Ladle capping and uncapping device

A technology of adding cover and ladle, which is applied in the direction of metal processing equipment, casting molten material container, casting equipment, etc., can solve the problems of adding long track, poor adaptability, difficult disassembly and assembly, etc., and achieves easy installation accuracy and convenient installation and disassembly , The effect of reducing the frequency of slagging along the edge of the ladle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

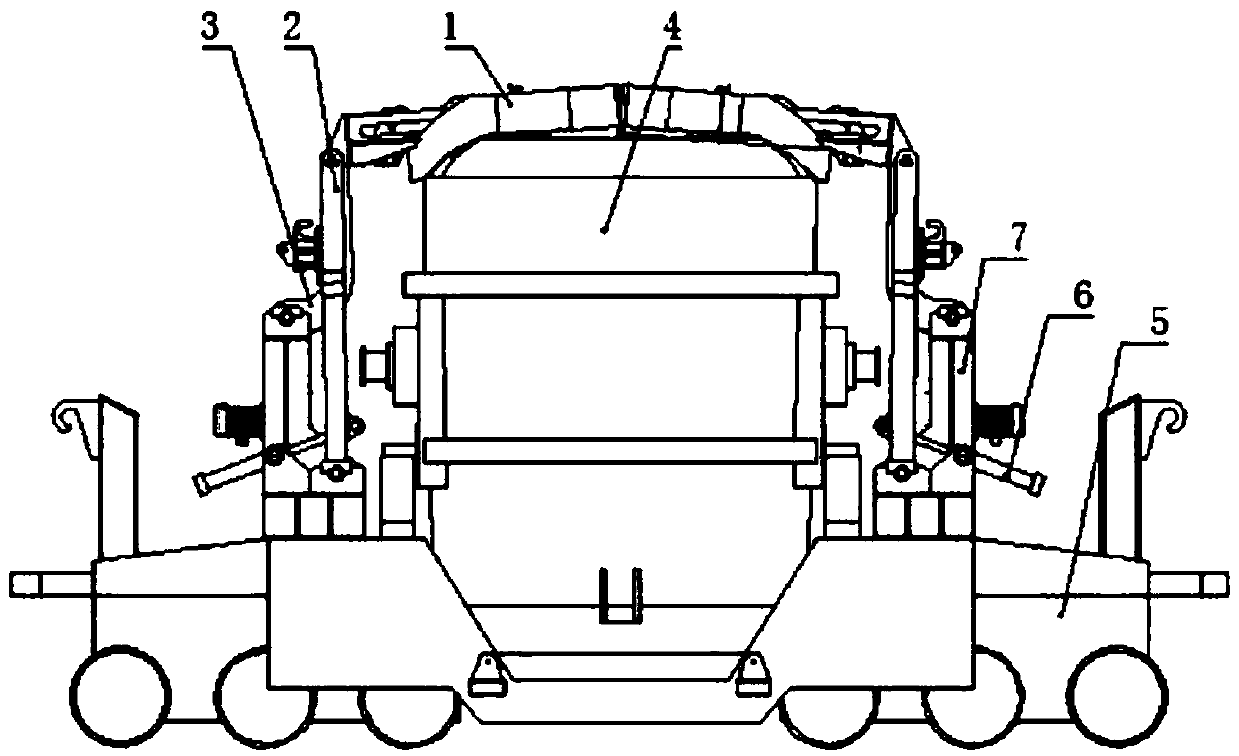

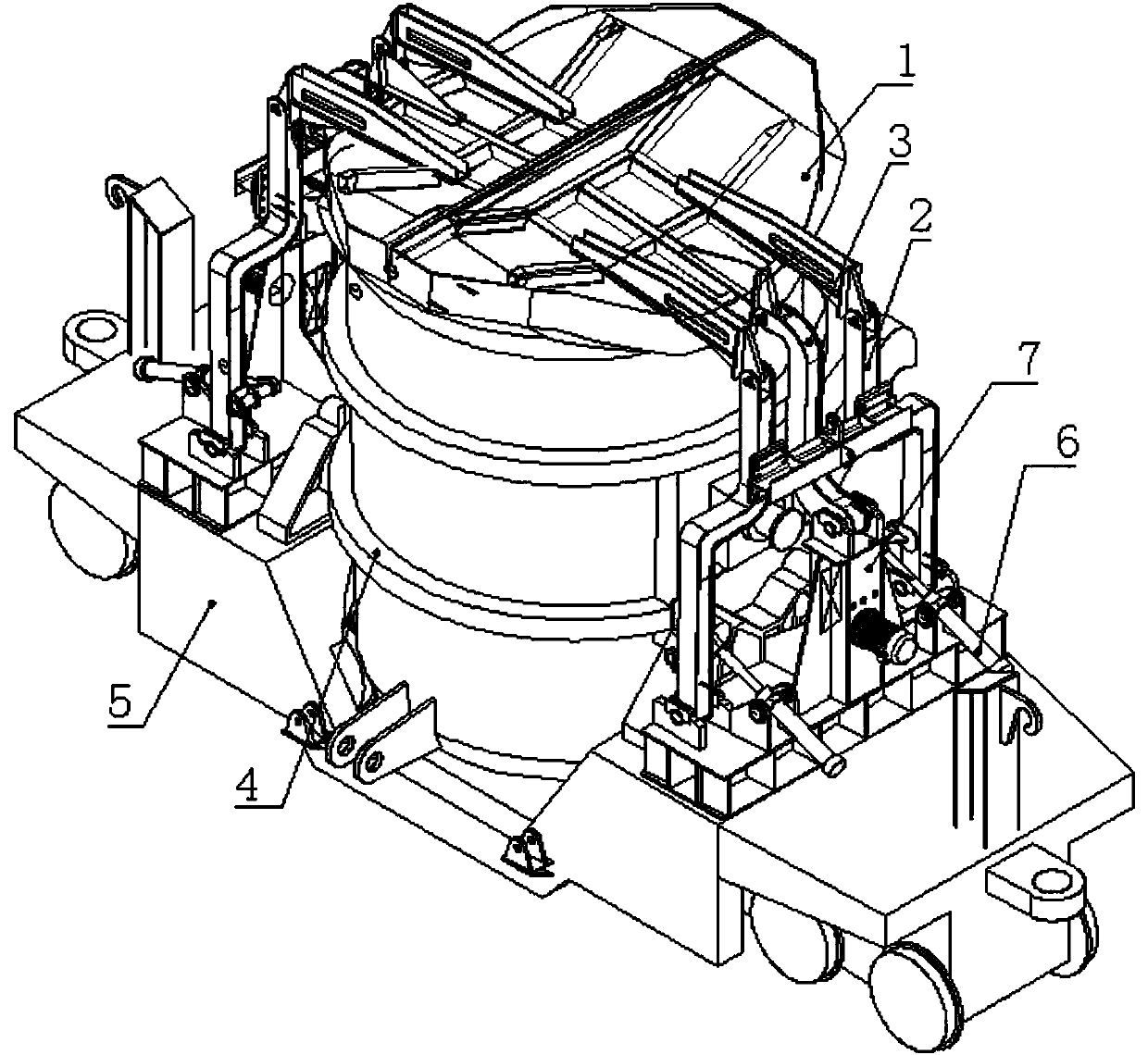

[0033] Such as figure 1 , figure 2 A ladle uncovering device shown is provided with a capping mechanism on both sides of the ladle 4 on the iron ladle car 5, and the capping mechanism includes a semicircular ladle cap 1, an active rocker 2, a connecting rod 3. Oil cylinder 6 and base 7. The two upper ends of the active rocker 2 are hinged to the semicircular iron cover 1, the lower legs are hinged to the base 7, and an oil cylinder 6 is hinged to the inside of the two legs; the other end of the oil cylinder 6 is hinged to the base 7; The two ends of the connecting rod 3 are hinged with the base 7 and the semicircular iron clad cover 1 respectively.

[0034] The hinged hole of the semicircular iron ladle cover 1 and the connecting rod 3 is a waist-shaped hole in the vertical direction. When there is slagging along the mouth of the molten iron ladle 4, the semicircular iron ladle cover 1 in the closed state can be moved along the The waist-shaped hole moves up and down, and...

