Circular disc permanent magnetism wind water double cold linear motor oil pumping machine

A technology of linear motors and pumping units, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of difficult maintenance, excessive wear of sliding bearings, long secondary, etc., easy to achieve installation accuracy, and reasonable force distribution , the effect of short working time

Active Publication Date: 2008-10-22

HENGDA ELECTRIC MACHINE GROUP WEIHAI

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, most of the pumping units widely used in oil fields are driven by rotating motors, and the rotary motion is converted into linear motion through a reducer, a complex transmission mechanism and a cantilever; The transmission mechanism is used to directly drag the sucker rod, but because the gap between the secondary and the primary is too small, the secondary is too long, and the linearity is difficult to guarantee. Sliding operation under strong magnetism, the sliding bearing wears too fast, and the theoretical change during operation Many factors are difficult to overcome

The above generally have the disadvantages of complex structure, bulky volume, high energy consumption, difficult maintenance and high cost.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

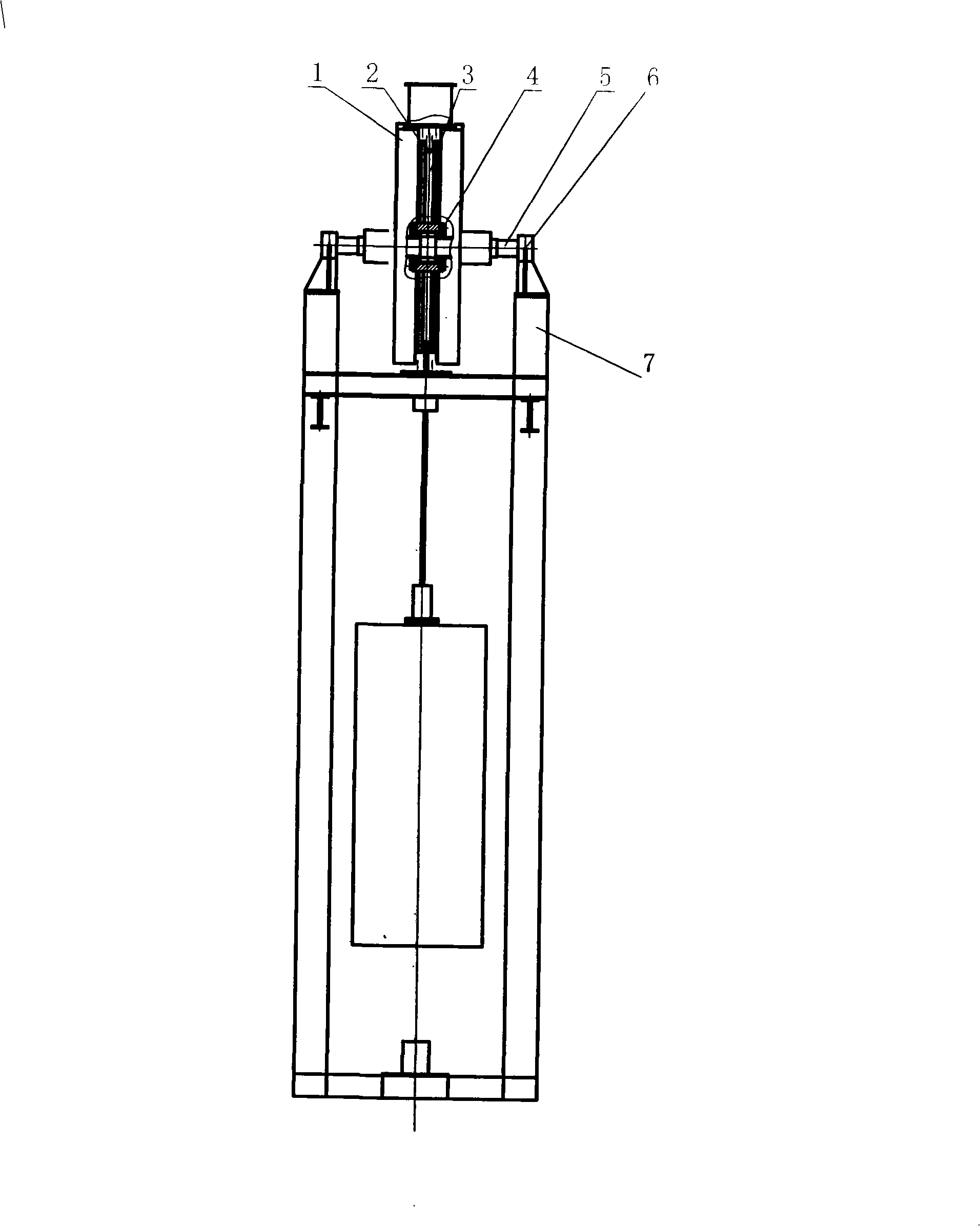

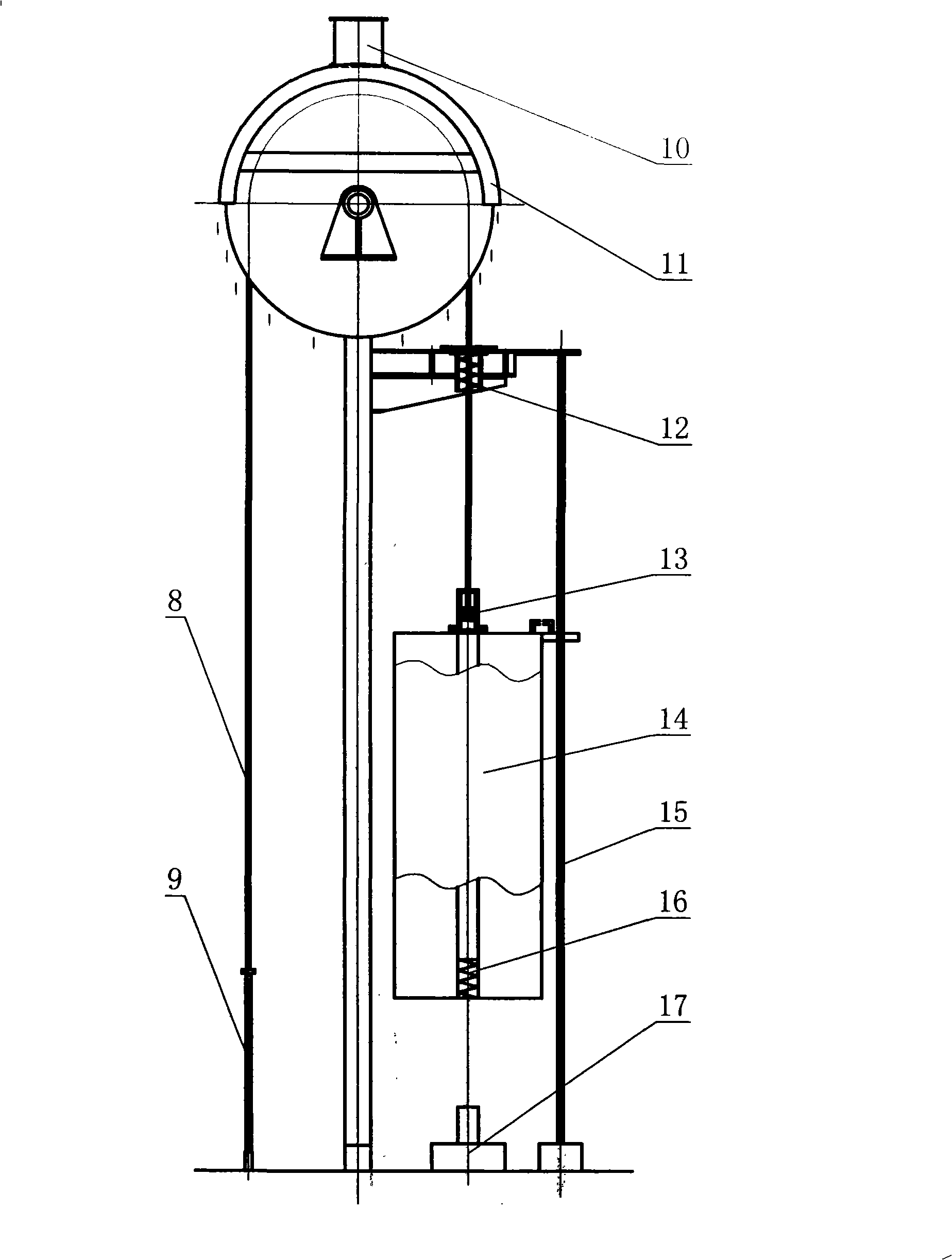

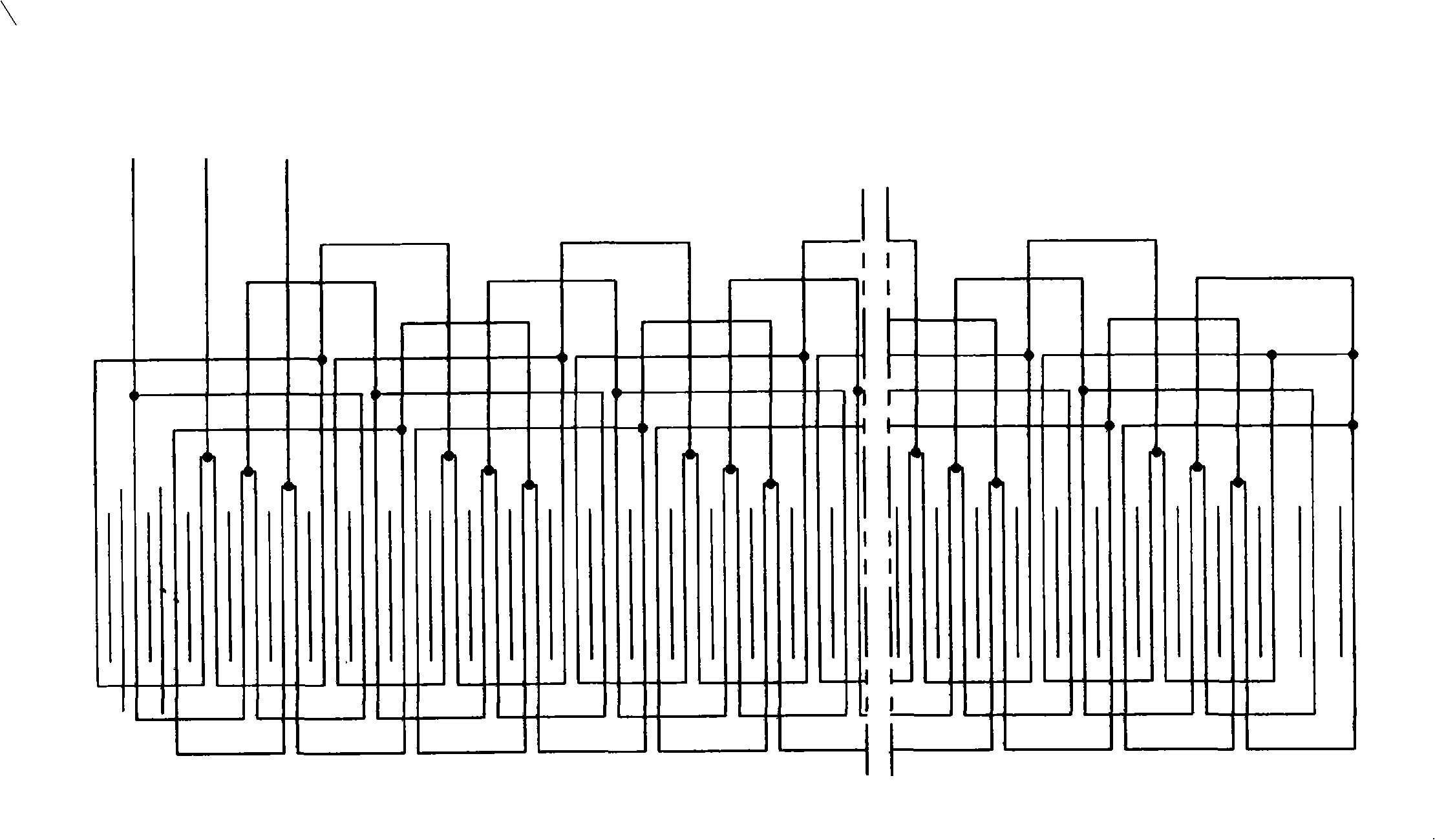

The invention relates to a pumping unit with a disk permanent magnet water-cooled and air-cooled linear motor. Two sides of a rope pulley are respectively provided with a set of disk permanent magnetic water-cooled and air-cooled synchronous three-phase linear motor drive set the primary of which is a stator, the secondary of which is a motor and the secondary is a permanent magnet; the motor adopts water-cooled and air-cooled motor. The secondary is respectively fixed on the two sides of the rope pulley to form a whole; the primary is fixed on the same shaft outside the secondary; a gap is arranged between the primary and the secondary; the primary drives the secondary which drives the rope pulley to rotate; an inner hole of the rope pulley is provided with a rolling bearing; an outer sleeve of the bearing is rotated along with the rope pulley; and an inner sleeve of the bearing is fixed with the shaft. The pumping unit has the advantages of simple structure, multi-pole, low rotating speed, big torque, no environmental pollution, no lubricant, long service life, convenient maintenance, few replaceable parts and easy matching.

Description

Disc permanent magnet Fengshui double cooling linear motor pumping unit Technical field: The invention relates to a disc permanent magnet wind-shui double-cooled linear motor pumping unit. Background technique: At present, most of the pumping units widely used in oil fields are driven by rotating motors, and the rotary motion is converted into linear motion through a reducer, a complex transmission mechanism and a cantilever; The transmission mechanism is used to directly drag the sucker rod, but because the gap between the secondary and the primary is too small, the secondary is too long, and the linearity is difficult to guarantee. Sliding operation under strong magnetism, the sliding bearing wears too fast, and the theoretical change is variable during operation. There are many factors that are difficult to overcome. Above ubiquitous structure is complicated, bulky, energy consumption is many, maintenance difficulty is big, the shortcoming such as high expense. Inven...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E21B43/00H02K41/02

Inventor 杨振学

Owner HENGDA ELECTRIC MACHINE GROUP WEIHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com