Spherical iron oxide and ultra-high density drilling fluid adopting spherical iron oxide as weighting agent

A technology of iron oxide and spherical shape, which is applied in the field of cementing and drilling fluids, which can solve the problems of low and serious wear and loss rate, and achieve the effects of reducing production costs, small wear and small friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

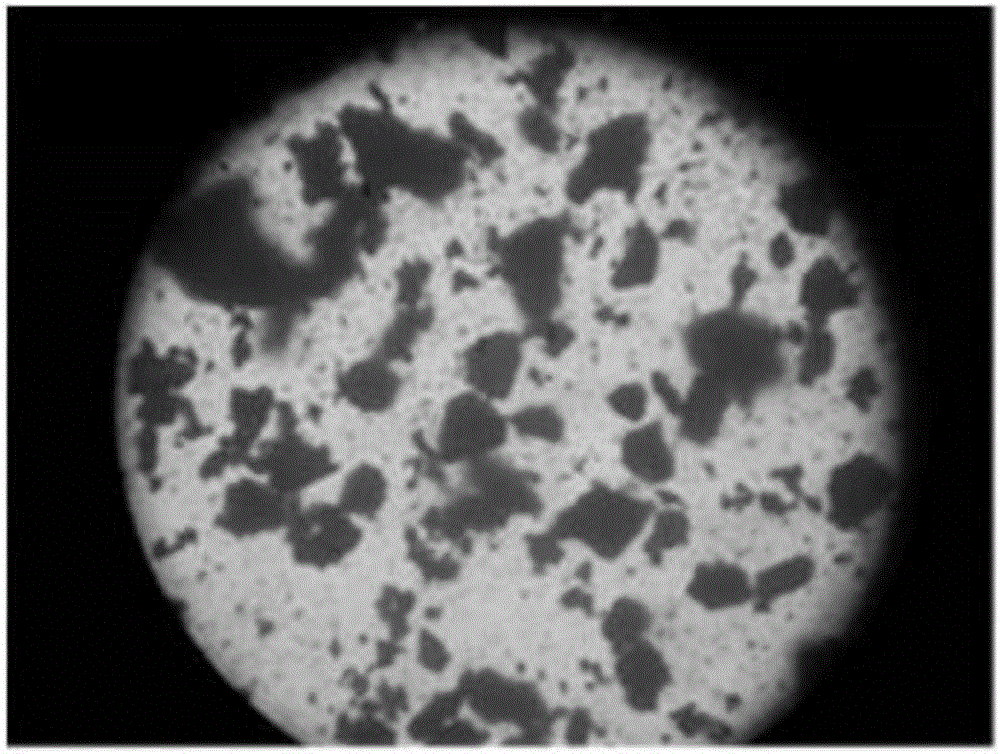

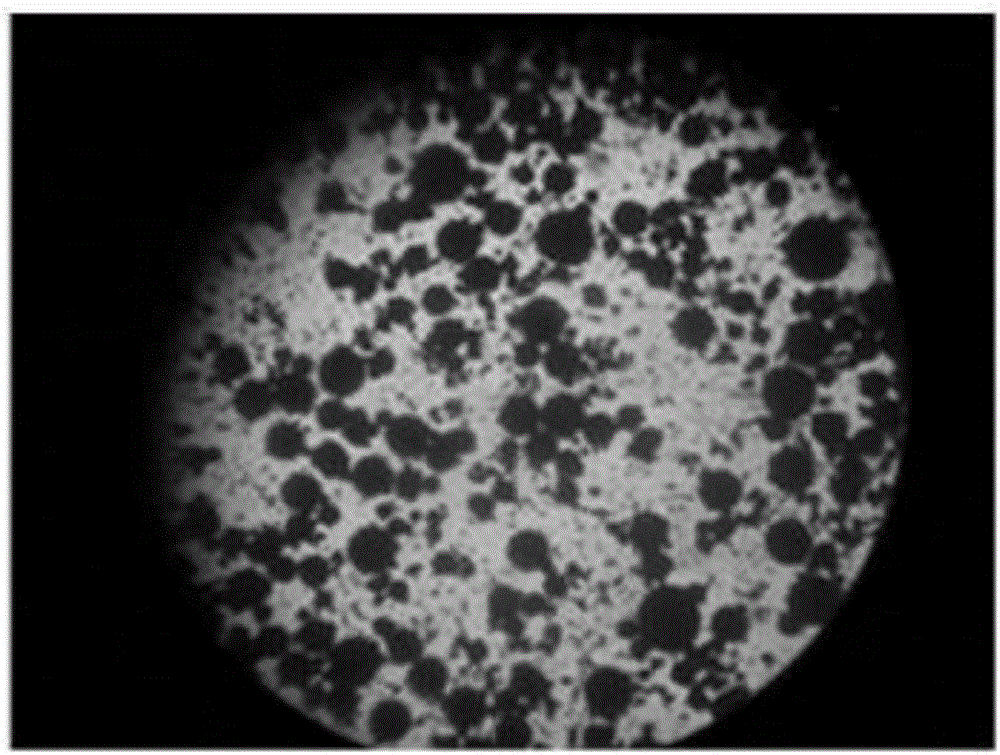

Image

Examples

Embodiment 1

[0041] A spherical iron oxide produced from hematite by high temperature flame melting. The hematite is transported with high-pressure oxygen to the flame of the main combustion oxygen and natural gas, the temperature reaches above 2400°C, the feeding speed of hematite is 20Hz, and the high-pressure oxygen delivery volume is 140m 3 / h, main fuel oxygen volume 550m 3 / h, natural gas consumption 250m 3 / h, the oxygen enrichment coefficient is 1.0; dispersed small droplets are formed after flame melting, quickly enter the cooling zone under the action of negative pressure, and condense into spherical small particles to obtain spherical iron oxide weighting agent, spherical iron oxide 200 mesh And 1800 mesh two sections, and mix according to the ratio of 1:0.1, the mixing time is 30min.

[0042] Ultra-high density drilling fluid with spherical iron oxide as weighting agent. The spherical iron oxide mixed above is used as a weighting agent to prepare ultra-high-density drilling ...

Embodiment 2

