Gear ring turning clamp with axial positioning structure

A technology of axial positioning and car fixtures, which is applied to components with teeth, gear teeth, gear cutting machines, etc., and can solve problems such as meshing quality degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

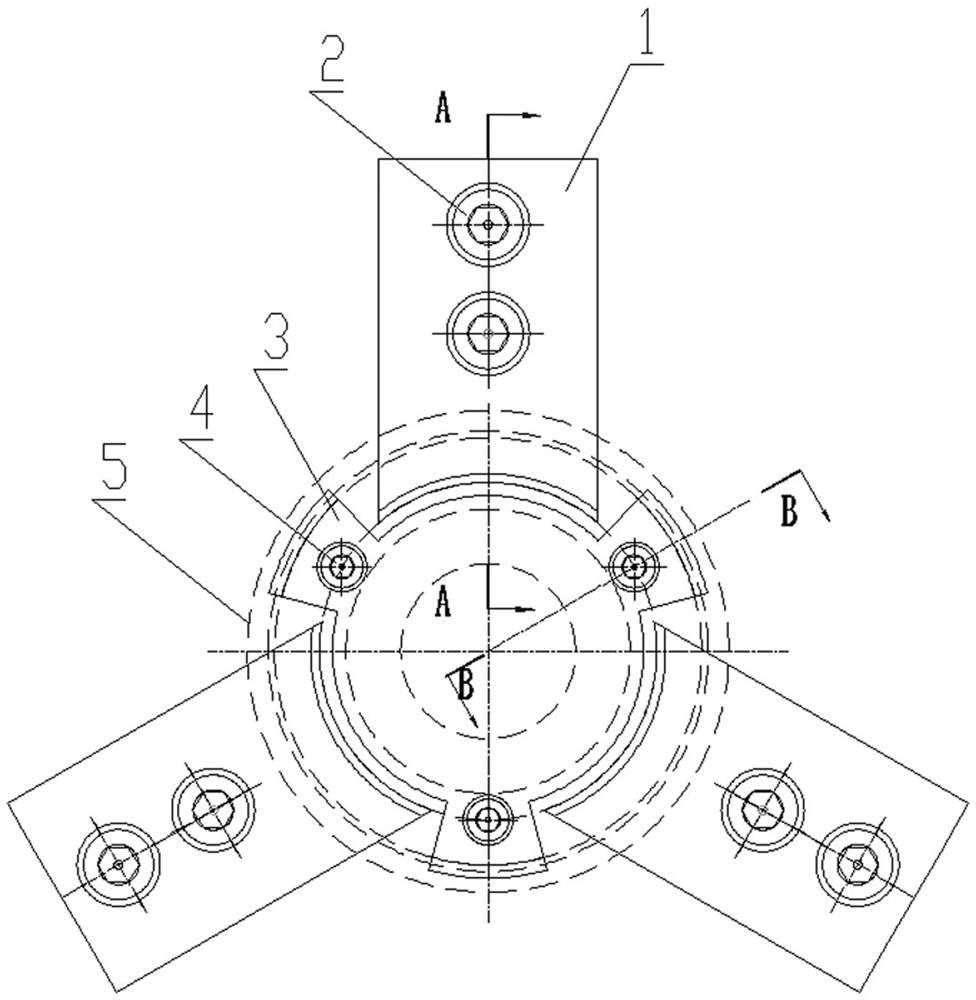

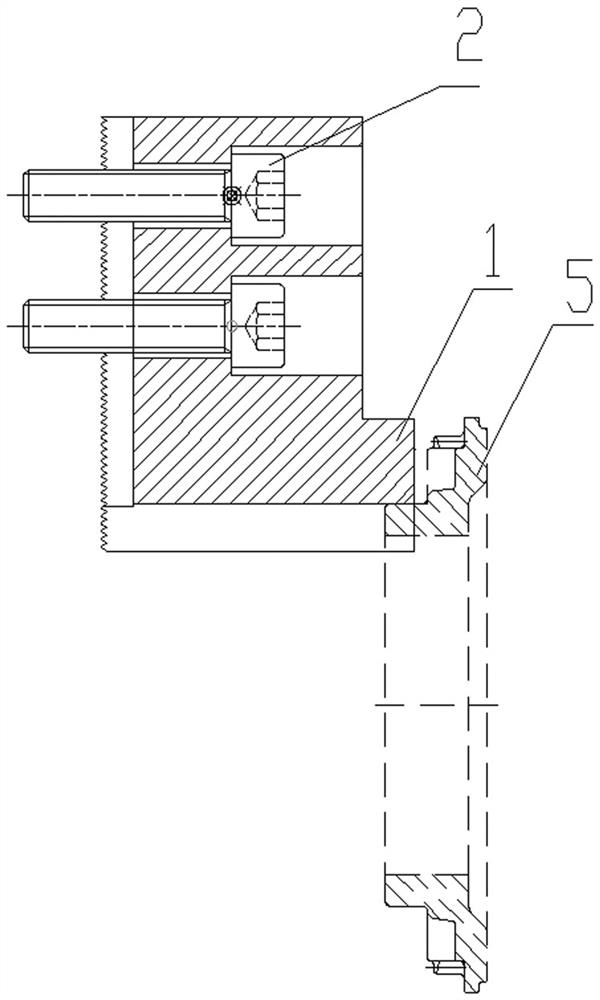

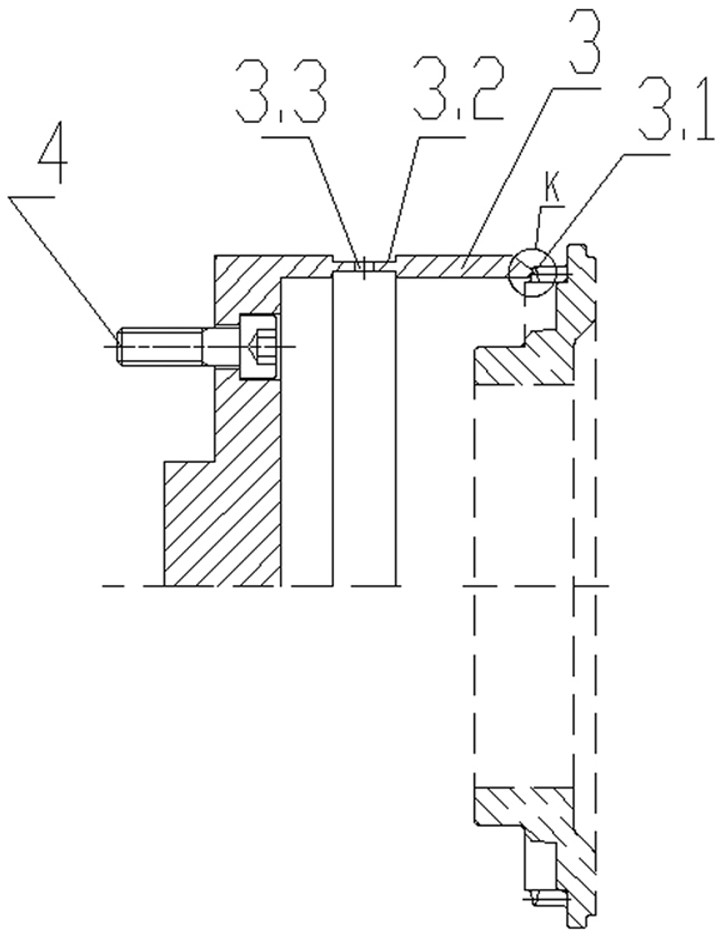

[0020] figure 1 Shown is a ring gear jig with an axial positioning structure, which includes a pressure block 1, a bolt 2, a three-leaf disc 3 and a bolt 4. The briquetting block 1 is used to clamp the workpiece ring gear 5, which is a rectangular block member made of soft metal. The workpiece ring gear 5 turned in this embodiment is matched with a car gearbox, and the briquetting block 1 made is selected from Made of silicon brass. In the vehicle fixture structure, the pressure block 1 is directly attached to the jaws of the matching three-jaw chuck and locked with a bolt 2 to form a self-centering clamping structure in which the pressure block 1 moves radially with the three-jaw chuck. figure 2 The pressing block 1 shown in the figure directly presses the inner and outer shoulders of the ring gear 5, and this kind of three-equal pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com