Fluid end of culvert body and pump body and machine body series combined structure

A liquid end and pump body technology, which is applied to the components of pumping devices for elastic fluids, liquid fuel engines, pump components, etc. and other problems to achieve the effect of improving pump efficiency, prolonging life, and reducing vibration and noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

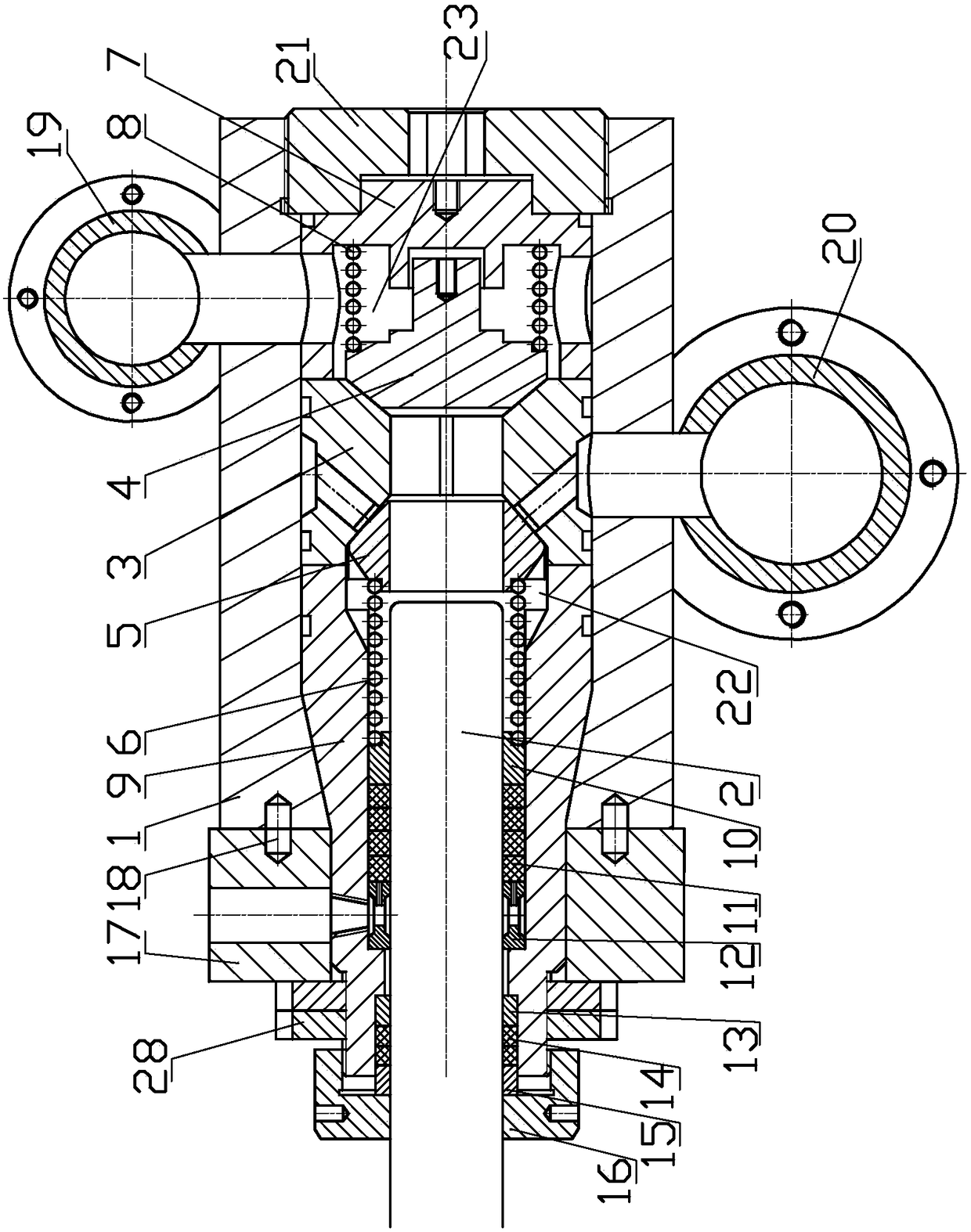

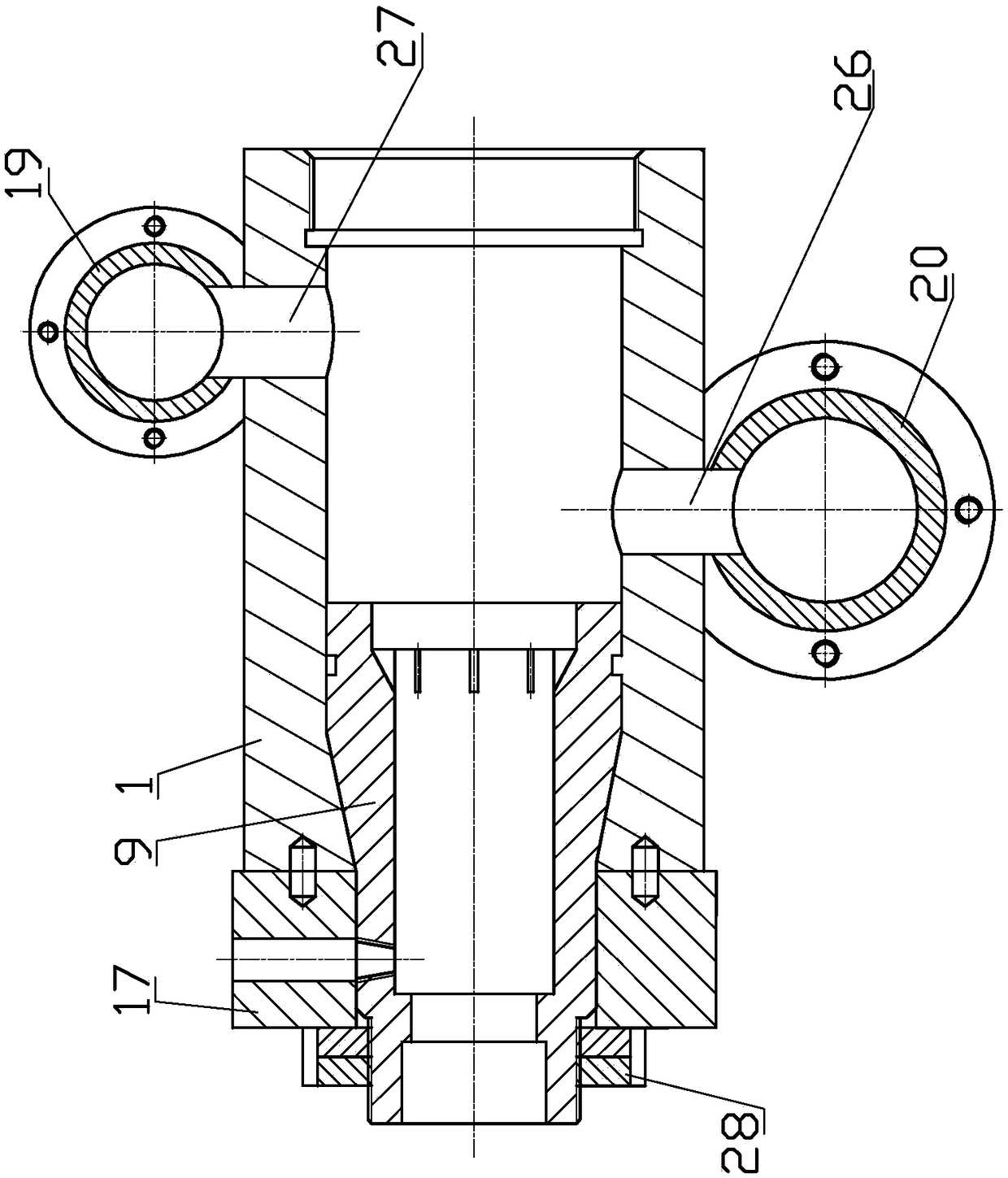

[0029] combine figure 1 As shown, the hydraulic end of the series combined structure of the body, the pump body and the fuselage of the present invention mainly includes a fuselage, a pump body 1, a plunger 2, a body 9, a sealing assembly, a combined valve, and a drain valve Set 7, spell cap 28 and cock 21, etc., wherein:

