Construction method of prefabrication and reverse installation of concrete decorative components for cornices of antique buildings

A technology for decorative components and antique buildings, applied in building components, building structures, buildings, etc., can solve the problems of difficult construction quality control, many safety control items, complex construction processes, etc. Process high-quality effects with simple method steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

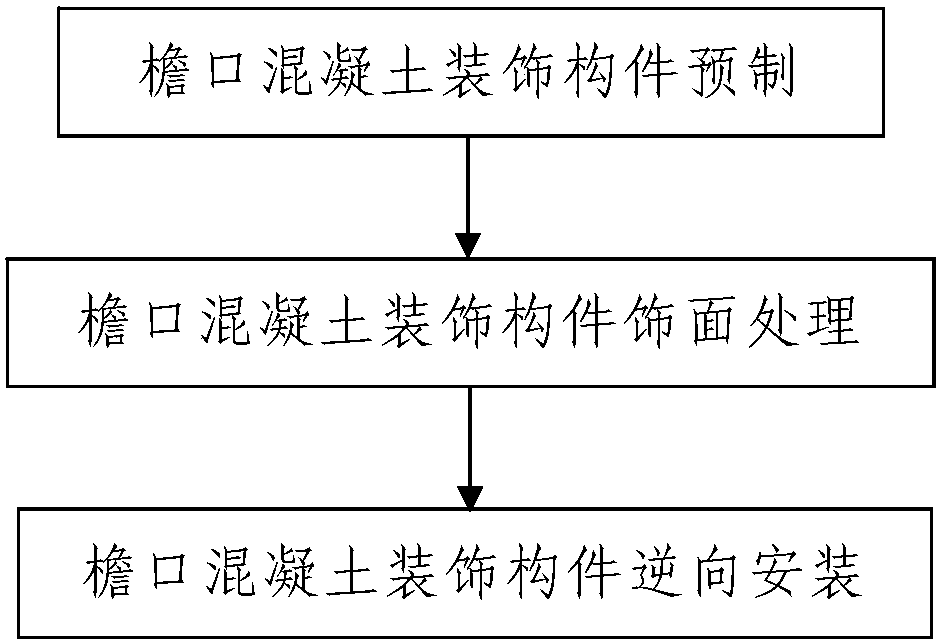

[0059] Such as figure 1 A construction method for prefabrication and reverse installation of concrete decorative components on cornices of antique buildings is shown, including the following steps:

[0060] Step 1. Prefabrication of cornice concrete decorative components: each concrete decorative component in the cornice system of the antique building constructed is prefabricated in the prefabrication site;

