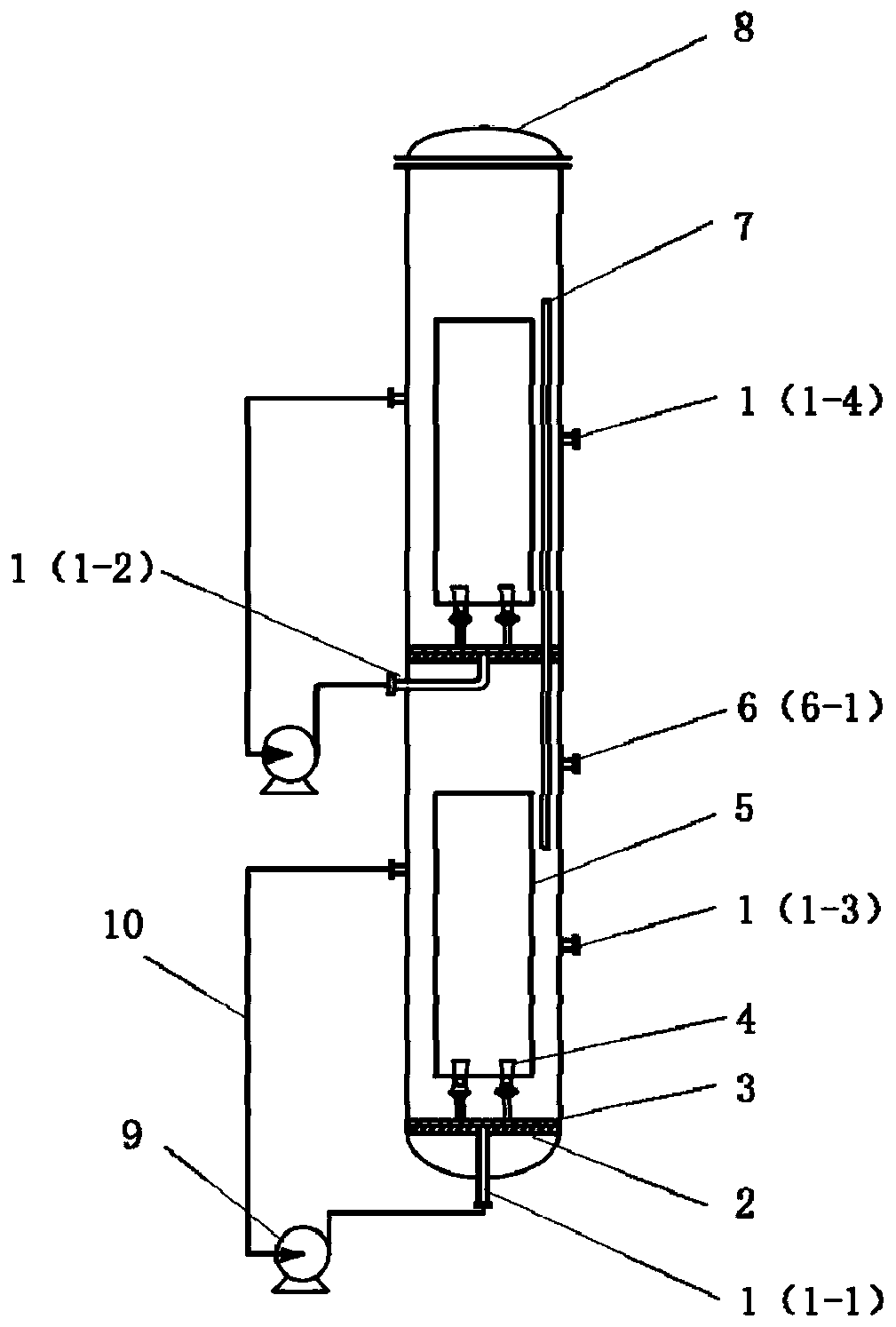

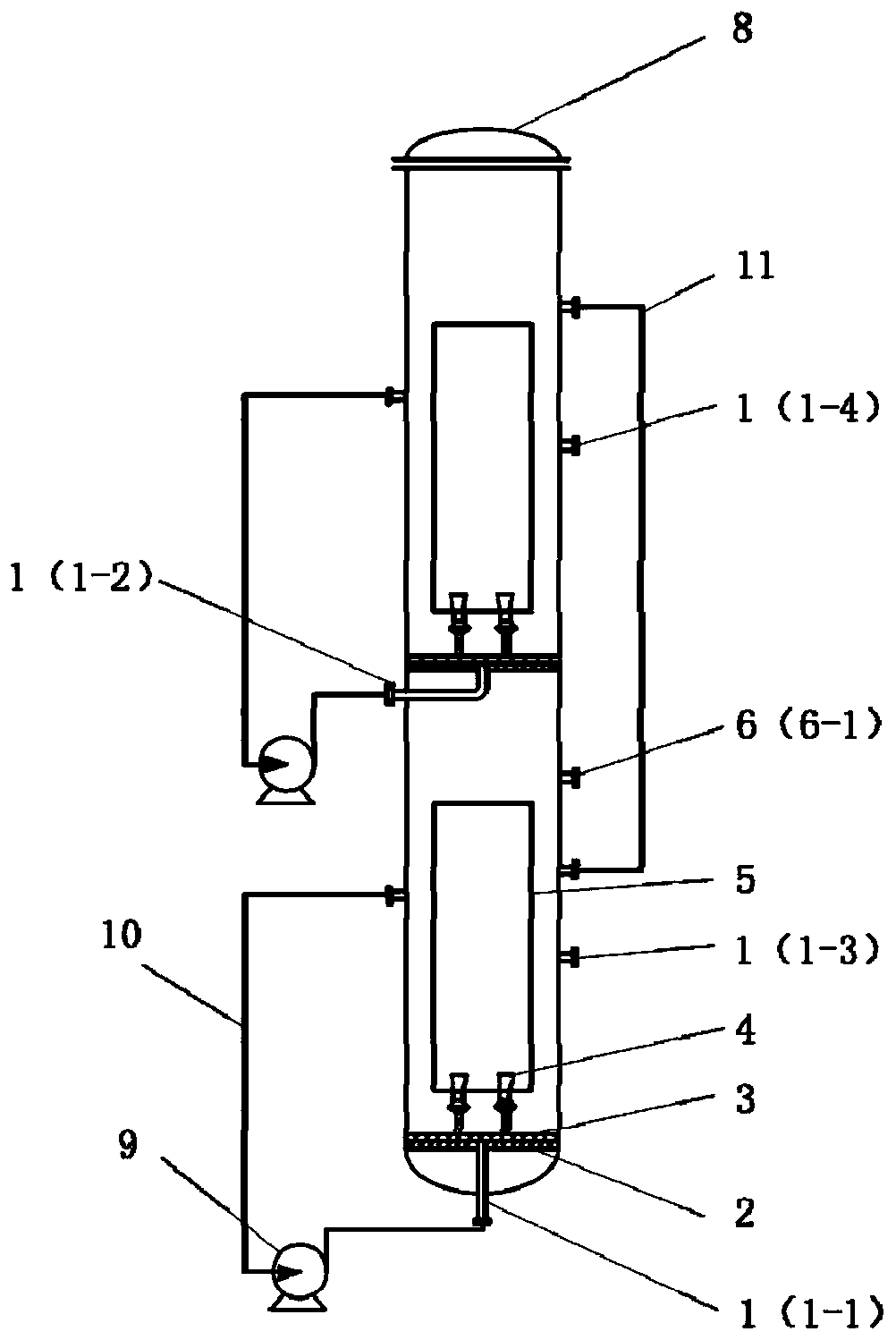

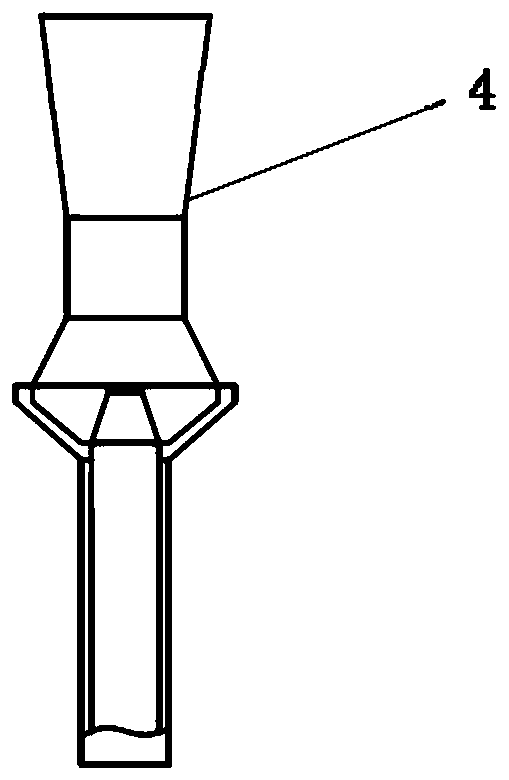

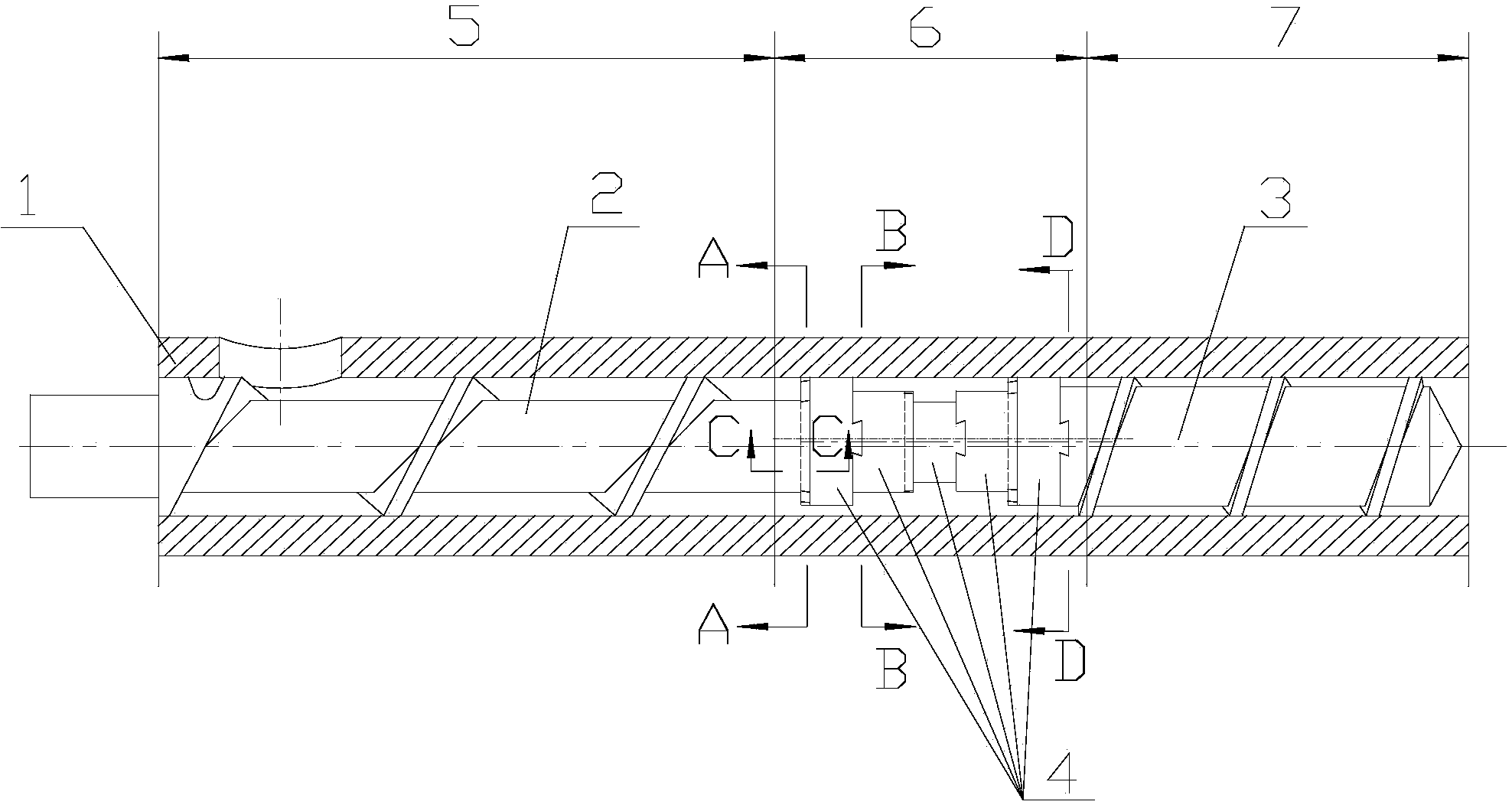

Strong mixing reactor

PendingCN111135778ASimple structureMix all phases evenlyFlow mixersTransportation and packagingMechanical engineeringMechanics

A strong mixing reactor relates to a strong mixing reactor suitable for liquid-liquid, liquid-solid and gas-liquid, gas-liquid-solid multiphase reaction processes with relatively low gas quantity. Thereactor is mainly and technically characterized in that energy is carried through liquid external circulation, and the circulation flow in a fluid is amplified in a mode of combined use of a venturimixed flow nozzle and an inner sleeve, so that each phase in the reactor is quickly, uniformly and strongly mixed; through the flow amplification effect of the coupling nozzle and the inner sleeve, mechanical stirring or gas carrying energy is replaced, and strong mixing of multi-phase fluids can be well achieved; and the reactor has the advantages of simple structure, uniform mixing of each phase, uniform particle suspension, high reactor efficiency and large fluid circulation flow in the reactor. According to the reactor, the effect of a multi-kettle series reactor is achieved through a simple structure, continuous operation of multiple reaction steps is achieved in a single reaction tower, the size of the reactor is reduced under the same reaction conversion rate, and the efficiency ofthe reactor is improved.

