A high-temperature resistant seawater-based polymer fracturing fluid capable of continuous blending and a preparing method thereof

A fracturing fluid, seawater-based technology, applied in drilling compositions, chemical instruments and methods, etc., to achieve the effects of increasing hydrodynamic volume, less formation damage, and increasing dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Evaluation of the antibacterial stability of the high-temperature-resistant seawater-based polymer fracturing fluid that can be continuously mixed provided by the present invention:

[0053] The formulation of the fracturing fluid used in the experiment is shown in Table 1.

[0054] The main ions and total salinity in the simulated seawater used in the experiment are as follows:

[0055] Ca 2+ 1410mg / L, Mg 2+ 1310mg / L, Na + 13800mg / L, K + 2390mg / L, SO 4 2- 1740mg / L, HCO 3 - 152mg / L, Cl - 19700mg / L, total salinity 45000mg / L.

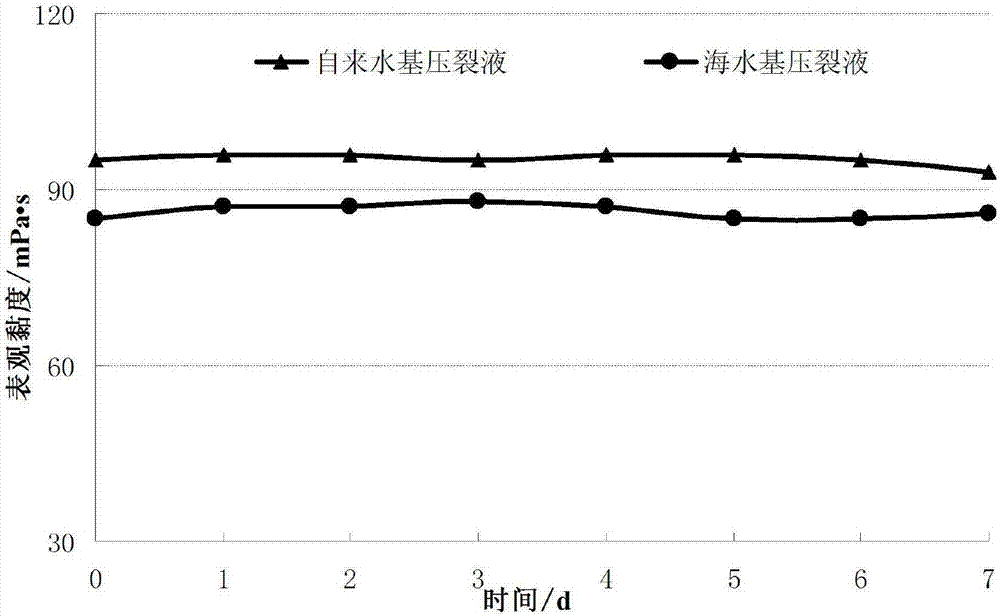

[0056] The fracturing fluid was prepared with tap water and seawater respectively, and placed at 30°C for a week, and the fracturing fluid was set at 170s with a six-speed rotational viscometer. -1 Test its apparent viscosity change under the following conditions and record, the test results are shown in figure 1 . It can be seen that no matter whether it is prepared with tap water or seawater, the apparent viscosity of the fracturing f...

Embodiment 2

[0060] The formulation optimization scheme of the high-temperature-resistant seawater-based polymer fracturing fluid that can be continuously mixed at 90°C and 140°C provided by the present invention:

[0061] A seawater-based fracturing fluid formula suitable for 90°C and 140°C reservoir fracturing was obtained through a large number of laboratory experiments and simulations. The components and dosage are shown in Table 2 and Table 3.

