A kind of limited and reliable juicer

A technology of a juicer and a limiting structure, which is applied to household machinery, kitchen utensils, household utensils, etc. for filtering food, can solve the problems of complicated upper cover structure, difficult to clean, unsatisfactory automatic feeding effect, and large upper cover occupied space, etc. problems, to achieve the effect of reasonable appearance and structure, stable transmission, and balanced force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

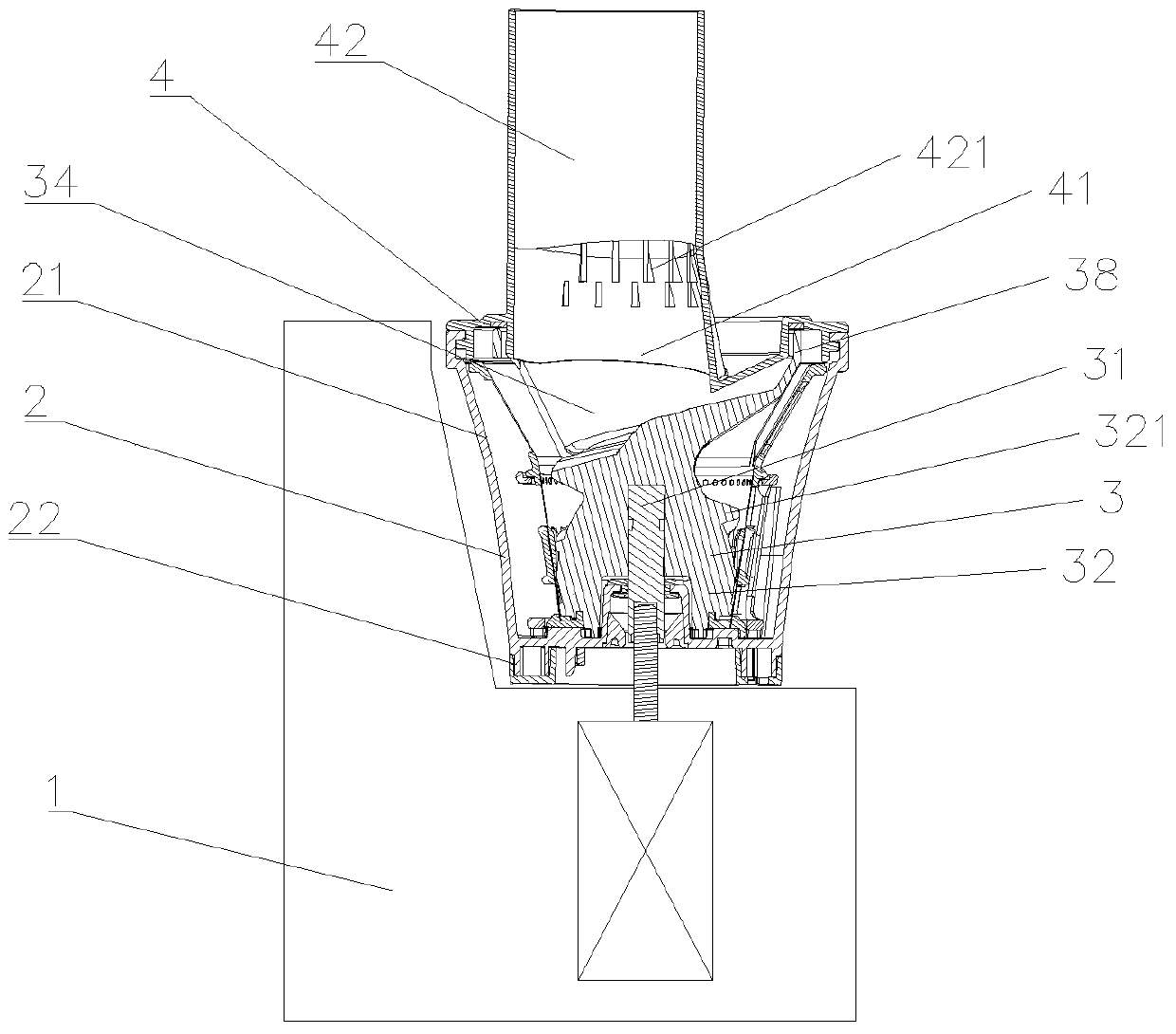

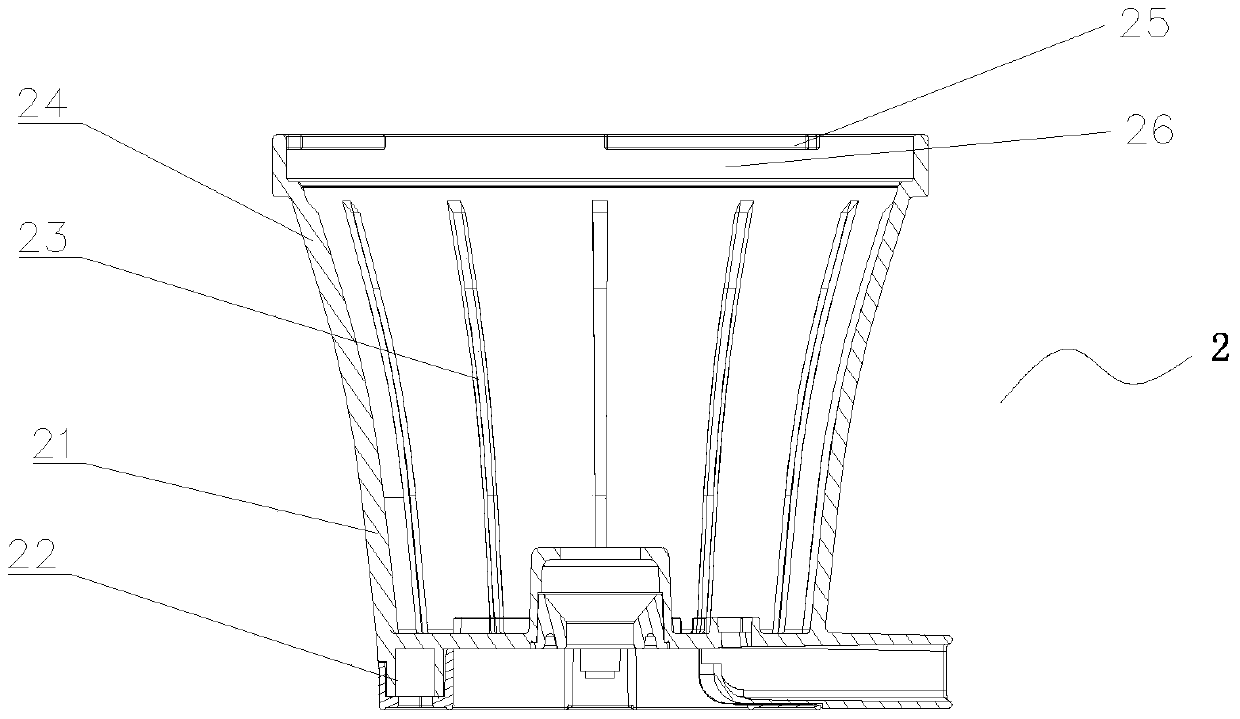

[0053] Such as Figure 1 to Figure 6 As shown, an easy-feeding juice extractor includes a machine base 1, a juice collection container 2 connected to the machine base, an extrusion screw 3 longitudinally arranged in the juice collection container, and a cover on the upper port of the juice collection container. The upper cover 4 is provided with an opening 41 and a feed channel 42 communicating with the opening. The extruding screw includes a body 32 and a screw shaft 31. The body is provided with a screw, and the opening 41 covers all The center of rotation of the extruding screw, the upper end of the extruding screw 3 is provided with a positioning structure 38 arranged in the circumferential direction, and the opening of the upper cover is provided with a limiting structure arranged in the circumferential direction. The positioning structure cooperates to limit the extrusion screw. In this embodiment, the positioning structure 38 is an annular wall, and the positioning str...

