Rail transit turnout busbar transition piece and contact line clamping device

A rail transit and contact wire clip technology, applied in the field of rail transit, can solve the problems of large amount of suspension parts, poor adaptation of existing devices, and difficult to control installation accuracy, and achieve the effect of small bending radius, reduced consumption, and high consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

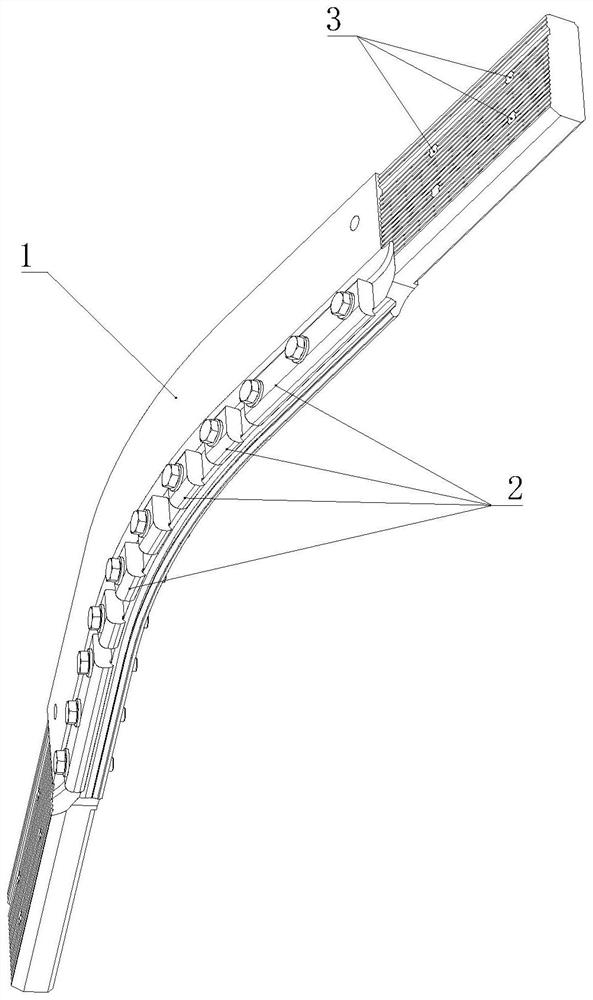

[0031] Such as figure 1 The busbar transition piece shown is used at the rail transit turnout. Since the turnout guides the train to change its route, the contact line here needs to follow the vehicle to change direction. The transition piece is used to change the direction of the contact line. The transition piece Including the transition piece body 1, the transition piece body 1 is bent along the length direction, that is, the bending direction of the transition piece body 1 is consistent with the branch flow direction of the switch, and a splint 2 is arranged on the lower edge of the transition piece body 1, and the contact line is clamped by the splint 2, The contact line is fixed at the bend of the turnout instead of the busbar; installation holes 3 are provided at both ends of the transition piece body 1, and the busbar is fixed on both ends of the transition piece body 1 through the installation holes 3.

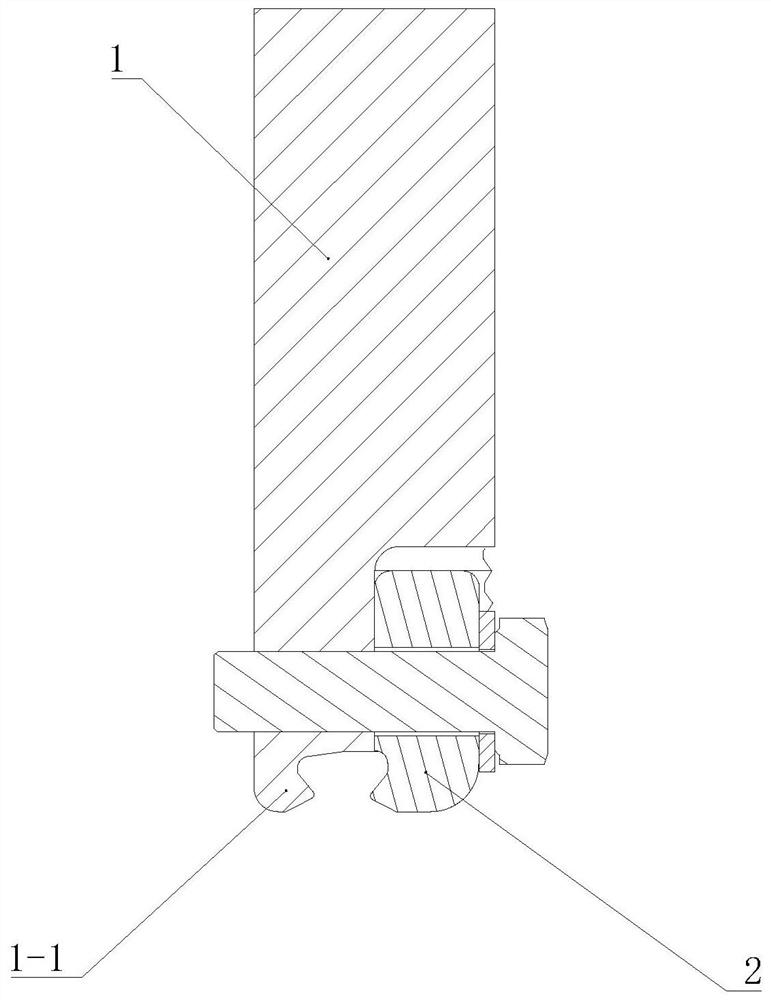

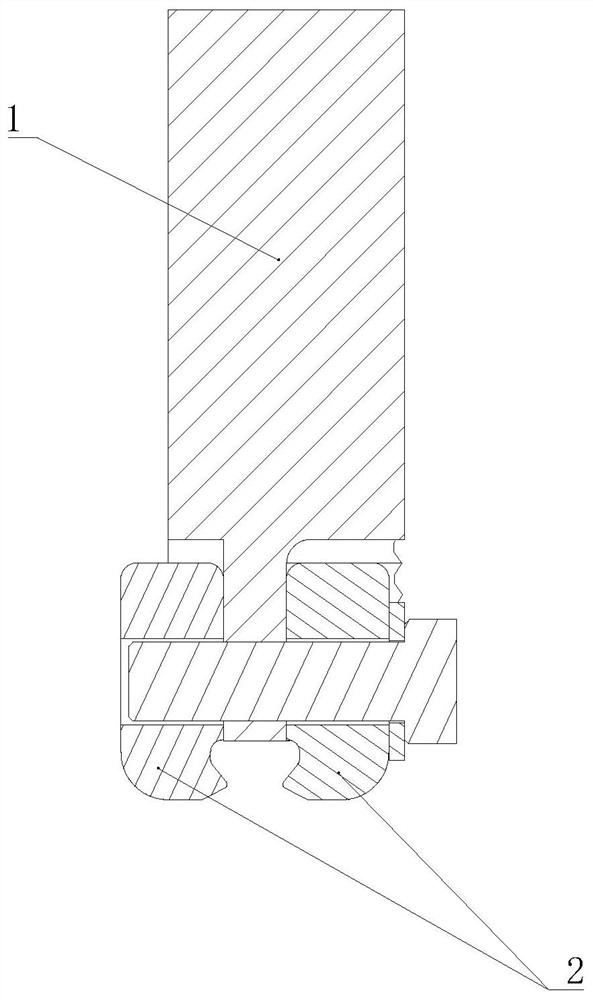

[0032] figure 2 The clamping plate 2 shown is only provided on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com