Owner:TSINGHUA UNIV

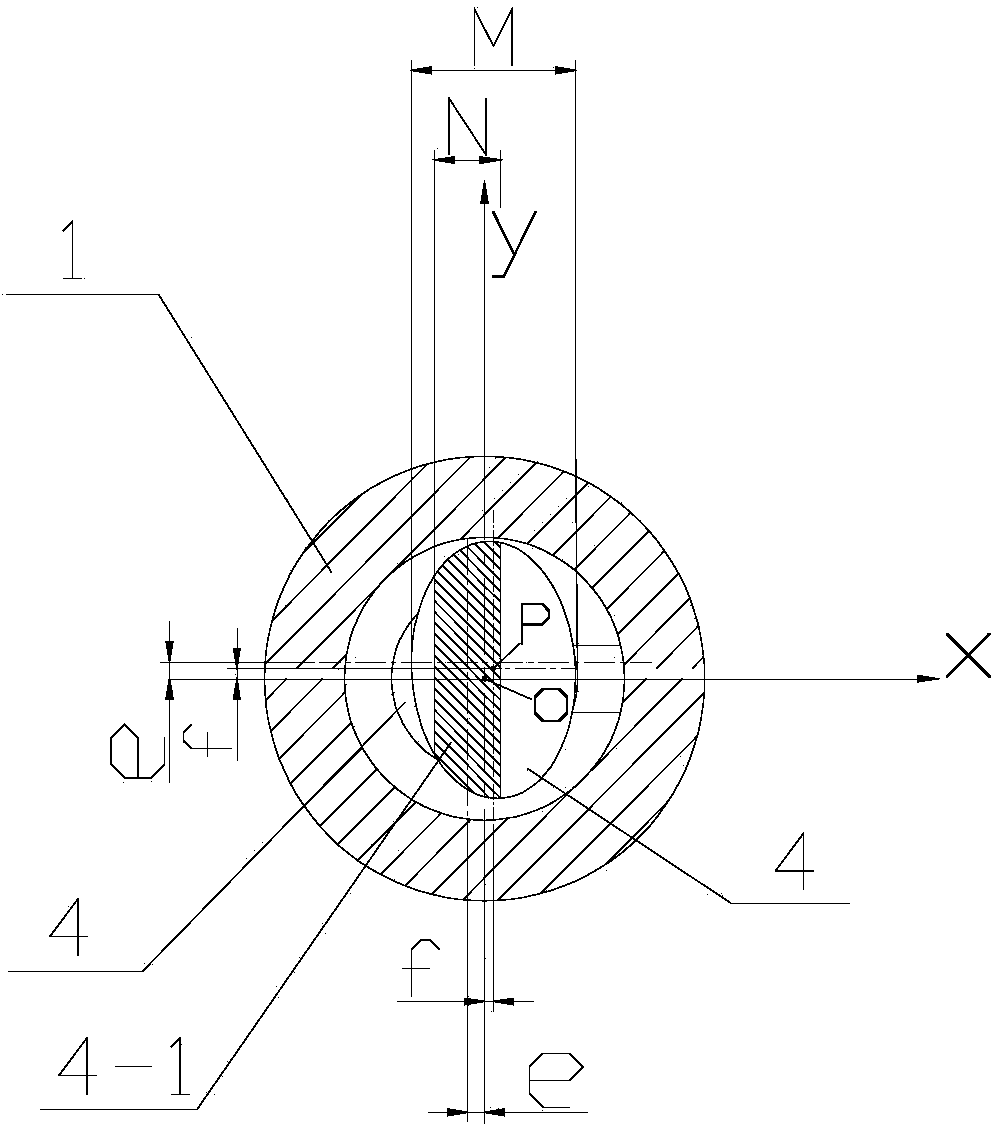

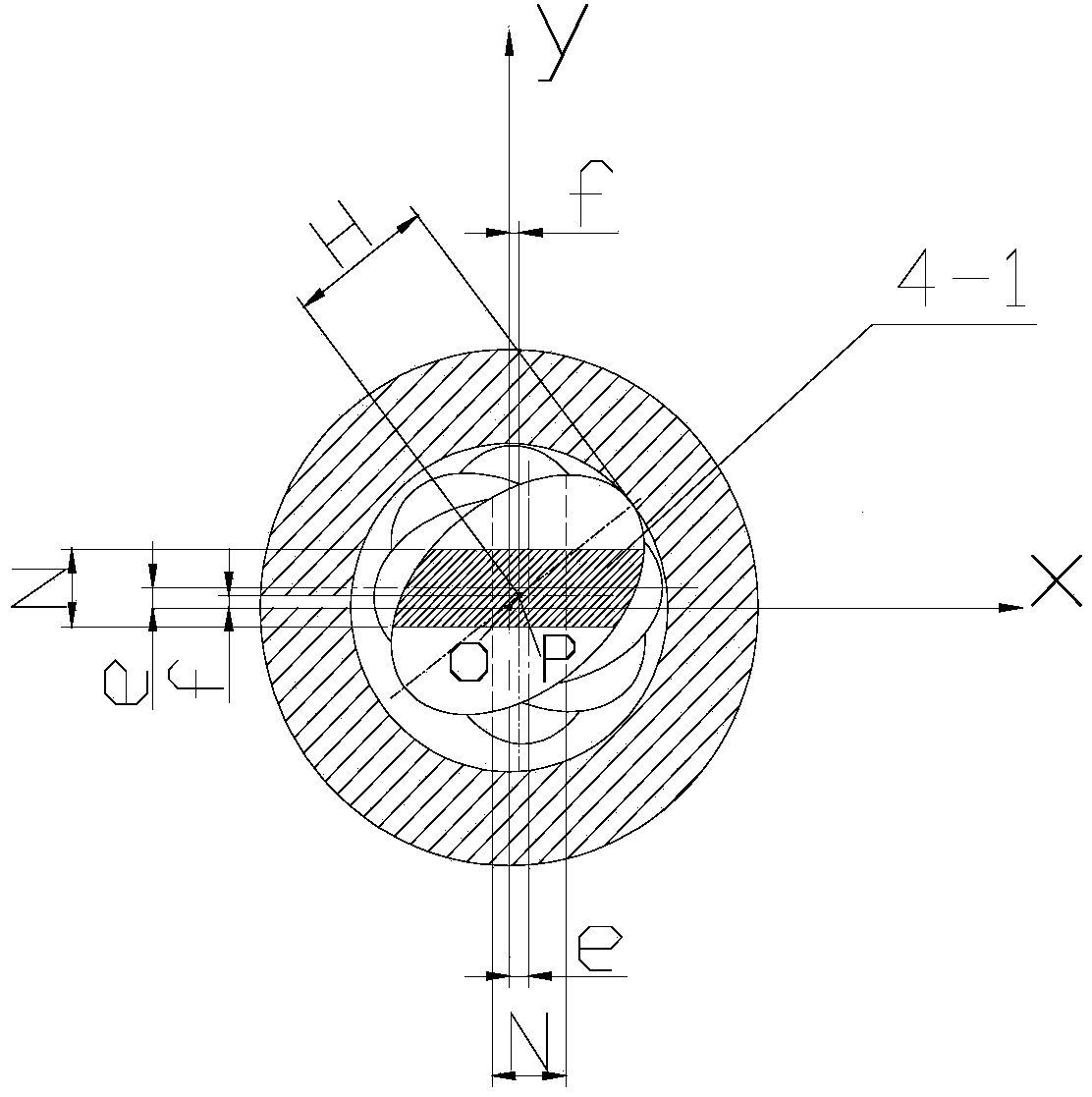

Sliding self-adaptive plasticizing extruding device and method

The invention discloses a sliding self-adaptive plasticizing extruding device and method. In the device, a screw rod mechanism comprises a forced feeding screw rod and a measuring extruding screw rod, which are coaxially arranged, wherein the forced feeding screw rod is connected with the measuring extruding screw rod through an eccentric rotating assembly; the eccentric rotating assembly comprises a plurality of eccentric rotating discs which are coaxially arranged, and every two adjacent eccentric rotating discs are engaged with each other through a sliding groove. The method comprises the following steps of transporting a material on a solid transporting section through the forced feeding screw rod, melting, plasticizing and mixing the material at a melt mixing section through the eccentric rotating assembly, and finally extruding and molding the material inn a measuring extruding section through the measuring extruding screw rod. Through the eccentric rotating mechanism, the melting efficiency can be increased through the alternating effect of the primary compression process and the secondary compression process of different eccentric rotating discs in the eccentric rotating mechanism, so that the self-adaptive high-efficient melting can be realized for different kinds of materials according to different machining yield requirements, the melting efficiency can be improved, organic combination of the mixing and melting process can be enhanced, and the mixing and heat conduction process can be enhanced.