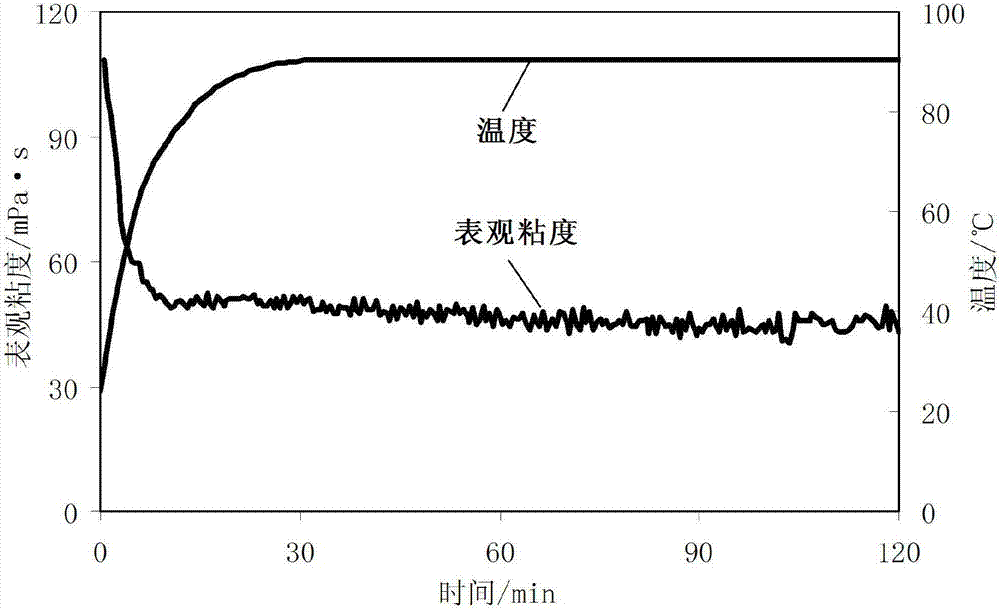

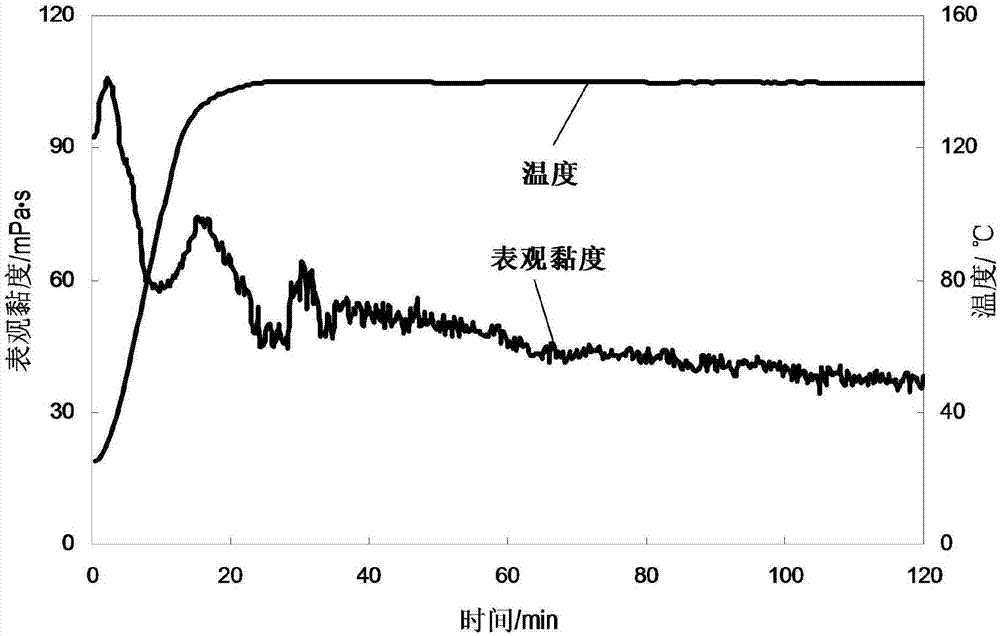

[0062] According to SY / T5107—2005 "Water-based Fracturing Fluid Performance Evaluation Method", the temperature and shear resistance tests were carried out on the 90℃ and 140℃ seawater-based fracturing fluid formulations.

[0063] Experimental equipment: Haake RS6000 rheometer, rotating cylinder test system, using rotor PZ38;

[0064] Test conditions: shear rate 170s -1 , the experiment temperature is 90°C and 140°C, and the experiment time is 120min.

[0065] The experimental results of the temperature and shear resistance tests of seawater...

Embodiment 3

[0071] The formulation optimization scheme for continuous mixing and fracturing construction of the continuous mixing high temperature resistant seawater-based polymer fracturing fluid provided by the present invention:

[0072] Since continuous mixing has high requirements on the swelling performance of fracturing fluid (the swelling time is less than 10 minutes, and the thickener can only swell about 80% in a short period of time), the laboratory test must use the form of online simulation to optimize the construction formula. The specific method is as follows :

[0073] Start the rheometer and adjust the program, set the experimental conditions, prepare for the temperature and shear resistance test of the fracturing fluid, prepare the seawater-based fracturing fluid base fluid according to the designed formula, stir for 10 minutes, add the auxiliary synergist and stir evenly , Immediately transfer to the rheometer rotating cylinder test system, start the temperature and she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com