Patents

Literature

70results about How to "Work around space constraints" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

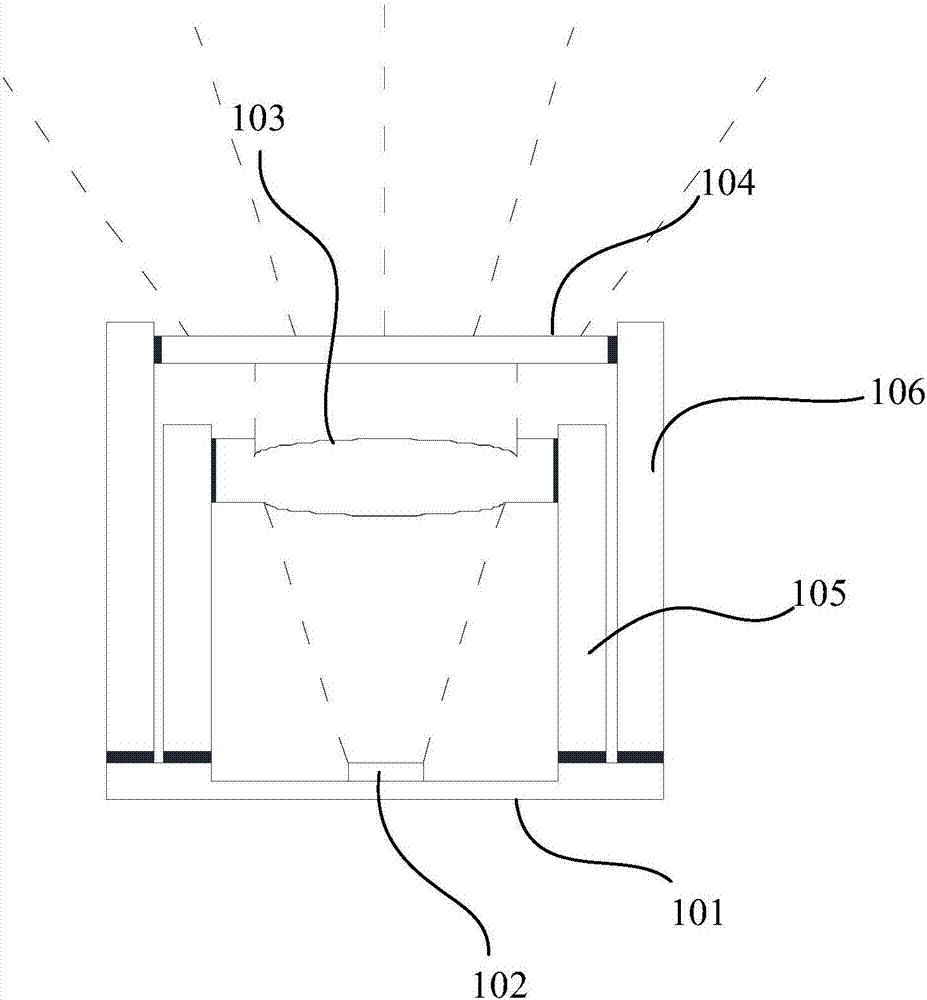

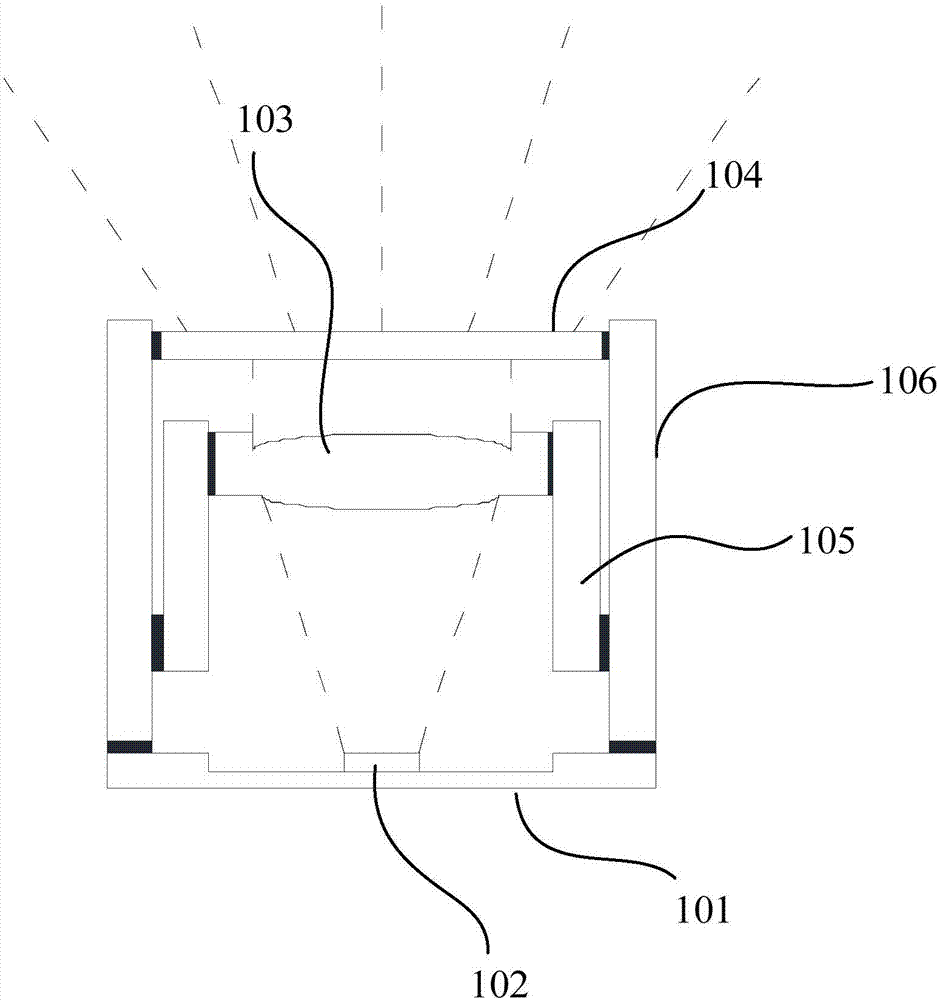

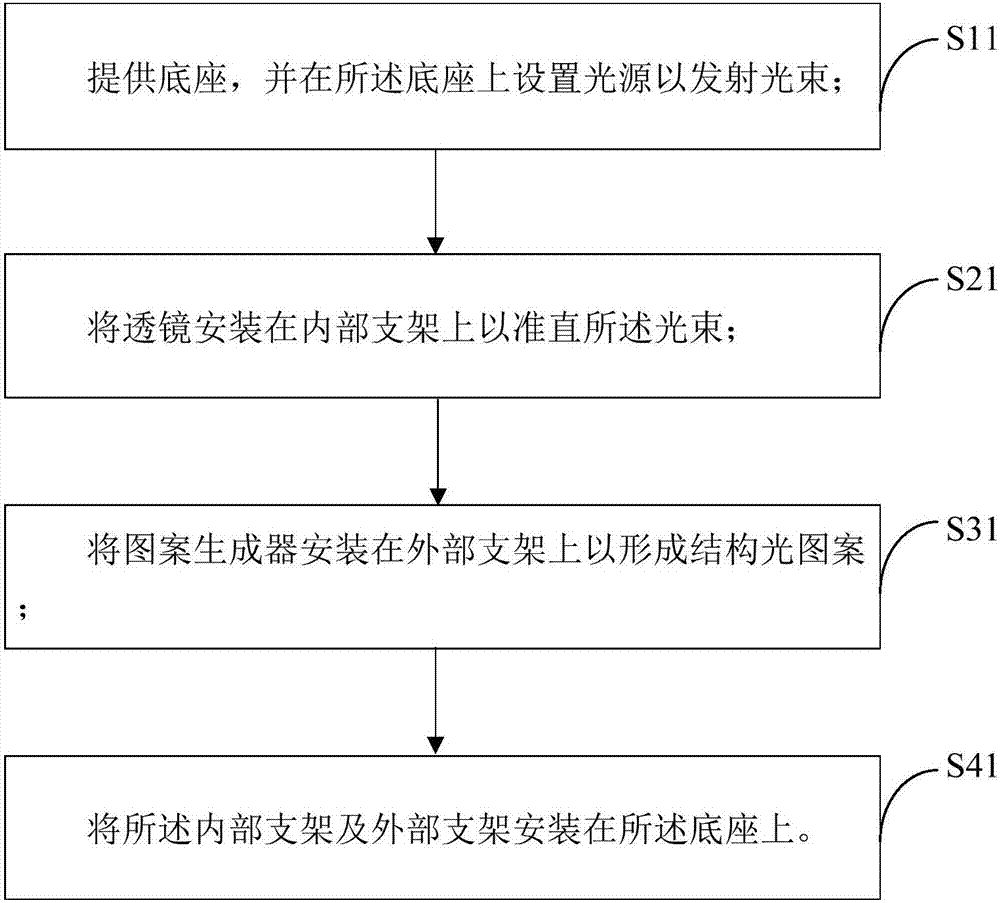

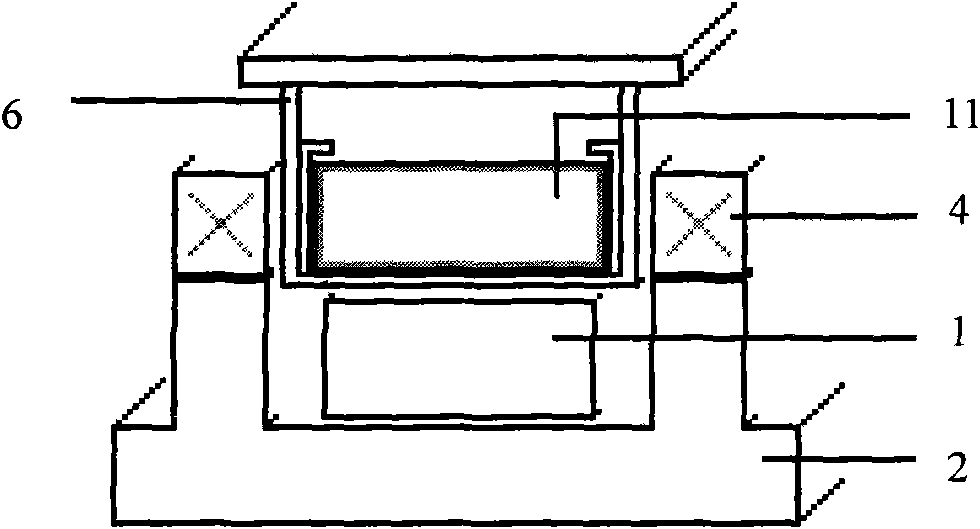

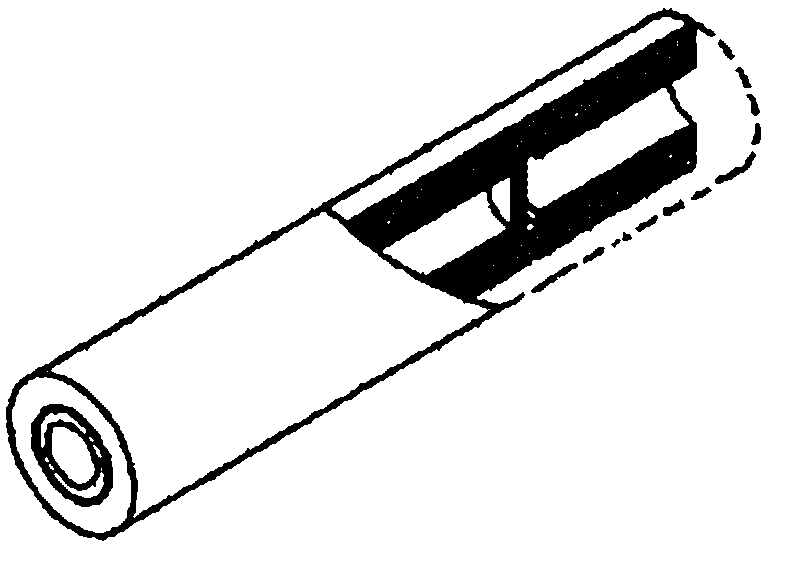

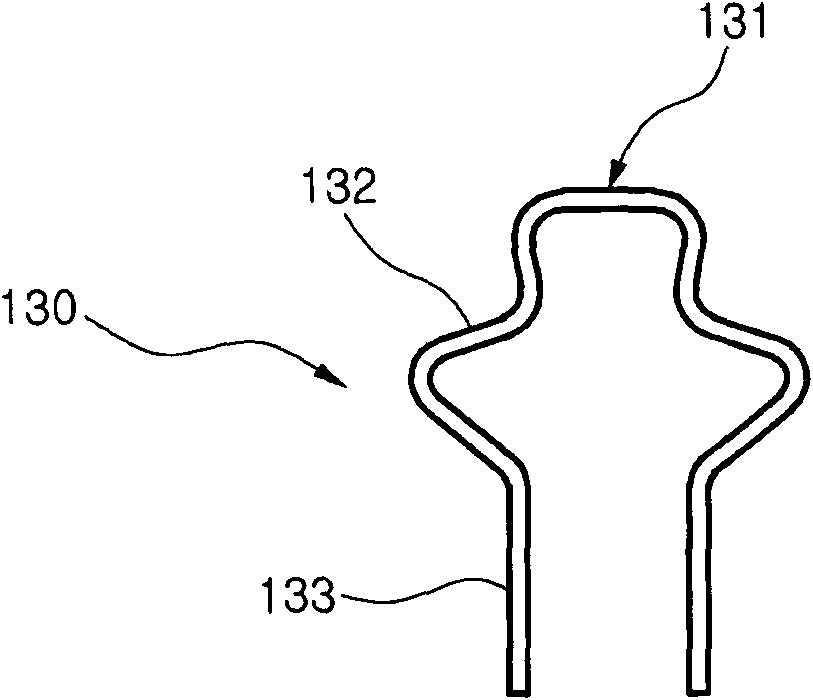

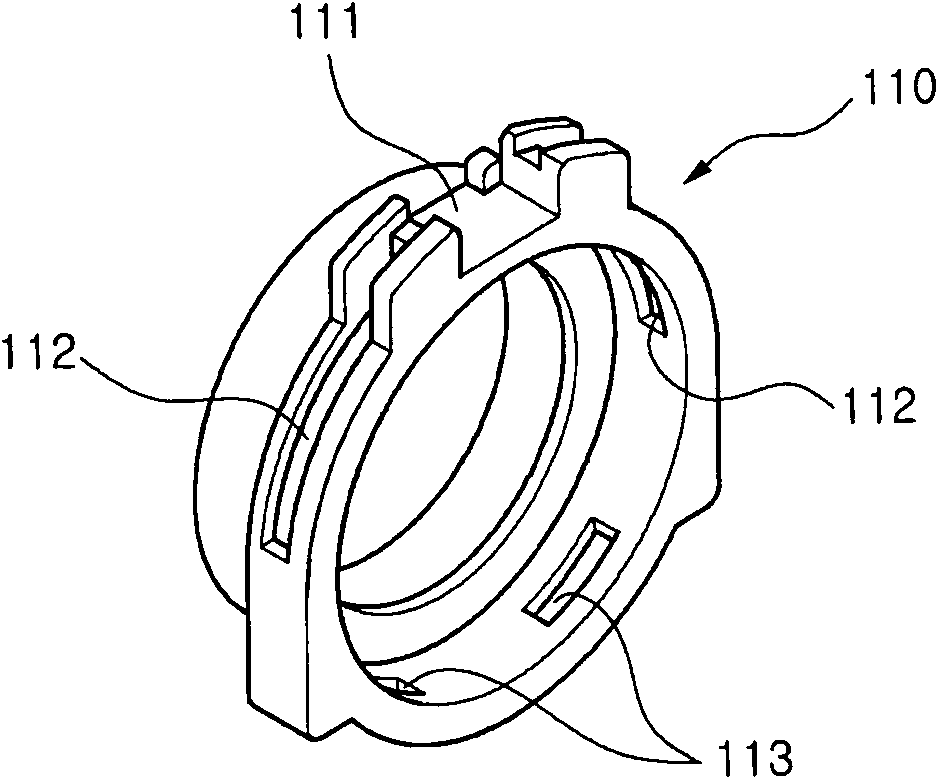

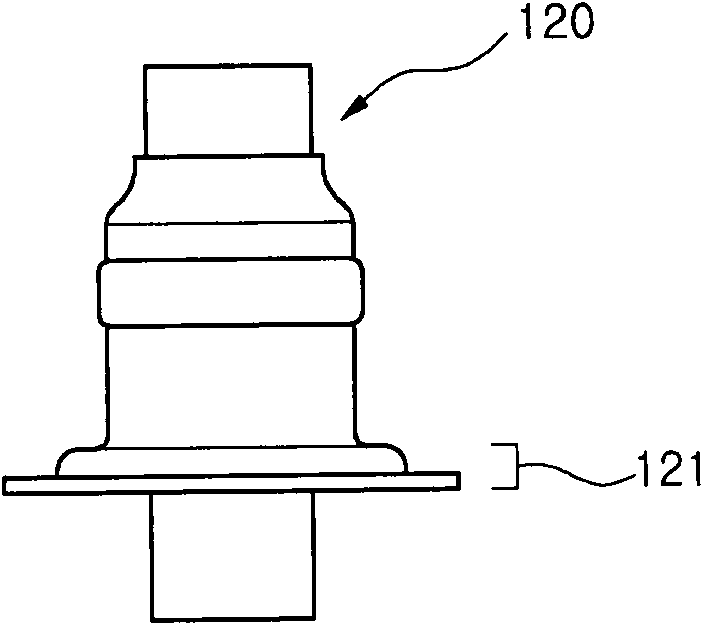

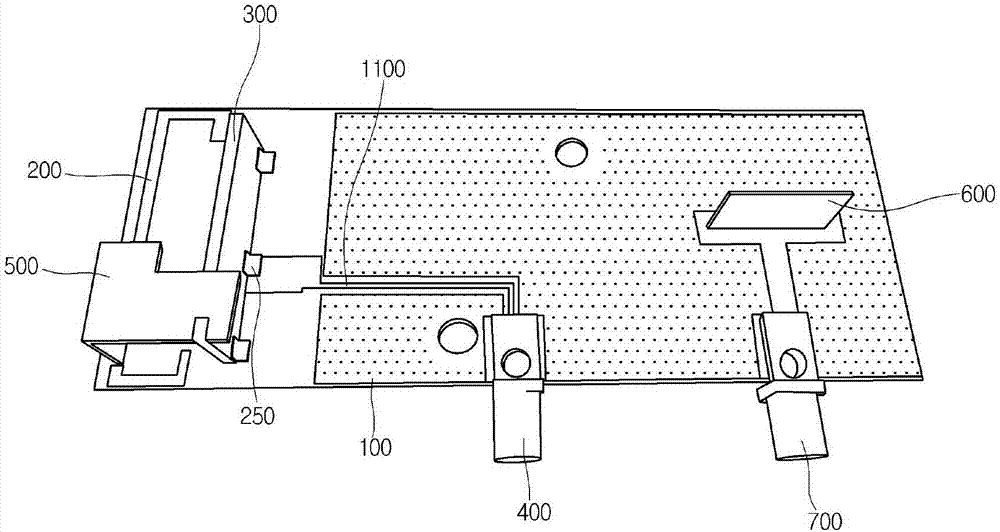

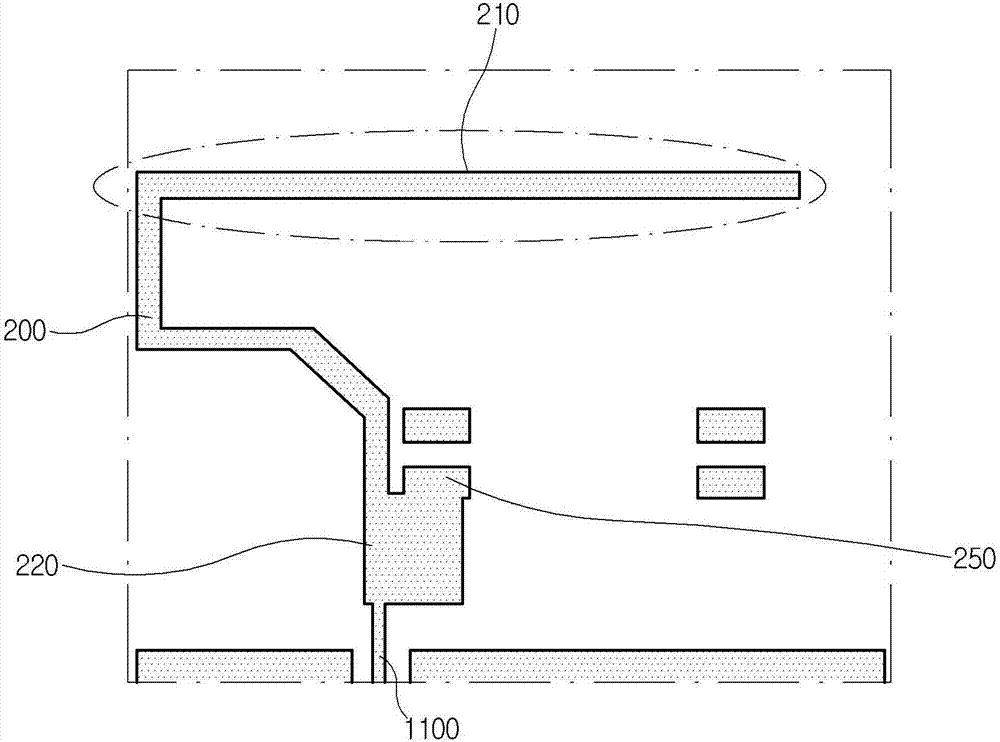

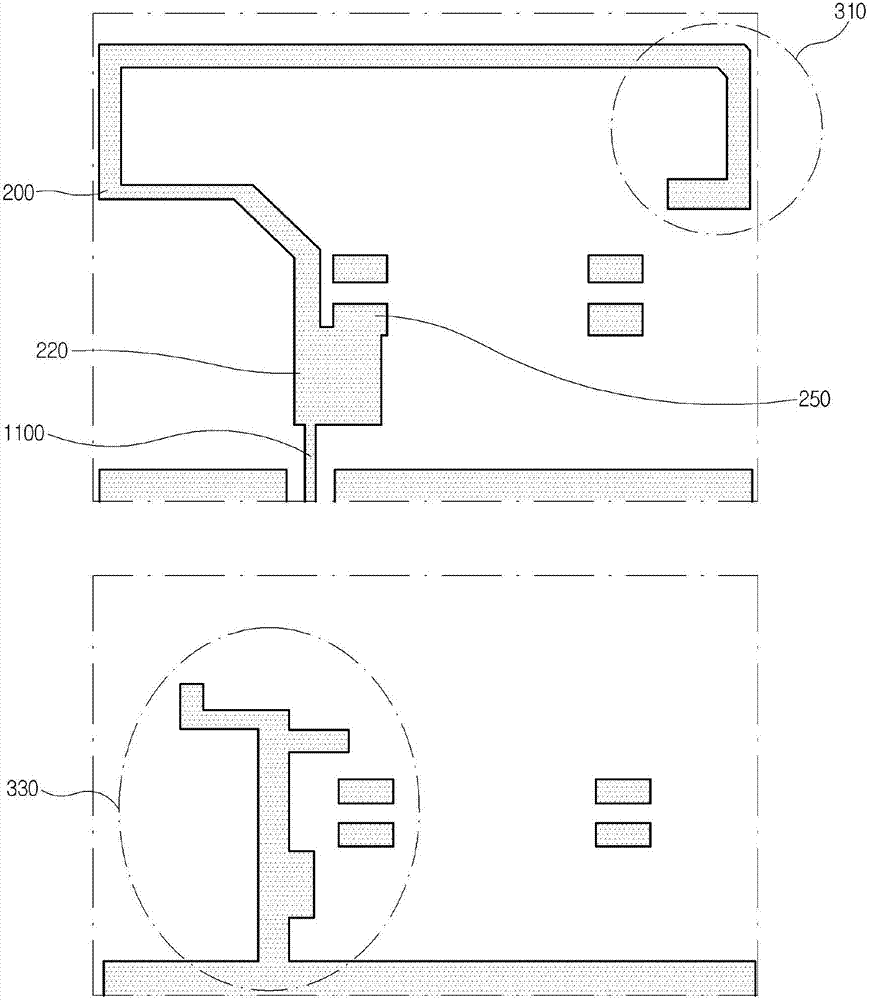

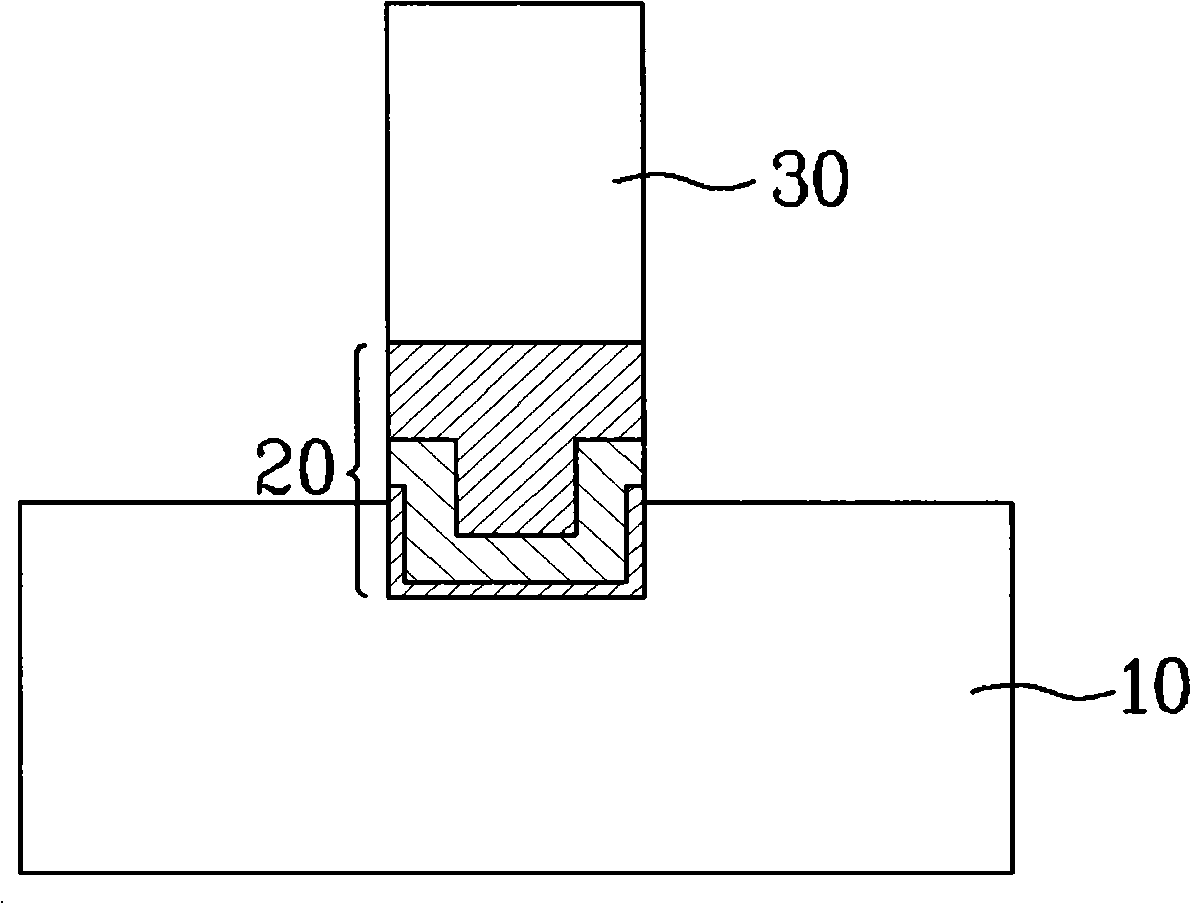

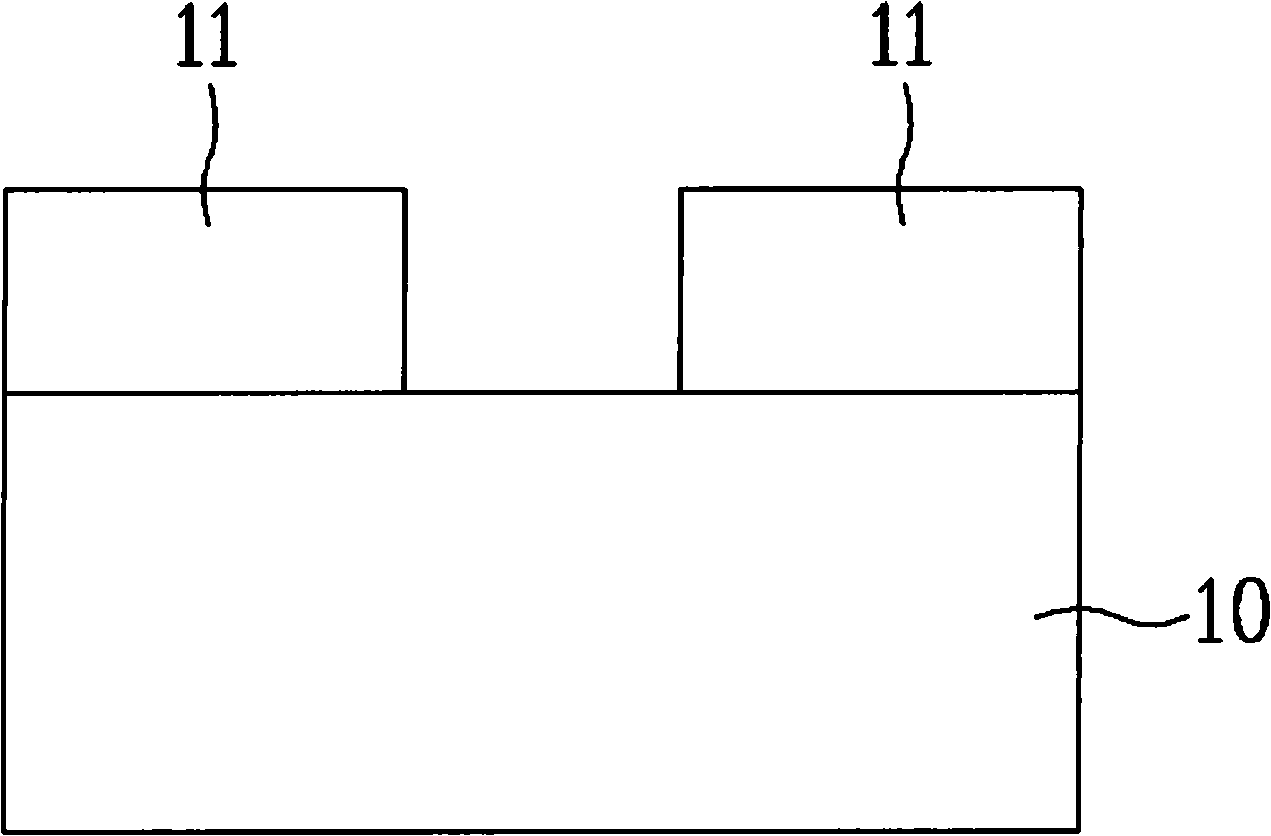

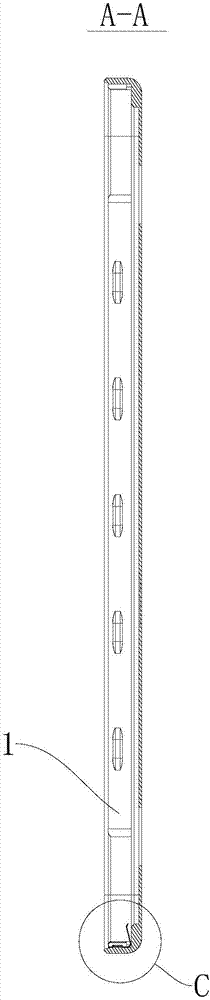

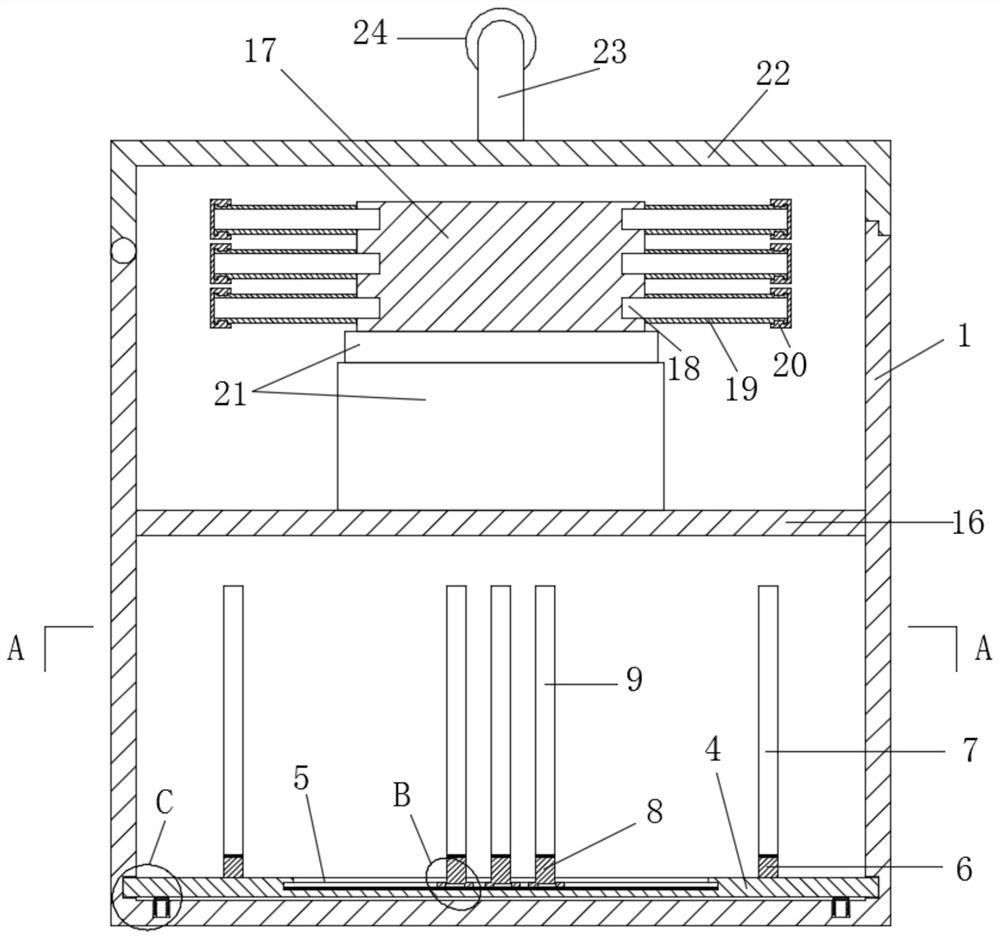

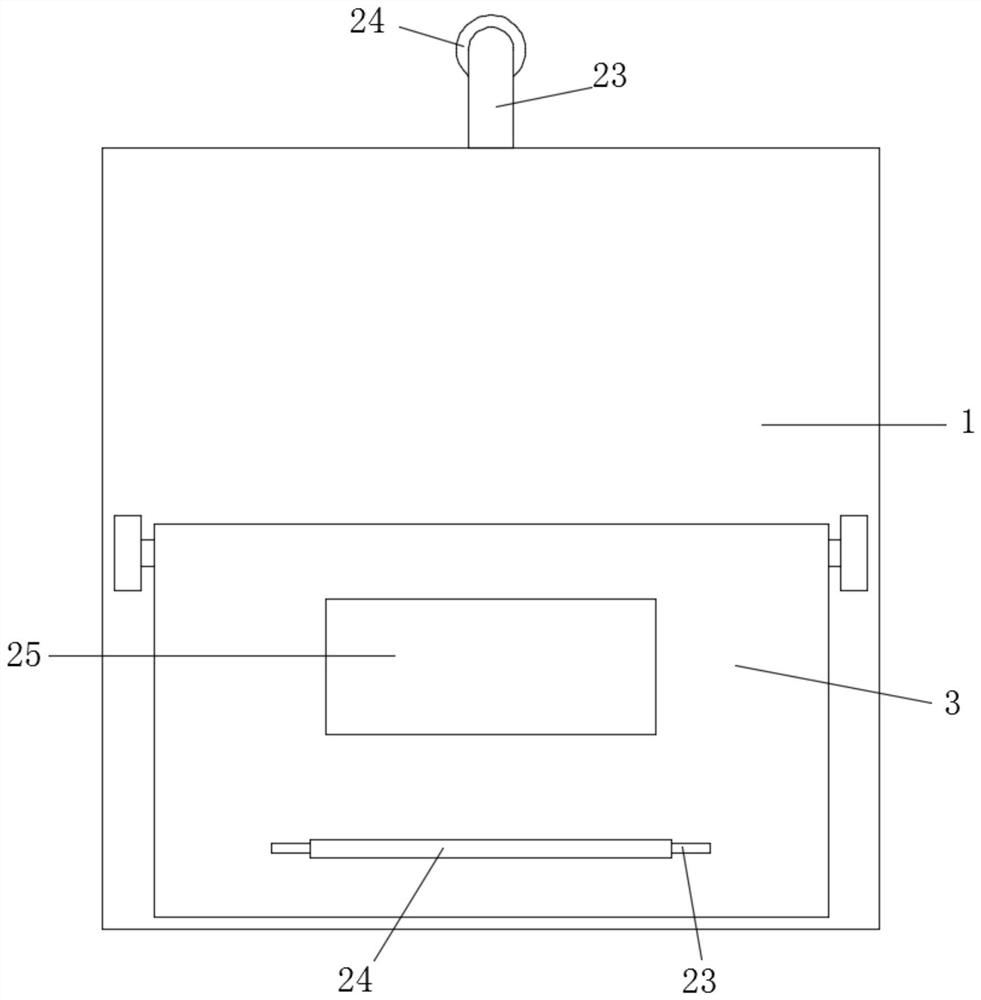

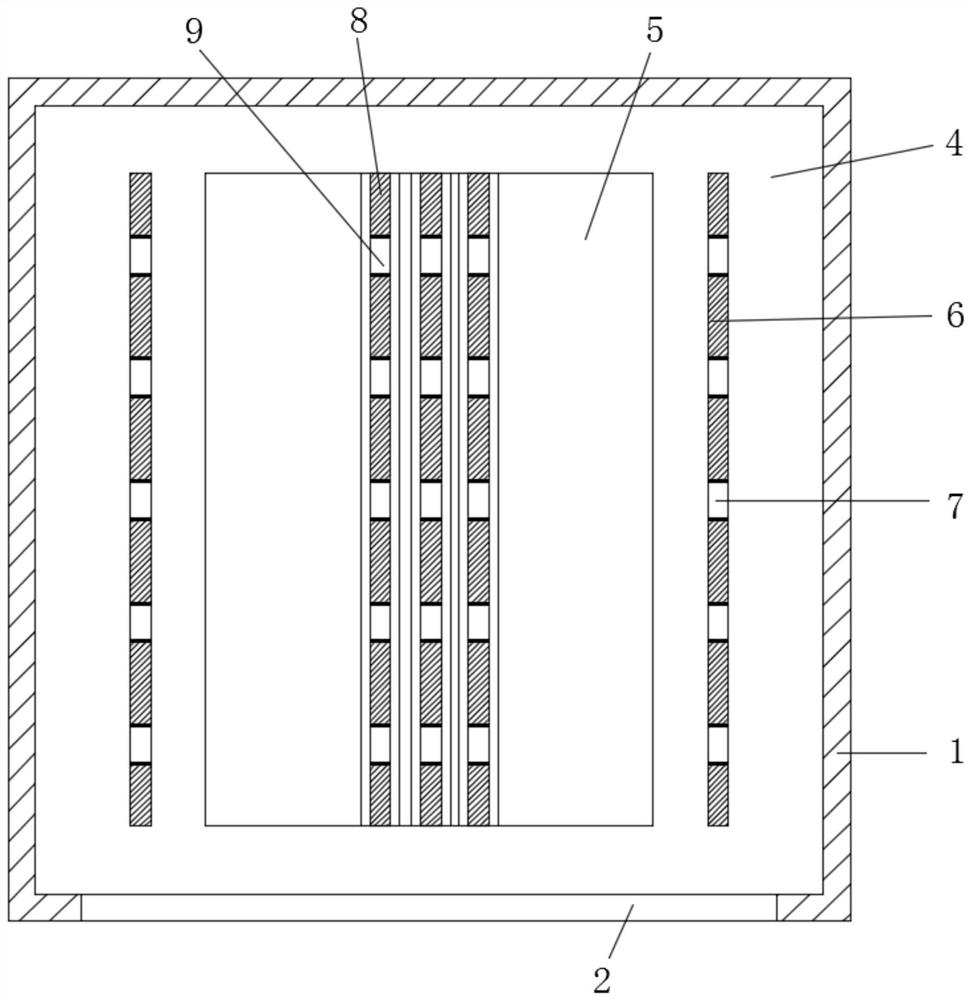

Projection module and manufacturing method therefor and depth camera

PendingCN107229173AMiniaturizationGuaranteed performanceProjectorsCamera body detailsForeign matterMiniaturization

Embodiments of the invention relate to the photoelectric technical field, and provide a projection module and a depth camera. The projection module comprises a base, a light source, a lens supported by an internal bracket, and a pattern generator supported by an external bracket for generating structural optical patterns, wherein the internal bracket and the external bracket are independent non-integrated structures; the internal bracket and the external bracket are mounted on the base; the projection module adopts the internal bracket to support the lens, and adopts the external bracket to bear the pattern generator; the internal bracket and the external bracket are independent structures, so that installation of the lens and the pattern generator can be performed separately without causing mutual constraint; when the internal bracket equipped with the lens and the external bracket equipped with the pattern generator are mounted on the base, the relative positions of the light source, the lens and the pattern generator can be adjusted in a relative easy manner, the installation precision can be controlled easily, the installation efficiency is high and the miniaturization of the depth camera can be facilitated; and in addition, falling off of foreign matters, such as dust and chippings and the like, in the installation process can be avoided, and the lens performance can be ensured.

