Anti-fall graphene lacquer and preparing method thereof

An anti-shedding, pure stone technology, applied in the field of wall paint, can solve problems such as bubbling and peeling, and achieve the effects of improving thermal stability, improving adhesion, and avoiding peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

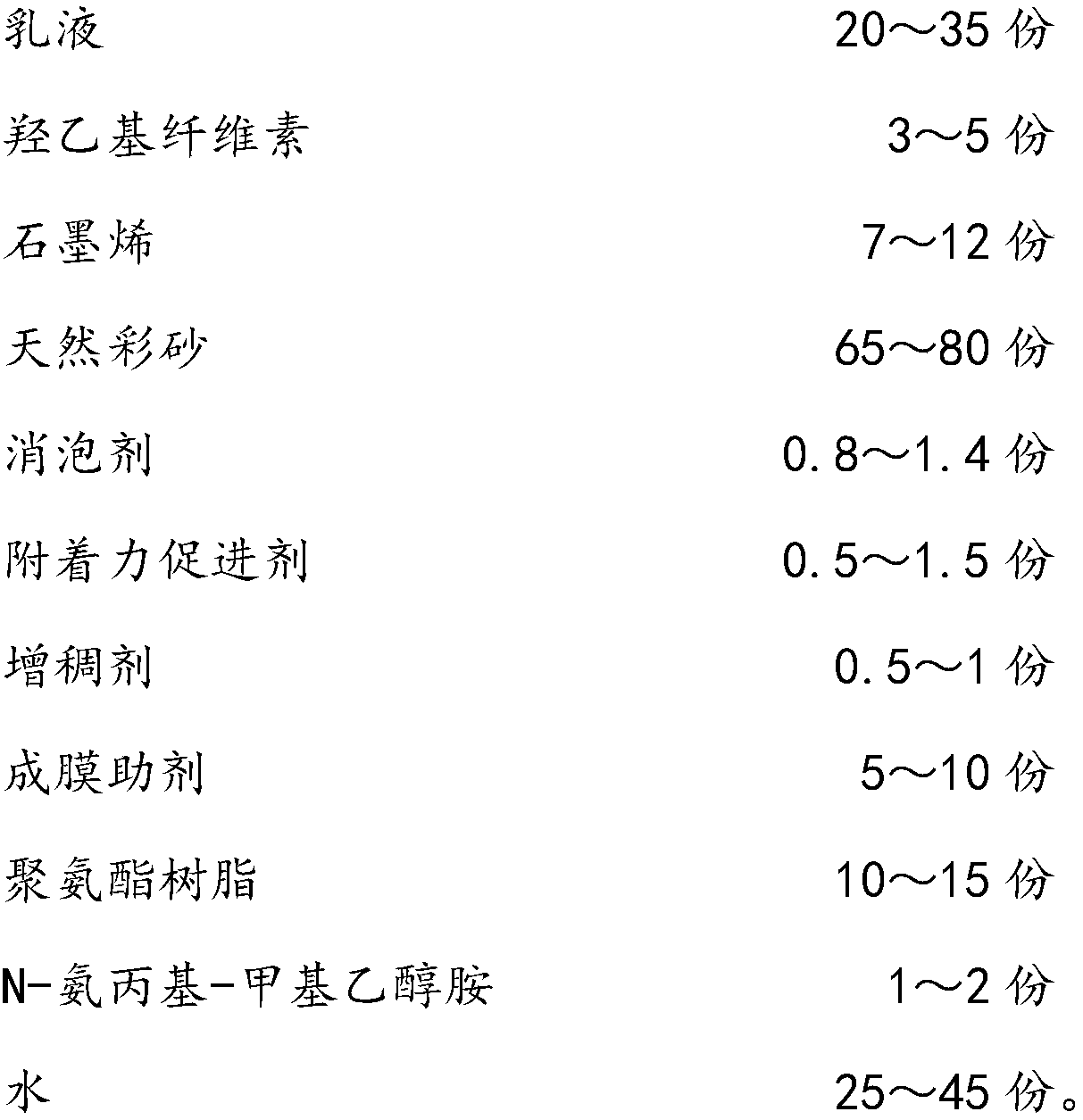

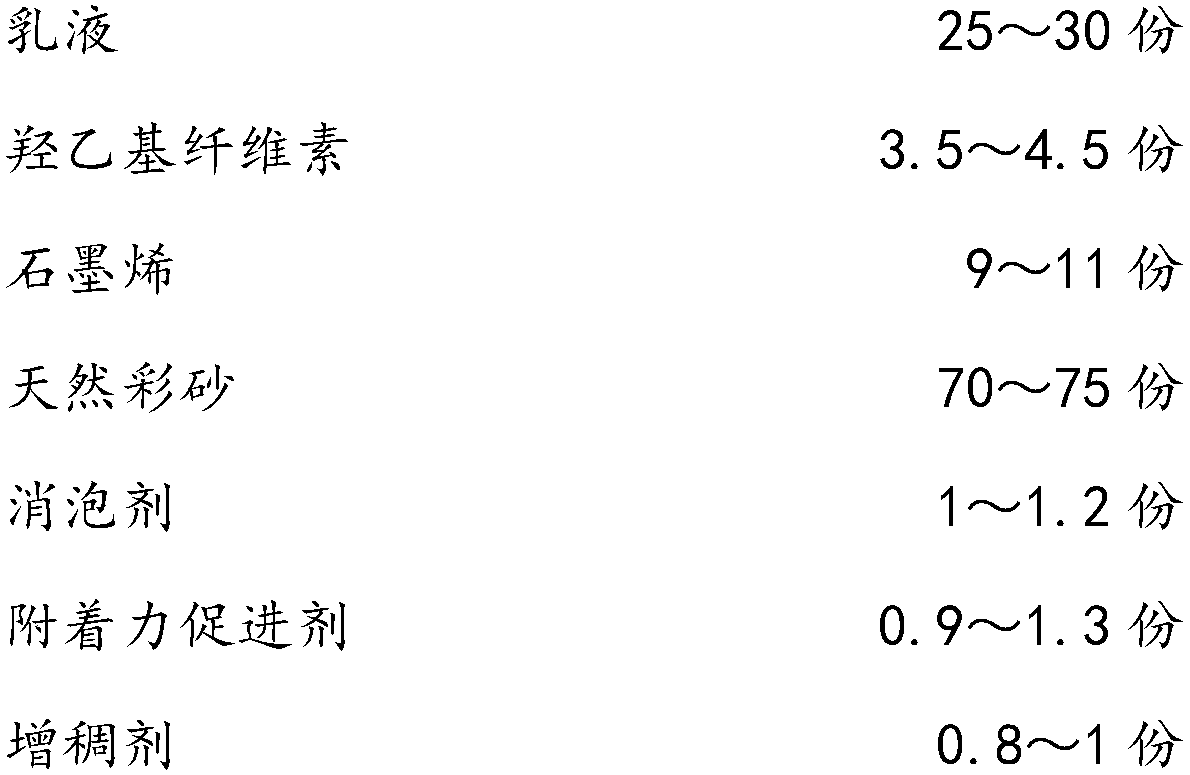

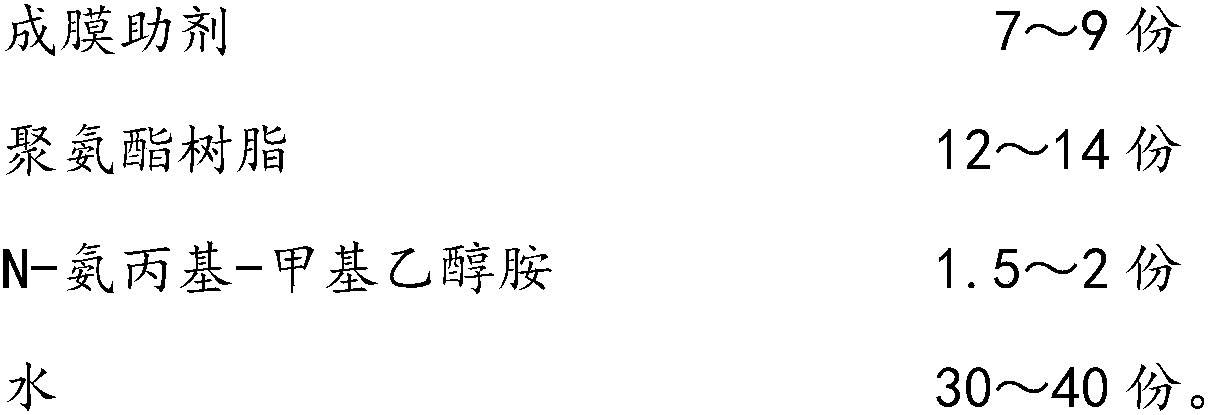

Method used

Image

Examples

Embodiment 1

[0036] Step 1. Add 3.5 parts of hydroxyethyl cellulose and 30 parts of water to the stirring device, and stir for 5-7 minutes at a stirring rate of 300-500 rpm; then add 10 parts of graphene and continue stirring for 15-25 minutes;

[0037] Step 2. Add 25 parts of emulsion to the mixing equipment and stir for 15-20 minutes at a stirring rate of 500-700 revolutions / min; then add 70 parts of natural colored sand and stir for 50- at a stirring rate of 600-800 revolutions / min. 75min;

[0038] Step 3. Add 7 parts of film-forming aids, 1 part of defoamer, 1 part of adhesion promoter, 12 parts of polyurethane resin to the stirring equipment, and stir for 20-30 minutes at a stirring rate of 600-800 revolutions / min;

