Small high-dynamic and high-precision digital output magneto-electricity encoder and mounting control method thereof

A magnetoelectric encoder, digital output technology, applied in the direction of program control, computer control, using electrical devices, etc., can solve the problems of large amount of calculation, high processor performance requirements, large angle output delay, etc., to improve the rotation accuracy and The effect of axial positioning accuracy, improving dynamic response, and improving output accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Through the following embodiments, the present invention can be explained in detail in conjunction with the accompanying drawings, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

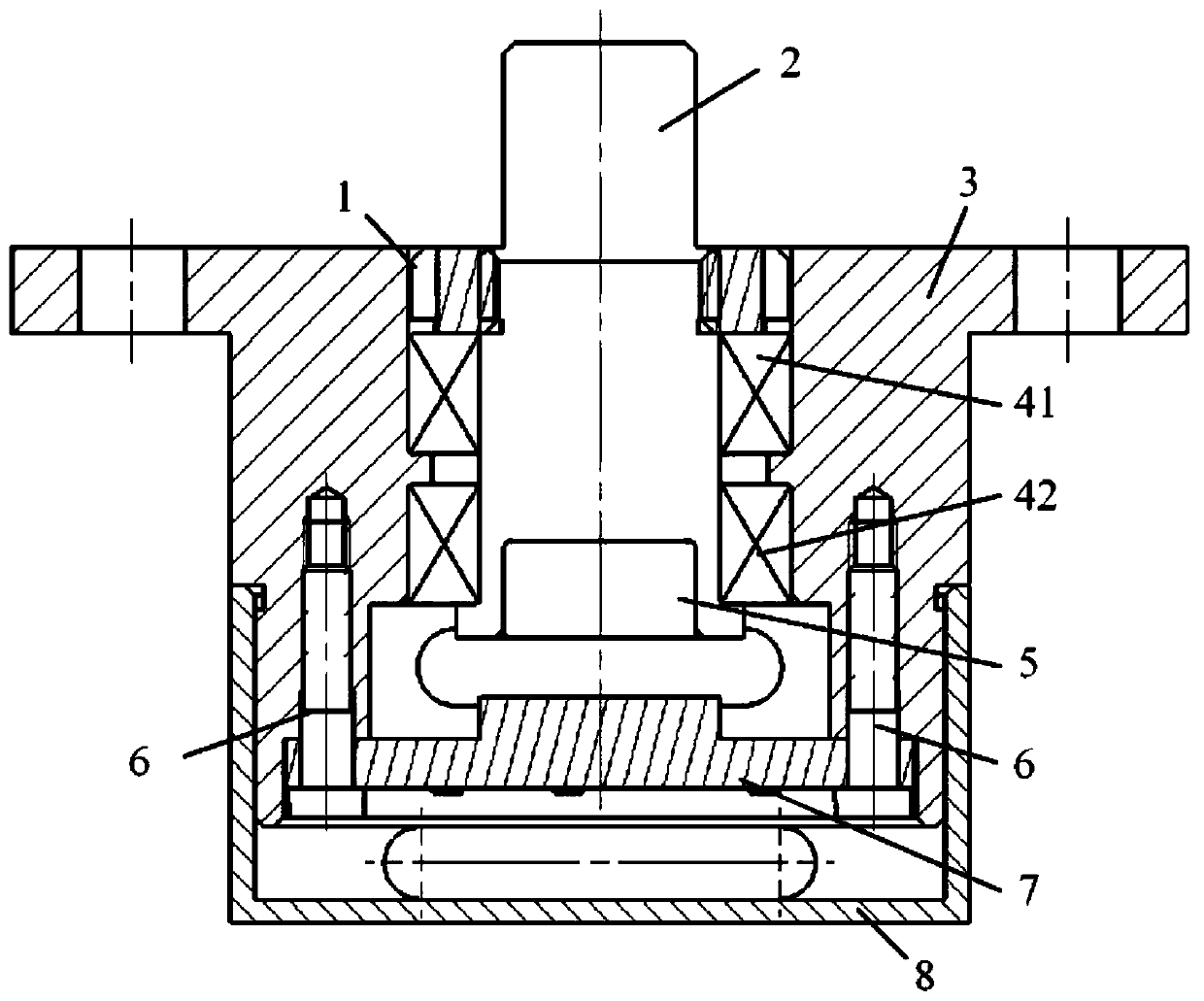

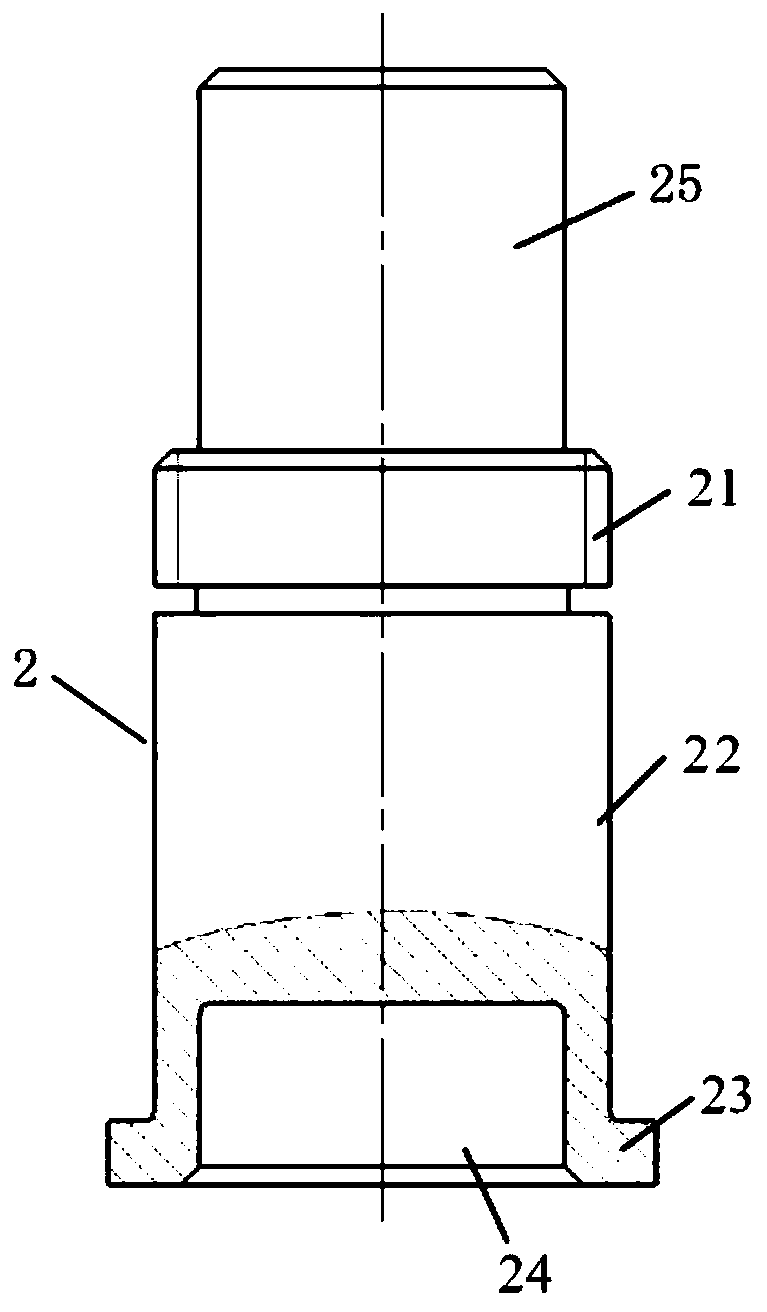

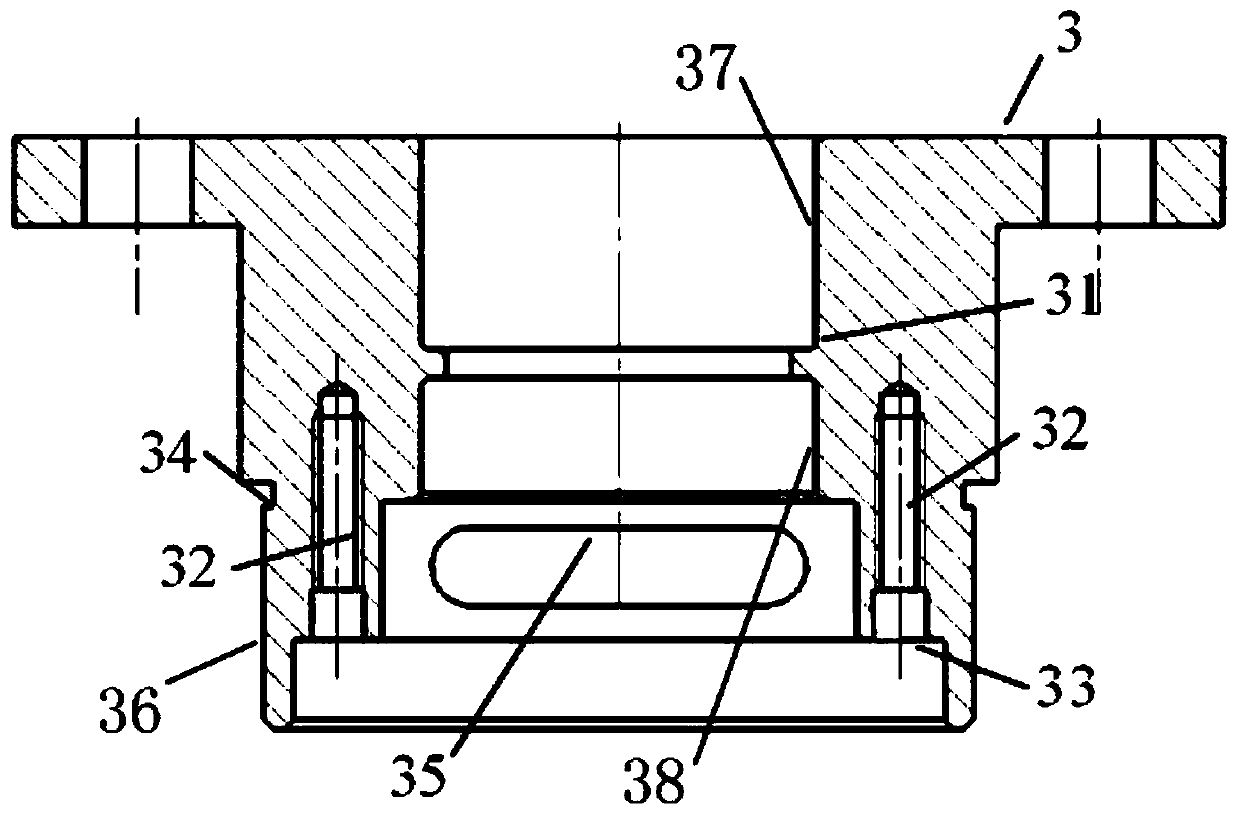

[0031] A small high-precision magnetoelectric encoder structure, including a main shaft 2, a main body 3, a signal processing circuit board 7 and a housing 8. The displacement input shaft 25 on the main shaft 2 is used to connect the rotating parts that need to measure the angle; The magnet 5 can rotate around the axis of the main shaft without radial runout, and the front bearing 41 and the rear bearing 42 used to support the rotation have a seal ring structure. The casing 8 is buckled and installed on the stepped shaft 36 of the main body 3 , and glue is filled between the casing 8 and the ring groove 34 on the main body 3 to improve the overall sealing performance.

[0032] A signal processing circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com