Owner:SHENZHEN ORBBEC CO LTD

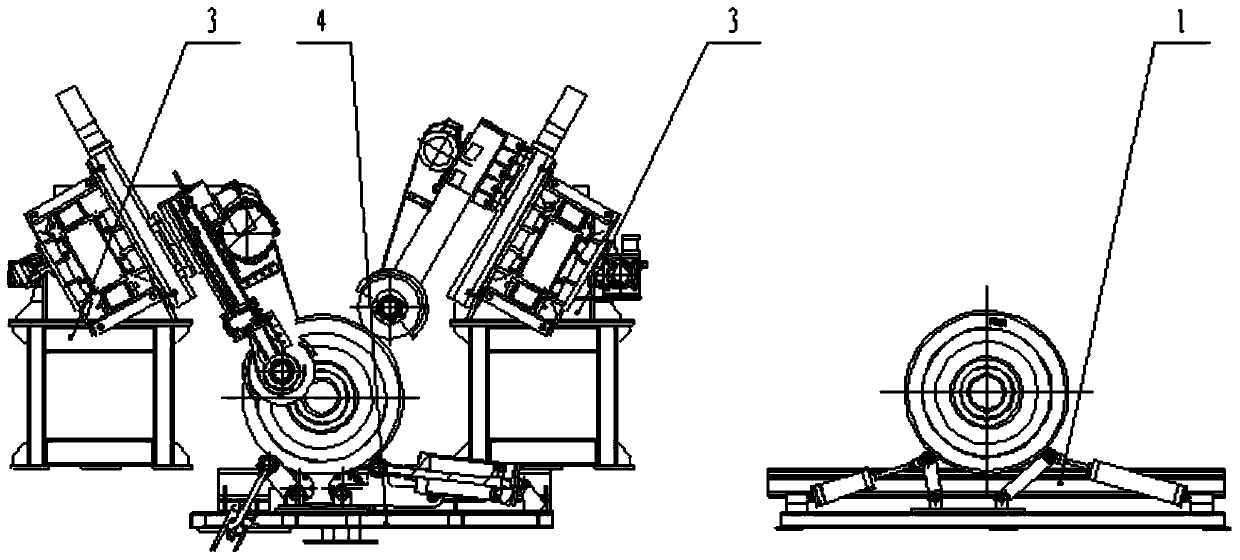

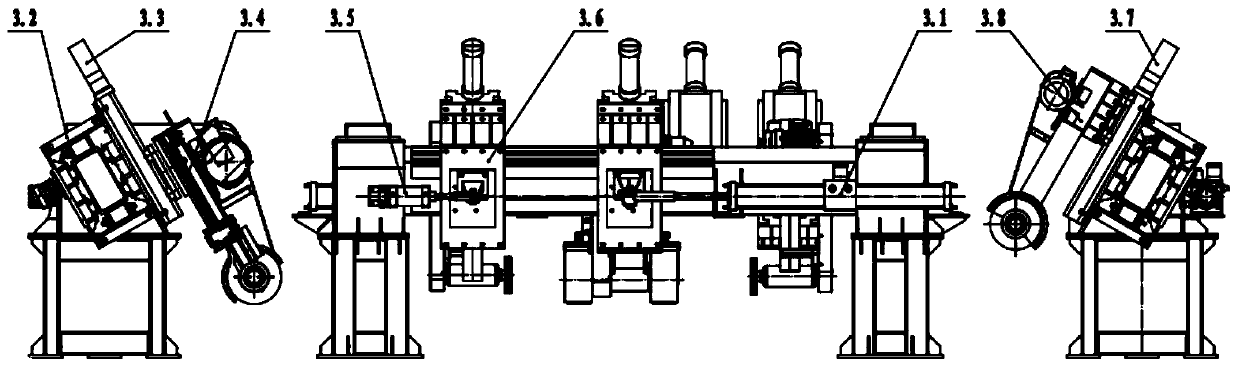

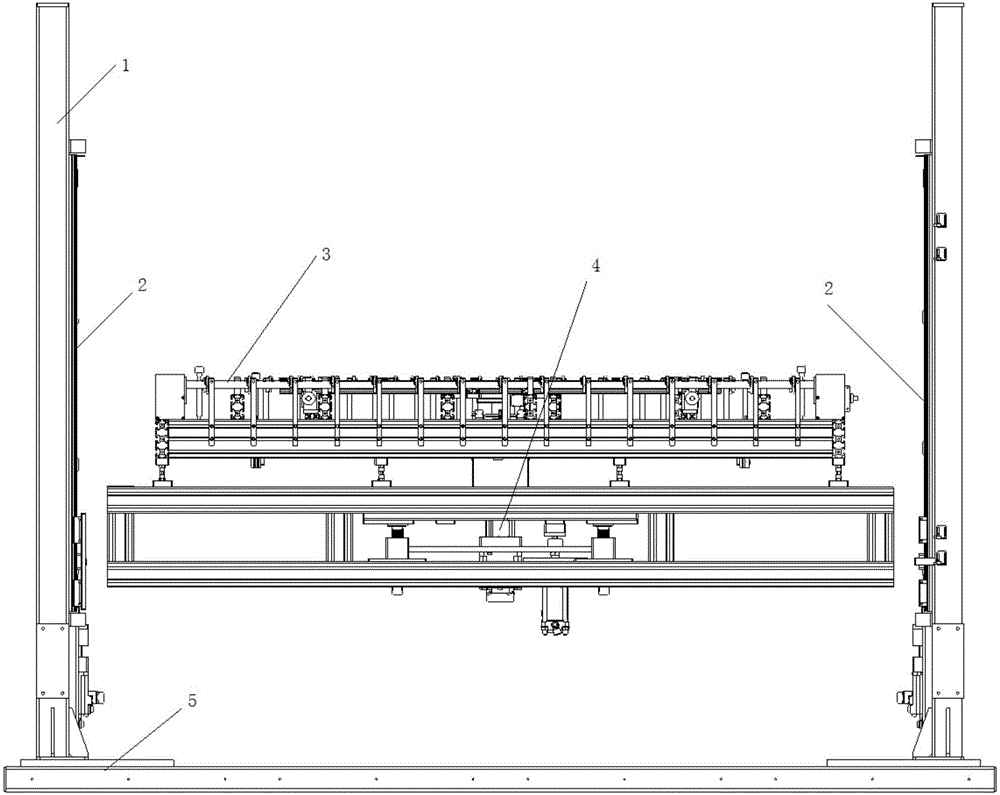

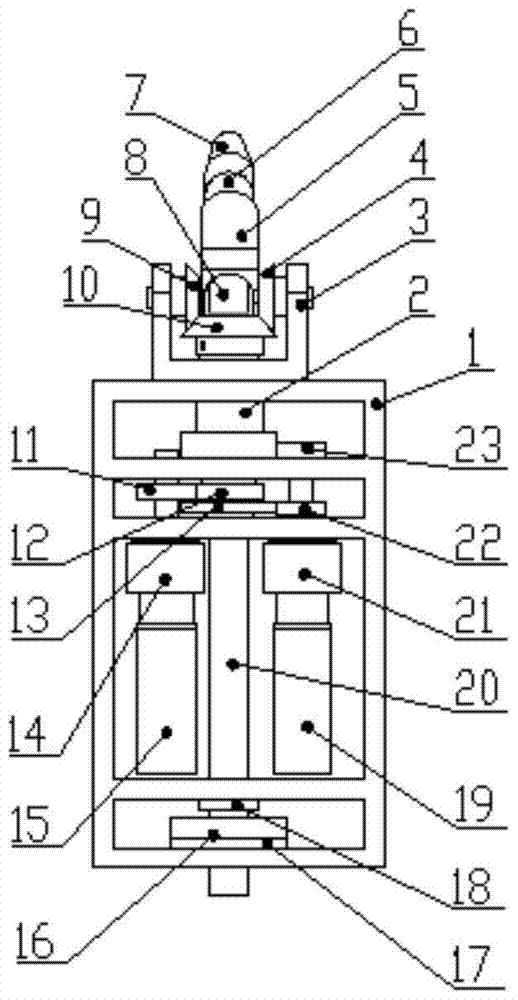

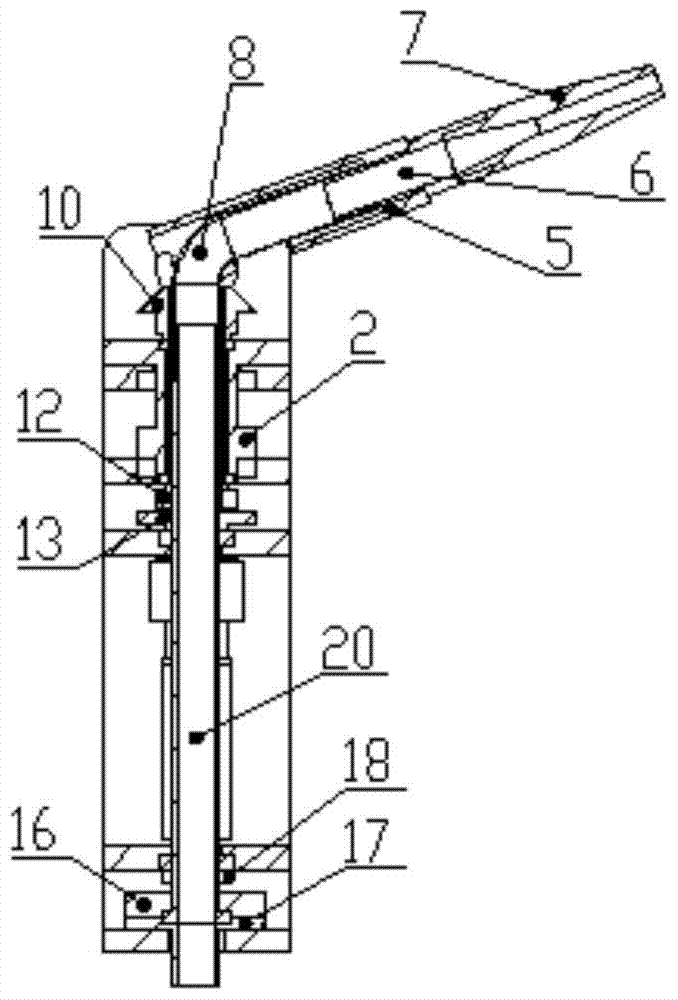

Method for core-crossing hanging large-scale motor hydraulic ram lifting

ActiveCN101277049AWork around space constraintsHigh lifting control precisionLifting devicesManufacturing dynamo-electric machinesElectric machineHydraulic ram

The present invention relates to a method for installing the large-scale electric motor, and especially to a method for coaxially hanging the large-scale electric motor. The method comprises the following procedures: a procedure 1, surveying on site to ensure the installing position of the rail of the hydraulic jacking device, and measuring the service performance of the hydraulic jacking device; a procedure 2, hoisting and unloading the stator of the electric motor, hoisting the stator with the hydraulic jacking device, and orienting the orientation of the load side of the stator; a procedure 3, hoisting and unloading the rotor of the electric motor and installing an extended shaft, hoisting the rotor with the hydraulic jacking device, and installing the extended shaft on the coupler of the rotor with a travelling crane; a procedure 3, core pulling, regulating the central height of the rotor, moving the hoisting device on which the rotor is hanged to pull the rotor on the stator; and a procedure 4, installing the electric motor to the right position. The method of invention overcomes the conditional restriction that the hoisting capacity of the travelling crane between the vehicles is not enough and the clearance height of the clearance height is not enough. The method of the invention overcomes the restriction of the space at the circumference of the base of the electric motor, smoothes the hoisting operation and saves the working procedure of adjusting at the installing position of the electric motor.

Owner:CHINA MCC20 GRP CORP

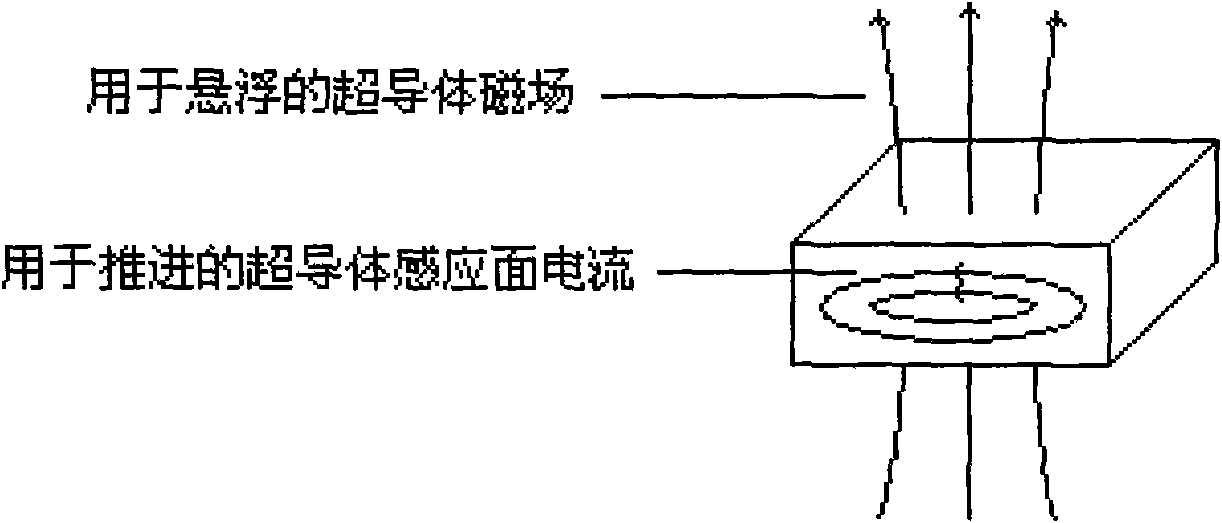

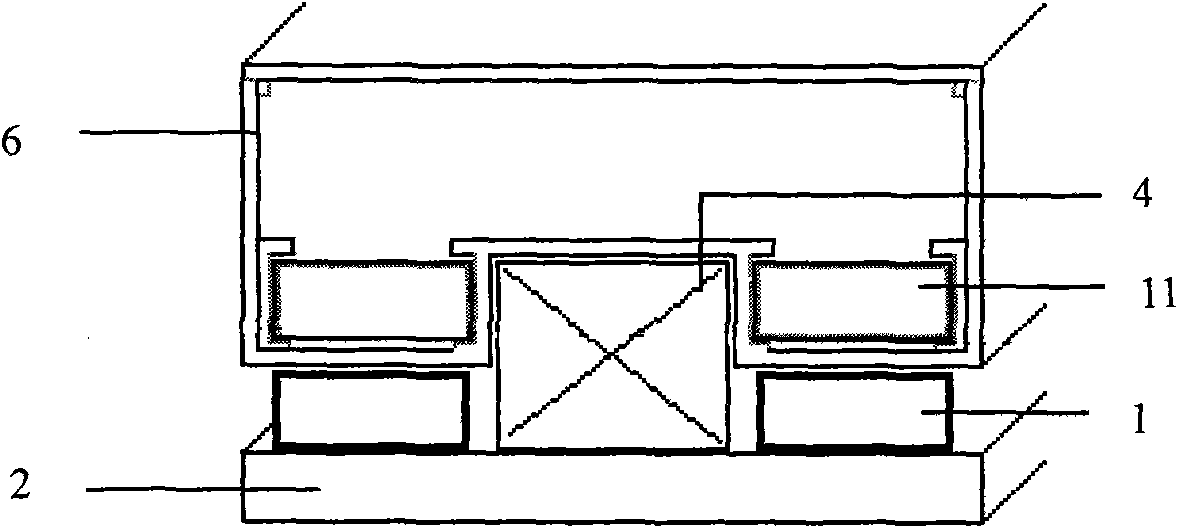

High-temperature superconducting linear suspension propulsion system

InactiveCN102114790AImprove efficiencyReduce volumeDynamo-electric machinesMagnetic holding devicesElectrical conductorHigh-temperature superconductivity

The invention discloses a high-temperature superconducting linear suspension propulsion system, which comprises a high-temperature superconducting magnetic suspension system and a high-temperature superconducting linear propulsion system which share the same cryostat to form a composite integrated rotor, wherein only one cryostat is arranged in the high-temperature superconducting linear suspension propulsion system. Compared with the prior art, the invention has the advantages that: the high-temperature superconducting magnetic suspension system and the high-temperature superconducting linear propulsion system share a set of refrigerating system to form a composite integrated rotor structure, so that the magnetic suspension system and the propulsion system are combined into a whole, the characteristics of a high temperature superconductor are fully utilized, and space limitation and limitation of minimum volume brought by the refrigerating system are avoided; moreover, the problem of characteristic difference of the high temperature superconductor due to temperature difference is solved in the independent refrigerating process, so that the high-temperature superconducting linear suspension propulsion system is lower in loss, smaller in volume, lighter in weight, higher in efficiency and easier to operate.

Owner:南京索普超导科技有限公司

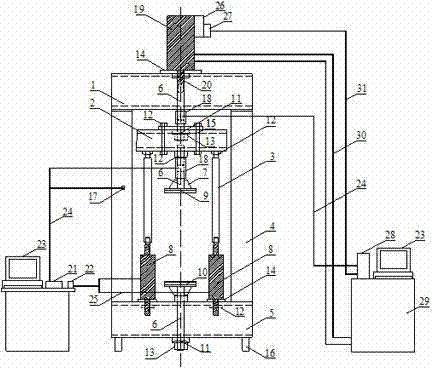

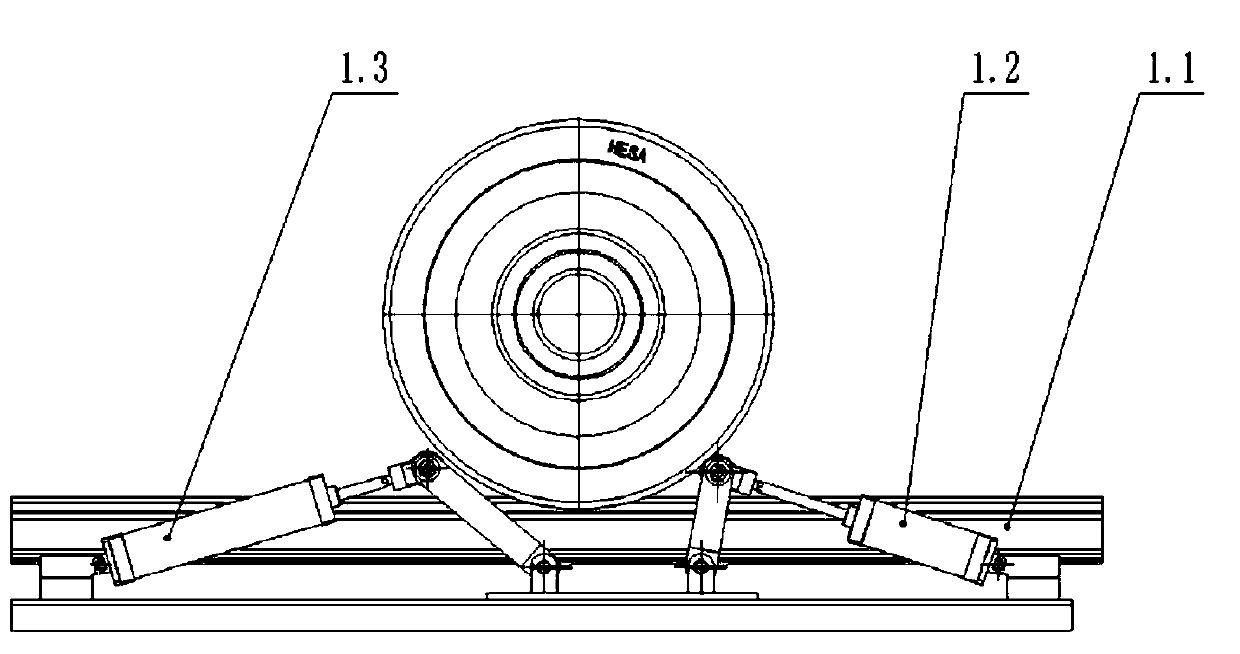

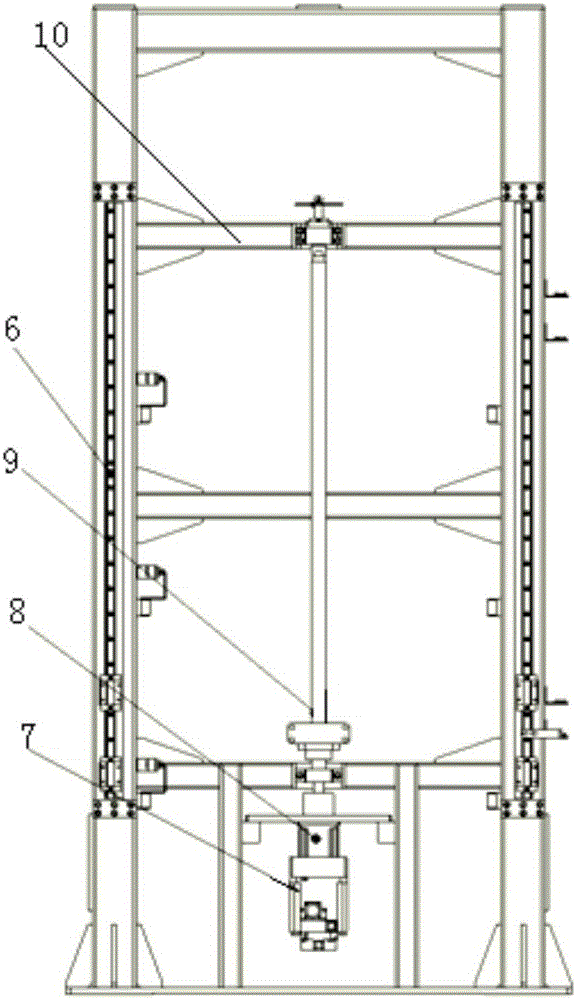

Large-scale fully graded concrete shaft tensile testing machine

InactiveCN102288485AImprove performanceLow priceMaterial strength using tensile/compressive forcesClassical mechanicsMachine

Owner:HOHAI UNIV

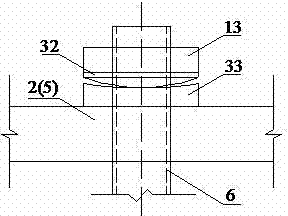

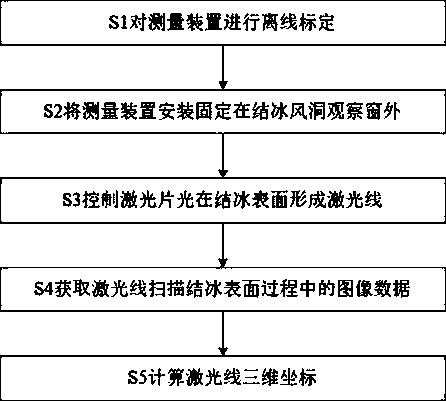

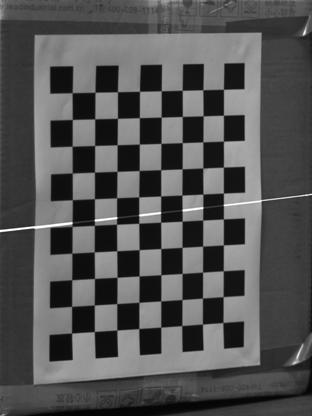

Three-dimensional ice shape online measuring device and method for icing wind tunnel test

InactiveCN111473946AWork around space constraintsEasy to installAerodynamic testingUsing optical meansRotary stageTest measurement

The invention discloses a three-dimensional ice shape online measuring device and method for an icing wind tunnel test, and belongs to the technical field of icing wind tunnel test measurement. The measuring device is composed of a camera, a line laser, a dielectric film reflector, an optical mirror bracket, a supporting rod, a rotating table and a base. The camera is fixedly installed on the baseand used for collecting images. The line laser is fixedly installed on the base through a supporting rod and used for generating laser sheet light. The dielectric film reflector is mounted and fixedin the center of the rotary table through the optical mirror bracket and is used for reflecting laser sheet light generated by the line laser; the rotating table is fixedly installed on the base and used for rotating the dielectric film reflector. After off-line calibration is carried out on the measuring device, the measuring device can be integrally and directly installed and fixed outside an icing wind tunnel observation window for application, icing three-dimensional ice shape on-line measurement in the icing wind tunnel test process can be effectively achieved, and the measuring device has the advantages of being convenient to install, easy to operate, non-contact, good in safety and the like.