Owner:GUANGDONG IND TECHN COLLEGE

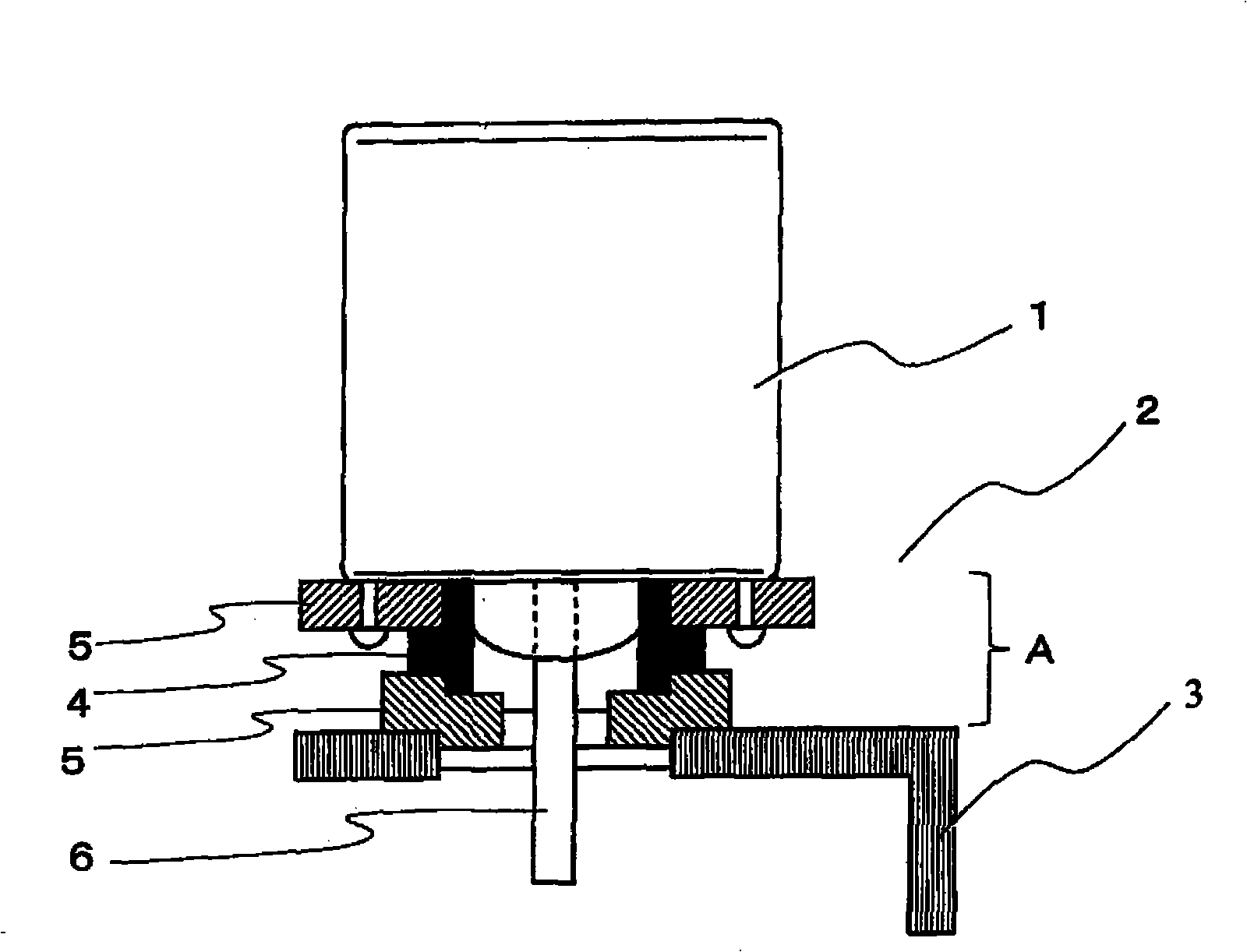

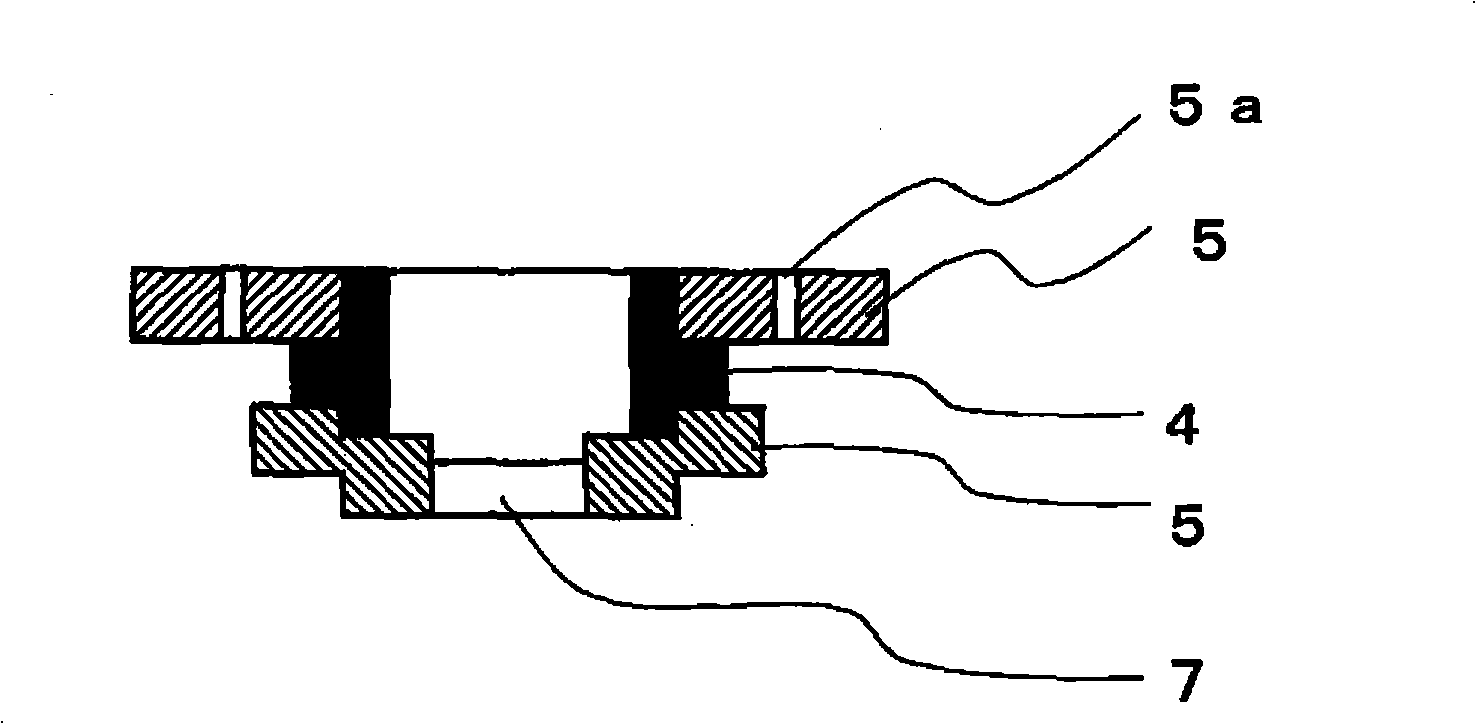

Vibration damping rubber and motor fixing mount

InactiveCN101343385AImprove thermal conductivityEasy to processNon-rotating vibration suppressionHeat resistanceEngineering

