Twin-screw extruder with specially crafted yin and yang rotor profiles

A twin-screw extruder and rotor profile technology, applied in the field of extrusion equipment, can solve the problems of distribution mixing capacity, uniformity of plasticizing and mixing, shearing force can not meet the requirements, processing difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

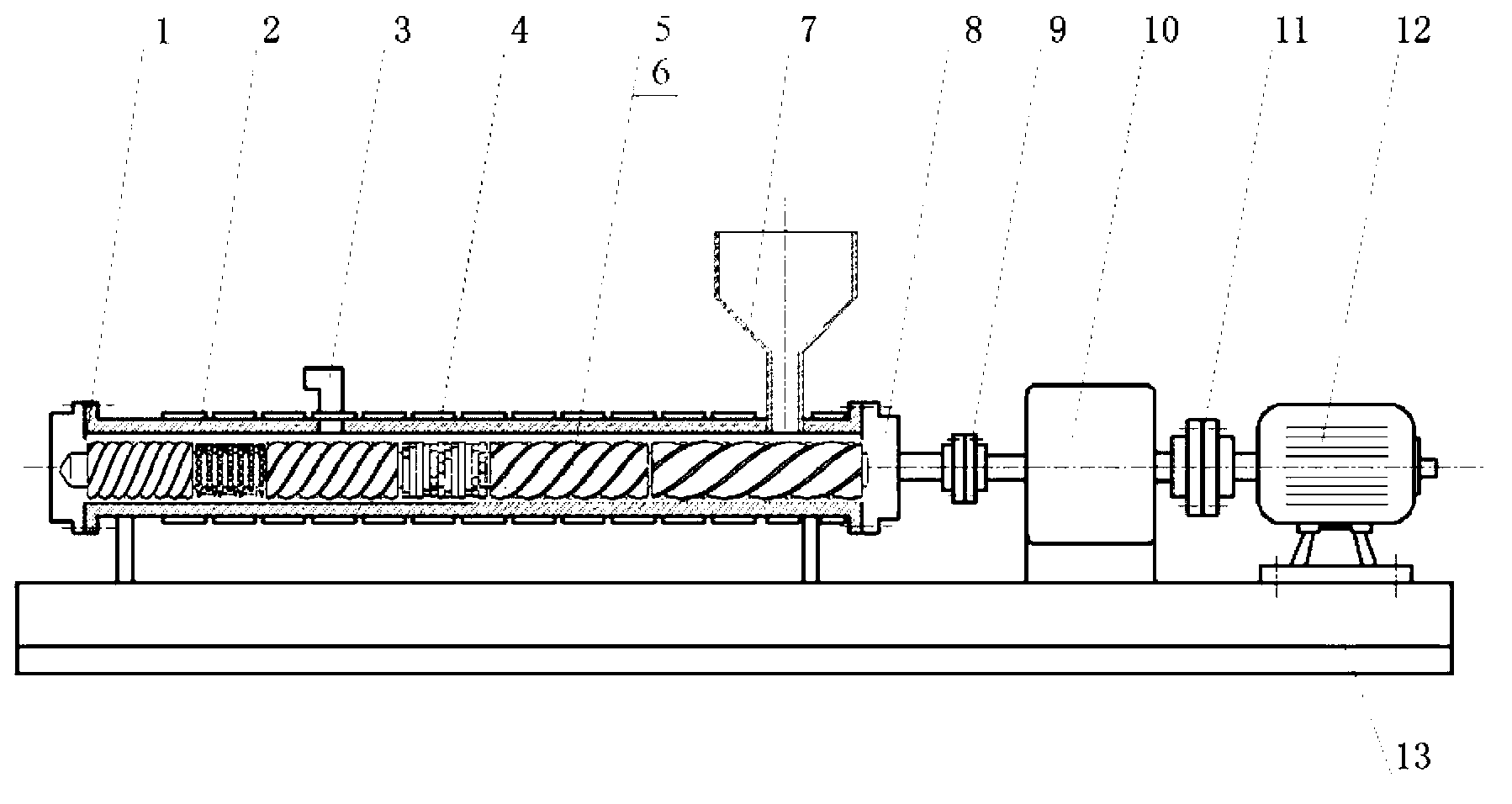

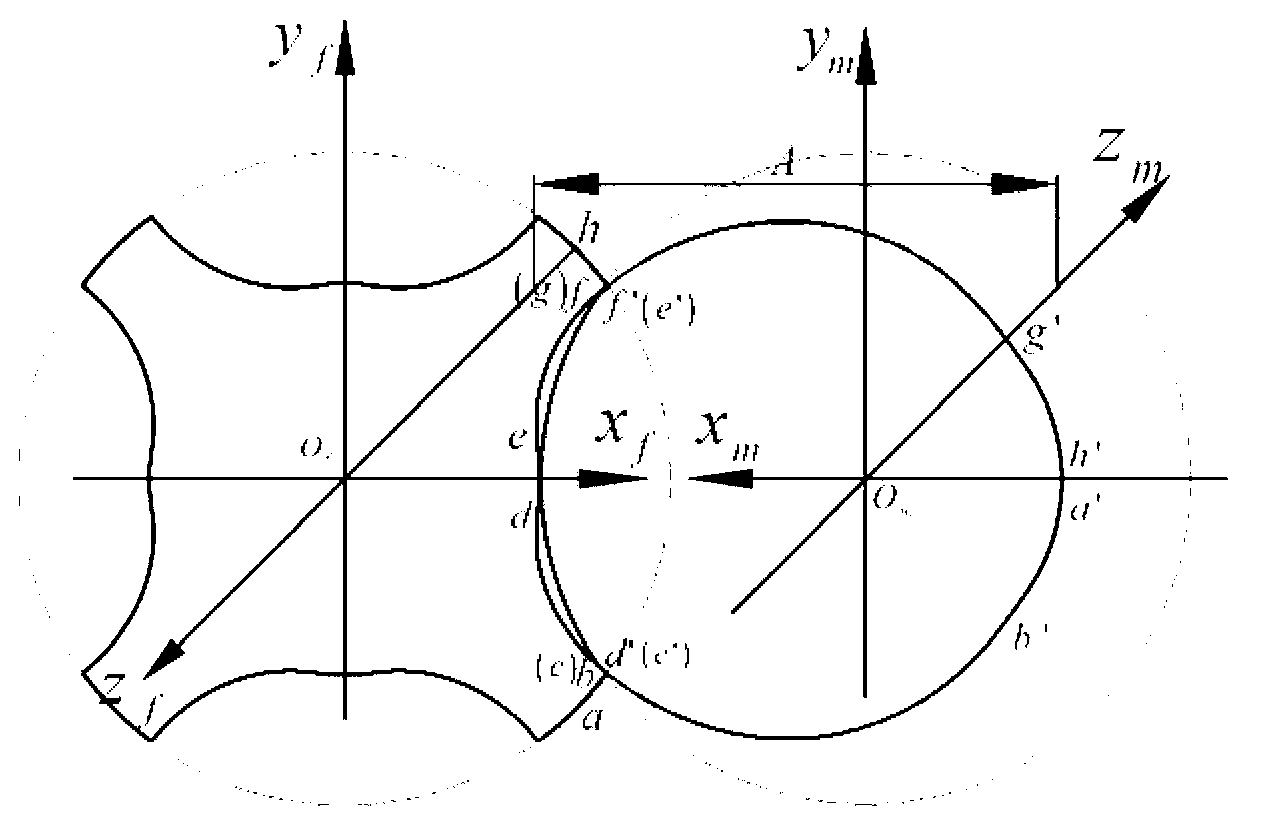

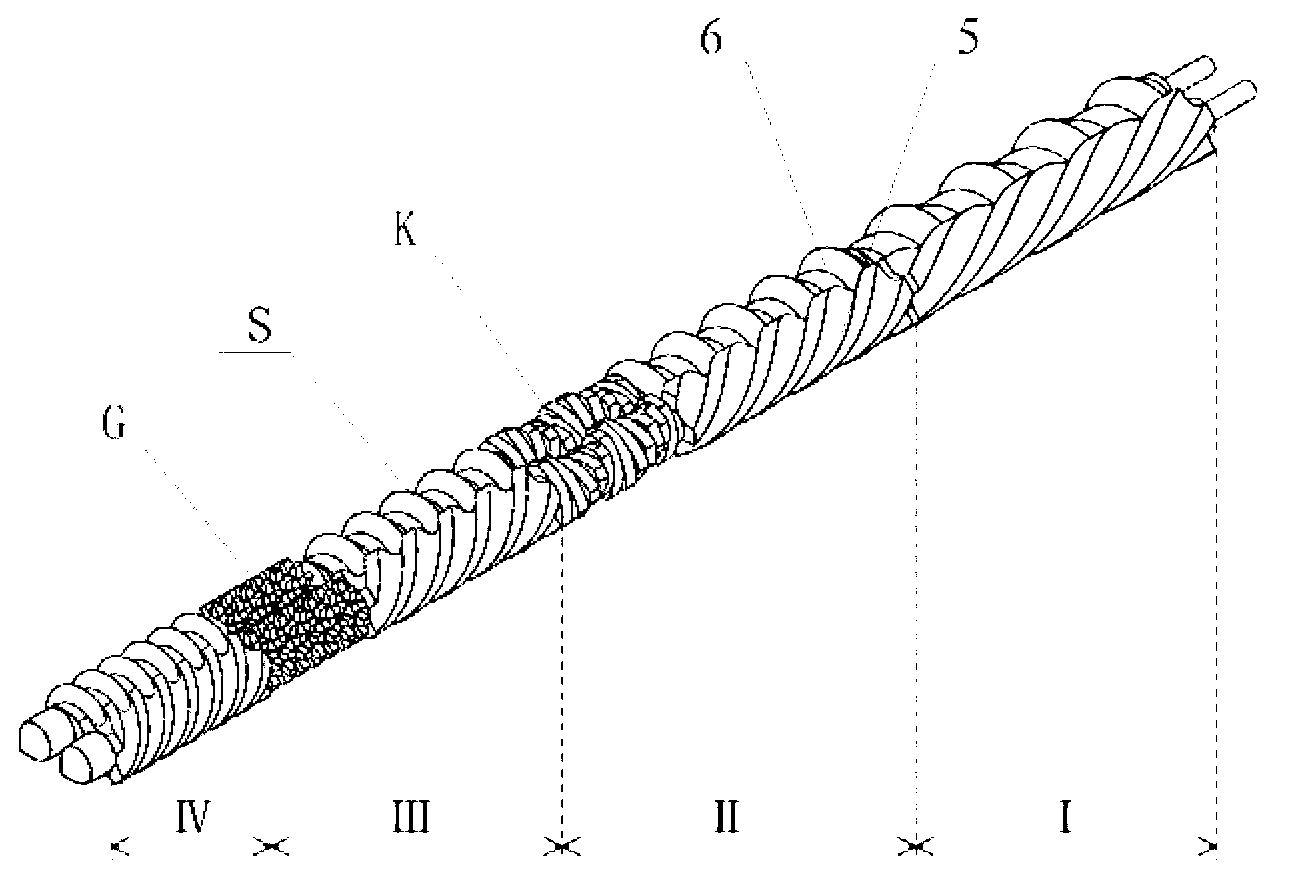

[0045] In Embodiment 1, both the male and female rotors use cylindrical screws, and a twin-screw extruder with a head ratio of 4:1 between the male and female rotors is used. The schematic diagram of the structure is as follows figure 1 As shown, the position relationship of the male and female rotors in the extruder is as follows figure 2 