Owner:LOW SPEED AERODYNAMIC INST OF CHINESE AERODYNAMIC RES & DEV CENT

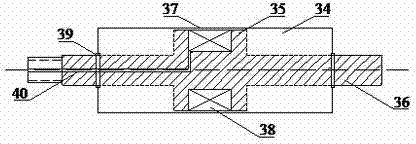

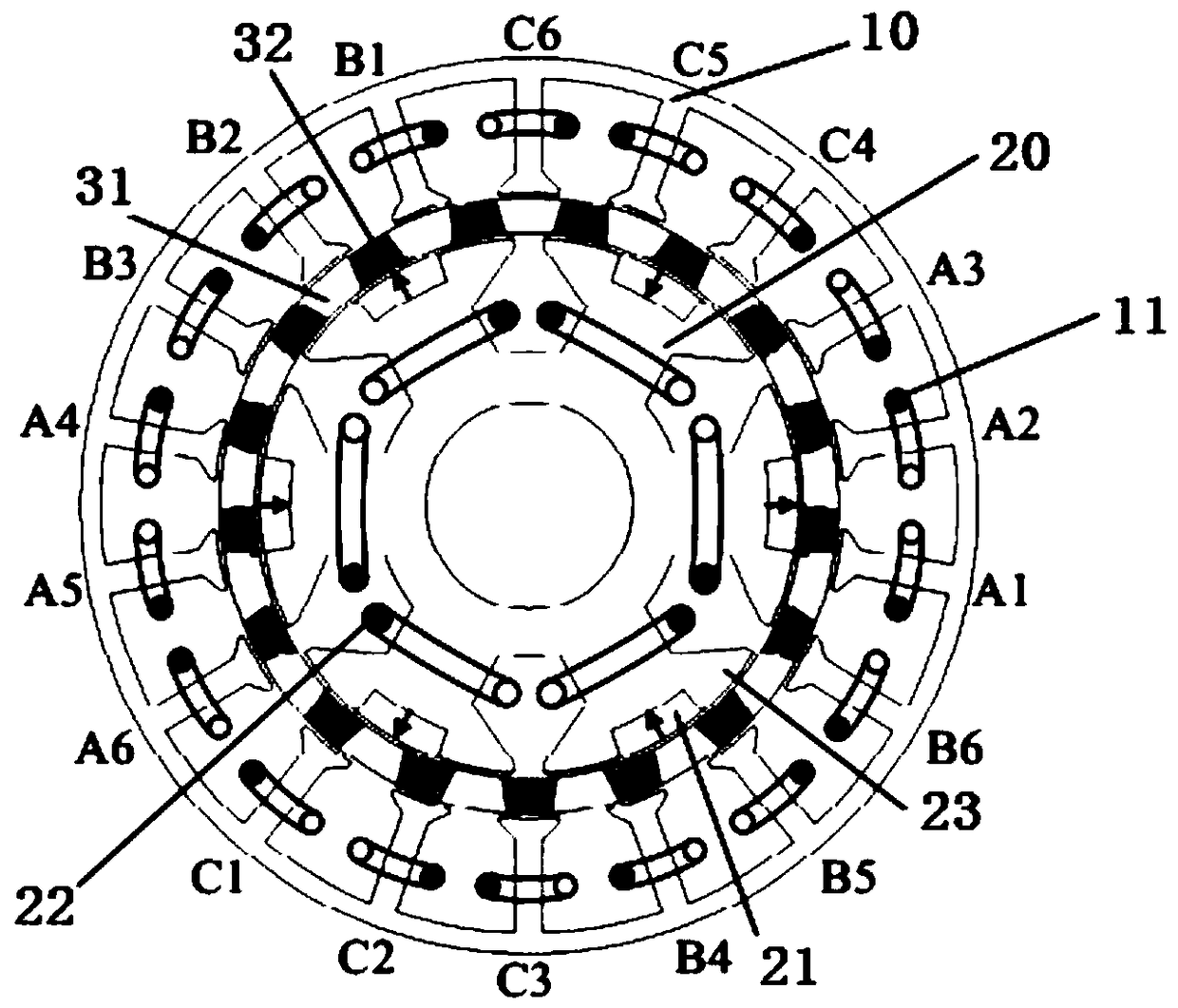

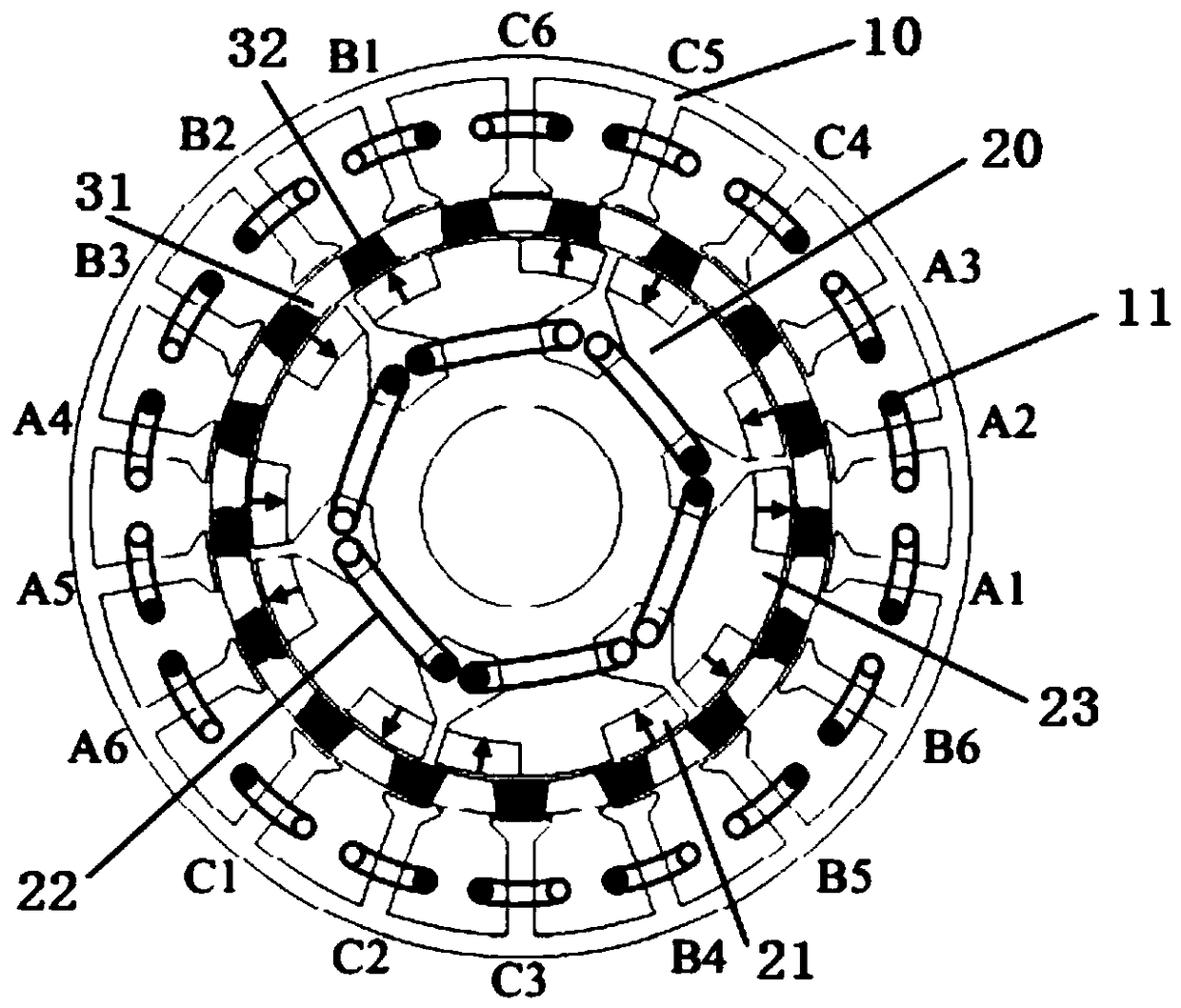

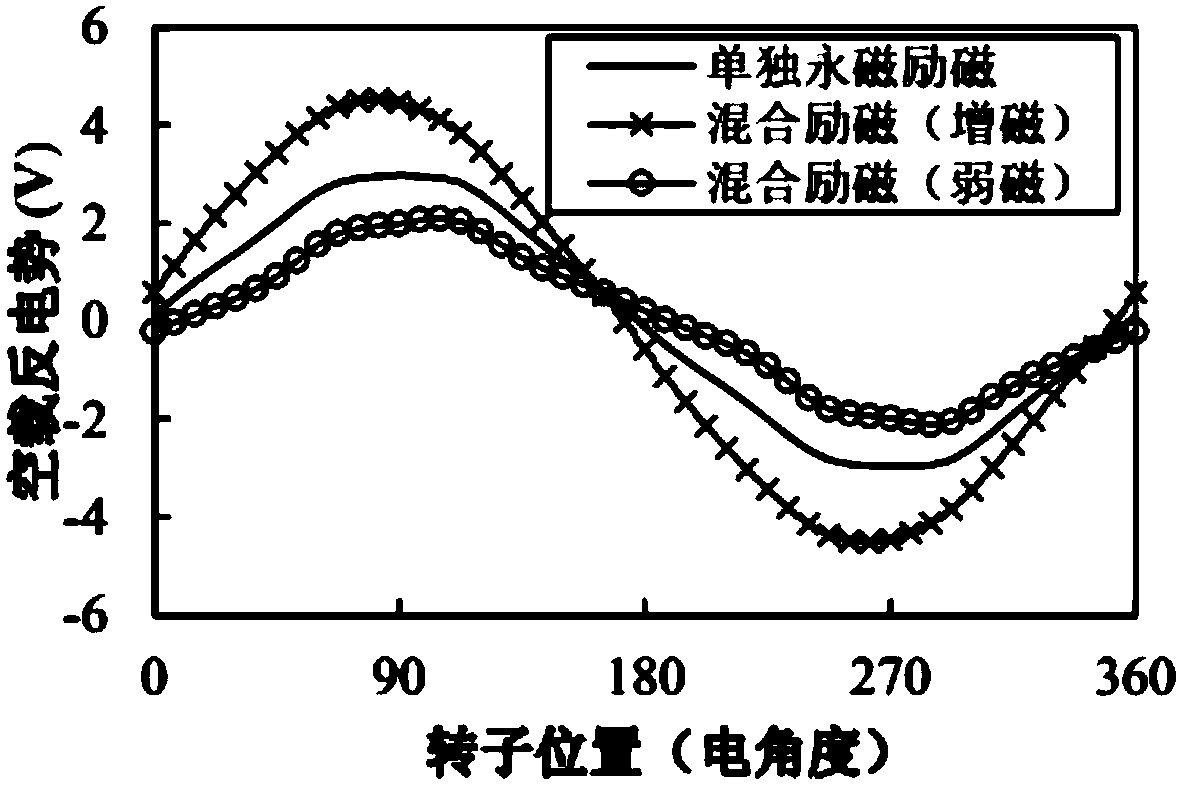

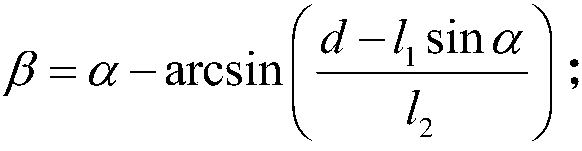

A stator-partition type consequent-pole hybrid excitation motor

ActiveCN108964396AAvoid irreversible demagnetizationAchieve magnetizationSynchronous machine detailsMagnetic circuit stationary partsConductor CoilPole number

The invention discloses a stator-partition type consequent-pole hybrid excitation motor which comprises armature windings, exciting windings, permanent magnets, a stator where the armature windings are located, a rotor and a stator where the exciting windings are located. The stator where the armature windings are located and the stator where the exciting windings are located are respectively disposed on both sides of the rotor. When the stator where the armature windings are located is the outer stator, the stator where the excitation windings are located is the inner stator; and when the stator where the excitation windings are located is the outer stator, the stator where the armature windings are located is the inner stator. The number of teeth of the stator where the armature windingsare located is Nst, and the number of teeth of the stator where the field windings are located is Nst / 3. The tooth tips of the stator teeth where the exciting windings are located face the rotor direction, and the tooth tip of the stator tooth where each exciting winding is located has one or two permanent magnet poles, and the number of poles formed is three; and the magnetizing directions of the permanent magnets of the stator teeth where the adjacent exciting windings are located are reversed. The motor of the invention solves the problem of space restriction on the permanent magnets and the armature windings, and meanwhile realizes effective adjusting of air-gap fields through setting the set of exciting windings on the stator.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

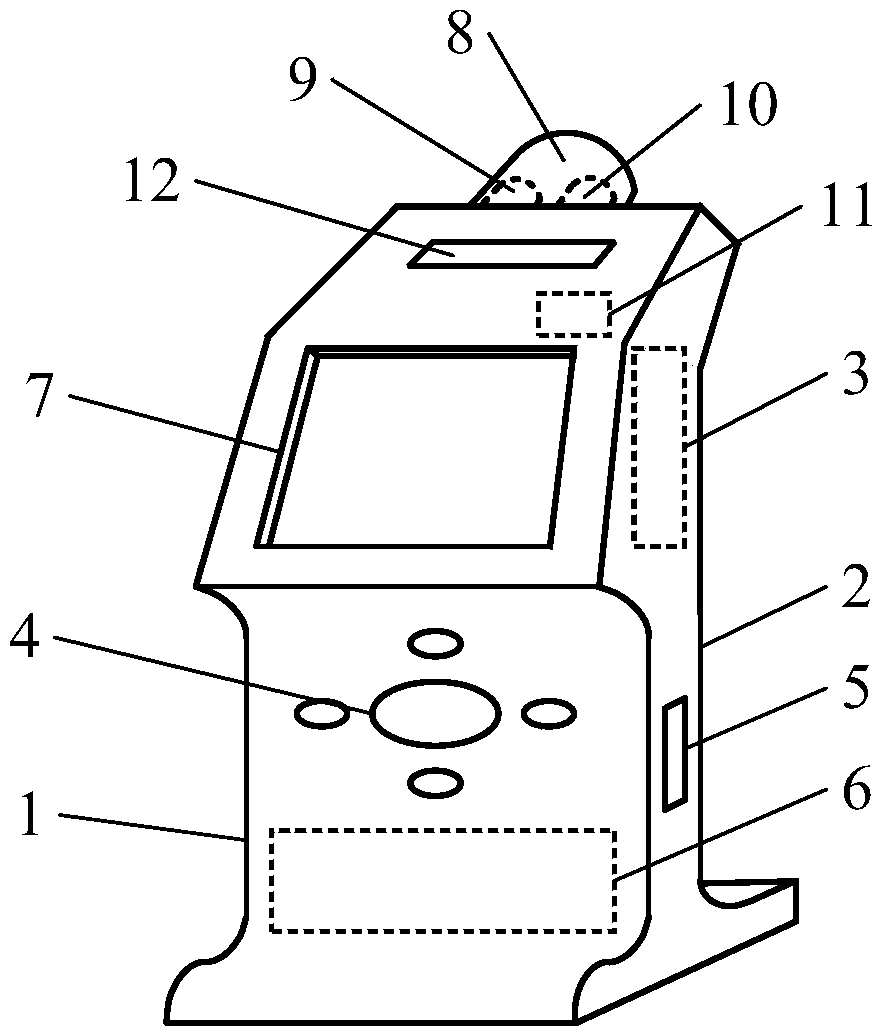

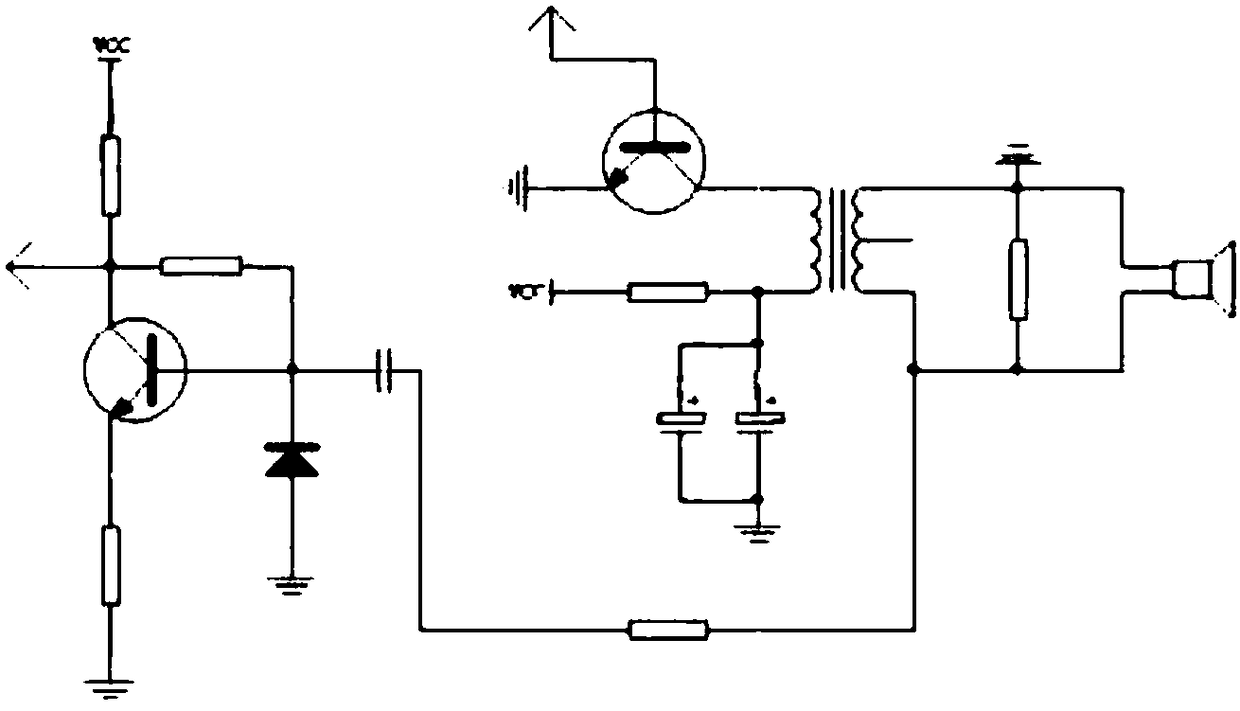

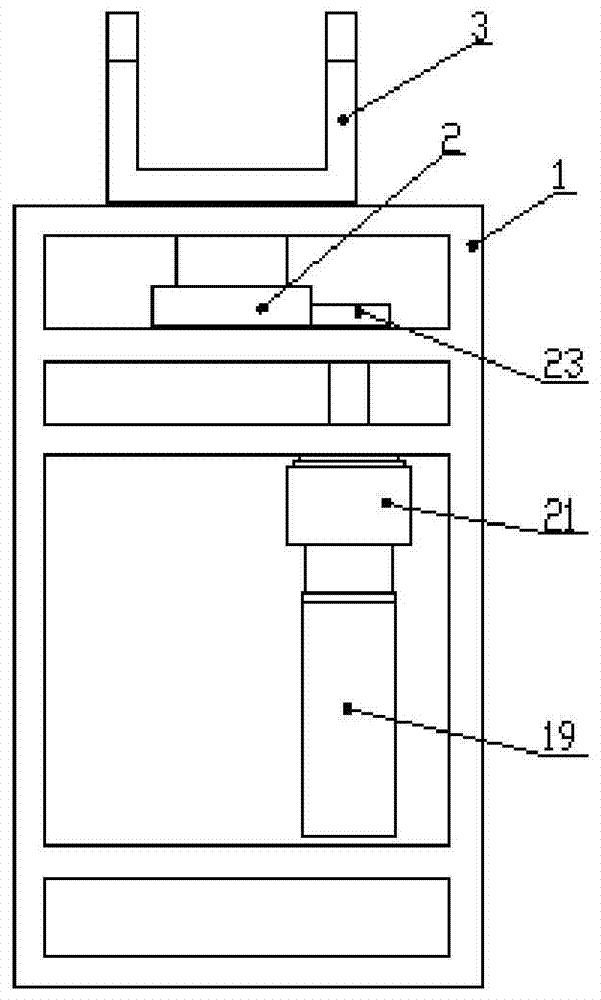

Ball head milling cutter abrasion detection system and detection method thereof

InactiveCN108214102AWork around space constraintsReduce the requirement for repeated installation positioning accuracyMeasurement/indication equipmentsInfraredUltrasonic sensor

The invention discloses a ball head milling cutter abrasion detection system and a detection method thereof. A shell, a base, a circuit board, a control chamber button, a data transmission interface,a battery bin, a liquid crystal display screen, a detection head, an infrared scanning head, an ultrasonic sensor, a single-chip microcomputer and a signal transmitter are included. The liquid crystaldisplay screen is arranged on the surface of the shell, the base is arranged below the shell, and the circuit board is arranged in the shell. The data transmission interface and the battery bin are arranged below the base. The detection head is arranged above the shell and internally provided with the infrared scanning head and the ultrasonic sensor. The detection head is in threaded connection with the shell. A data memory strip and the single-chip microcomputer controlling the ultrasonic sensor are arranged at the bottom of the infrared scanning head. The signal transmitter is arranged above the liquid crystal display screen, and a computer and wireless data receiving equipment which are used in cooperation are additionally arranged. The ball head milling cutter abrasion detection system can directly detect a ball head milling cutter abraded part, and is convenient to operate and high in measuring precision.

Owner:HARBIN UNIV OF SCI & TECH

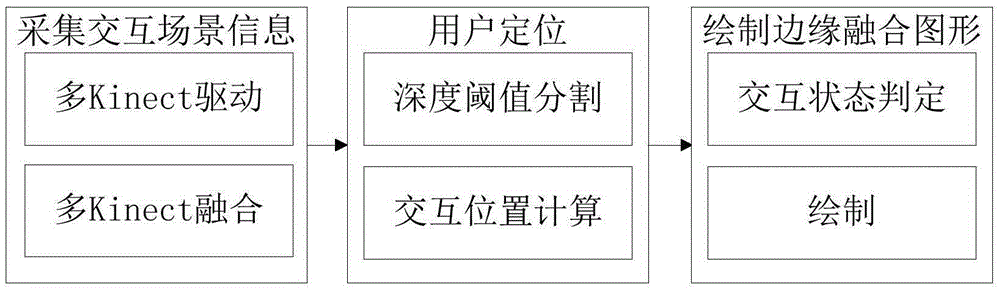

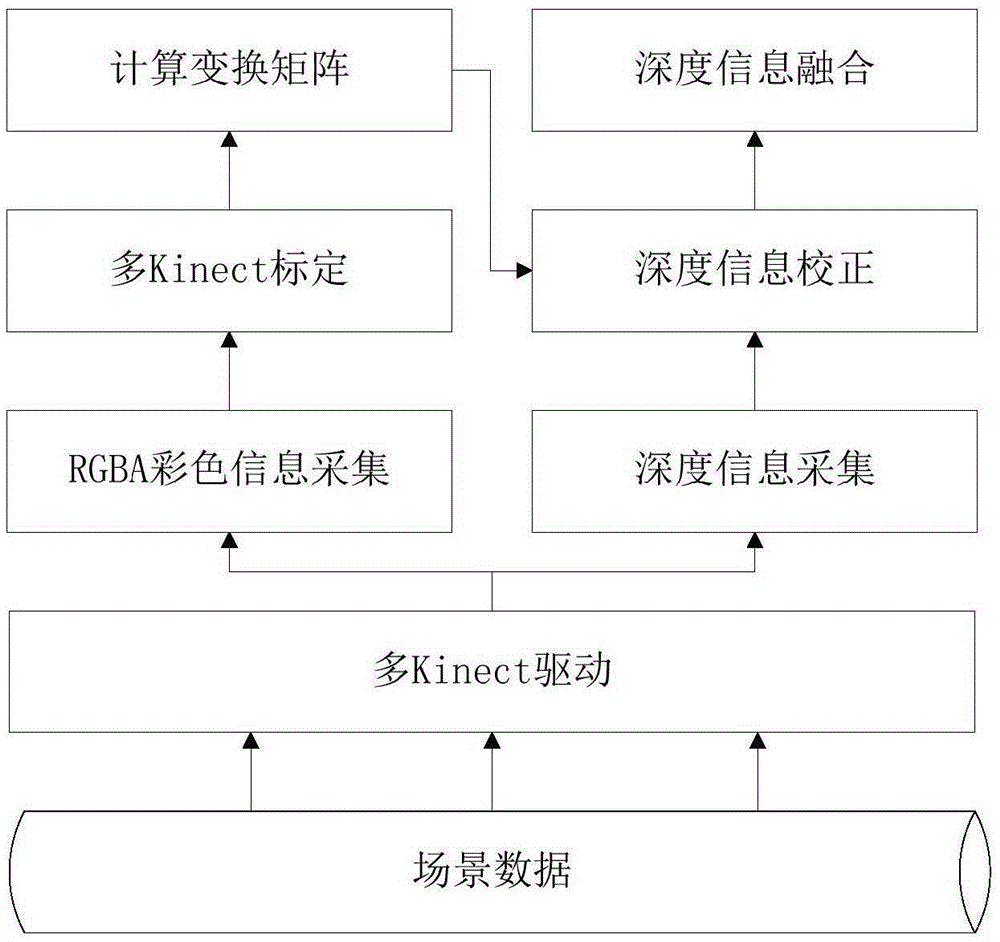

Method for identifying profile interaction based on multi-Kinect collaboration depth threshold segmentation algorithm

InactiveCN105354812AWork around space constraintsGuaranteed real-timeImage analysisGraphicsAlgorithm

The invention discloses a method for identifying a profile interaction based on a multi-Kinect collaboration depth threshold segmentation algorithm. The method includes the main steps: (1) multi-Kinect collaboration: simultaneously driving a plurality of Kinect depth sensors on one control host, and correcting acquired information; (2) user identification and position based on depth threshold segmentation: acquiring depth information of a scene, processing and screening the depth information, and calculating a position of a user; (3)displaying the profile interaction through edge fusion, displaying interactions among different individuals through simulation of fluid edge fusion or separation, and drawing out a graph with the effect of fluid edge fusion by adoption of a graph drawing method based on spatial distribution features. According to the invention, somatosensory devices are combined to draw out the edge fusion graph, and behaviors of the user can be timely and vividly fed back, so that the user experience can be greatly improved; in additional, the method of the invention cannot limited by a scene space, and can be applied to various interactive experiences including interactive floors, interactive walls and the like.

