Automobile alternator integral pulley assembly

A technology of alternator and pulley assembly, which is applied in the direction of mechanical equipment, electric components, electromechanical devices, etc. It can solve the problem of slipping failure between the one-way clutch and the mandrel, the effective length of the transmitted torque is not uniform, and the axial positioning of the gear train is affected Accuracy and other issues, to achieve the effect of long service life, high axial positioning accuracy, and avoid slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

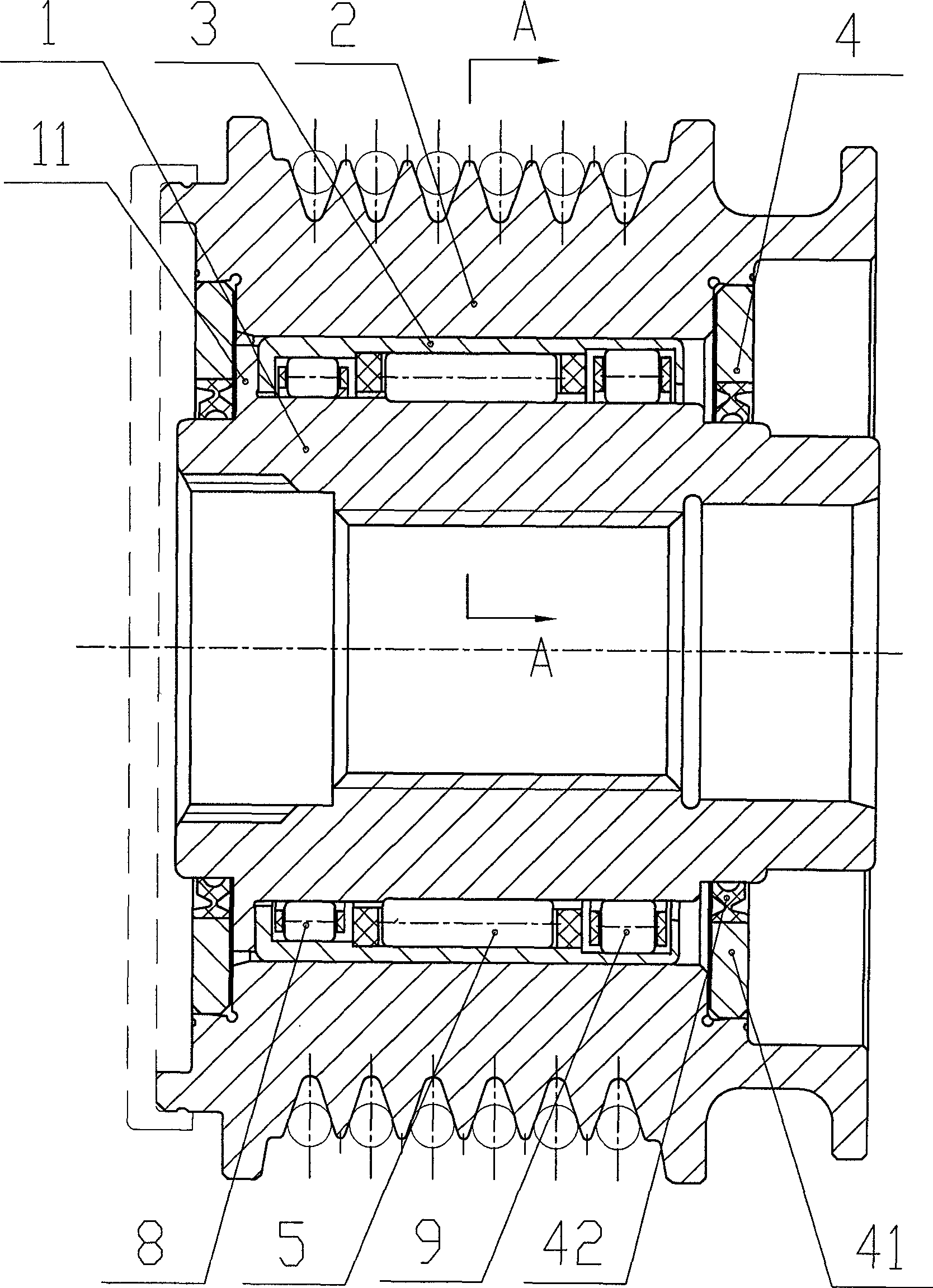

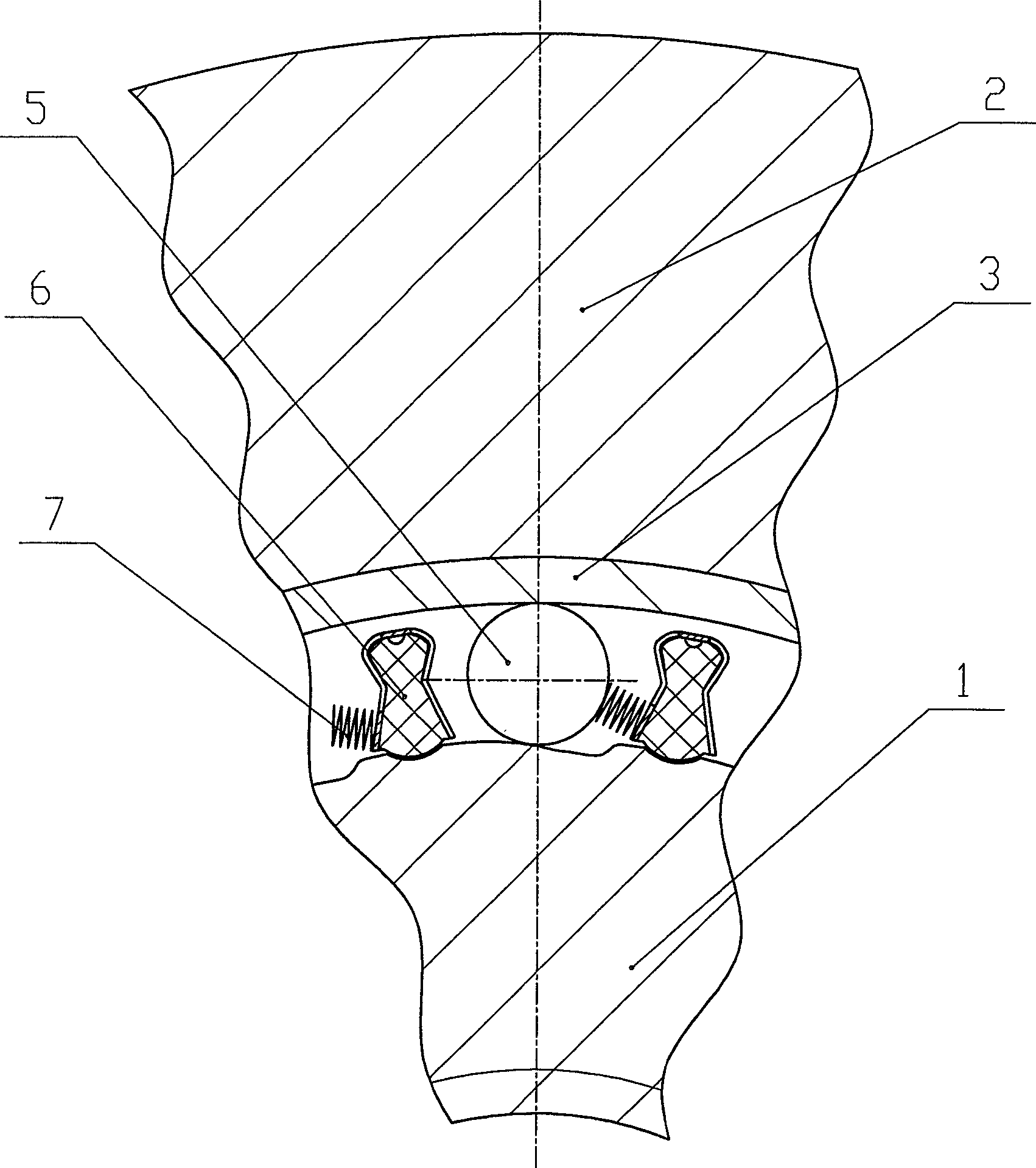

[0013] Such as figure 1 , 2 The automobile alternator integral pulley assembly shown in the present invention has a cylindrical structure as a whole, and has a mandrel 1 set on the end of the rotating shaft of the alternator, and the inner circle surface in the middle of the mandrel 1 has internal threads 1. It is threadedly connected with the rotating shaft of the alternator. There is an internal spline on the inner surface of the front end of the mandrel 1, which is matched with a tool with an external spline on the head, and is used for assembling the mandrel 1 and the rotating shaft of the alternator. A driven pulley 2 is arranged concentrically with the mandrel 1 outside the circumference of the mandrel 1, and a one-way clutch, a front support bearing and a rear support bearing, a front support bearing and a rear support are arranged between the mandrel 1 and the driven pulley 2. The bearings are respectively arranged at the front end and the rear end of the one-way clut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com