Embodiment 2

[0038] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown, a kind of molten iron ladle adds and uncovers the capping method of capping device among the present invention, and step is as follows:

[0039] When the iron-clad car 5 with the cover moves to the iron-connecting nozzle station, start the ladle adding and uncovering device, and open the semicircular iron-ladle cover 1 to both sides at the same time;

[0040] When the cover is uncovered, the active rocker 2 is driven by the oil cylinder 6 to rotate, and then the active rocker 2 drives the semicircular iron cover 1 to move, and the semicircular iron cover 1 drives the connecting rod 3 to rotate. The iron ladle cover 1 moves to both sides respectively, and becomes an open state, after which, the operation of connecting molten iron or hanging ladle can be carried out;

[0041] After receiving the molten iron, start the ladle adding and uncovering device again, and cover the semicircular iron ladle cover 1 from...

Embodiment 3

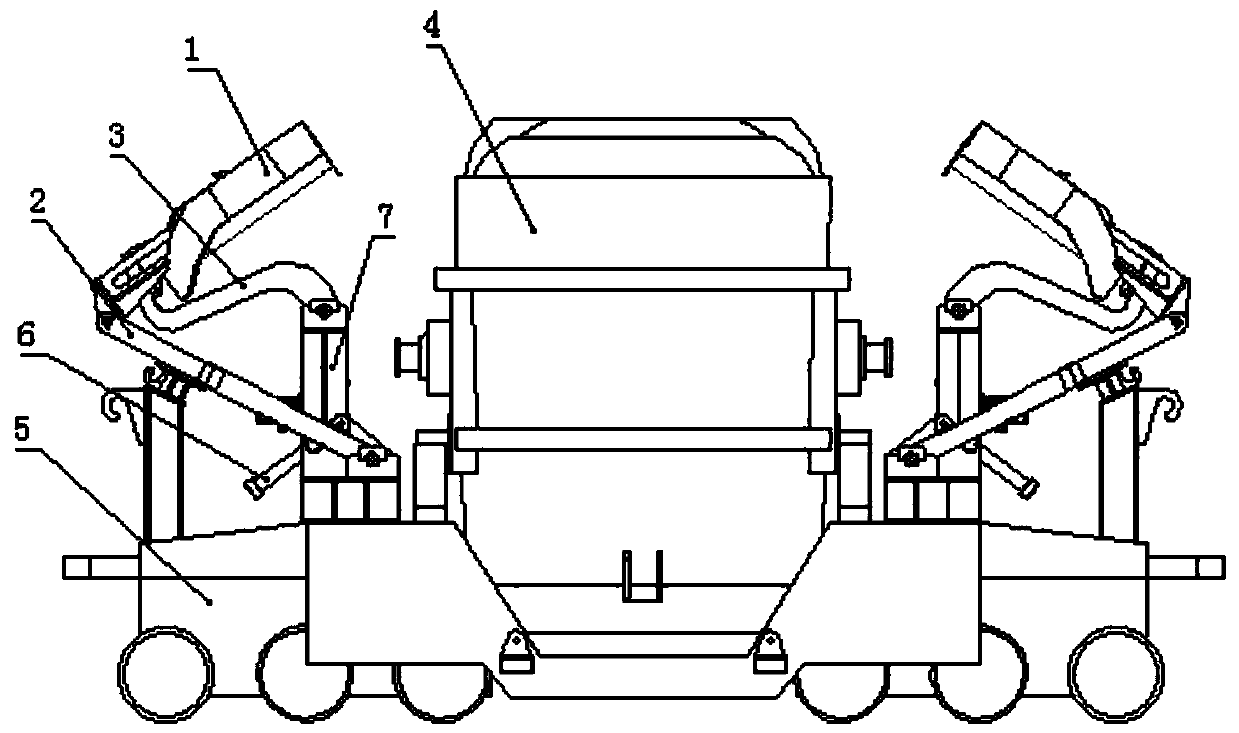

[0045] combine Figure 5 And the method for adding and uncovering the ladle adding and uncovering device in the above-mentioned embodiment 2, it can be seen that the final trajectory of the iron ladle cover in the prior art scheme one is from bottom to top, and the iron ladle lid movement track in the prior art scheme two It is a horizontal movement, and the movement track of the last section of the capping device in the present invention is that the last section of the track is a crimping movement from top to bottom. By simulating design and optimizing the length and positional relationship of the connecting rod mechanism, it can be ensured that the movement track of the ladle cover in the present invention meets the expected effect, and can better adapt to slagging at the mouth of the ladle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com