Feed pipe spiral preheating device for molecular distillation equipment

A technology of molecular distillation and preheating device, applied in the field of molecular distillation, can solve the problems of heat loss and little preheating effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

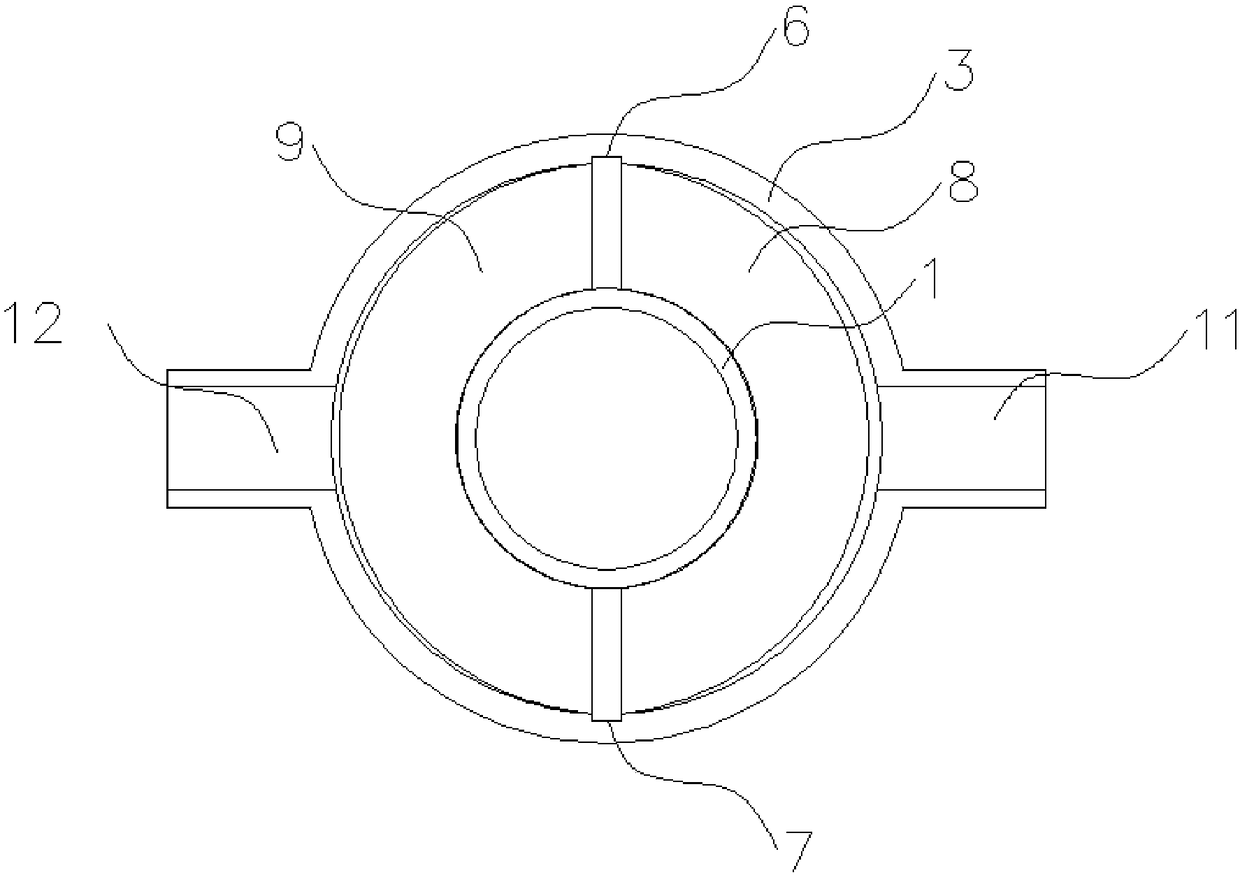

[0029] see figure 1 The disclosed molecular distillation equipment uses a feed pipe to spiral to a preheating device.

[0030] The feed pipe spiral preheating device for molecular distillation equipment includes: an inner spacer 2 matched with the outer wall of the feed pipe 1 and a hollow cylindrical outer protective tube 3 ringed outside the inner spacer 2;