[0039] Step 4. Add 0.8 parts of thickener and 1.5 parts of N-aminopropyl-methylethanolamine to the stirring equipment, and stir for 10-15 minutes at a stirring rate of 600-800 revolutions / min to obtain the anti-shedding graphite Real stone paint.

Embodiment 2

[0041] Step 1. Add 4.5 parts of hydroxyethyl cellulose and 35 parts of water to the stirring device, and stir for 5-7 minutes at a stirring rate of 300-500 rpm; then add 10 parts of graphene and continue stirring for 15-25 minutes;

[0042] Step 2. Add 28 parts of emulsion to the mixing equipment and stir for 15-20 minutes at a stirring rate of 500-700 rpm; then add 72 parts of natural colored sand and stir for 50- at a stirring rate of 600-800 rpm. 75min;

[0043] Step 3: Add 8 parts of film-forming aids, 1.2 parts of defoamer, 0.9 parts of adhesion promoter, and 13 parts of polyurethane resin into the stirring equipment, and stir for 20-30 minutes at a stirring rate of 600-800 revolutions / min;

[0044] Step 4. Add 0.8 parts of thickener and 1.6 parts of N-aminopropyl-methylethanolamine to the stirring equipment, and stir for 10-15 minutes at a stirring rate of 600-800 revolutions / min to obtain the anti-shedding graphite Real stone paint.

Embodiment 3

[0046] Step 1. Add 4 parts of hydroxyethyl cellulose and 40 parts of water to the stirring device, and stir for 5-7 minutes at a stirring rate of 300-500 rpm; then add 11 parts of graphene and continue stirring for 15-25 minutes;

[0047] Step 2. Add 30 parts of emulsion to the mixing equipment and stir for 15-20 minutes at a stirring rate of 500-700 rpm; then add 75 parts of natural colored sand and stir for 50- at a stirring rate of 600-800 rpm. 75min;

[0048] Step 3: Add 8 parts of film-forming aid, 1 part of defoamer, 1.2 parts of adhesion promoter, and 14 parts of polyurethane resin to the stirring equipment, and stir for 20-30 minutes at a stirring rate of 600-800 revolutions / min;

[0049] Step 4. Add 1 part of thickener and 1.9 parts of N-aminopropyl-methylethanolamine to the stirring device, and stir for 10-15 minutes at a stirring rate of 600-800 revolutions / min to obtain the anti-shedding graphite Real stone paint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com