A car radiator bracket structure

A technology of automobile radiator and bracket structure, which is applied to the arrangement of vehicle parts and power unit cooling combination, power unit, etc., which can solve the problems of numerous procedures and large investment in radiator bracket welding tooling, etc., and reduce the process links , improve assembly efficiency and front face precision, and simplify the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

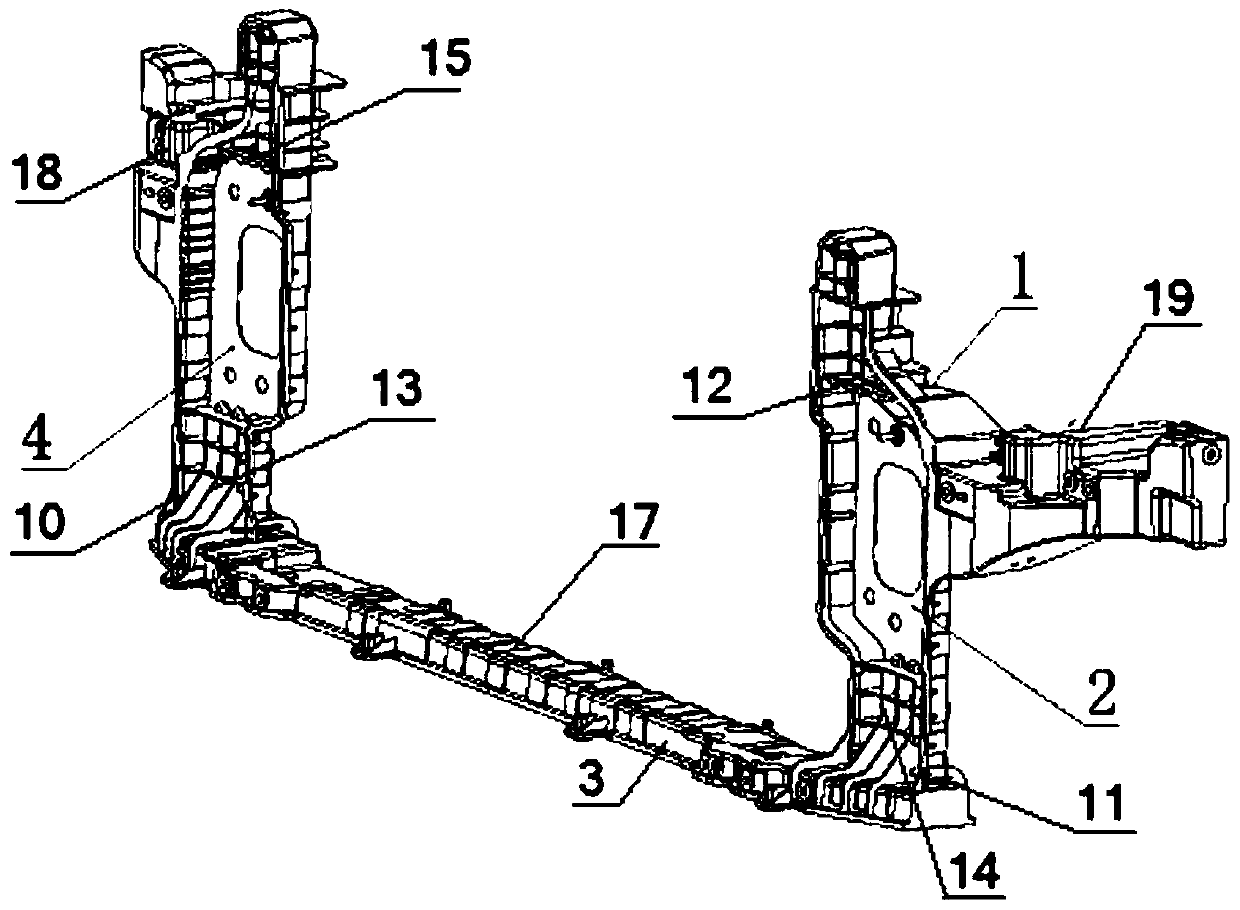

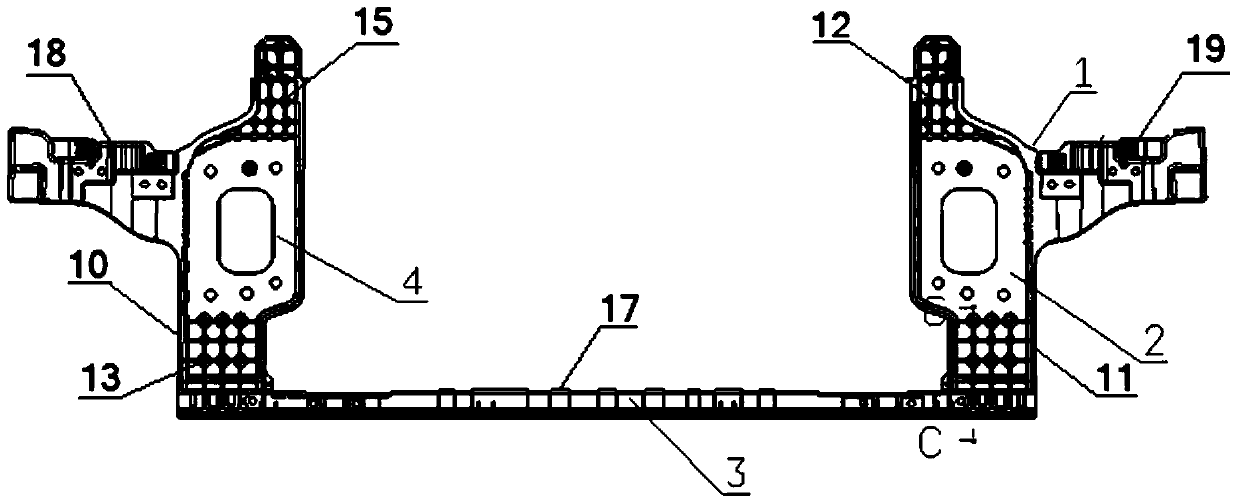

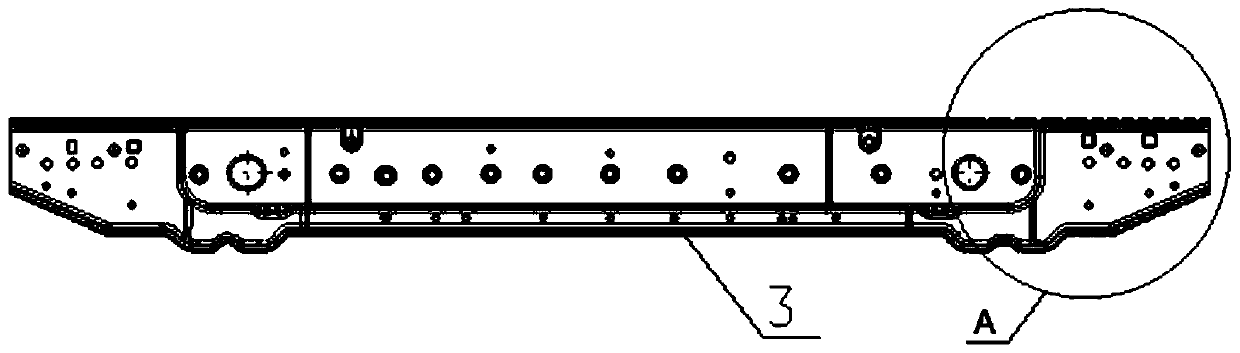

[0028] The automobile radiator bracket structure of the present invention includes a bracket for carrying the radiator. What is different from the prior art is that the bracket of the present invention is not a single welded metal sheet metal part, but a metal insert A composite part with plastic injection molding, the bracket includes the bracket body 1 and metal inserts, such as figure 1 and figure 2 shown. In the manufacturing process, the metal insert is first positioned and placed in the injection mold, and then injected into the plastic at one time. The injection-molded composite parts have good integrity, and the metal inserts are embedded in the bracket body 1 to be fixed as a whole, and installation positioning holes are left for installation at positions where other auto parts need to be installed.

[0029] For the installation requirement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com