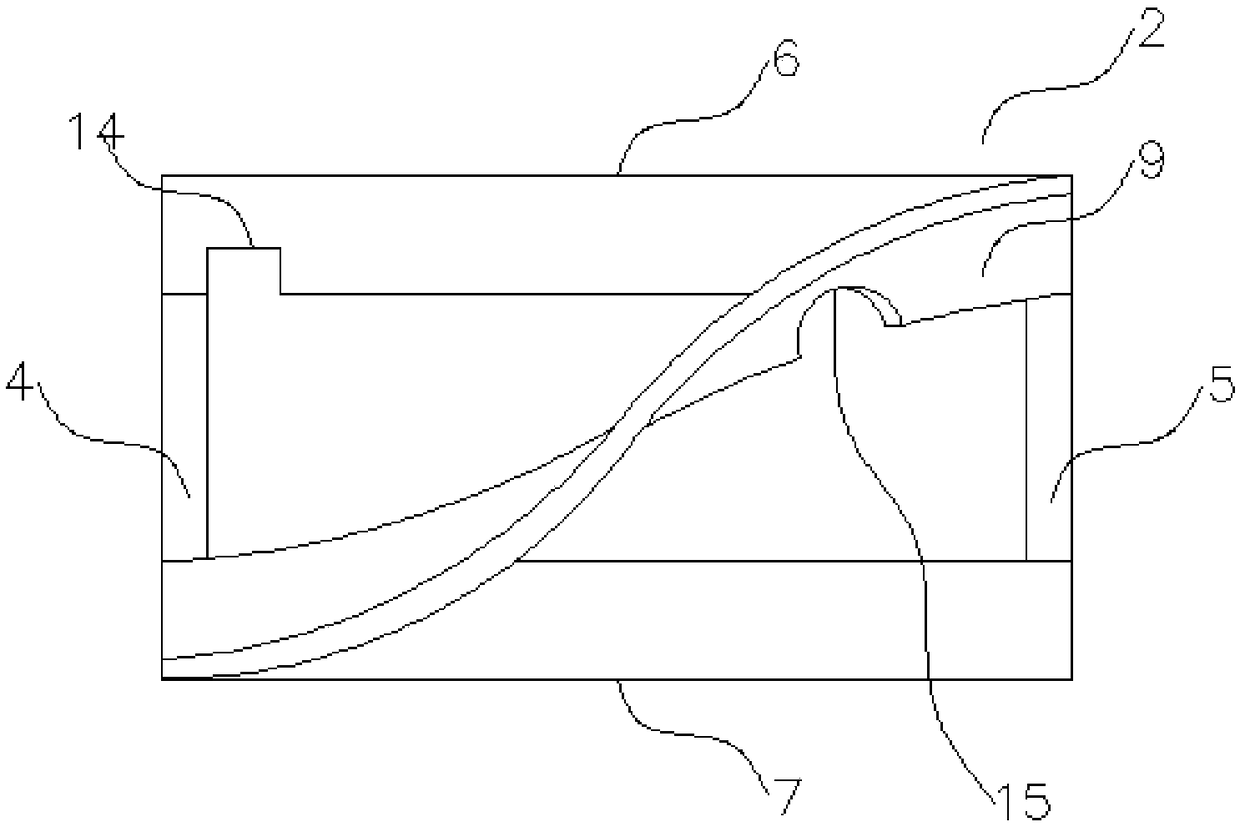

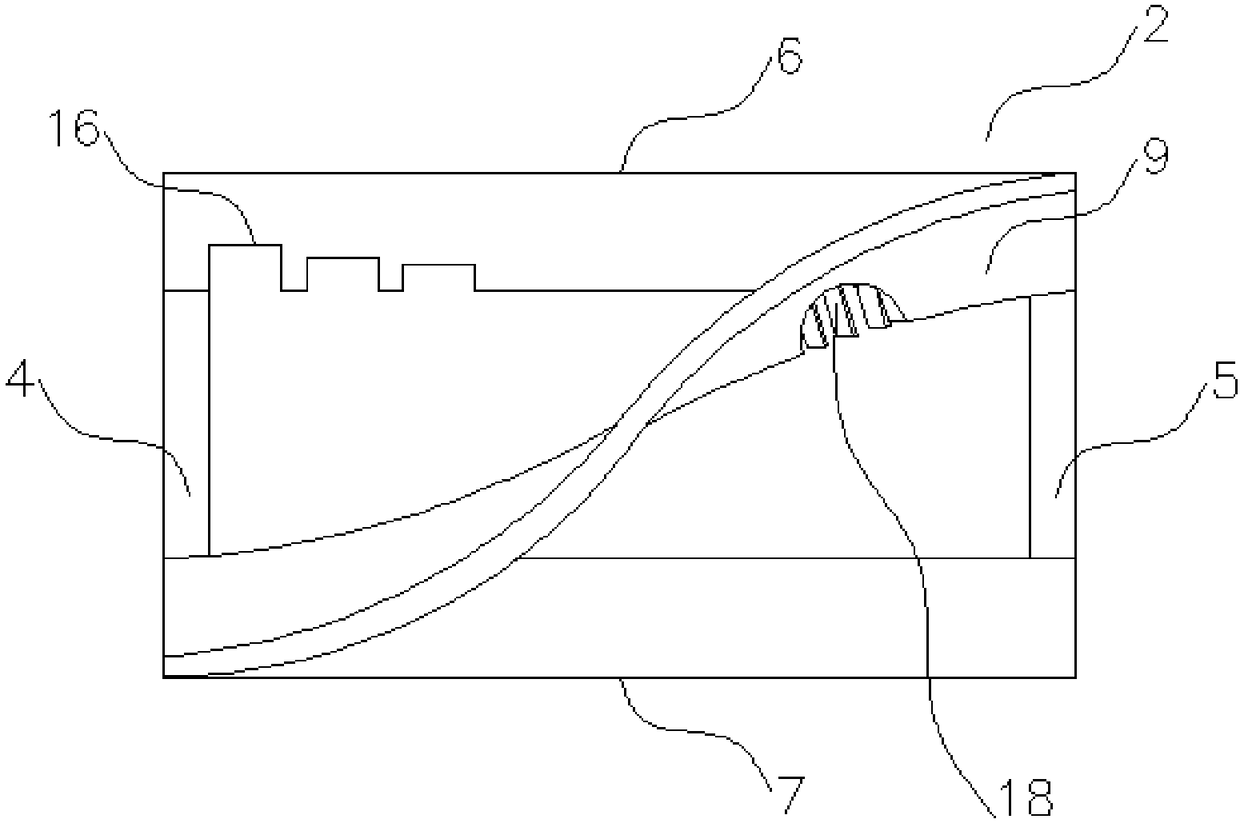

[0031] see figure 2 , image 3 , Figure 4 and Figure 5 , the inner spacer, the key component in this embodiment, is mainly used to restrict the path of the heat-conducting medium.

[0032] The inner spacer 2 includes: two separately arranged end rings, two partitions bridged between the two end rings, and two helical plates bridged between the two partitions.

[0033] see figure 2 , the two end rings are tightly sleeved on the feed pipe 1 respectively and are respectively the first end ring 4 and the second end ring 5; the first end ring 4 and the second end ring 5 are used for connecting with the feed The pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com