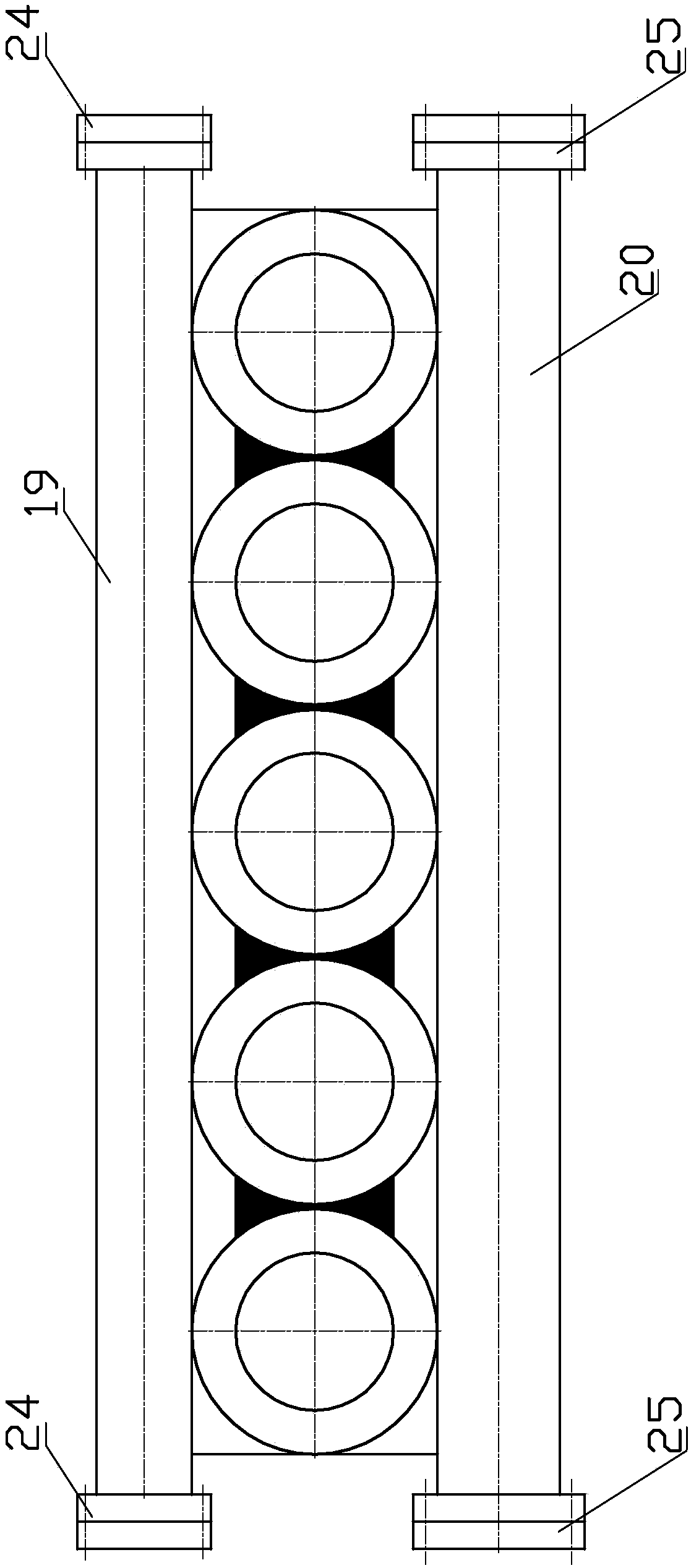

[0030] pump body 1 such as figure 2 As shown, it is configured according to the number of cylinders, which can be two cylinders, three cylinders, five cylinders, seven cylinders, nine cylinders, etc. The pump body 1 is assembled and welded with thick-walled profile pipes to form an "8" shape, and the upper end is at the drain port The discharge manifold 19 is assembled and welded at 27 places, and the liquid inlet manifold 20 is assembled and welded at the liquid inlet 26 at the lower end. After assembly and welding, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com