High-temperature superconducting linear suspension propulsion system

A high-temperature superconducting and propulsion system technology, which is applied to the usage of superconducting elements, holding devices using magnetic attraction or thrust, and electromechanical devices, etc. problems, achieving the effect of small size, avoiding space constraints and minimum volume constraints, and avoiding characteristic differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

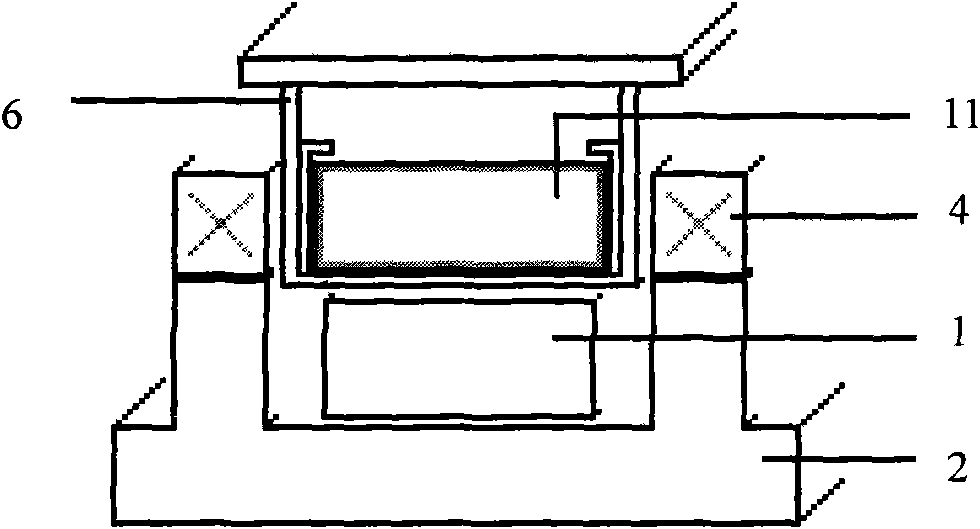

[0041] like figure 1 , figure 2 , Figure 11 shown. A high-temperature superconducting linear levitation propulsion system, including a high-temperature superconducting maglev system and a high-temperature superconducting linear propulsion system; the high-temperature superconducting maglev system includes a permanent magnet track 1, and a substrate 2 fixedly connected to the permanent magnet track 1; The linear propulsion system includes two electromagnets 4 arranged on the substrate 2, on both sides of the permanent magnet track 1, and composed of windings with iron cores, driven by a three-phase AC power supply; a high-temperature superconductor 11 for suspension and propulsion and a permanent magnet track 1 corresponds up and down, and is located in the middle of the two electromagnets 4 at the same time, on the side facing the two electromagnets 4; the high-temperature superconductor 11 used for suspension and propulsion is fixed at the bottom of the cryostat 6, and th...

Embodiment 2

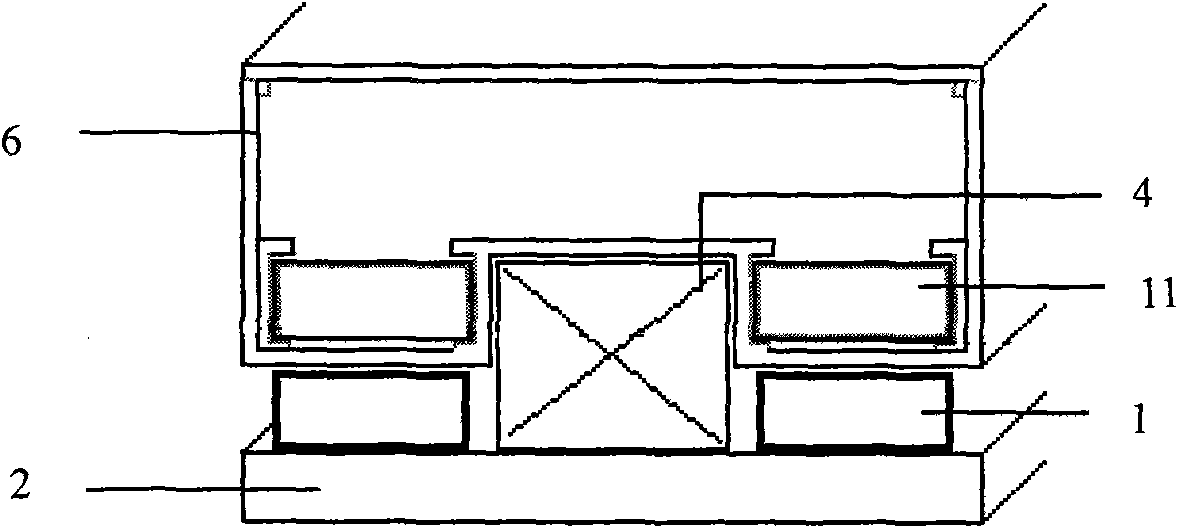

[0043] like figure 2 , image 3 shown. The same place as in Example 1 will not be repeated, the difference is that: the high-temperature superconducting maglev system includes two parallel permanent magnet tracks 1, and a substrate 2 fixedly connected to the permanent magnet tracks 1; the high-temperature superconducting linear propulsion system includes An electromagnet 4 arranged in the middle of the two permanent magnet tracks 1 on the base 2; two high-temperature superconductors 11 used for suspension and propulsion respectively correspond to the upper and lower sides of the two permanent magnet tracks 1, and are on the side facing the electromagnet 4; Two high-temperature superconductors 11 for suspension and propulsion are fixedly placed at the bottom of the same cryostat 6 .

Embodiment 3

[0045] like Figure 4 , Figure 12 shown. A high-temperature superconducting linear levitation propulsion system, including a high-temperature superconducting maglev system and a high-temperature superconducting linear propulsion system; the high-temperature superconducting maglev system includes two parallel permanent magnet tracks 1, and a substrate 2 fixedly connected to the permanent magnet tracks 1, Two high-temperature superconductors 3 for suspension corresponding to the upper and lower sides of the permanent magnet track 1; the high-temperature superconducting linear propulsion system includes an electromagnet 4 arranged on the base 2, between the two permanent magnet tracks 1, and composed of a winding with an iron core, Driven by a three-phase AC power supply, the high-temperature superconductor 5 for propulsion corresponding to the electromagnet 4 facing the electromagnet 4; the high-temperature superconductor 5 for propulsion is fixed together with two high-temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com