Preparation process and reaction device for synthesizing sodium dodecyl diphenyl ether disulfonate

A technology of dodecyl diphenyl ether and sodium disulfonate, which is applied in the preparation of sulfonate, the preparation of sulfonic acid, and the chemical/physical/physical-chemical stationary reactor, etc., can solve the problem that the molar ratio cannot be satisfied and increase production Cost, affecting product appearance and other issues, to avoid local peroxidation, avoid volatilization, and reduce viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

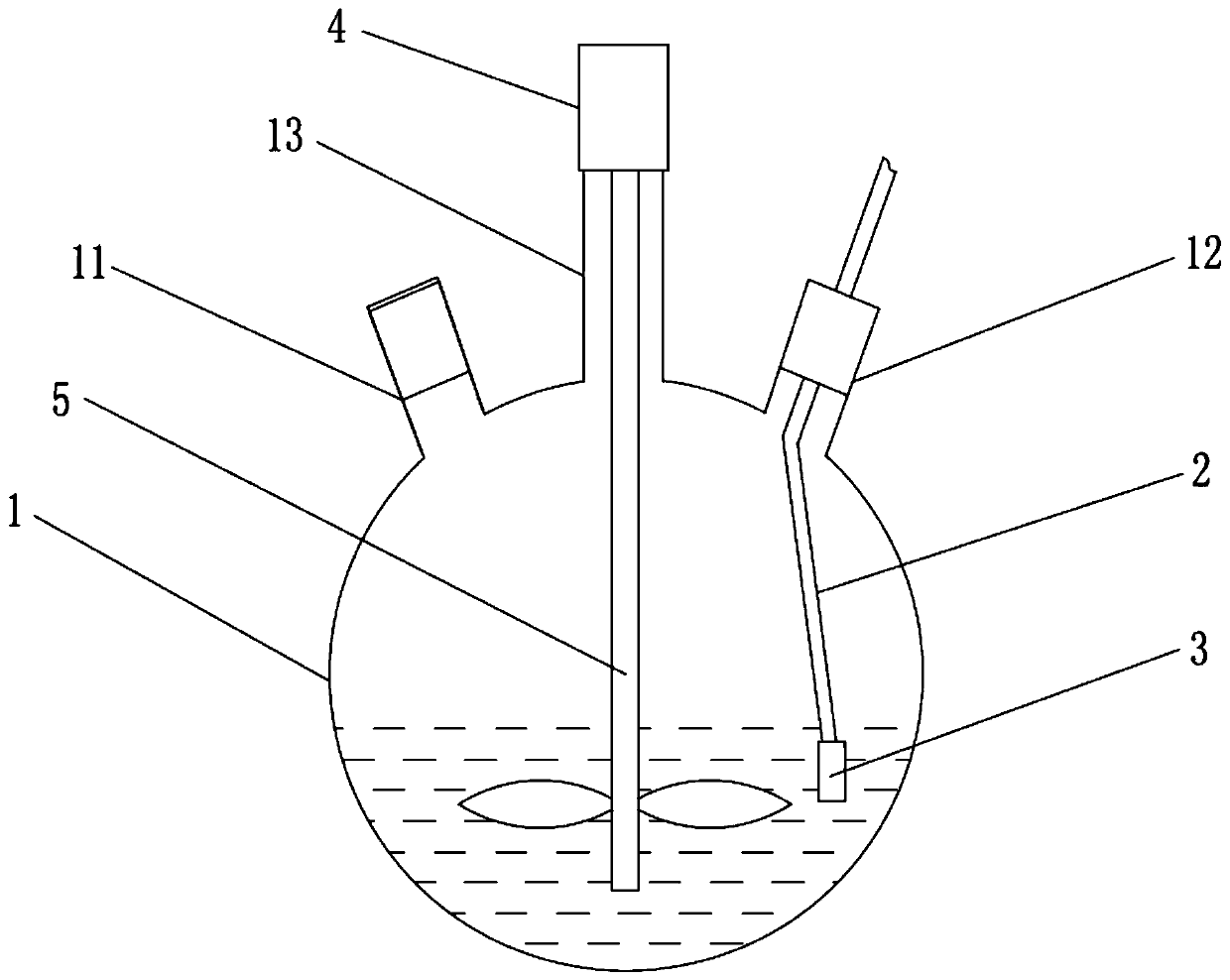

[0026] Such as figure 1 The shown reaction device includes a reaction kettle 1, a stirring device, a nozzle 3 and a peristaltic pump (not shown in the figure). The reactor has a reactant feed port 11, a sulfur trioxide feed port 12, and an installation port 13 at the top of the reactor 1 for installing a stirring device. Stirring device comprises motor 4 and stirring paddle 5. The motor 4 is installed on the installation port 13 , the stirring paddle 5 is located in the reactor 1 , and one end with the paddle extends close to the bottom of the reactor 1 . The nozzle 3 is located in the reactor 1 and close to the bottom of the reactor 1 . The nozzle 3 is connected with the sulfur trioxide raw material device (not shown in the figure) through the feed pipe 2 and the peristaltic pump. The nozzle is made of corrosion-resistant materials, such as polytetrafluoroethylene, 316L stainless steel, high-silicon cast iron, corrosion-resistant alloy materials, etc. The feed pipe 2 pass...

Embodiment 2

[0029] Place the reaction kettle in the water bath of the water bath. 71.4 g of dodecyl diphenyl ether and 300 g of dichloromethane were added to the reactor 1 from the reactant feed port 11 in advance. Take 40.5 grams of sulfur trioxide according to the molar ratio of dodecyl diphenyl ether to sulfur trioxide 1:2.2, and add 532 grams of dichloromethane to prepare a dichloromethane solution of sulfur trioxide with a mass fraction of 7%. The reaction kettle 1 was placed in a water bath, the temperature of the water bath was controlled at 40°C, and it was transported to the nozzle 3 according to the feeding speed of the peristaltic pump 40r / min for spray sulfonation. After the sulfonation was completed, the reaction system was kept warm and aged for 1 hour, and samples were taken to measure the acid value.

[0030] Add an appropriate amount of sodium hydroxide solution to the reaction system for neutralization, the volume of the sodium hydroxide solution is 8 times the volume o...

Embodiment 3

[0032] Place the reaction kettle in the water bath of the water bath. Add 74.07 g of dodecyl diphenyl ether and 300 g of dichloromethane in advance. Prepare 40.1 grams of sulfur trioxide according to the molar ratio of 1:2.1, and add 530 grams of solvent to prepare a 7% dichloromethane solution. The reaction kettle 1 was placed in a water bath, the temperature of the water bath was controlled at 30° C., and the spray sulfonation was carried out at a feeding speed of 50 r / min by a peristaltic pump. After the sulfonation is completed, heat preservation and aging for 1 hour, and take samples to measure the acid value.

[0033] Add an appropriate amount of sodium hydroxide solution to the reaction system for neutralization, the volume of the sodium hydroxide solution is 8 times the volume of the reaction system, extract and filter, and vacuum-dry the obtained aqueous phase to obtain the crude sodium salt of dodecyl diphenyl ether disulfonate product, then dissolve the crude prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com