Embodiment 2

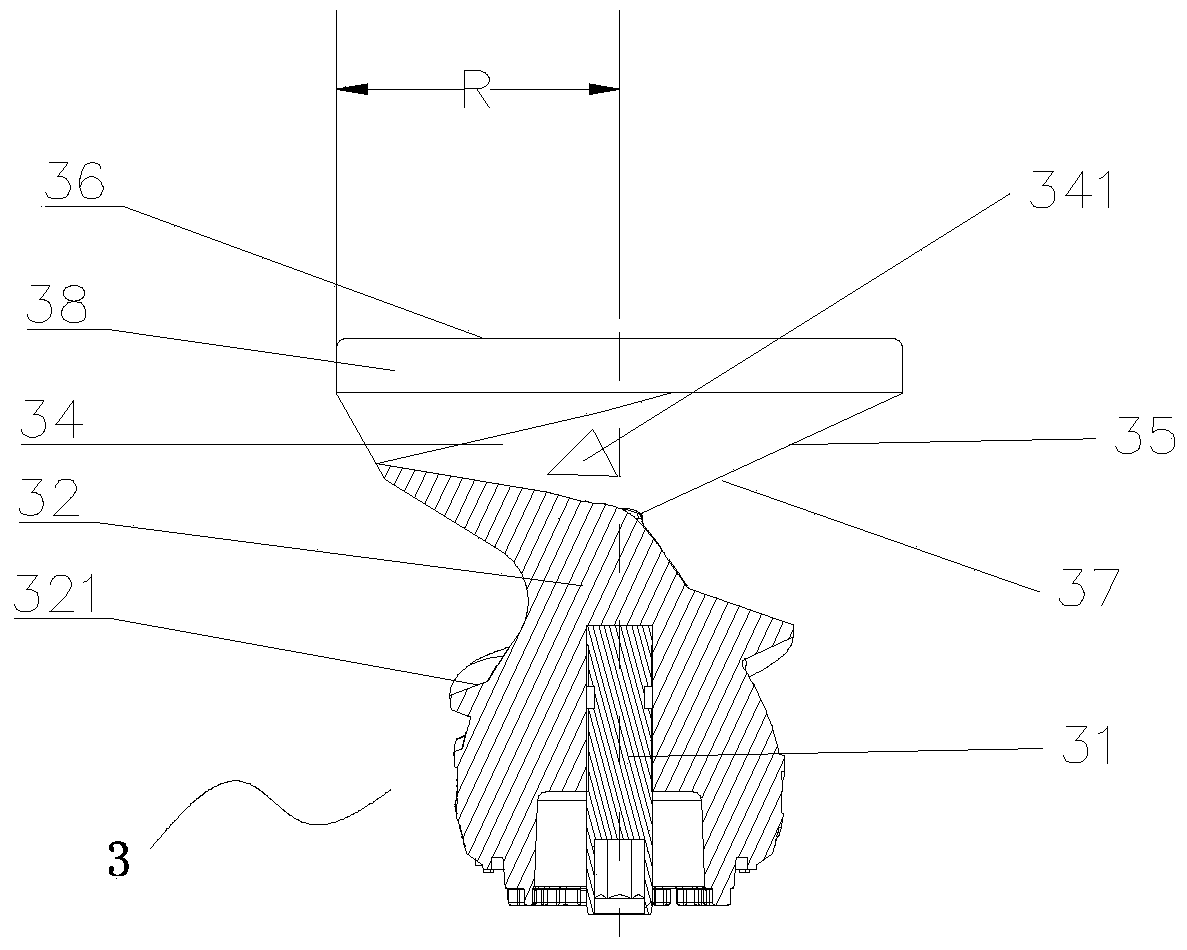

[0067] Such as Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that the positioning structure 38 is an arc-shaped positioning protrusion, and the positioning structure at least partially extends downward to the extruding screw to form a connecting wall 34, and the connecting wall 34 surrounds A feed transition area is formed, and the transition area communicates the feed channel 42 with the juice collection container 2 . The arc-shaped positioning protrusion is discontinuous, but it is easier to assemble with the limiting structure, and the arc-shaped positioning protrusion has a certain adjustment space relative to the circumferential limiting structure, so as to prevent the positioning structure 38 and the limiting structure from being stuck when they move relative to each other.

[0068] The connecting wall 34 is an arc surface or a curved surface, which can make the circumferential positioning structure 38 at the upper end of the extrusion sc...

Embodiment 3

[0072] Such as Figure 8 to Figure 11 As shown, the difference between this embodiment and Embodiment 1 is that a squeeze filter cartridge 5 is also provided in the juice collection container 2, and the squeeze screw 3 is sleeved in the squeeze filter cartridge 5, and the squeeze filter cartridge 5 includes a cylinder body and a filter screen embedded in the cylinder body, the filter screen is provided with filter holes 512, and an extrusion cavity is formed between the extrusion screw rod and the extrusion filter cylinder. The material enters the extrusion chamber along the connecting wall 34, and is driven by the extrusion screw 321 to move downward for crushing and extrusion. The squeeze filter cartridge 5 divides the space formed by the squeeze screw 3 and the juice collection container 2 into two chambers, the squeeze chamber formed between the squeeze screw 3 and the inner wall of the squeeze filter cartridge 5, and the squeeze filter. The juice outlet chamber formed be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com