Owner:北京中科盘古科技发展有限公司

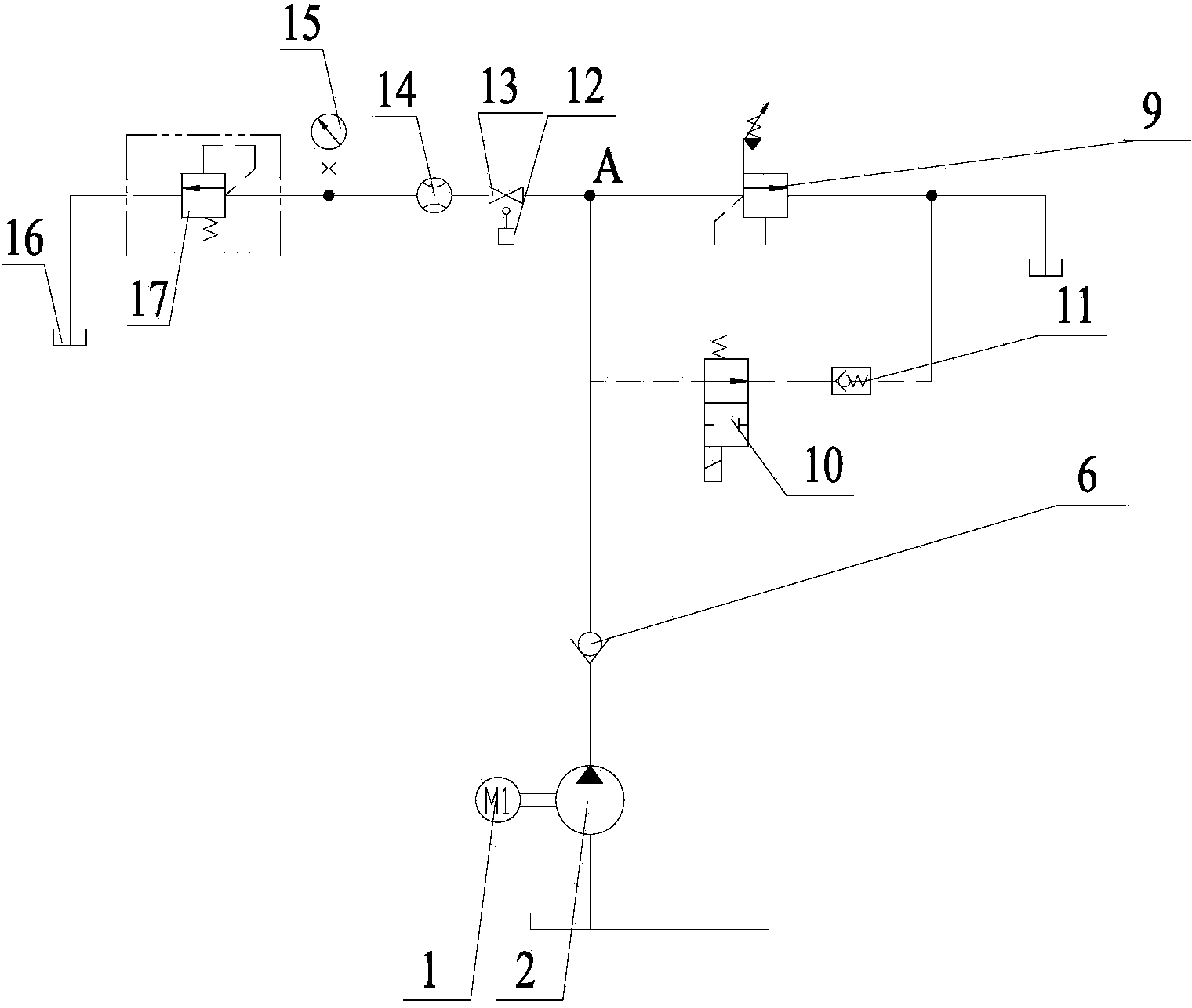

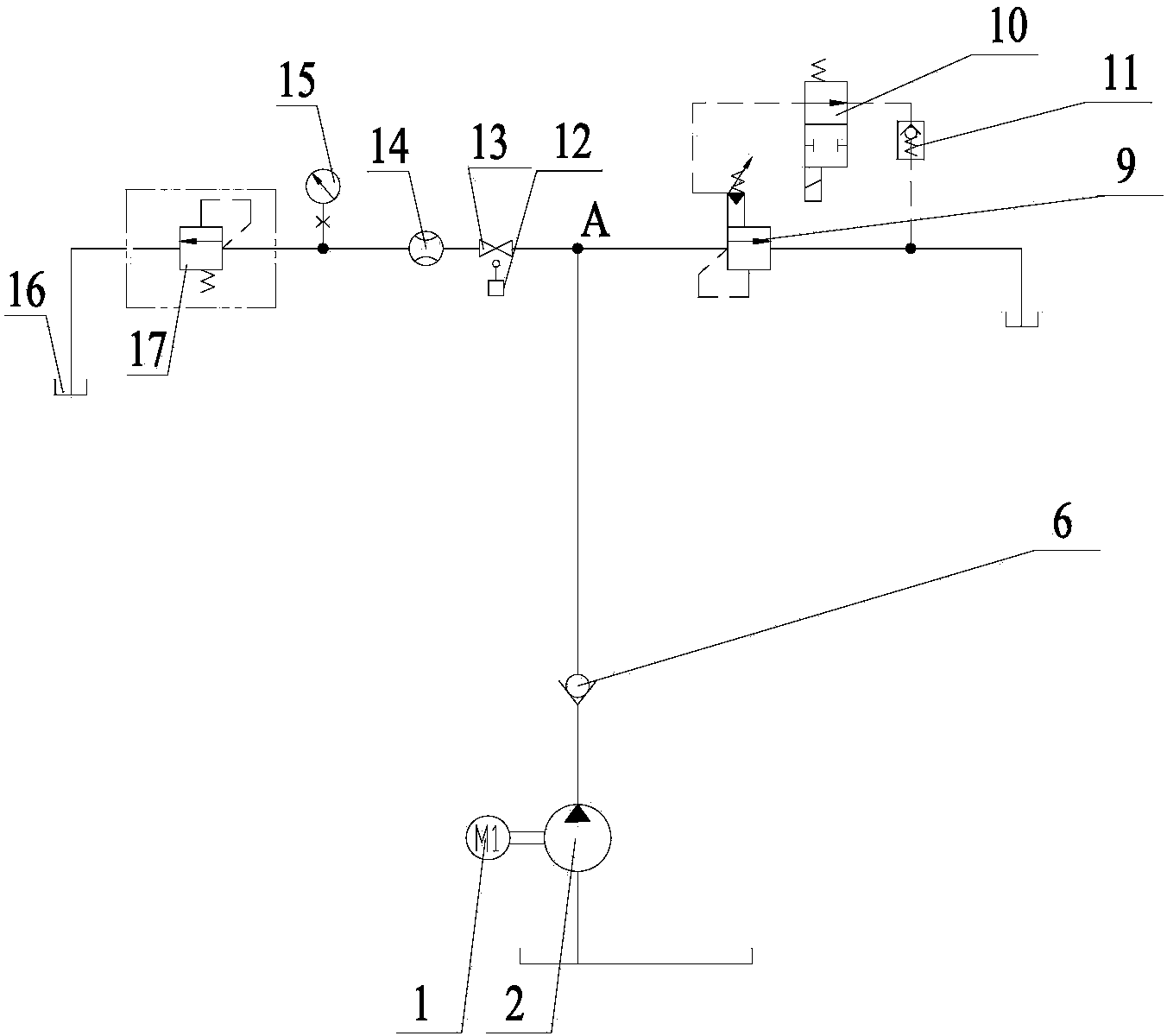

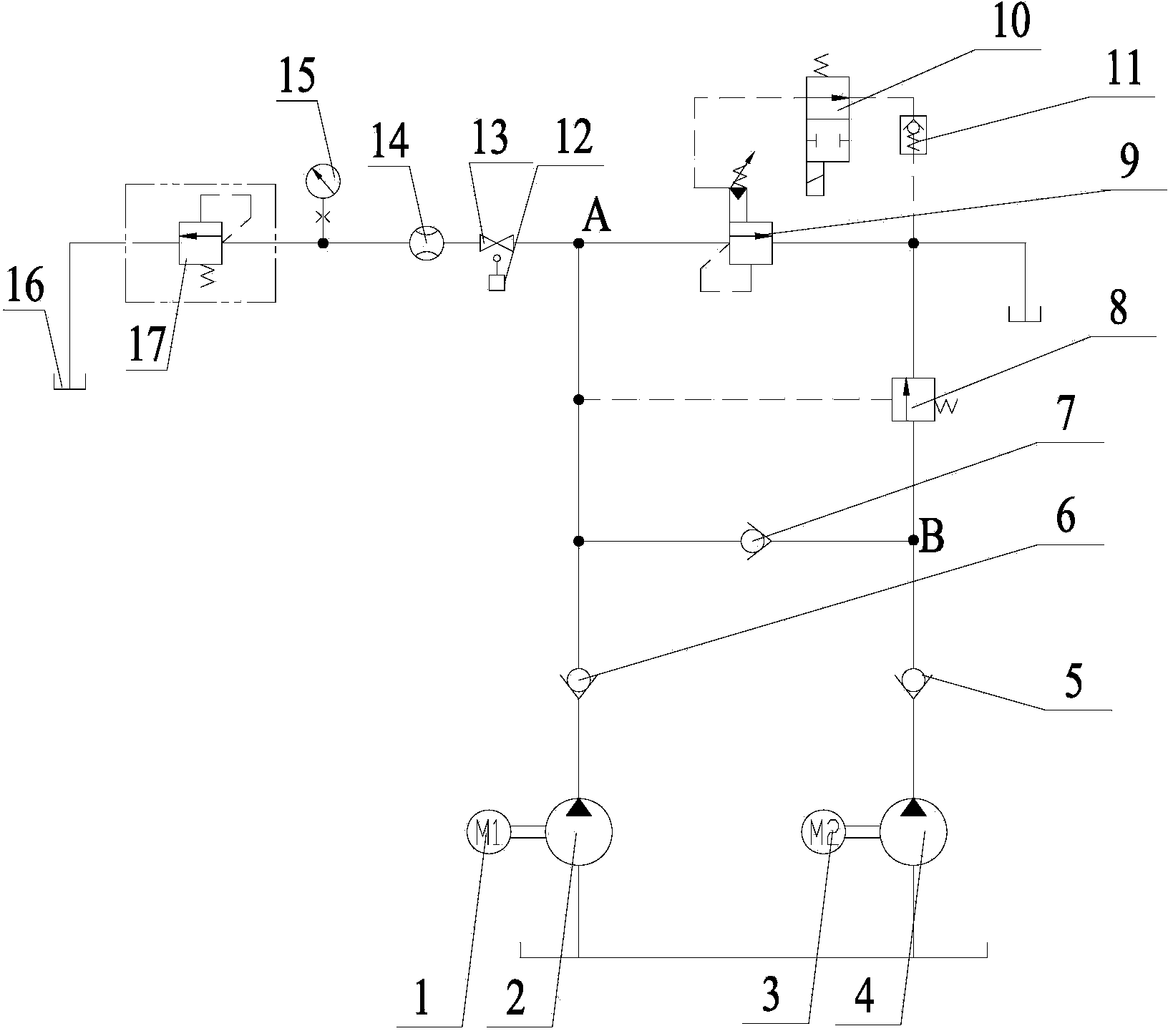

Pressure valve debugging system

ActiveCN103452958AReduce the amount of operationWork around space constraintsFluid-pressure actuator testingPressure detectionPetroleum engineering

The invention provides a pressure valve debugging system which comprises an oil supply way, a pressure-regulating test oil way and a pressure limiting oil way, wherein the oil supply way comprises at least one oil pump, and a first output node is arranged on an output pipeline of the oil pump; the pressure-regulating test oil way is connected with the first output node and is used for installing a valve to be pressured-regulated, and the pressure-regulating test oil way comprises a flow meter and pressure detecting access point which are connected between the valve to be pressured-regulated and the first output node in series; the pressure limiting oil way is connected with the first output node and is used for limiting the pressure of the pressure-regulating test oil way. The valve to be pressured-regulated is connected onto the pressure-regulating test oil way, and the oil supply way regulates the pressure and flow of the pressure-regulating test oil way, namely the valve to be pressured-regulated adopts a unified connection mode. During regulation, the pipeline does not need to be refitted, so that the amount of operation of pressure regulation is effectively relieved, the limiting problem of an operating space is solved, and the influence of disassembling and assembling the pipeline on the cleanliness of a hydraulic system. In addition, pressure-regulating operating personnel do not need to understand a working principle of a loop, and the requirement on the operating personnel is reduced.

Owner:ZOOMLION HEAVY IND CO LTD

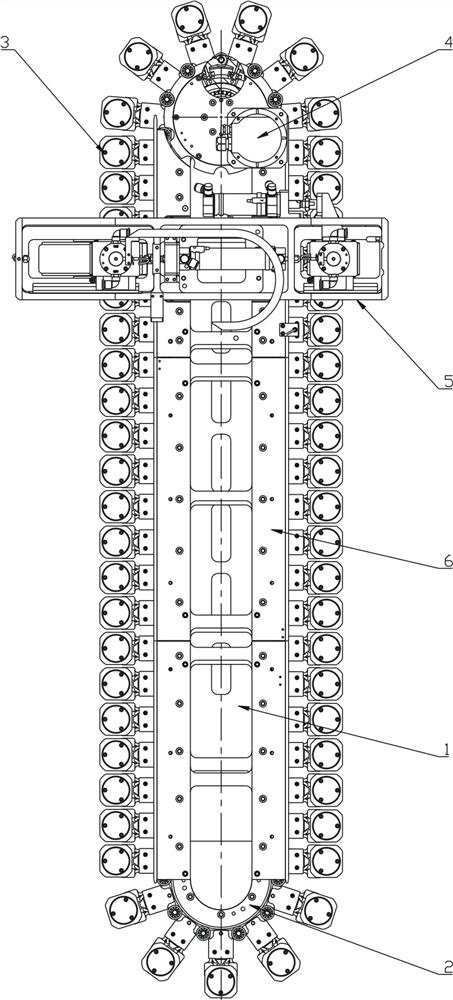

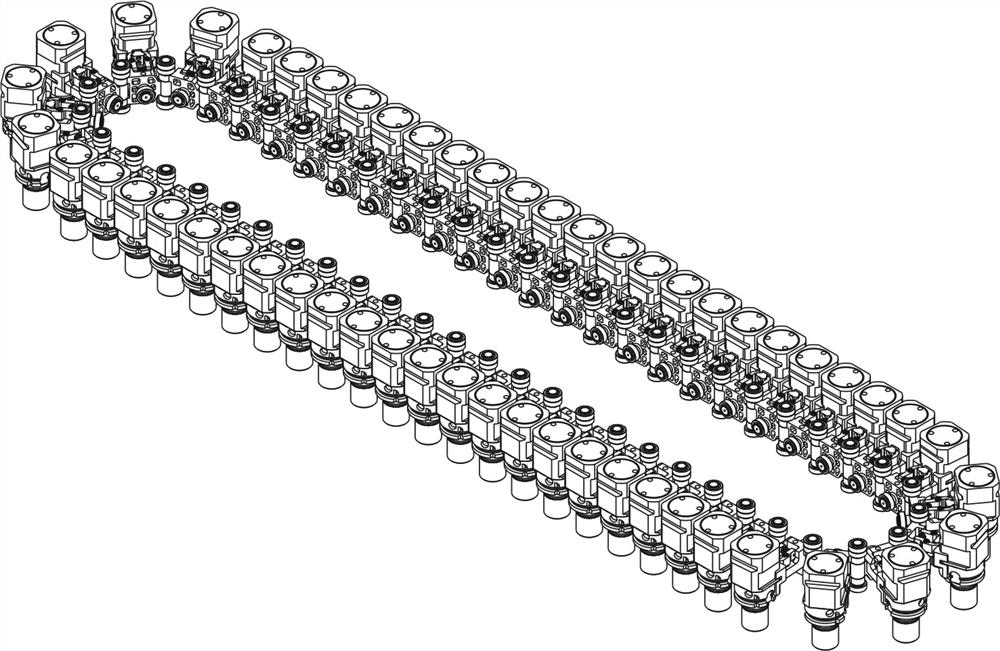

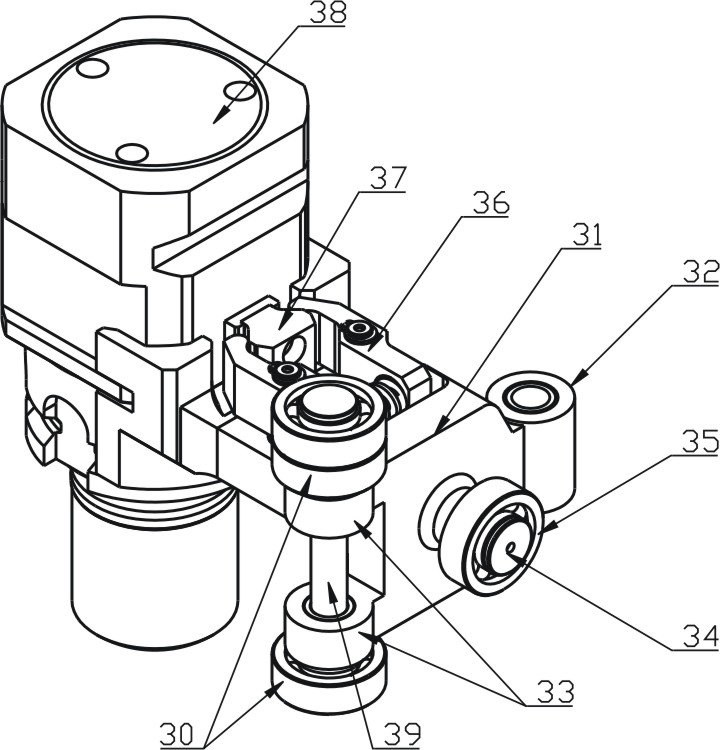

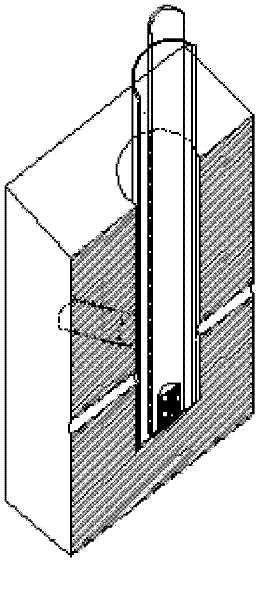

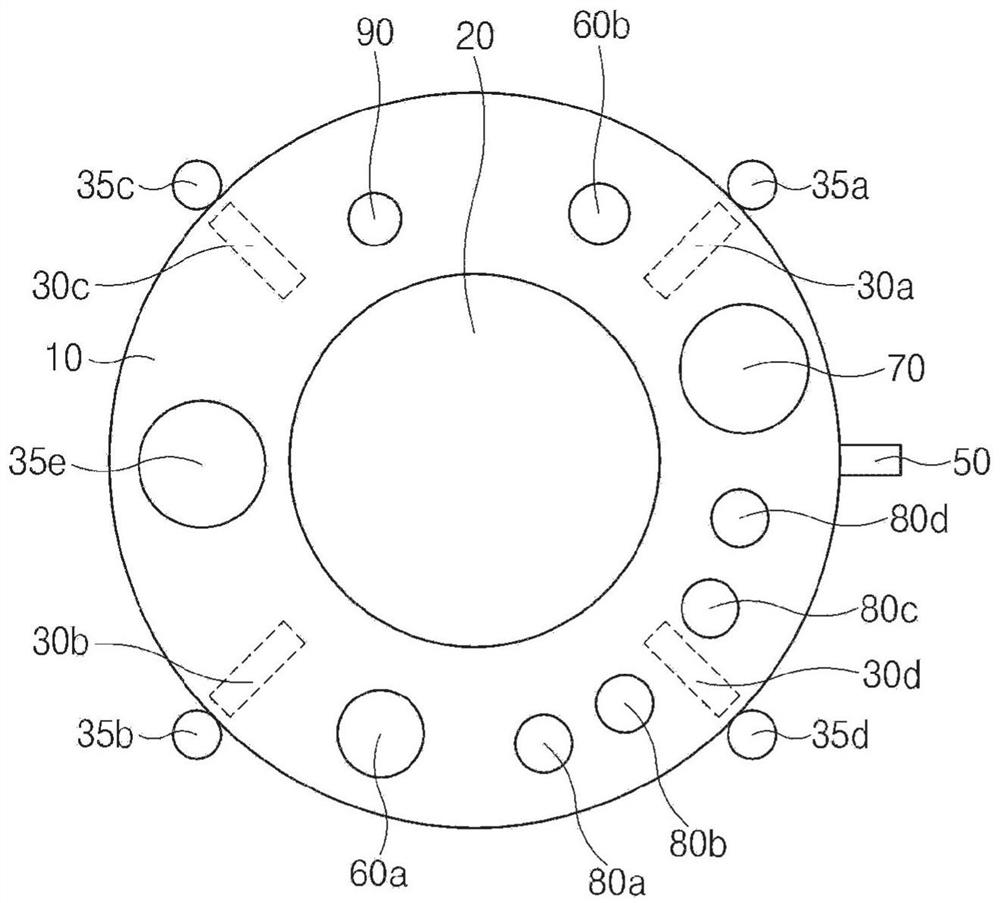

Knife pouch push-out type chain type tool magazine

PendingCN111843578AHigh precisionIncrease line speedPositioning apparatusMetal-working holdersChain typeChain link

The invention relates to a knife pouch push-out type chain type tool magazine, and aims to provide a chain type tool magazine structure which is simple in structure, small in structural space, high inmotion precision, high in tool changing speed, stable in operation, small in vibration, long in service life, low in use cost, convenient to adjust and flexible in application. The knife pouch push-out type chain type tool magazine comprises a base, an annular guide rail, a chain mechanism, a chain driving unit and a knife pouch push-out device. The base is connected with a machine tool, the annular guide rail is arranged on the base, and the chain mechanism comprising a plurality of knife pouches is arranged on the annular guide rail and can rotate along the annular guide rail under the action of the chain driving unit. The knife pouch push-out device is erected above the chain mechanism and installed on the base through a push-out installation plate, and the knife pouches can be pushedout of the chain mechanism to conduct automatic tool changing or manual tool installing.

Owner:北京精雕精密机械制造有限公司

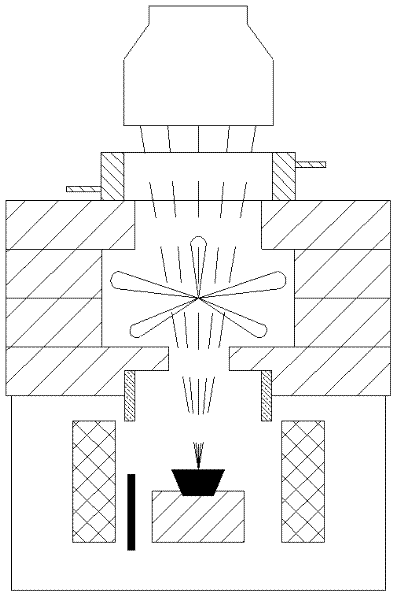

Microscope heating stage for Raman spectral measurement of high-temperature volatile molten salt

The invention provides a microscope heating stage for the Raman spectral measurement of high-temperature volatile molten salt. The microscope heating stage comprises a heating stage main body and an internal heating body, wherein a microlens hole is arranged on one side of the heating stage main body; a heating stage cover is arranged above the heating stage main body; a thermocouple insertion hole and an air hole are formed on the heating stage cover; a platform for placing a sample pool is arranged at the lower part of the interior of the heating stage main body, and a winding post is fixedat the bottom part of the interior of the heating stage; a bobbin is sleeved outside the winding post; a heating wire is wound on the bobbin; the winding post, the bobbin and the heating wire form the internal heating body; the heating wire extends out of the heating stage main body and is connected with an external power supply; the bottom part of the heating stage main body is connected to a strut and a base; and a sample pool made of quartz is correspondingly arranged in the heating stage main body. The heating stage provided by the invention adopts a heating mode in the sample pool and avoids influence of non-uniform volatilization of the molten salt on the accuracy of the Raman spectral measurement by sealing the sample pool; and as the excitation laser enters from the side of the sample pool, a thermocouple and a measurement focus are located on the same horizontal line, and the accuracy of temperature measurement is ensured.