shown. image 3 is the three-dimensional diagram of the cylindrical male and female rotors, the design parameters of the male and female rotors are: the number of female rotors with 5 heads is Z f =4, the number of 6 male rotors is Z m =1, top circle radius R a =63mm, installation center distance A=50mm, female rotor 5' helical auxiliary lead L f =400mm, male rotor 6' helical auxiliary lead L m =100mm and the length of the helical pair of male and female rotors L=800mm. The motor 12 drives the differential gear box 10 to rotate through the motor coupling 11, and the differential gear box 10 is connected with the male and female rotor s...

Embodiment approach 2

[0047] In Embodiment 2, both male and female screws are conical screws, that is, conical screws with the same outer taper angle of the outer diameter of the screw and the same inner taper angle of the root diameter of the screw groove. And a conical twin-screw extruder with a male-to-male rotor head ratio of 4:1 is used, and its structural diagram is as follows figure 1 As shown, the position relationship of the male and female rotors in the extruder is as follows figure 2 as shown, Figure 4 It is a three-dimensional diagram of the conical male and female rotors. The male and female rotors in Embodiment 2 adopt the same end surface profile as Embodiment 1. The design parameters are: the number of female rotors 5' is Z f =4, helical auxiliary lead L f =400mm; the number of heads of the male rotor 6' is Z m =1, helical auxiliary lead L m =100mm, the length of the helical pair of the male and female rotors L=800mm and the radius R of the top circle of the large end of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com