Ultrahigh-density drilling fluid

An ultra-high-density drilling fluid technology, applied in the field of drilling fluid, can solve the problems of drill bit and pump wear, achieve the effects of reducing wear, high filling rate, and ensuring abutment strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

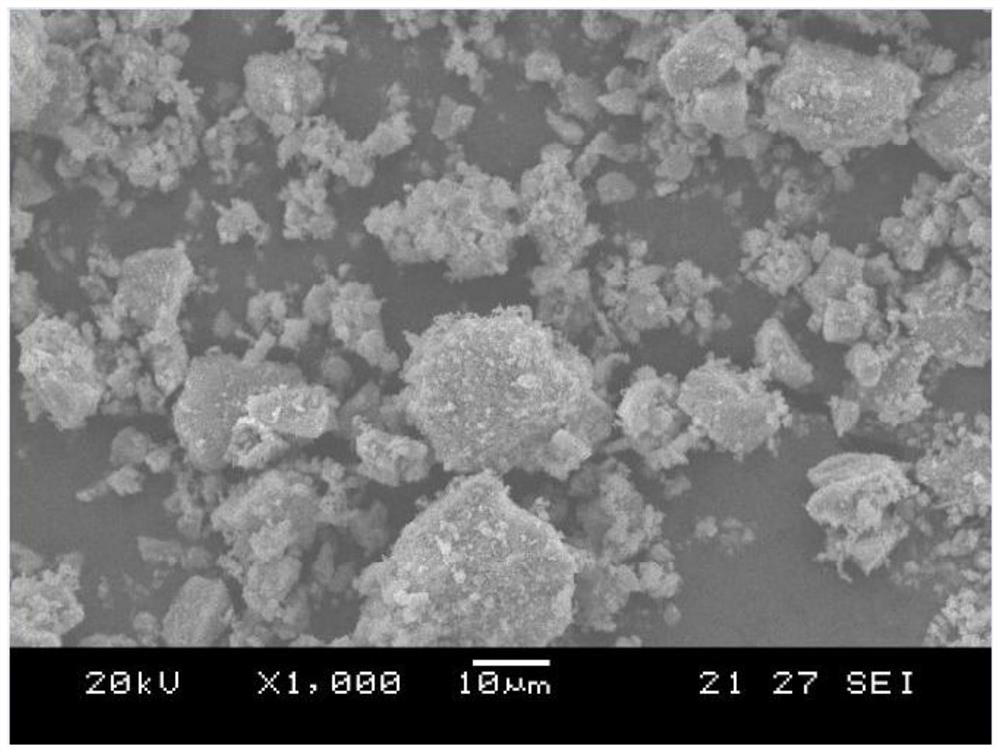

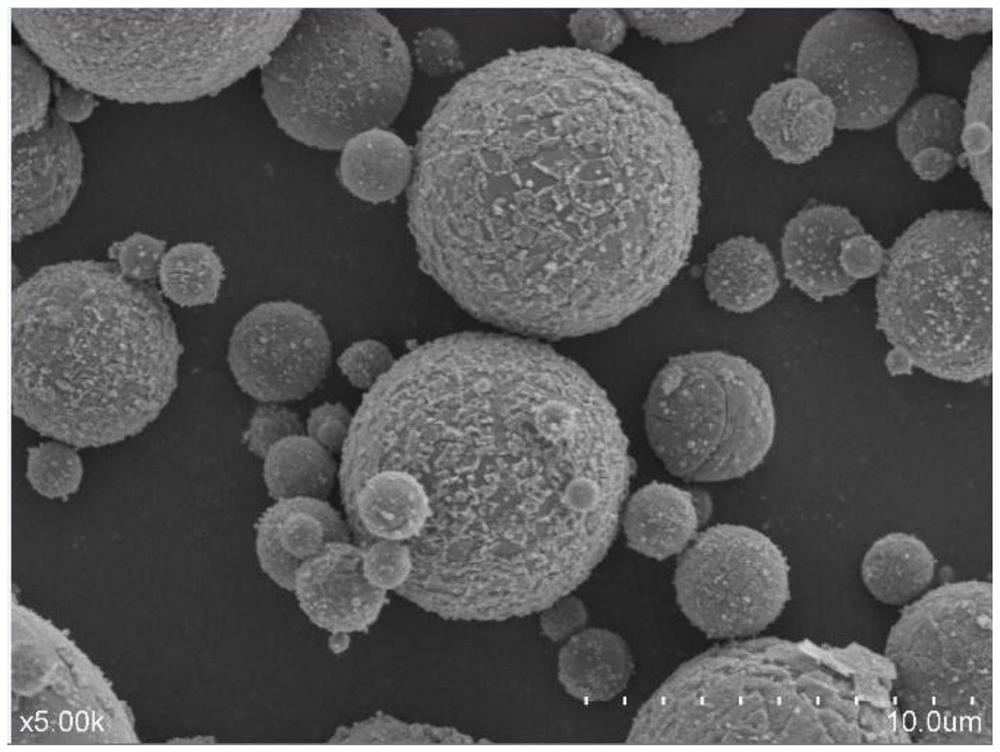

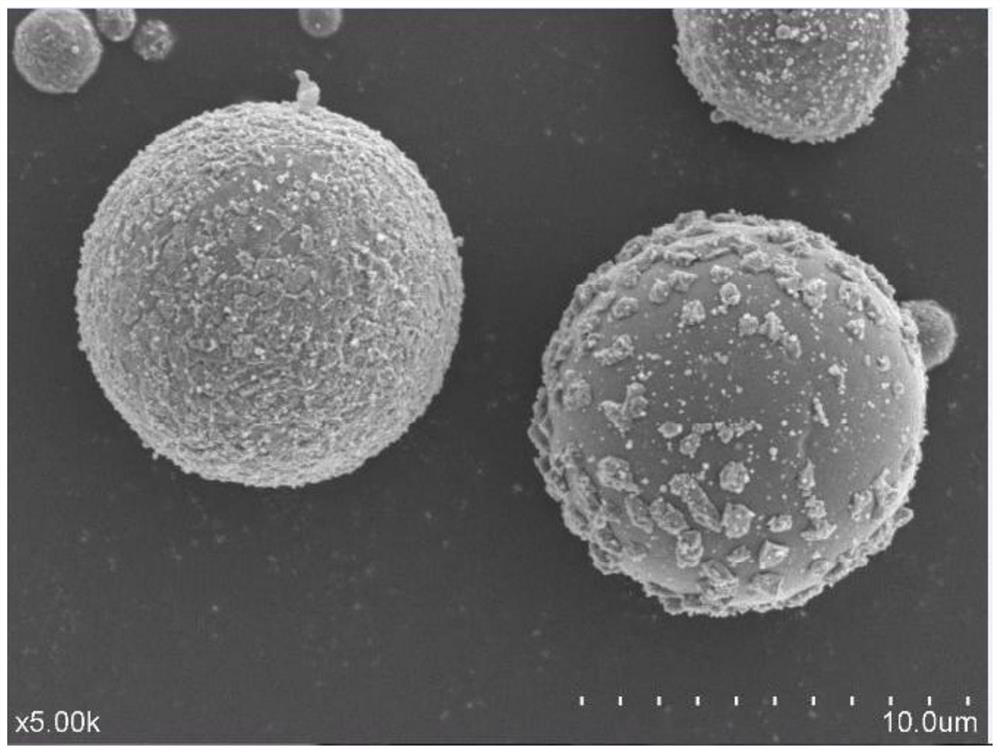

[0041] see Figure 1-3 , the present invention provides a kind of technical scheme:

[0042] An ultra-high density drilling fluid is composed of the following components by weight: 50 parts of weighting agent modified spherical iron oxide, 20 parts of cement, 20 parts of water, 0.1 part of defoamer, 0.15 part of solid fluid loss reducer, 0.1 part of liquid water loss reducer, 0.2g of dispersant, 1g of retarder, 0.05 part of coarse silica fume, 0.1 part of expansion agent, and 0.1g of anti-channeling enhancer;

[0043] The preparation method of the modified spherical iron oxide specifically comprises the following steps:

[0044]S101. Dissolve hematite powder and modified polyethylene glycol in distilled water, add ammonium carbonate solution and sodium dodecyl sulfonate solution slowly dropwise under ultrasonic vibration, after obtaining colloid, add distilled water and sewage ethanol After alternate washing and vacuum drying for a period of time, nano-scale modified spheric...

Embodiment 2

[0049] Different from Embodiment 1, this embodiment also discloses an ultra-high density drilling fluid, which is composed of the following components by weight: 65 parts of weighting agent modified spherical iron oxide, 40 parts of cement, 24 parts of water, 0.15 part of defoamer, 0.20 part of solid water loss reducer, 0.2 part of liquid water loss reducer, 15g of dispersant, 15g of retarder, 0.8 part of coarse silicon powder, 0.2 part of expansion agent, and 0.2g of anti-channeling enhancer;

