Heavy loading shaft push device for hole

A heavy-duty, hole-use technology, applied to mechanical equipment, connecting components, etc., can solve the problems of bolts being prone to partial load, low design safety factor, bolt overload, etc., and achieve small design limitations, large safety factor, axial load high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

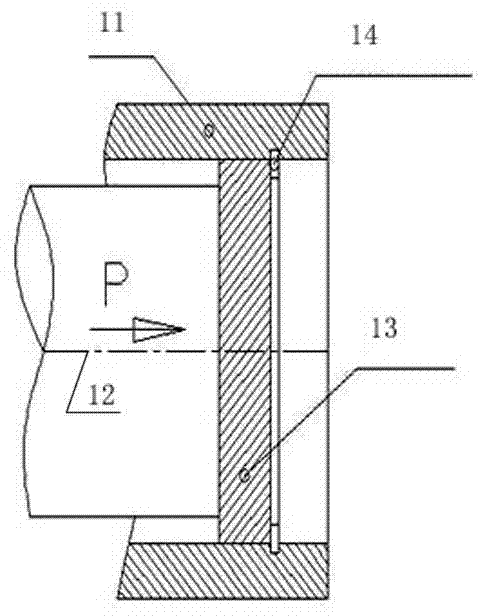

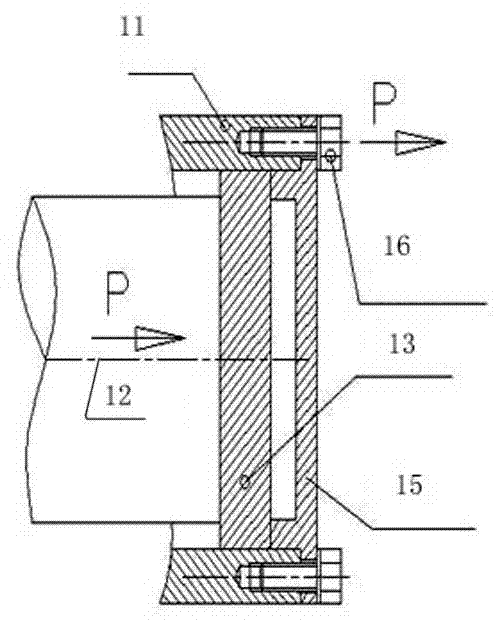

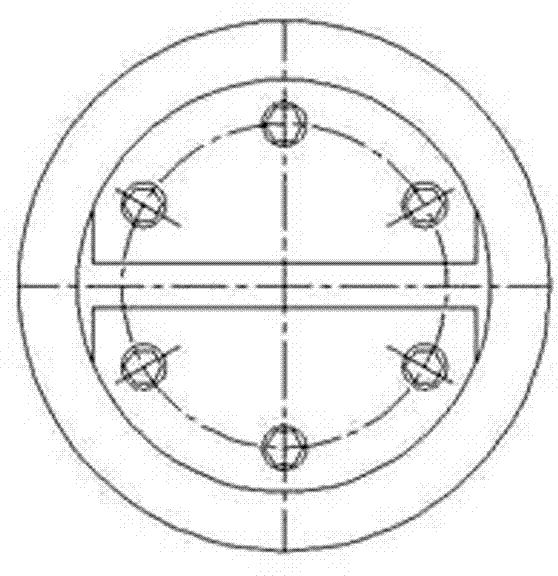

[0018] The present invention will be described in detail below in conjunction with accompanying drawing: image 3 , 4 As shown, the present invention includes a thrust shaft 22 placed in the outer shaft 21, and a thrust plate 23 fixed on the inner wall of the outer shaft 21 is arranged at the shaft end of the thrust shaft 22 radially (axially). At least two shear plates 25 radially embedded in the grooves 24 of the inner wall of the outer shaft 21 are disposed on the outside of the push plate 23 , and the shear plates 25 are fixedly connected to the push plate 23 by bolts 26 .

[0019] The shear plate 23 has two left and right pieces symmetrically embedded in the ring groove 24 of the inner wall of the corresponding outer shaft 21; the bolts 26 are evenly distributed on the outer side of the shear plate 25 according to the circumference It is fixedly connected with thrust plate 23.

[0020] The structural principle of the present invention is: the thrust shaft 22 generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com