[0044]A spherical iron oxide produced from hematite by high temperature flame melting. The hematite is transported with high-pressure oxygen to the flame of the main combustion oxygen and natural gas, the temperature reaches above 2400°C, the feeding speed of hematite is 35Hz, and the high-pressure delivery oxygen volume is 190m 3 / h, main fuel oxygen volume 650m 3 / h, natural gas consumption 320m 3 / h, the oxygen enrichment coefficient is 1.3; dispersed small droplets are formed after flame melting, quickly enter the cooling zone under the action of negative pressure, and condense into spherical small particles to obtain spherical iron oxide weighting agent, spherical iron oxide 220 mesh and two sections of 2000 mesh, and mix at a ratio of 1:0.3, and the mixing time is 40 minutes.

[0045] Ultra-high density drilling fluid with spherical iron oxide as weighting agent. The spherical iron oxide mixed above is used as a weighting agent to prepare ultra-high density drilling f...

Embodiment 3

[0047] A spherical iron oxide produced from hematite by high temperature flame melting. The hematite is transported with high-pressure oxygen to the flame of the main combustion oxygen and natural gas, the temperature reaches above 2400°C, the feeding speed of hematite is 25Hz, and the high-pressure oxygen delivery volume is 180m 3 / h, main fuel oxygen volume 600m 3 / h, natural gas consumption 300m 3 / h, the oxygen enrichment coefficient is 1.1; dispersed small droplets are formed after flame melting, quickly enter the cooling zone under the action of negative pressure, and condense into spherical small particles to obtain spherical iron oxide weighting agent, spherical iron oxide 210 mesh And 1900 mesh two sections, and mix according to the ratio of 1:0.2, the mixing time is 35min.

[0048] Ultra-high density drilling fluid with spherical iron oxide as weighting agent. The spherical iron oxide mixed above is used as a weighting agent to prepare ultra-high density drilling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com