The invention provides a vibration-damping rubber and a motor-fixing mount, which exhibit good processability, and exhibit improved heat dissipation properties (thermal conductivity) while maintaining a low compression permanent deformation even at high temperatures, by blending specific amounts of acetylene black and graphite into NBR rubber. A vibration-damping rubber is characterized by comprising a NBR composition containing 10 to 120 parts by weight of graphite, 10 to 80 parts by weight of acetylene black and 100 parts by weight of NBR rubber. The NBR composition preferably has a hardness of 75 or less as measured according to JIS K6253 (using a durometer A), having a compression permanent deformation of 36% or less as measured after an aging and heat resistance test at 100 DEG C for 70 hours according to JIS R6262 (using a large test piece), having a tan delta (10 Hz) of 0.3 or more, and also having heat dissipation properties such that the measured value of a thermal conductivity test is 60 DEG C or more. And a motor-fixing mount preferably is composed of the vibration-damping rubber interposed between plates.

Owner:NOK CORP

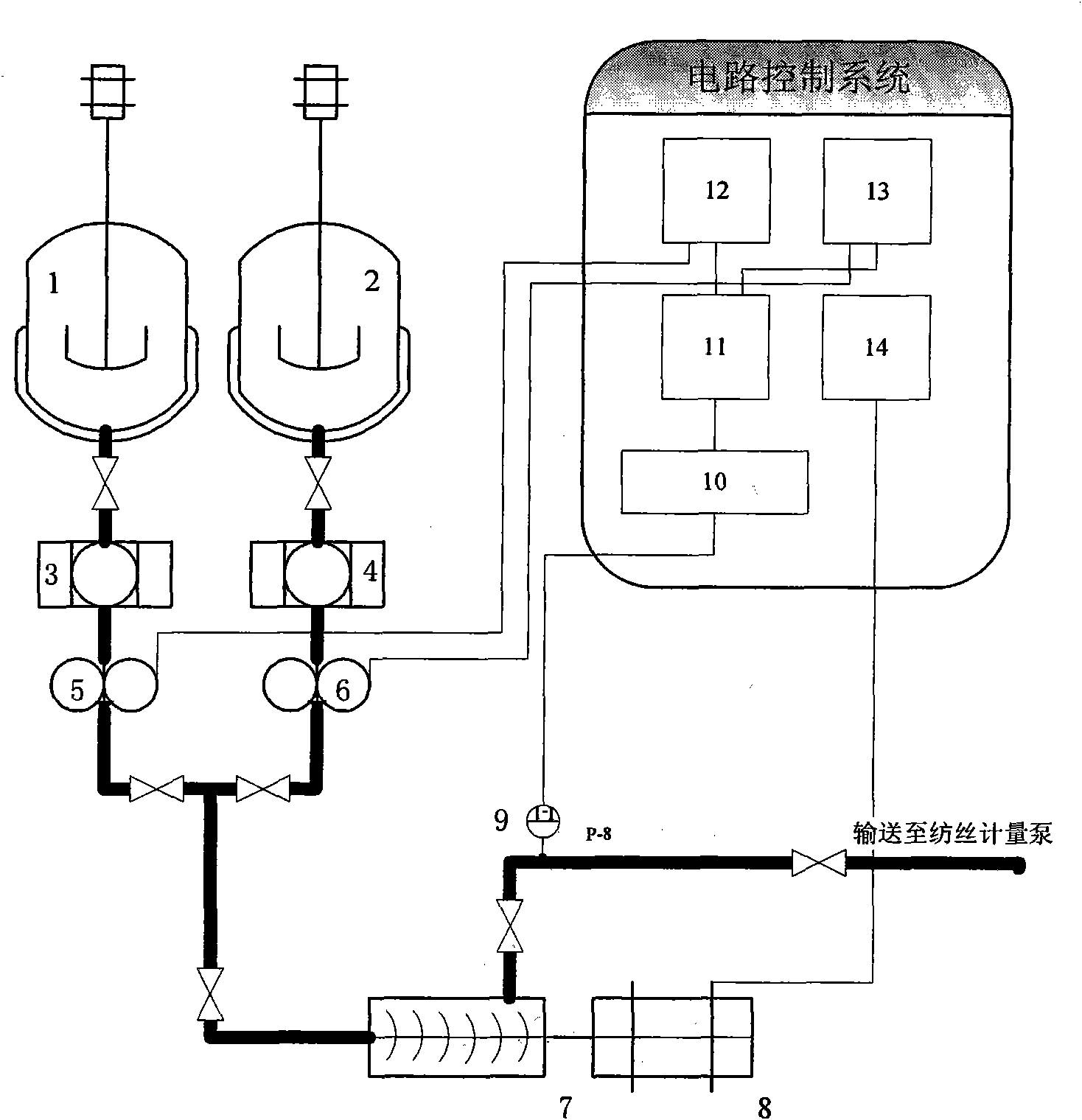

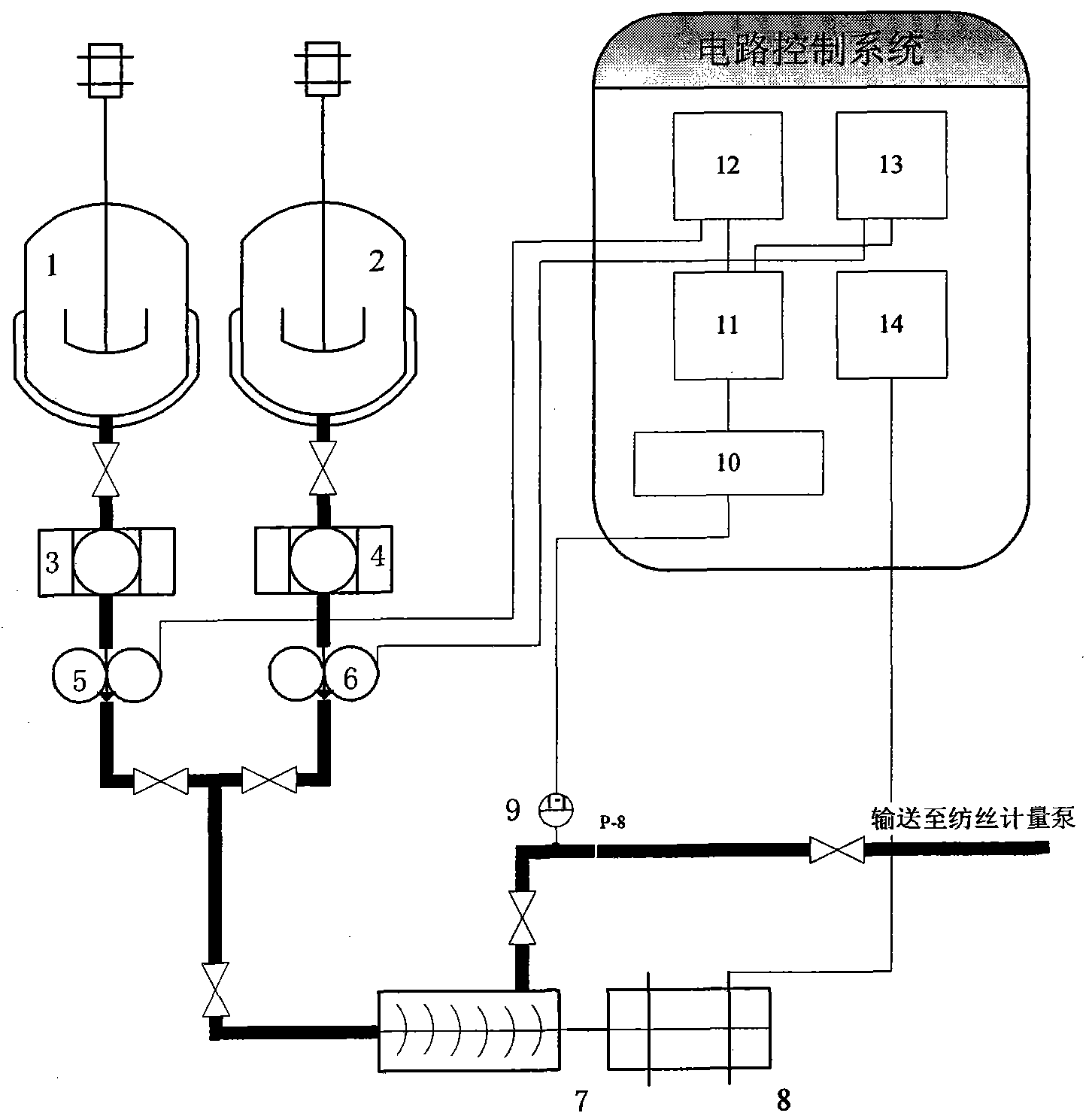

Wet spinning solution premixing and delivery device

InactiveCN102312295ASimple equipment structureEasy to assembleSpinning head liquid feederWet spinning methodsFrequency changerVariable-frequency drive

The invention discloses a wet spinning solution premixing and delivery device, which is characterized in that: the device sequentially utilizes a first charging barrel (1) and a second charging barrel (2) to be connected with the inlet end of a dynamic mixer through a first metering pump (3), a first filter (5), a second metering pump (4) and a second filter (6) respectively, wherein the outlet end of the dynamic mixer is connected with a spinning metering pump through a pipeline to spin; a motor (8) of the dynamic mixer is connected with a third frequency converter (14); and the pipeline is respectively connected with a first frequency converter (12) and a second frequency converter (13) through a valve, a pressure transmitter (9), a multifunctional controller (10) and a synchronous controller (11), and the first frequency converter and the second frequency converter are respectively connected with the first filter (5) and the second filter (6). The wet spinning solution premixing and delivery device has the advantages of simple structure, convenience in assembly, easiness in operation control and strong mixing capability, and is applicable to producing various wet spinning composite fibres, functional fibres, special fibres and various diversified fibre products.

Owner:SICHUAN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com