Owner:NORTHEASTERN UNIV

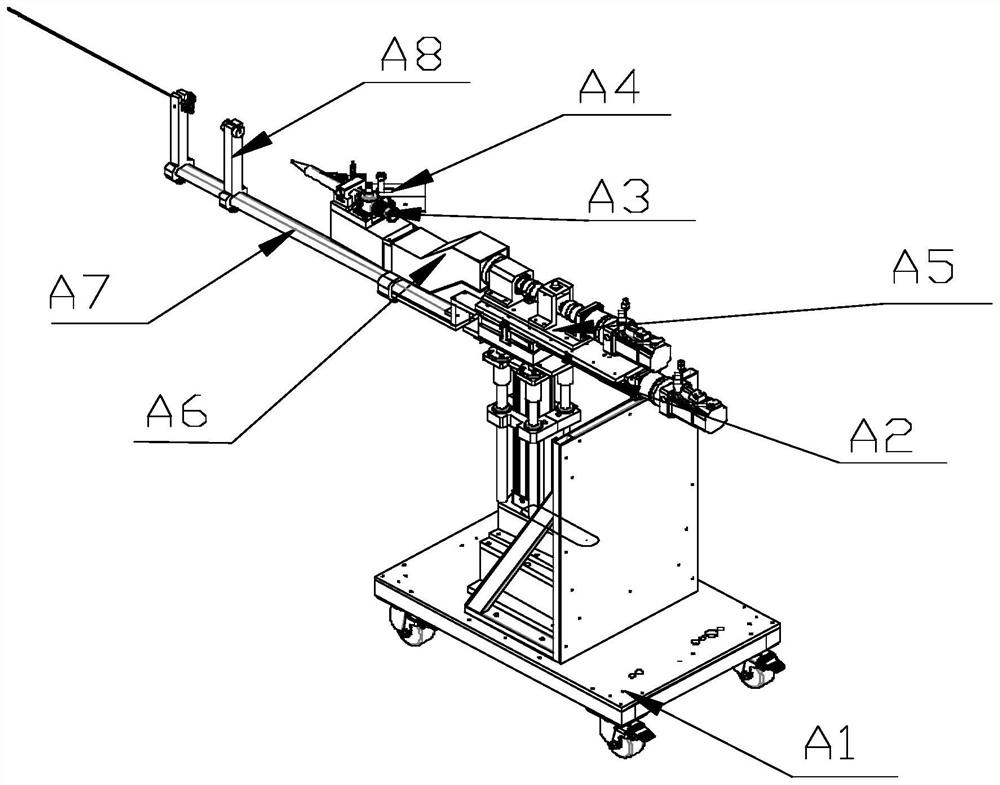

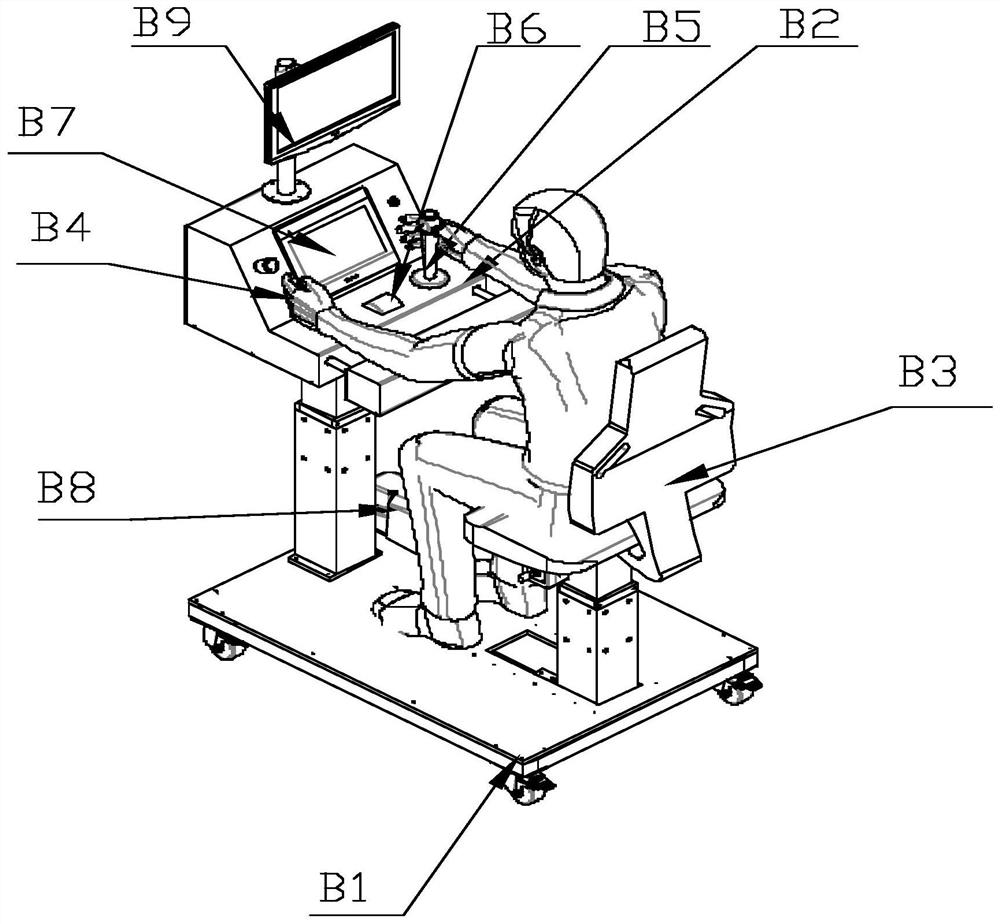

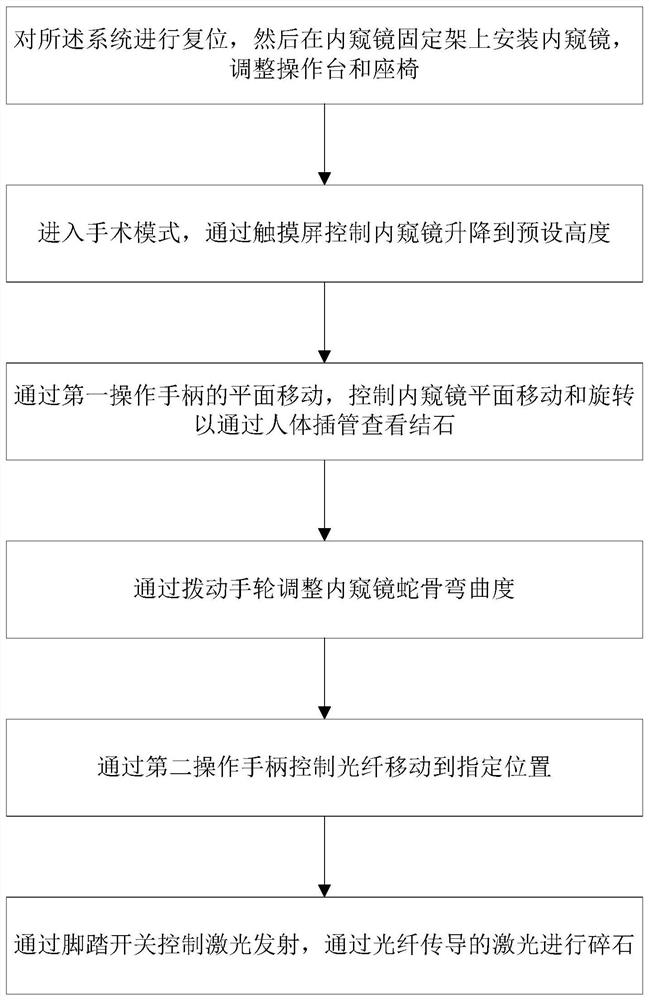

Soft endoscopic surgical robot system based on closed-loop feedback and control method thereof

PendingCN111887994AFlexible operationEasy to operateDiagnosticsSurgical instrument detailsClosed loop feedbackMedicine

The invention provides a soft endoscope surgical robot system based on closed-loop feedback. The soft endoscope surgical robot system comprises a surgical robot, an operating mechanism and a control module. The surgical robot comprises a first bearing bottom plate, a top plate, an endoscope fixing frame, an optical fiber driving module and a guide support. The operating mechanism comprises a second bearing bottom plate, an operating table and a seat; the first telescopic rod is connected with a first driving device for driving the first telescopic rod to vertically stretch; the displacement plate is connected with a second driving device for driving the displacement plate to displace; the rotating body is connected with a third driving device for driving the rotating body to rotate; the endoscope fixing frame is connected with a fourth driving device for driving the endoscope fixing frame to adjust the bending angle of the endoscope snake bone; and the optical fiber driving module is connected with a fifth driving device. According to the invention, intelligent control and flexible operation of the surgical robot are realized, so that an operation can be performed through the surgical robot.

Owner:安徽航天生物科技股份有限公司

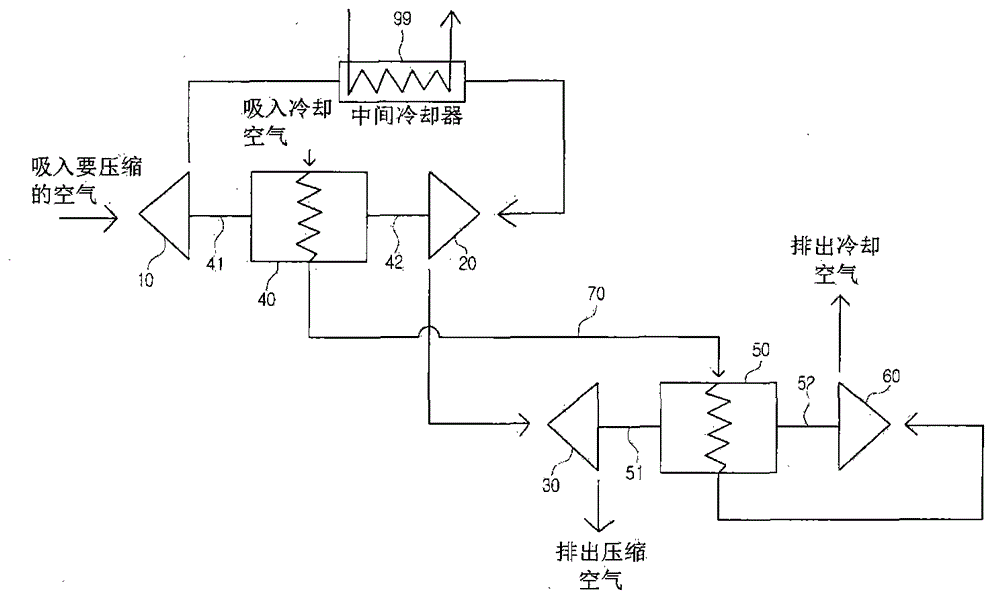

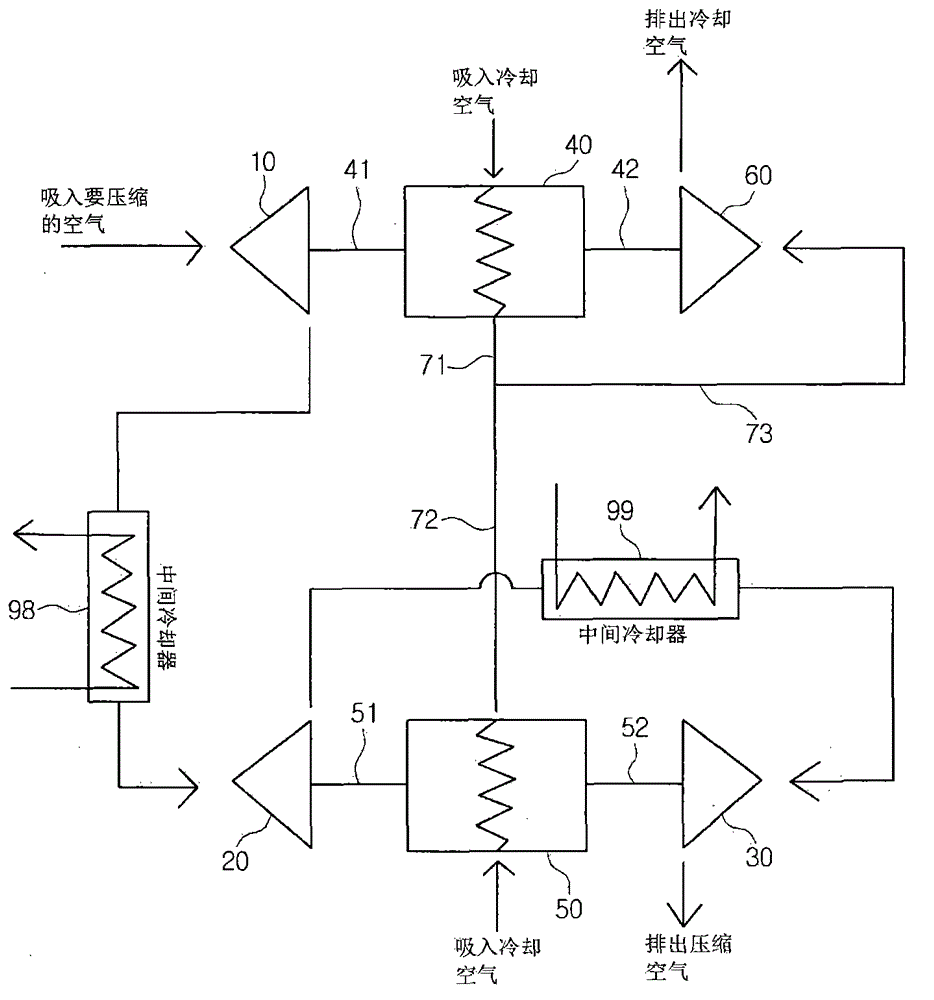

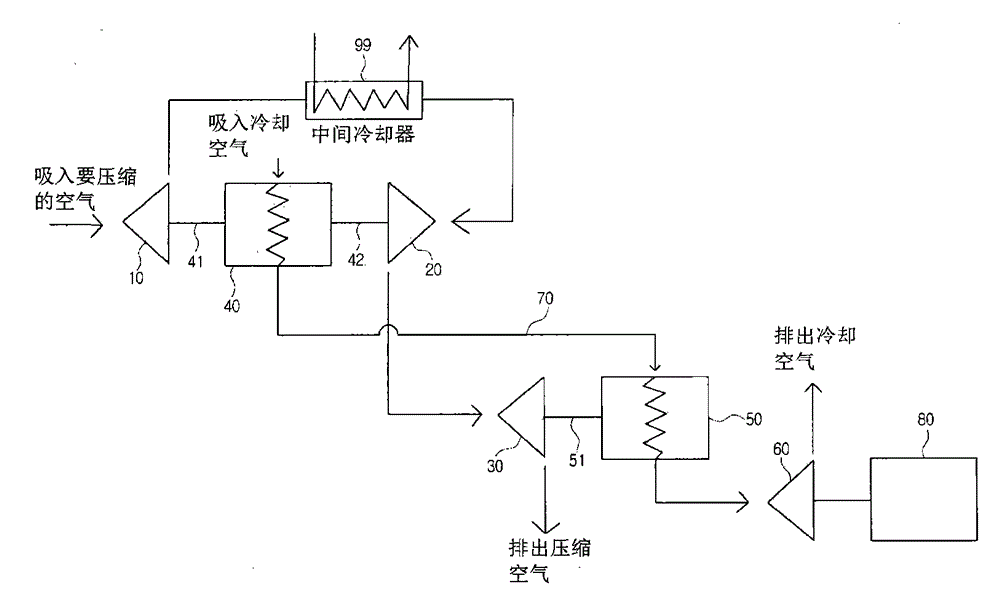

Turbo compressor system having at least two driving motors

InactiveCN104487713AImprove cooling efficiencyCompact structurePump componentsPump installationsImpellerDrive motor

The present invention relates to a turbo compressor system having a cooling system for driving motors so as to efficiently cool at least two driving motors and, more specifically, to a turbo compressor system comprising a direct-drive turbo compressor for a high-speed motor. The turbo compressor system having at least two driving motors, according to one embodiment of the present invention, comprises: a first impeller, a second impeller, and a third impeller which are provided separate from one another; at least two driving motors for rotationally driving the first impeller, the second impeller, and / or the third impeller; and one cooling impeller for simultaneously cooling the at least two driving motors, wherein the cooling impeller can be connected to one rotary shaft of the at least two driving motors so as to be rotated. However, the turbo compressor system having the two or more driving motors, according to another embodiment of the present invention, can further comprise a fan motor which is provided separate from the two or more driving motors, and which is configured to rotate the cooling impeller.

Owner:KTURBO INC

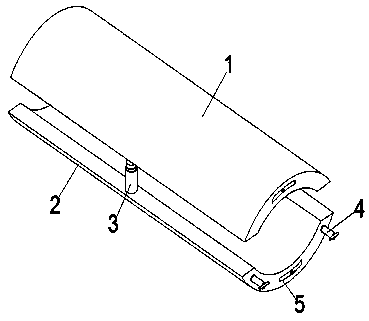

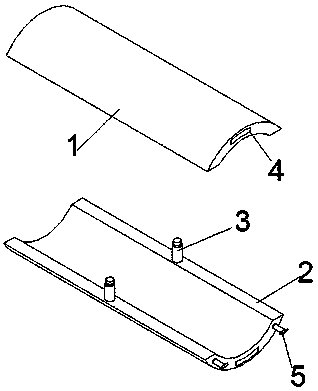

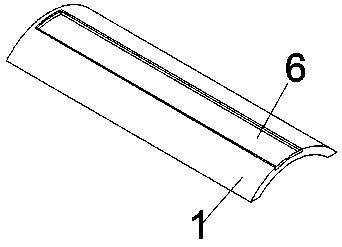

Vaginal dilator for gynaecology and obstetrics

The invention discloses a vaginal dilator for gynaecology and obstetrics. The vaginal dilator comprises an upper expansion plate, a lower expansion plate, expansion pieces, rotating rods and sealing covers, wherein the upper expansion plate and the lower expansion plate are both designed to be arc-shaped and are oppositely arranged; the upper expansion plate is connected with the lower expansion plate through the expansion pieces; the bottom parts of the expansion pieces are positioned in the lower expansion plate; circular holes are arranged on the lower expansion plate; the rotating rods areconnected with the lower expansion plate through the circular holes; each rotating rod is connected with an expansion piece; an interlayer is respectively arranged in the upper expansion plate and the lower expansion plate; one end of each interlayer is in closed design, while the other end of each interlayer is in opened design; the sealing covers are respectively and fixedly arranged on the upper expansion plate and the lower expansion plate through screws; each interlayer is blocked through a sealing cover; a water inlet is welded on each sealing cover; and a plug is arranged at the position of each water inlet in a threaded connection manner. The vaginal dilator provided by the invention is reasonable in design; and the upper expansion plate and the lower expansion plate are opened byutilizing the expansion pieces to facilitate observation.

Owner:张常慧

Full-automatic CNC paint and rust remover for railway wagon axles

PendingCN111203789ASave the painting processReduce labor intensityGrinding carriagesGrinding drivesControl systemAgricultural engineering

The invention provides a full-automatic CNC paint and rust remover for railway wagon axles. The full-automatic CNC paint and rust remover mainly comprises an axle paint and rust removing device and adigital control system, wherein a front main brush, a rear main brush, a left brush and a right brush feed to realize automatic digital control. During operation, the digital control system detects the motor current driving a wire brush to rotate and feeds back to the digital control system; the digital control system issues an instruction to a servo feed mechanism to realize automatic advancing and retreating of the wire brush, so that the wire brush exerts a constant force on the axle, the efficiency and quality of the paint and rust removal are high, and no paint stripper is needed. Meanwhile, the front main brush and the rear main brush are located on opposite sides of the upper part of the axis of the wheelset axle body to maintain the stability of the axle in the paint and rust removal process; and further, conversion control of positive and negative rotation for the front and rear main brushes, the left and right brushes and a wheel runner according to the number of cleaning wheelsets is automatically realized by the digital control system, and the life of the wire brush is significantly prolonged.

Owner:石家庄华信石正重工机械科技有限公司

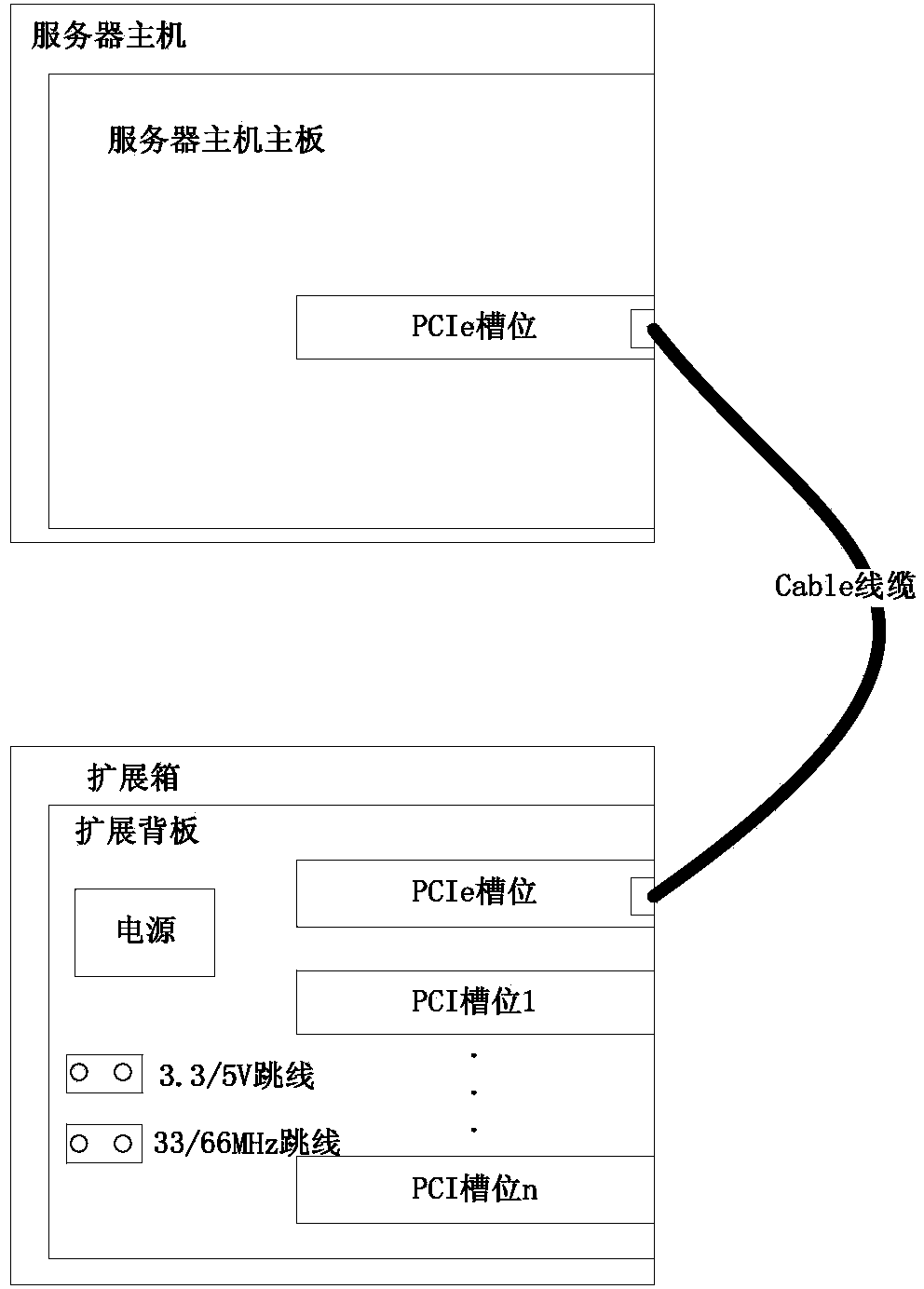

Implementation method for transforming PCIe (peripheral component interface express) card into PCI (peripheral component interface) card

InactiveCN104267794AOvercome space constraintsWork around space constraintsDigital processing power distributionPeripheralComputer hardware

The invention provides an implementation system for transforming a PCIe (peripheral component interface express) card into a PCI (peripheral component interface) card. The system comprises a server host, an extension box and a Cable; the server host is connected with the extension box through the Cable. A PCIe slot is extended to the outside of a server host case through the Cable, then the PCIe card is transformed into the PCI card to extend PCI slots, space limitations of the server host case are overcome, and more PCI slots can be extended. The system is applicable to extension of the PCIe slots into the PCI slots under the condition that the PCI slots of the server host are enough.

Owner:DAWNING INFORMATION IND BEIJING

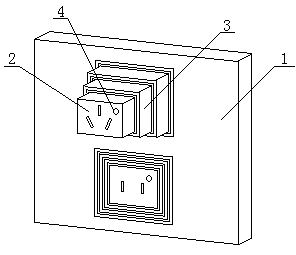

Extensive power socket panel

InactiveCN103647175ASimple structureReduce manufacturing costCoupling device detailsArray data structureElectrical and Electronics engineering

The invention relates to an extensive power socket panel. The extensive power socket panel includes a panel body (1) and several sets of jacks (2), and further includes a plurality of retractable blocks (3), wherein the number of the retractable blocks (3) is the same as that of the sets of jacks (2); each set of jacks (2) corresponds to one end of each retractable block (3); and the other end of each retractable block (3) is disposed on a surface of the panel body (1). The extensive power socket panel designed in the invention is simple in structure and low in manufacturing cost, can effectively overcome space limitations, facilitates power taking of people, and enables the power socket panel design to become more user-friendly.