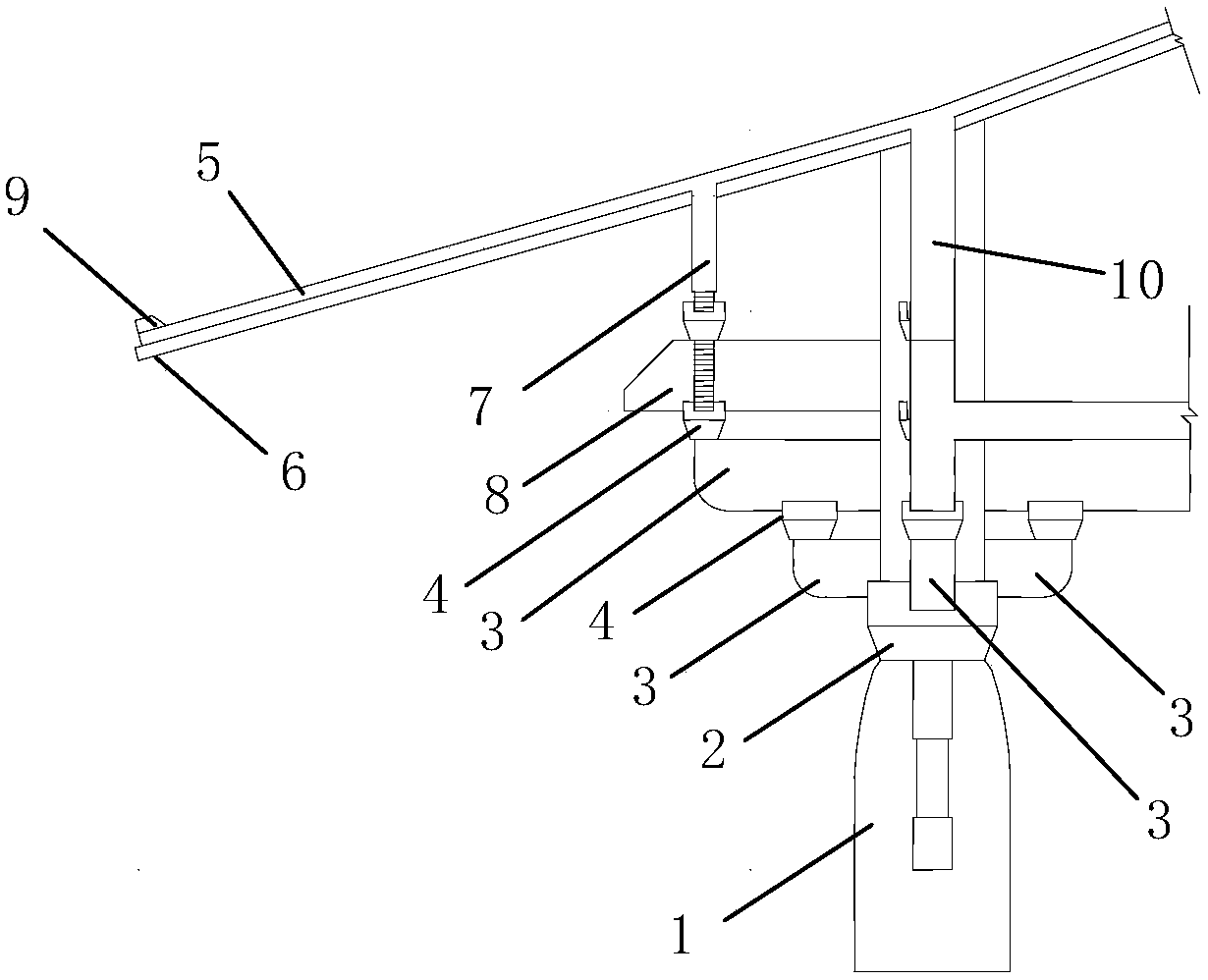

[0061] The main structure of the constructed antique building includes a frame structure and a roof structure erected on the frame structure, the frame structure includes a vertically arranged load-bearing column 1, and the load-bearing column 1 is a cast-in-place concrete column;

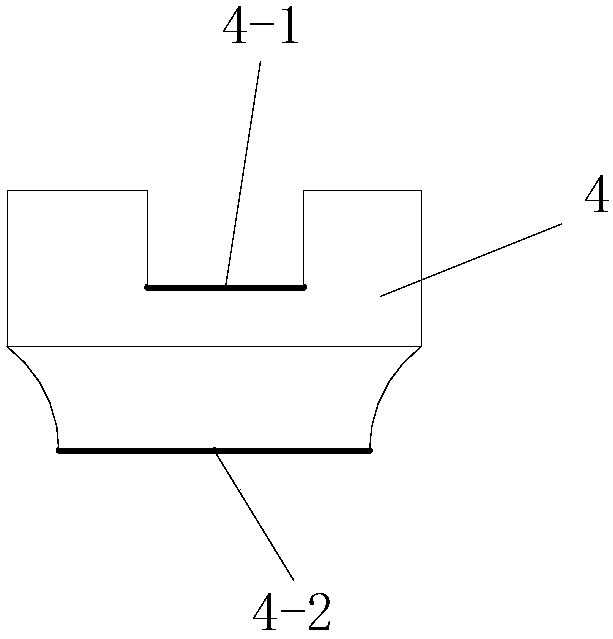

[0062] The eaves system includes a roof support structure supporting the roof structure and a Dougong structure supported between the roof support structure and the load-bearing column 1, the roof support structure is located below the roof structure, and the Dougong structure Located below t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com