Clamping and positioning method and tool for special-shaped transverse beam

A technology for positioning tooling and positioning method, applied in positioning devices, clamping, manufacturing tools, etc., can solve the problems of reducing the machining efficiency and quality of beams, poor clamping stability, and difficult operation, and shortening the clamping and positioning time. , The effect of improving rigidity and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

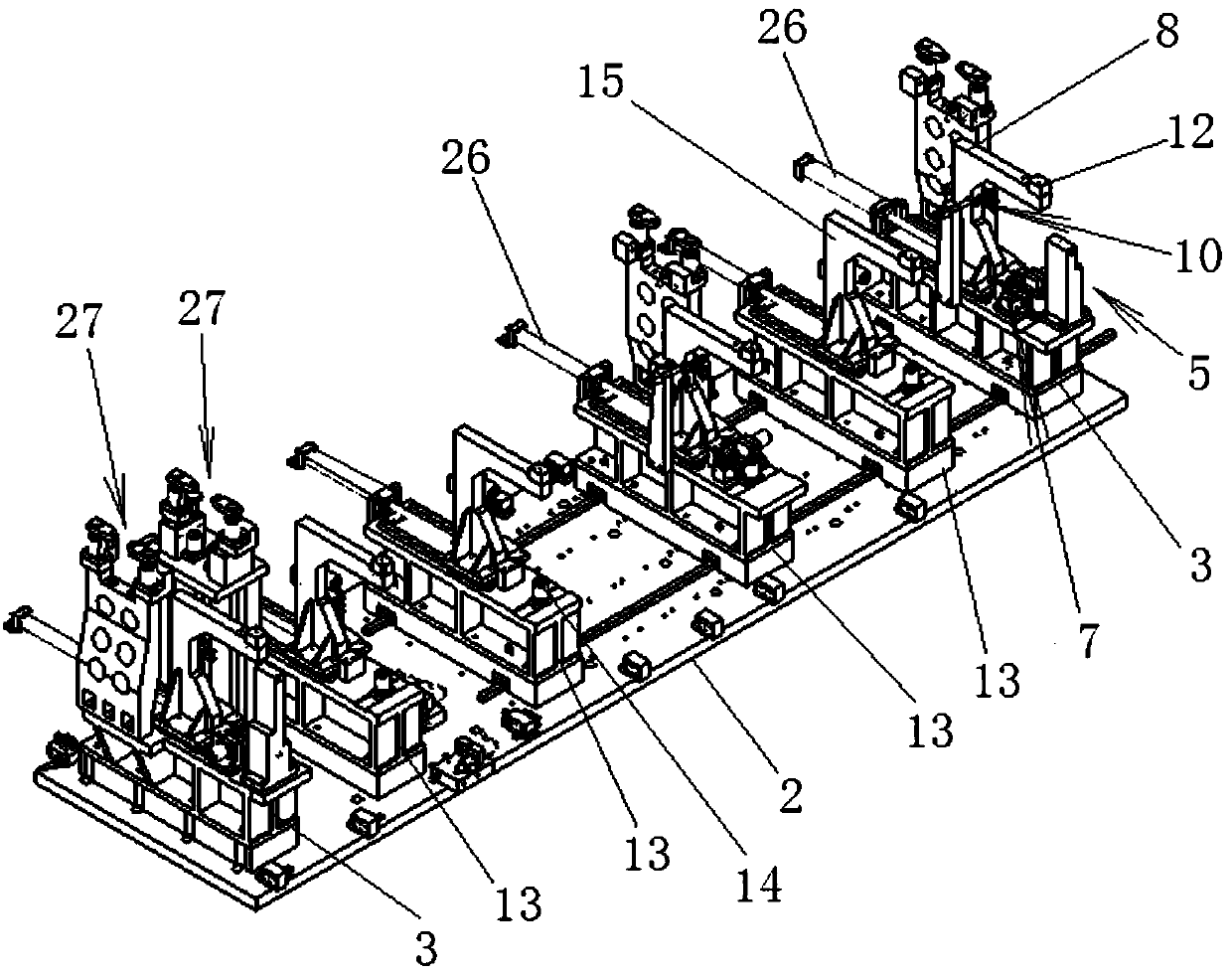

[0053] Such as Figures 1 to 5 Shown is an embodiment of a clamping and positioning method for a special-shaped beam, including the following method steps:

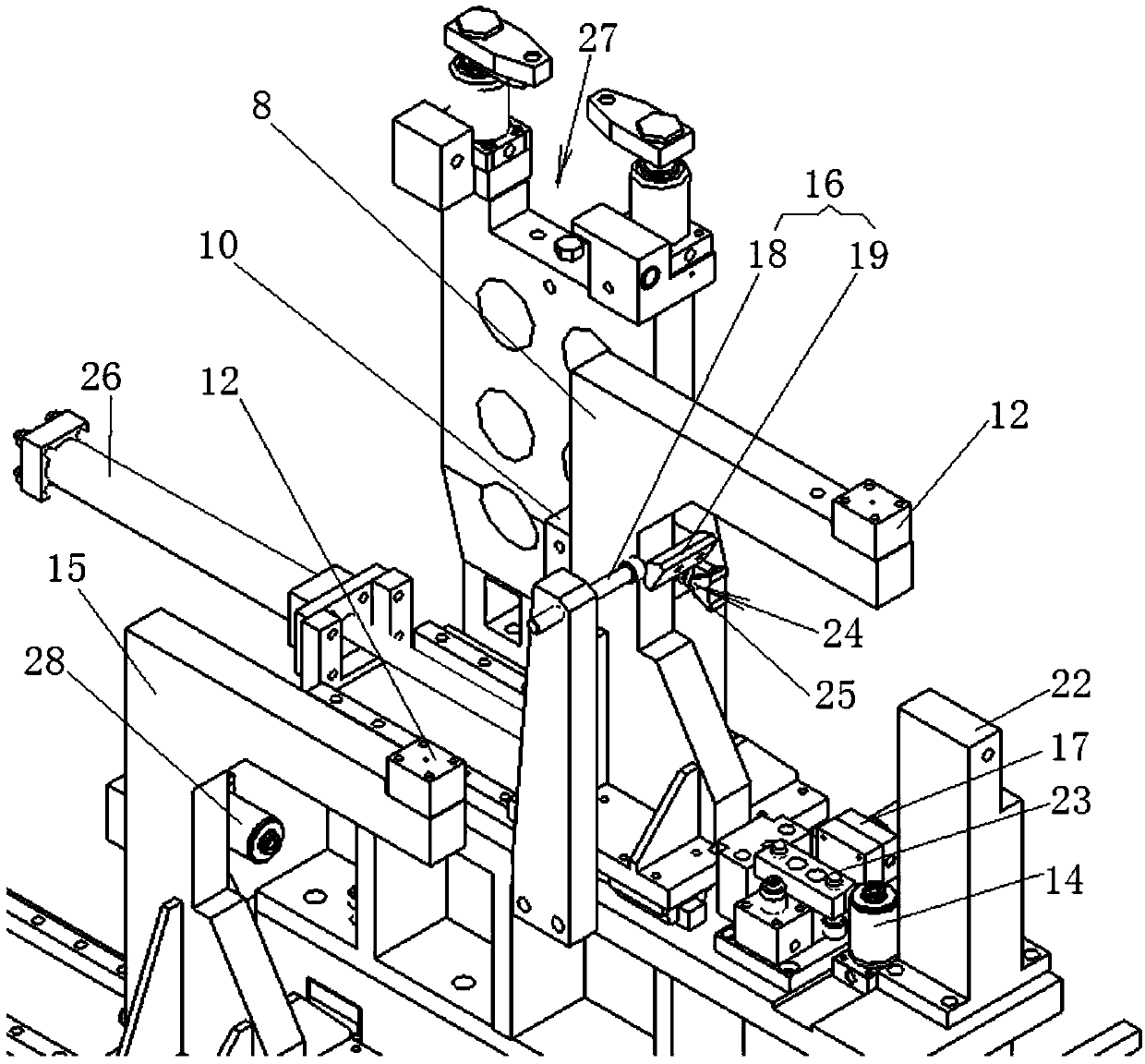

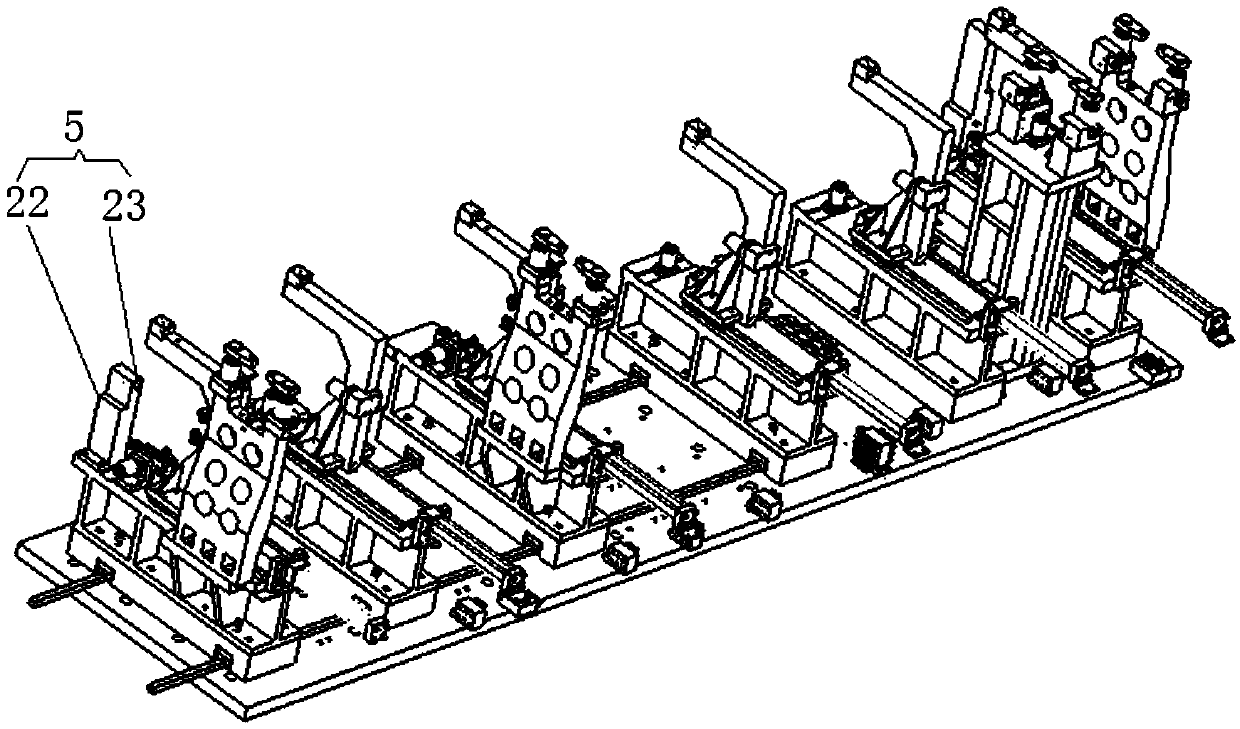

[0054] (1) Setting of the clamping and positioning tooling: a main base 3 is respectively arranged at the left and right ends of the base plate 2, and several sub-bases 13 are arranged between the main bases 3, and on the main base 3 and the sub-bases 13 The main moving frame 8 and the auxiliary moving frame 15 are respectively arranged, and the front side positioning element 5 and the bottom end surface positioning element 7 for positioning the beam are arranged on the main base 3, and the lateral tightening element 10 is set on the main moving frame 8 And the vertical pressing element 12, the floating support oil cylinder 14 that is used to auxiliary support the bottom end face 6 of the beam is set on the auxiliary base 13 at the same time, and the auxiliary side top element 28 and the vertical pressing element 12 are s...

Embodiment 2

[0065] Such as Figures 1 to 5 Shown is an embodiment of a clamping and positioning tool for a special-shaped beam of the present invention, including a base plate 2, a main base 3 respectively arranged on the upper plane of the left end of the base plate 2 and the upper plane of the right end of the base plate 2, and the main base 3 The front upper plane of the front part of the main base 3 is respectively provided with a front side positioning element 5 for positioning the front side of the beam 4 and a bottom surface positioning element 7 for positioning the bottom end surface 6 of the beam. The rear part of the main base 3 is provided with a The moving main mobile frame 8 is respectively provided with a lateral pressing element 10 for pressing the rear side 9 of the crossbeam and a vertical pressing element 12 for pressing the upper end surface 11 of the crossbeam on the main moving frame 8. The main mobile frame 8 moves backward to the position before the hoisting and pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com