Owner:WUXI LAIJITE INFORMATION TECH

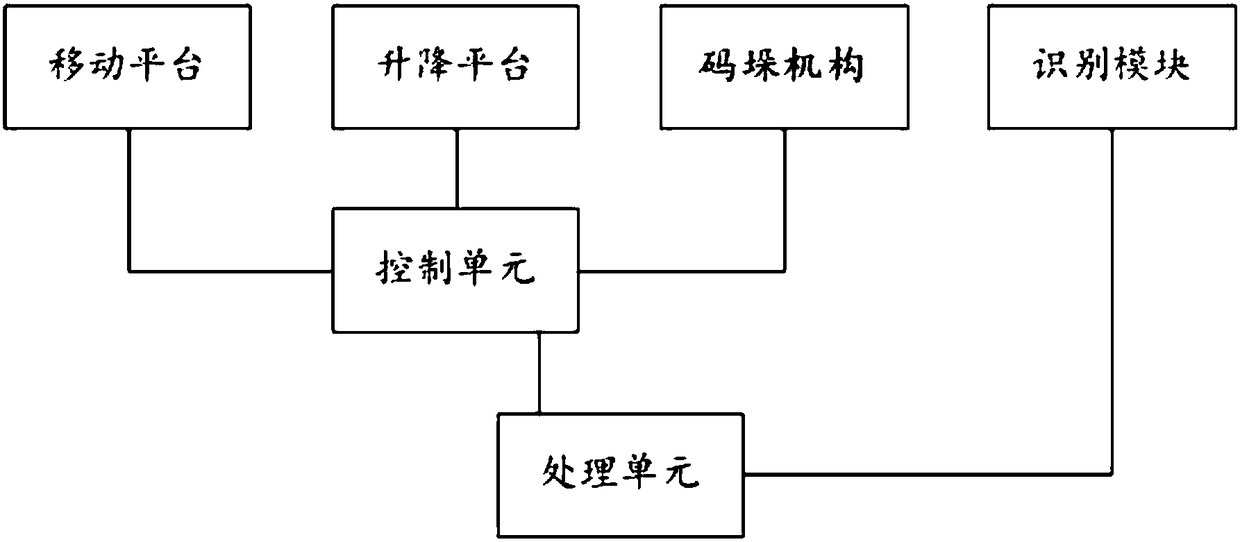

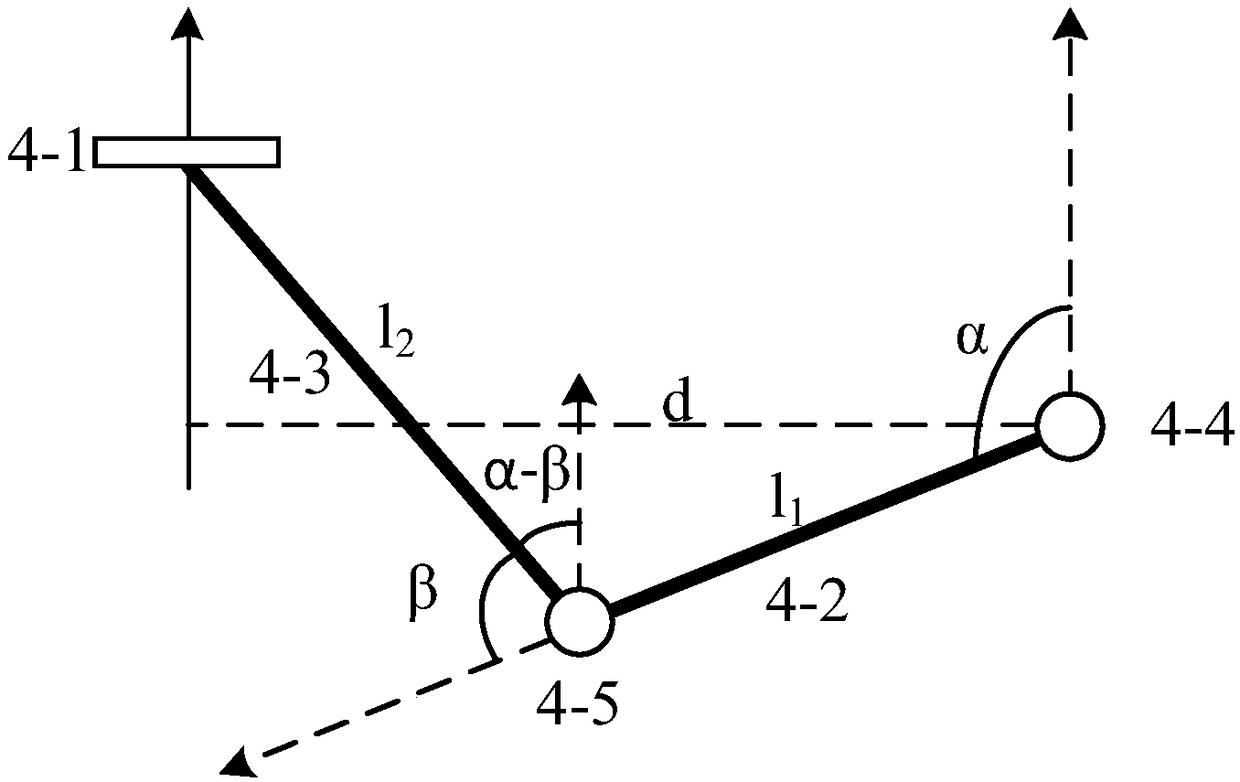

Mobile stacking system

InactiveCN108082944AWork around space constraintsImprove palletizing efficiencyStacking articlesProcessing InstructionControl engineering

The invention discloses a mobile stacking system. The mobile stacking system comprises a moving platform, a lifting platform, a stacking mechanism, a control unit, a recognition module and a processing unit, wherein the moving platform is used for moving the system; the lifting platform is used for storing to-be-stacked cargos and horizontally and fixedly arranged on the upper surface of the moving platform, and the platform surface at the top end of the lifting platform makes lifting motion in the vertical direction; the stacking mechanism is used for horizontally pushing the cargos from thelifting platform to a stacking area; the control unit is used for controlling moving of the moving platform and the lifting platform as well as moving and pushing of the stacking mechanism according to a processing instruction of the processing unit; the recognition module is used for recognizing the outline and pushing faces of the cargos; the processing unit is used for acquiring a moving and pushing control instruction of the stacking mechanism and a lifting control instruction of the lifting platform according to the cargo outline and pushing faces recognized by the recognition module, andthe control unit controls the stacking mechanism to move and push the cargos and controls the lifting platform to ascend and descend; and the processing unit is further used for setting a moving control instruction according to preset rules, and the control unit controls the moving platform to move.

Owner:深圳市鸿益达供应链科技有限公司

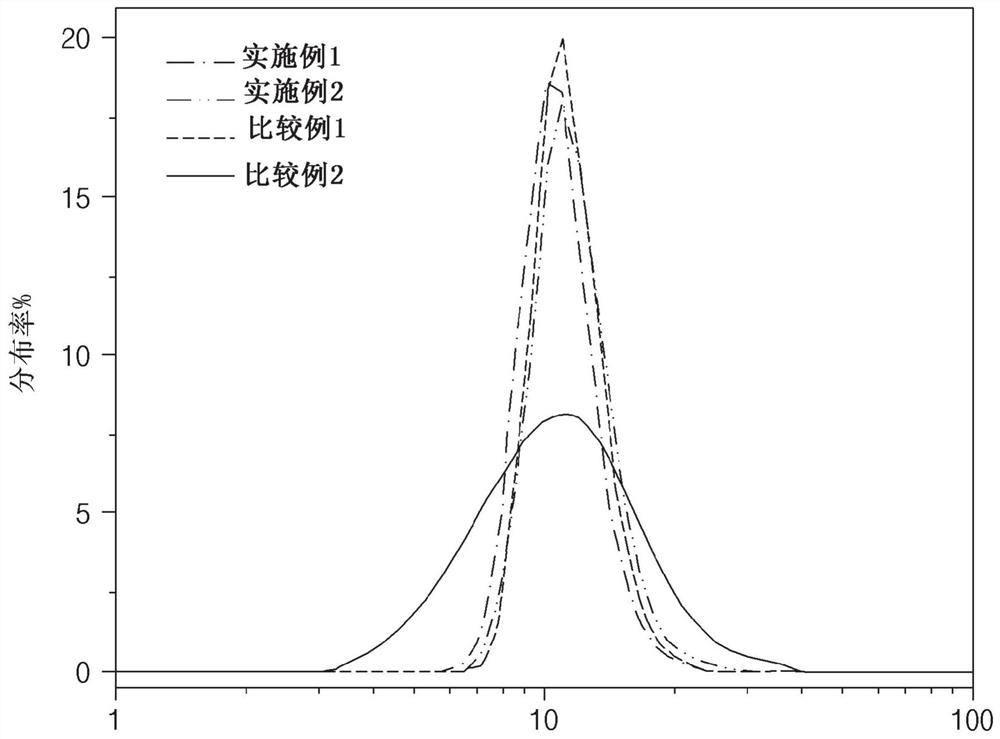

Device and method for manufacturing positive electrode active material precursor

PendingCN112672820AUniform particle sizeUniform shapeChemical liquid solidificationPositive electrodesChemical engineeringElectrode

The present invention provides a device for manufacturing a positive electrode active material precursor, the device comprising: a reactor into which a reaction solution is introduced; a stirrer which is inserted into the reactor and stirs the reaction solution; and a filter-type baffle which is inserted into the reactor and includes the filter.

Owner:LG CHEM LTD

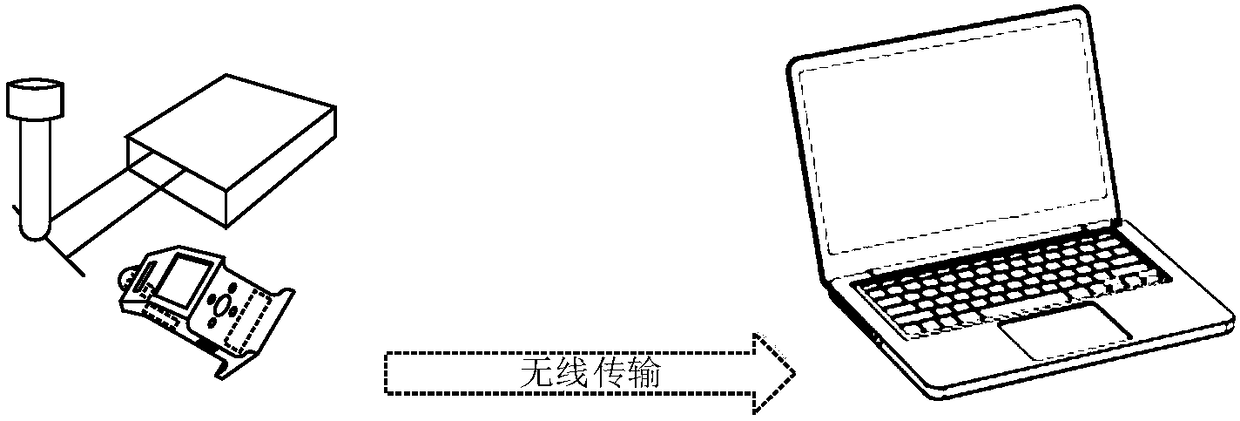

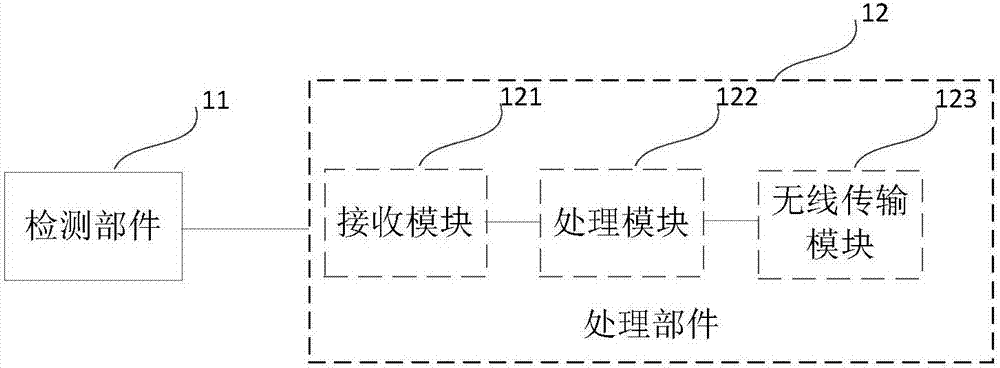

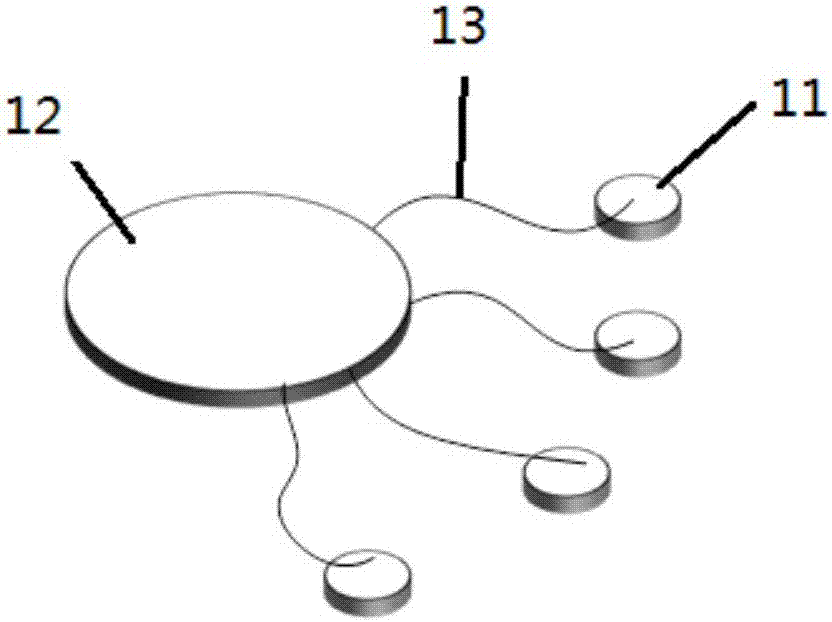

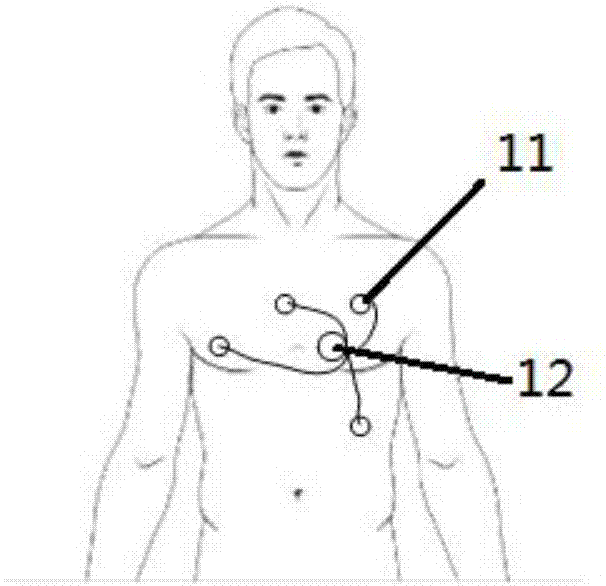

Physiological information detecting device

PendingCN107374613AReal-time detectionEfficient detectionSensorsTelemetric patient monitoringWireless transmissionTerminal equipment

The invention relates to a physiological information detecting device. The physiological information detecting device comprises a detecting component and a processing component, wherein one side of the detecting component is provided with a detecting electrode and used for gaining detecting signals associated with physiological information of a user, the processing component is connected with the detecting component through a connecting wire, one side of the processing component is provided with a reference electrode, and the processing component is used for gaining reference electrode signals. The processing component comprises a receiving module, a processing module, a wireless transmission module, wherein the receiving module receives the detecting signals and the reinforce electrode signals, the processing module is connected to the receiving module, signal processing is conducted on the detecting signals and the reinforce electrode signals, and processed detecting data are obtained, the wireless transmission module is connected to the processing module and sends the detecting data to terminal equipment, and wherein, the detecting component and the processing component are of flexible patch type structures. By means of the physiological information detecting device, the physiological information detecting device can be attached to skin of a detected object, the detecting signals are gained, processed and sent, space limiting of the detected object is avoided, the comfortableness of using the physiological information detecting device is improved, and physiological information is real-timely and effectively detected.

Owner:TSINGHUA UNIV

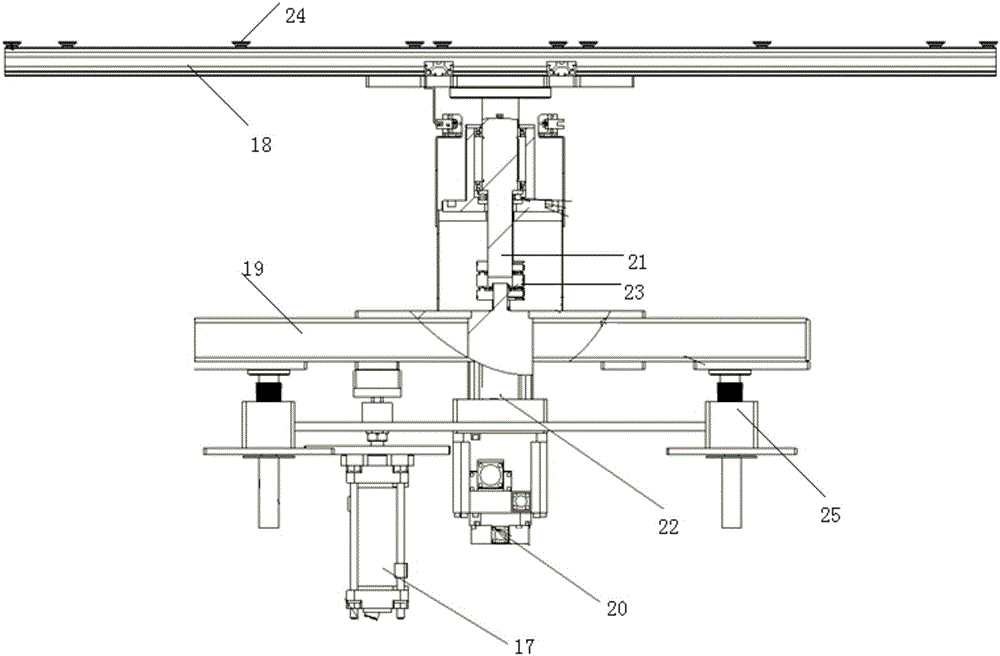

Multifunctional conveying device based on glass panel production line

PendingCN107521979AReliable transmissionReasonable layoutCharge manipulationConveyor partsElectric machineBall screw

The invention discloses a multifunctional conveying device based on a glass panel production line. The multifunctional conveying device based on a glass panel production line comprises a whole lifting device, a roller conveying device, a glass rotating and lifting device, and a device bottom frame, wherein the whole lifting device, the roller conveying device, the glass rotating and lifting device, and the device bottom frame are installed on a mechanism rack. The whole lifting device is installed at the two ends of the device bottom frame, and the glass rotating and lifting device is installed on the whole lifting device. The whole lifting device comprises linear guide rails on the two sides, and servo motors on the two sides. Each servo motor drives a ball screw to spin through a speed reducer. A lifting base is installed on each of the linear guide rails on the two sides. The roller conveying device is fixedly connected with the lifting bases. According to the multifunctional conveying device based on a glass panel production line, suction disks are used for sucking glass so that glass can be prevented from sliding in the rotation process, glass ascends by being ejected by air cylinders, glass is rotated by the servo motors and the speed reducers, the motors, couplers, magnetic force wheels and rollers are used as a glass conveying structure, and a special glass sorting mechanism is used. The multifunctional conveying device based on a glass panel production line is a conveying device mainly used for solving the problem that because the space of a plant is limited, large glass in conveying shifts a lot, and conveying is difficult.

Owner:HEFEI TONSAIL AUTOMATION EQUIP

Apparatus for connecting between intake manifold and EGR pipe

InactiveCN101994604AWork around space constraintsFirmly connectedNon-fuel substance addition to fuelInternal combustion piston enginesEngineeringInlet manifold

Disclosed herein is an apparatus for connecting between an intake manifold and an EGR pipe. The apparatus includes an intake manifold connector, connected to an intake side of the intake manifold in a ring shape with a prescribed thickness and having a plurality of holes passing through external perimeter and internal perimeter of the intake manifold connector. The EGR pipe is inserted into the intake manifold connector and connected to the intake side of the intake manifold to guide waste gas to the intake manifold. A clip is connected to the intake manifold connector through elastic attrition connection and passes through the plurality of holes to alternately contact the external perimeter and the internal perimeter of the intake manifold connector, so as to prevent the EGR pipe from separating from the intake manifold connector.

Owner:GM GLOBAL TECH OPERATIONS LLC

Nozzle mechanism of charged water washing equipment

ActiveCN104096653BWork around space constraintsImprove anti-staticSpraying apparatusCleaning using liquidsVertical planeReduction drive

Owner:STATE GRID CORP OF CHINA +2

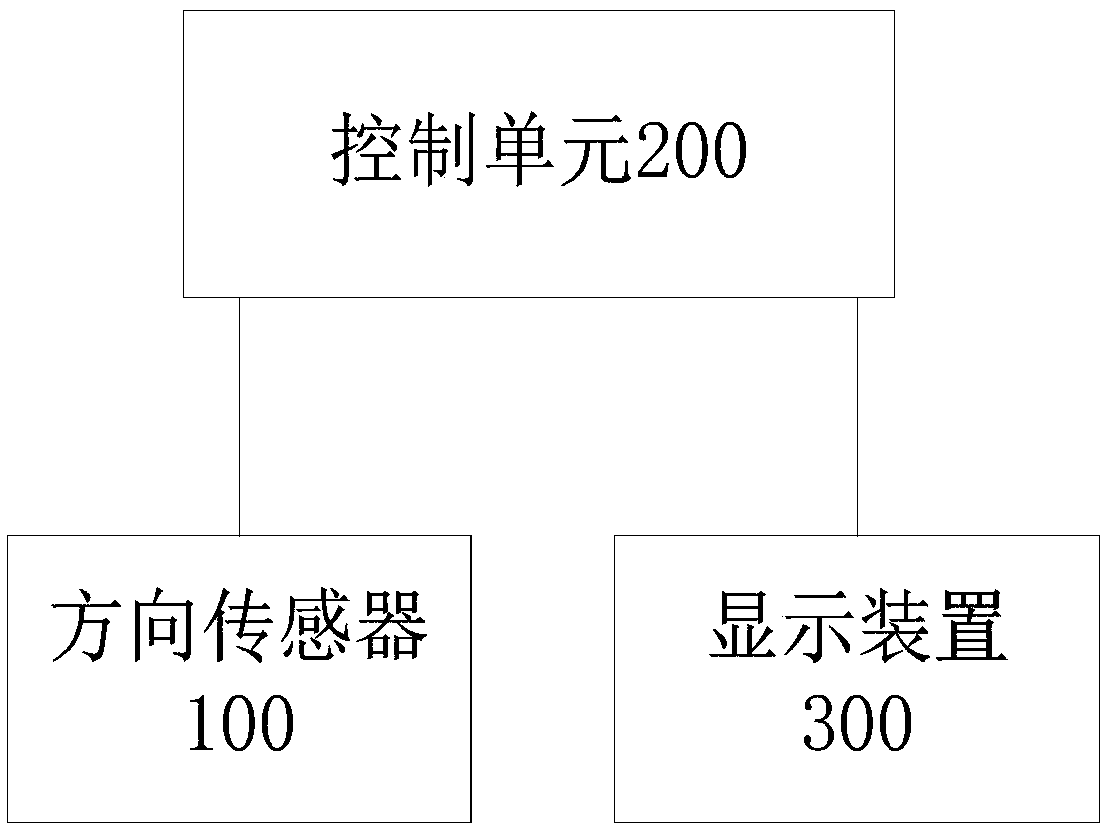

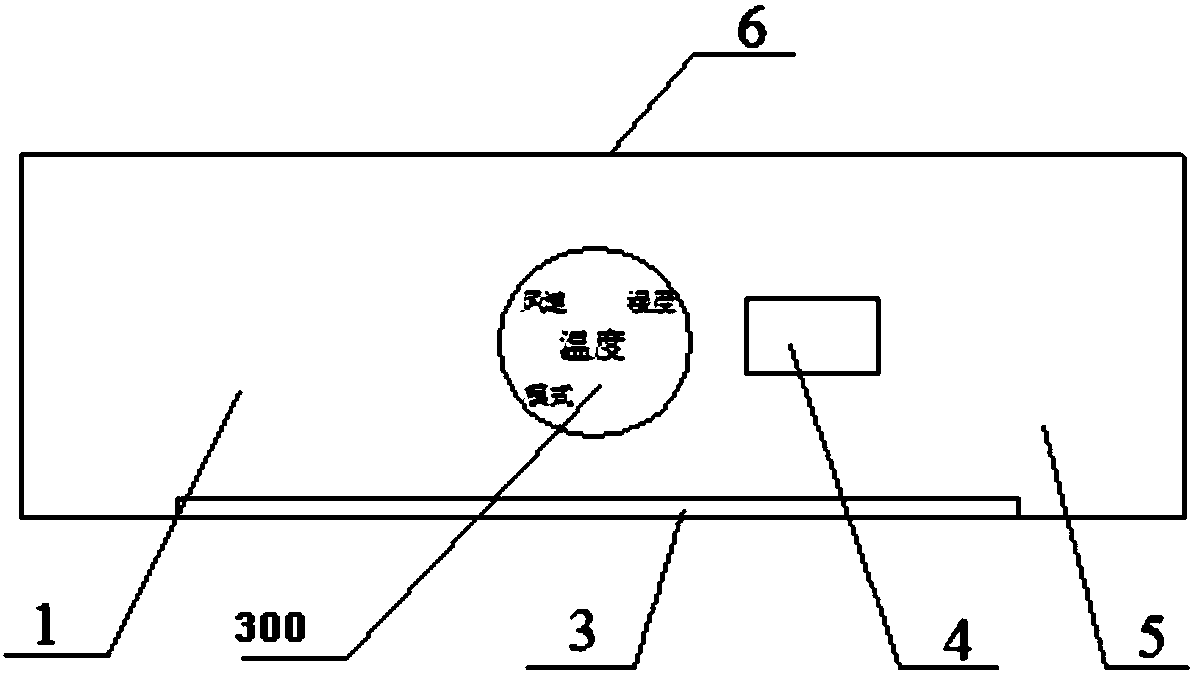

Display device based on equipment mounting direction, display method based on equipment mounting direction, storage medium and equipment

PendingCN107631452AOvercome space constraintsEnhance the sense of fashion and technologyMechanical apparatusLighting and heating apparatusDisplay deviceIndustrial engineering

The invention provides a display device based on the equipment mounting direction, a display method based on equipment mounting direction, a storage medium and equipment. The display device based on the equipment mounting direction comprises a direction sensor, a display device part and a control unit; the direction sensor is used for identifying the mounting direction of the equipment; the control unit is used for adjusting the display direction of the display device part to be adapted to the mounting direction of the equipment according to the mounting direction of the equipment identified by the direction sensor, or for selecting an adaptive display device part from the at least one display device part according to the mounting direction of the equipment identified by the direction sensor; and the display direction of the adaptive display device part is adapted to the mounting direction of the equipment. According to the technical scheme, when the equipment is located on occasions in different mounting directions, the display device part of the equipment is kept in a horizontal and positive display state all the time; and according to the scheme, the aesthetic demand is met during equipment mounting, the mounting space limitation is overcome, and user experience is good.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

Broadband Antenna In The Crash Pad For Vehicle

InactiveCN107453031AEffective compositionWork around space constraintsSimultaneous aerial operationsPedestrian/occupant safety arrangementBroadbandEngineering

Disclosed herein is a vehicle broadband antenna that is an antenna for LTE & V2X installed in the vicinity of a crash pad of a vehicle. The crash pad broadband antenna is installed in the vicinity of a vehicle crash pad and includes a main PCB, an LTE low-band antenna pattern formed on the main PCB to transmit and receive an LTE low-band signal, a first sub-PCB having LTE high-band antenna patterns configured to transmit and receive an LTE high-band signal, the first sub-PCB being vertically coupled to the main PCB, and a first terminal connected to an external communication module for transmitting and receiving the signals to / from the LTE low-band antenna pattern and the LTE high-band antenna patterns. It is possible to overcome existing spatial limitations by applying the broadband antenna to the vehicle, and to significantly reduce the time required to manufacture and develop an existing mold.

