Fluid static mixing device with corrugated pipeline

A static mixing device and wave-shaped technology, which is applied in the direction of fluid mixers, mixers, cement mixing devices, etc., can solve the problems of not too high flow rate of mixed fluid, large difference in density of mixed fluid, etc., to achieve improved mixing capacity, Increased flow rate and strong mixing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Application of the present invention on pesticide dilution, mixing, spraying, such as Image 6 shown.

[0062] The current pesticide spraying machines have to mix and dilute the pesticides through manual or mechanical exposure before spraying, which undoubtedly poses a certain threat to the safety of the environment and operators. And use the present invention just can solve this problem well.

[0063] 1. Production and connection of equipment

[0064] (1) Production of equipment

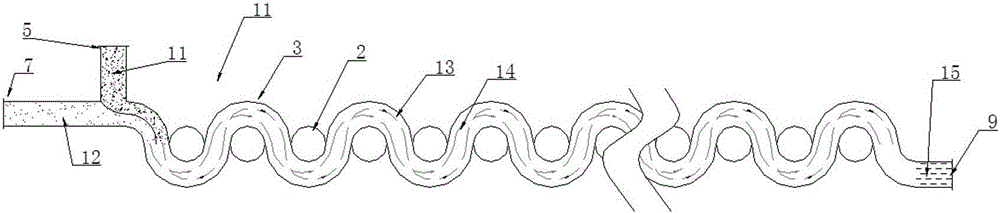

[0065] For the majority of farmers, such as figure 1 The shown structure makes the device (flexible pipe) of the present invention with a bending radius greater than the outer diameter of the pipe. In order to ensure that various pesticides can be mixed evenly, the number of semicircular pipes can be appropriately more, generally greater than 12.

[0066] (2) Device connection

[0067] Choose a small plunger pump and a peristaltic pump whose flow rate can be adjusted by rotating speed, p...

Embodiment 2

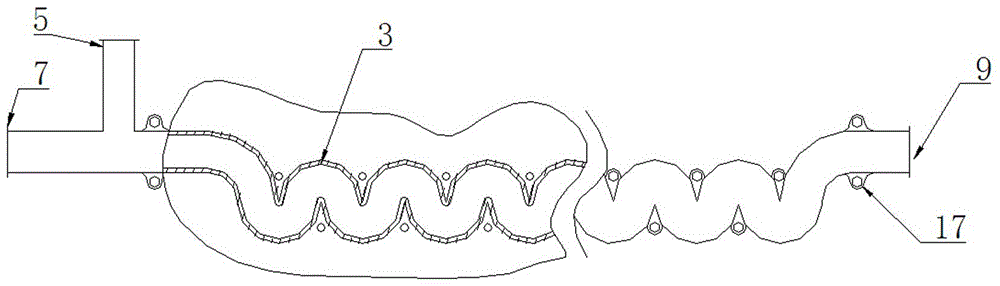

[0072] Application of the present invention on foam preparation, such as Figure 7 Shown, flexible pipe.

[0073] The current blowing agent dilution mixing device such as Figure 9 As shown, it only relies on the vortex formed by water at the end of the "U" tube to mix with the foaming agent stock solution, which is not effective and affects the foam quality, especially for foaming agents with high viscosity. The present invention can be applied to liquid foaming agents with different viscosities. Even for solid powder foaming agents, the input device can be uniformly diluted and mixed, thereby improving foam quality.

[0074] 1. Production and connection of equipment

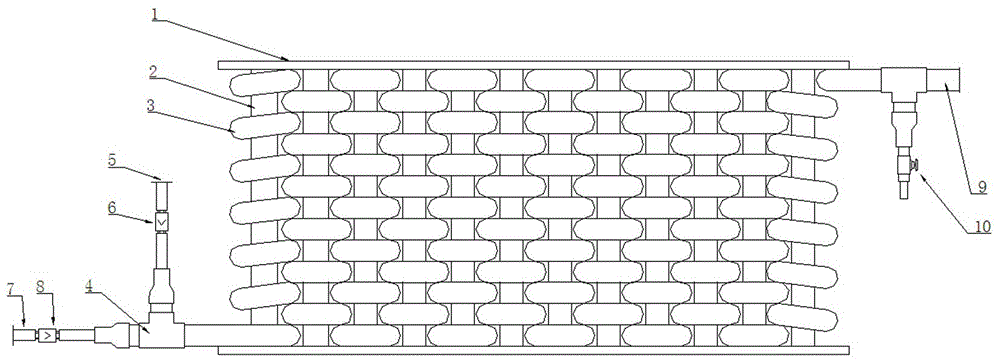

[0075] The design foaming energy capacity of present embodiment foaming machine is 18m 3 / h foam, so choose a plunger pump with an outlet pressure of 0.6MPa and a flow rate of 6.5kg / min, a peristaltic pump with a maximum flow rate of 0.4kg / min that can be adjusted by rotating speed, and a 3m-long inner diame...

Embodiment 3

[0083] Application of the present invention in the preparation of foamed concrete, such as Figure 10 As shown, rigid pipe.

[0084] 1. Production and connection of equipment

[0085] The design capacity of the foaming machine of the present embodiment is 18m 3 / h foam (same as Example 2), it is 300kg / m 3 The production capacity of foam concrete is 20m 3 / h, so choose one with a maximum flow rate of 3.5m3 / h, a maximum speed of 52rpm, an outlet pressure ≤0.8Mpa, a suction lift of not less than 9m, a hose inner diameter of 40mm, a power supply voltage of 380V, 50Hz, and a power of 4kW. Hose pumps (aka peristaltic pumps). The speed of the hose pump is regulated by a frequency converter.

[0086] Such as Figure 10 As shown, the mixing device of the foam and concrete slurry of this embodiment is formed. In the device, the manufacturing method of the present invention is as follows.

[0087] 1. First use the φ40 flexible pipe to conduct experiments, and determine that the n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com