[0050] The preparation method of the modified spherical iron oxide specifically comprises the following steps:

[0051] S101. Dissolve hematite powder and modified polyethylene glycol in distilled water, add ammonium carbonate solution and sodium dodecyl sulfonate solution slowly dropwise under ultrasonic vibration, after obtaining colloid, add distilled water and sewage ethanol After alternate washing and vacuum drying for a period of time, nano-scale modified spherical iron oxide par...

Embodiment 3

[0056] What is different from Examples 1-2 is that this example discloses an ultra-high density drilling fluid, which is composed of the following components by weight: 80 parts of weighting agent modified spherical iron oxide, 60 parts of cement, and 28 parts of water. , 0.2 part of defoamer, 0.25 part of solid water loss reducer, 0.3 part of liquid water loss reducer, 25g of dispersant, 10g of retarder, 0.15 part of coarse silicon powder, 0.3 part of expansion agent, and 0.3g of anti-channeling enhancer;

[0057] The preparation method of the modified spherical iron oxide specifically comprises the following steps:

[0058] S101. Dissolve hematite powder and modified polyethylene glycol in distilled water, add ammonium carbonate solution and sodium dodecyl sulfonate solution slowly dropwise under ultrasonic vibration, after obtaining colloid, add distilled water and sewage ethanol After alternate washing and vacuum drying for a period of time, nano-scale modified spherical i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com