Owner:因派克伊莱克斯

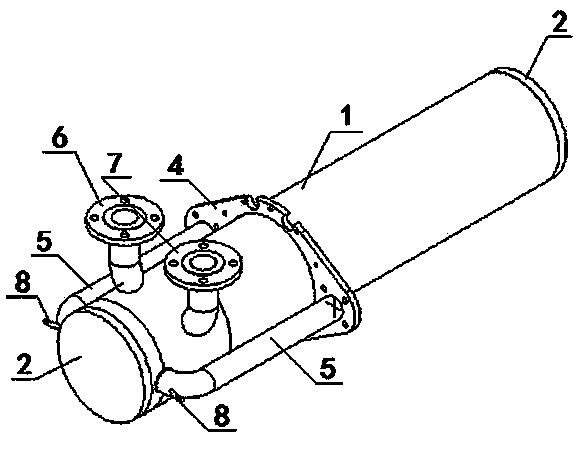

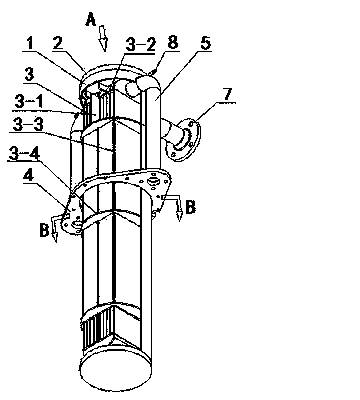

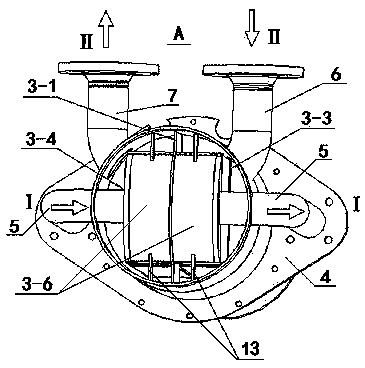

Main pump lubricating oil cooler

ActiveCN103424016AReduce resistanceNot suitable for scalingHeat exhanger sealing arrangementHeat exchanger casingsEngineeringHeat transfer efficiency

The invention relates to heat exchange equipment, in particular to a main pump lubricating oil cooler. The heat exchanger is heat exchange equipment developed specially for a nuclear power reactor main pump lubricating oil system. The heat exchanger comprises a barrel body, an upper end cover, a lower end cover, a plate bunch, a connecting flange, pipelines, an inlet flange and an outlet flange, wherein the barrel body, the upper end cover and the lower end cover form a sealed cavity of the heat exchanger, the connecting flange of a rhombic structure is arranged in the middle of the barrel body, the two L-shaped pipelines with discharge oil compensating ports are symmetrically arranged at the two sides of the barrel body, one end of each pipeline is communicated with the barrel body, the other end of each pipeline is arranged on the connecting flange, the inlet flange and the outlet flange are perpendicular to the axial direction of the pipelines and are arranged on the barrel body, and the plate bunch is arranged in the sealed cavity of the barrel body. The main pump lubricating oil cooler is simple and reasonable in structure, high in heat transferring efficiency, and convenient to install and use.

Owner:四平市巨元瀚洋板式换热器有限公司

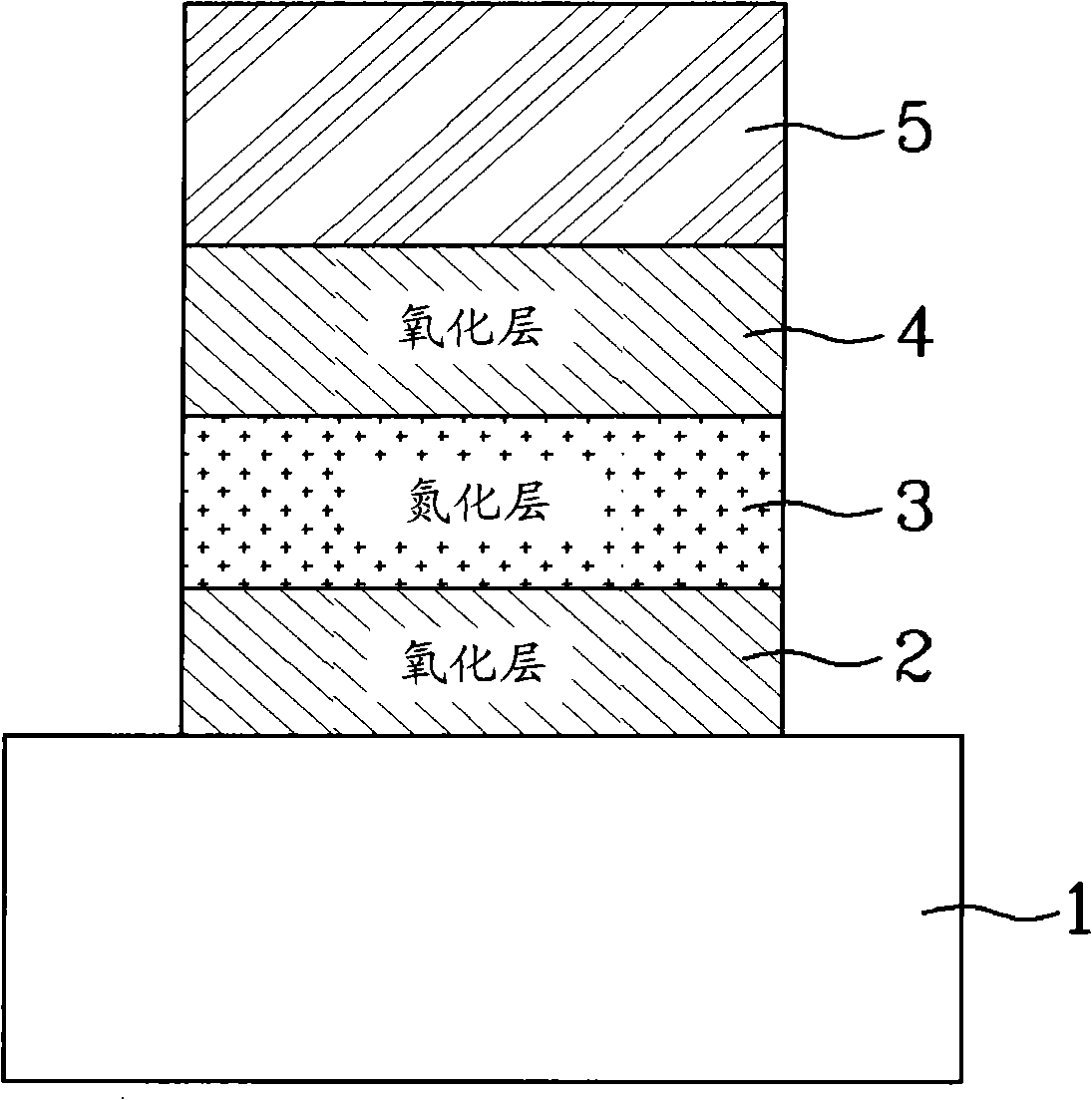

Semiconductor device, and method for fabricating thereof

InactiveCN101315946AImproved data retention featuresImprove reliabilitySemiconductor/solid-state device manufacturingSemiconductor devicesSilicon oxideNitride

A semiconductor device having silicon-oxide-nitride-oxide-silicon (SONOS) structure that overcomes spatial limitations which trap charges by not utilizing a flat, planar structure of the ONO film including a charging trap layer, thereby making it possible to improve reliability for data preserving characteristic of a SONOS device.

Owner:DONGBU HITEK CO LTD

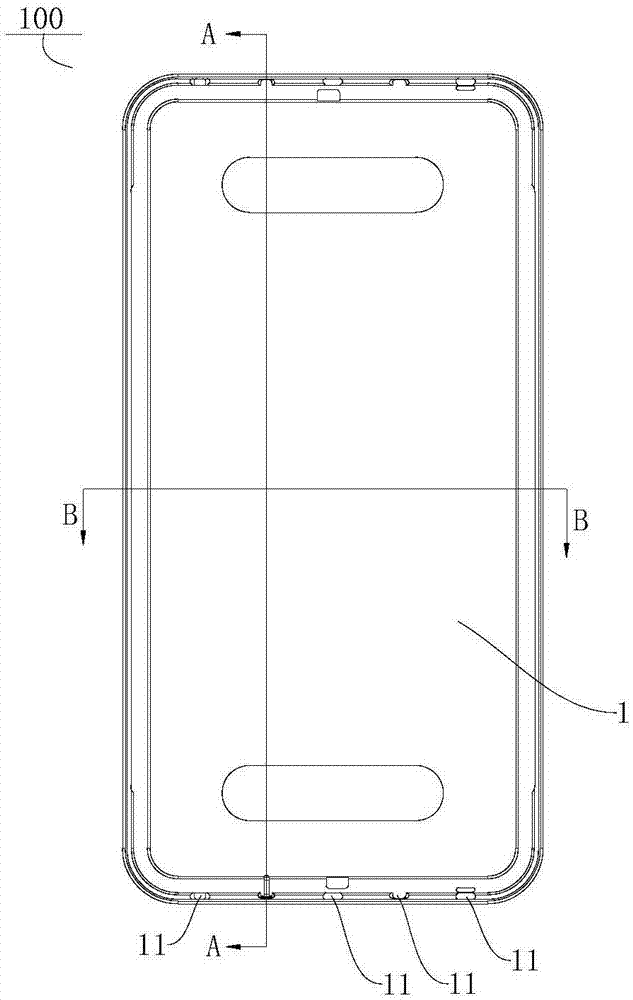

Housing assembly of terminal, and terminal

ActiveCN107395805ASimple structureImprove reliabilityAntenna supports/mountingsTelephone set constructionsMobile phoneIndustrial engineering

The invention discloses a housing assembly of a terminal, and a terminal. The housing assembly includes a housing, spring pieces and fasteners, wherein grooves are formed in the inner side wall of the housing; the part, being close to an opening of each groove, of the side wall of each groove, inclines to the inside of each groove, in the direction from the bottom wall of each groove to the opening; one part of each spring piece is located in the corresponding groove, and the other part of the spring piece is located outside the groove; and part of each fastener is located in the corresponding groove, and the fastener is connected with the housing and the corresponding spring piece. The housing assembly can improve the fixing reliability between the spring pieces and the housing, and can also solve the space limitation problem when a mobile phone housing is taken as one part of an antenna. Besides, the fixing mode of the spring pieces is simple in structure, thus being conductive to cost reduction.

Owner:SHENZHEN HEYTAP TECHNOLOGY CO LTD

Wire harness storing device

InactiveCN111646293ARealize storage limitAvoid clutterFilament handlingEngineeringStructural engineering

The invention discloses a wiring harness storing device. The wiring harness storing device comprises a wiring harness storing box body, wherein a wiring harness placing assembly is detachably mountedat the bottom of the wiring harness storing box body; the wiring harness placing assembly comprises a mounting plate; a T-shaped sliding groove is formed in the mounting plate; a fixed placing plate is fixedly mounted on the mounting plate; a plurality of uniformly distributed placing grooves are formed in the fixed placing plate; a plurality of T-shaped movable placing plates are slidably mountedin the T-shaped sliding groove; and the T-shaped movable placing plate is provided with movable placing grooves corresponding to the placing grooves one by one. According to the wire harness storingdevice, through setting the mounting plate, the fixed placing plate and the T-shaped movable placing plates, the positions of the T-shaped movable placing plates are adjusted according to the lengthsof wire harnesses, the wire harnesses with different lengths are clamped in the mutually corresponding placing grooves and the movable placing grooves, the storing and limiting of the wire harnesses with the same diameter and different lengths are achieved, and the wire harnesses with different sizes are prevented from being randomly placed together, so that the situation that the wire harnesses with different sizes are not convenient to take during using while the wire harnesses are not attractive is avoided.

Owner:曾缤

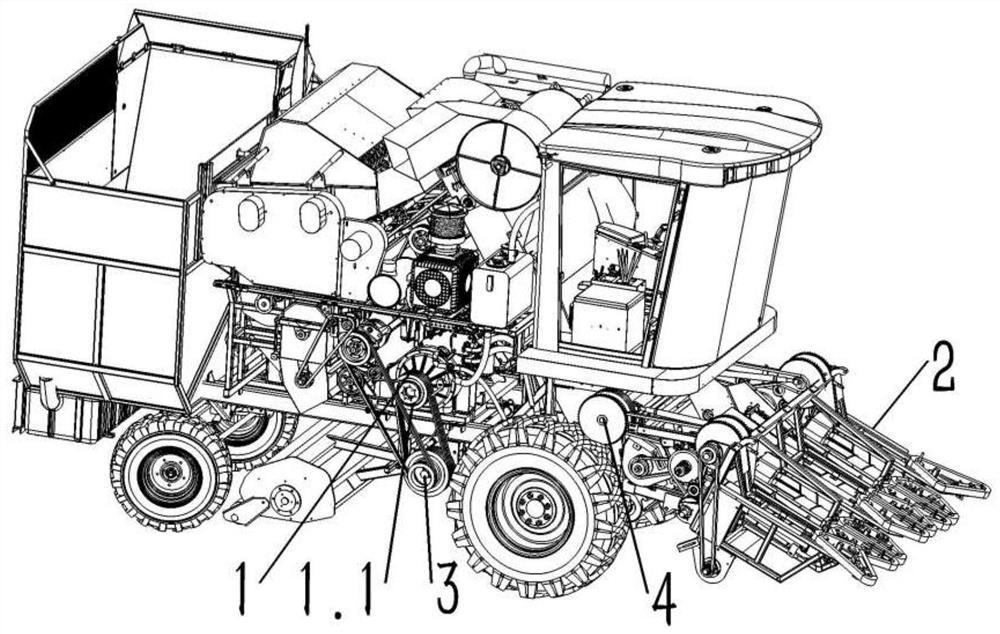

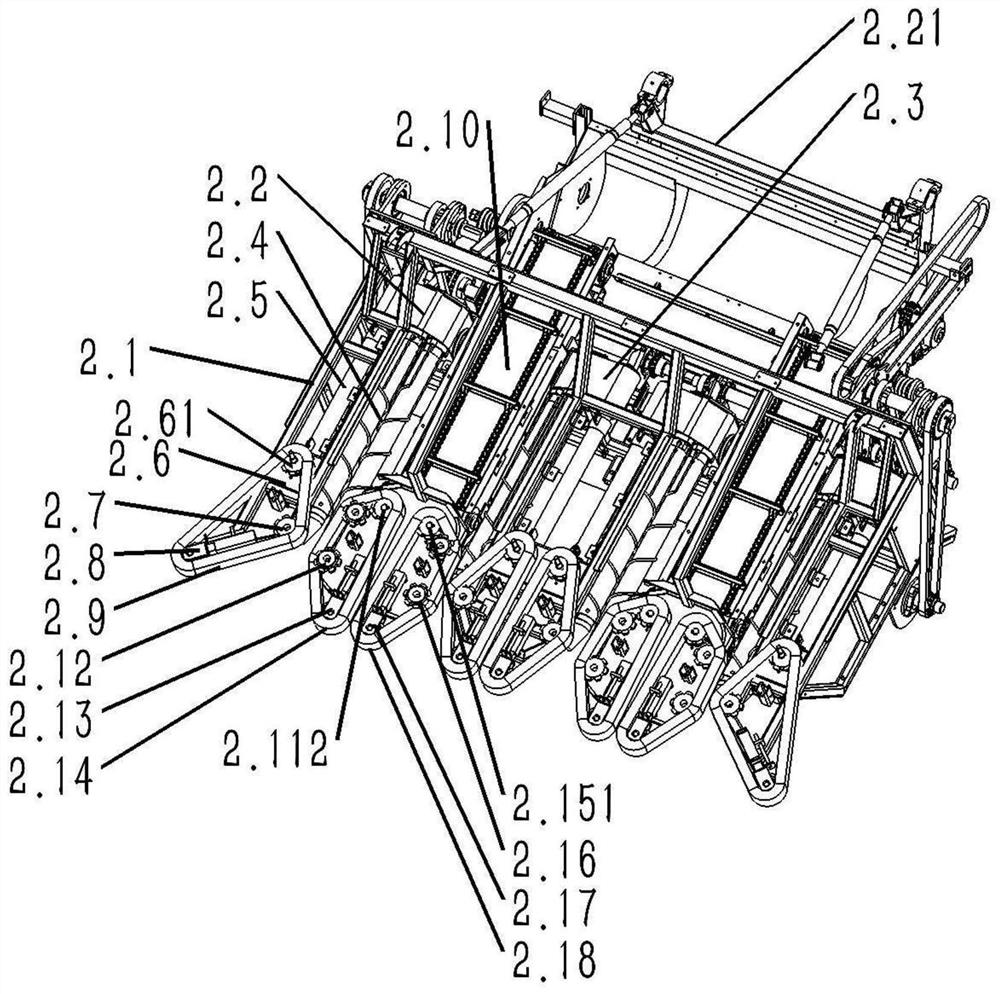

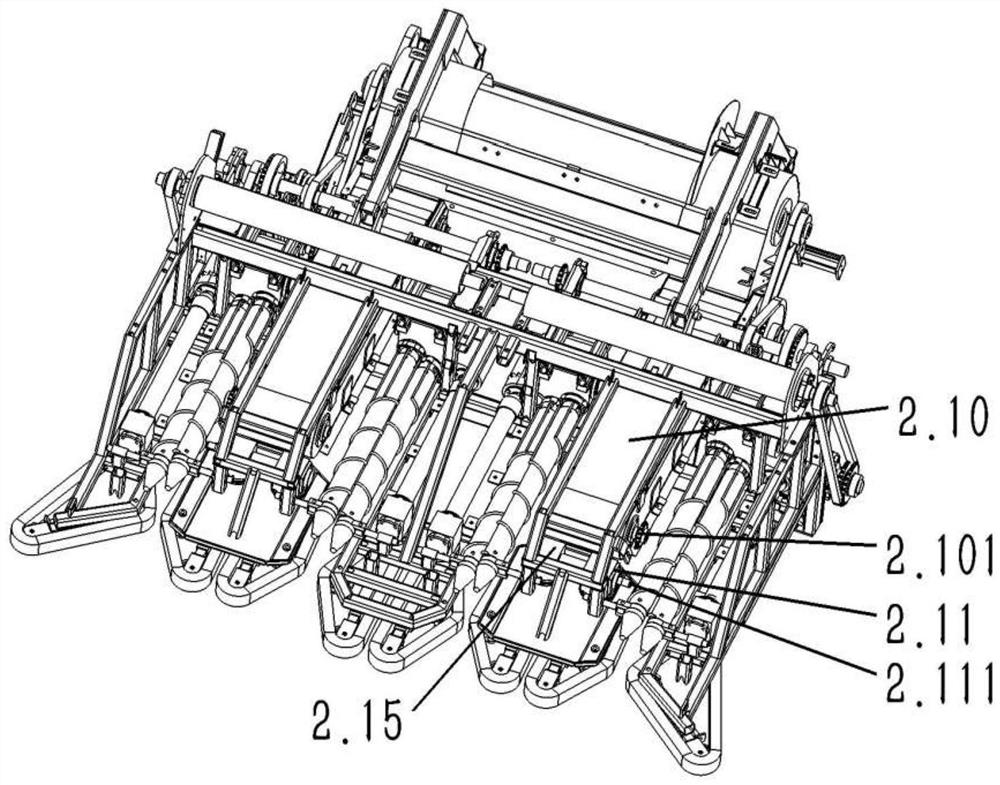

Harvester with hydraulic travelling system

PendingCN113475229AReduce the number of passesReduce usageLiquid coolingServomotor componentsHydraulic motorTransfer case

The invention discloses a harvester with a hydraulic travelling system. The harvester comprises a hydraulic travelling system body, the hydraulic travelling system body comprises a transfer case, a hydraulic pump, a hydraulic motor and a hydraulic oil tank, the transfer case is arranged on an engine, the engine drives the transfer case to work, the hydraulic pump is installed on the transfer case, the hydraulic pump is driven by the transfer case to work, an oil inlet pipe connector is arranged on the hydraulic pump and connected to the hydraulic oil tank through a hydraulic pipeline, and then hydraulic oil in the hydraulic oil tank is guided into the hydraulic pump. According to the harvester, the hydraulic travelling system body is adopted for driving, a header is only provided with one header main shaft for power input, a straw cutting roller is arranged below the header, straw pre-cutting is achieved, and the harvester is simple in driving structure, high in header transmission efficiency and high in returning quality.

Owner:河北英虎农业机械股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com