Apparatus for connecting between intake manifold and EGR pipe

A technology for intake manifolds and connectors, applied in connection components, charging systems, exhaust gas recirculation, etc., can solve problems such as inconvenience to operators, difficulty in disassembly and reassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A device for connecting an intake manifold and an EGR pipe according to a preferred embodiment of the present invention will be described below with reference to the accompanying drawings. For clarity and convenience of illustration, line thicknesses or component sizes in the drawings are shown exaggerated. In addition, the terms explained below are defined in consideration of the functions of the present invention and may be changed depending on the user's or operator's intention or use. Therefore, the terms should be defined based on the entire content of this specification.

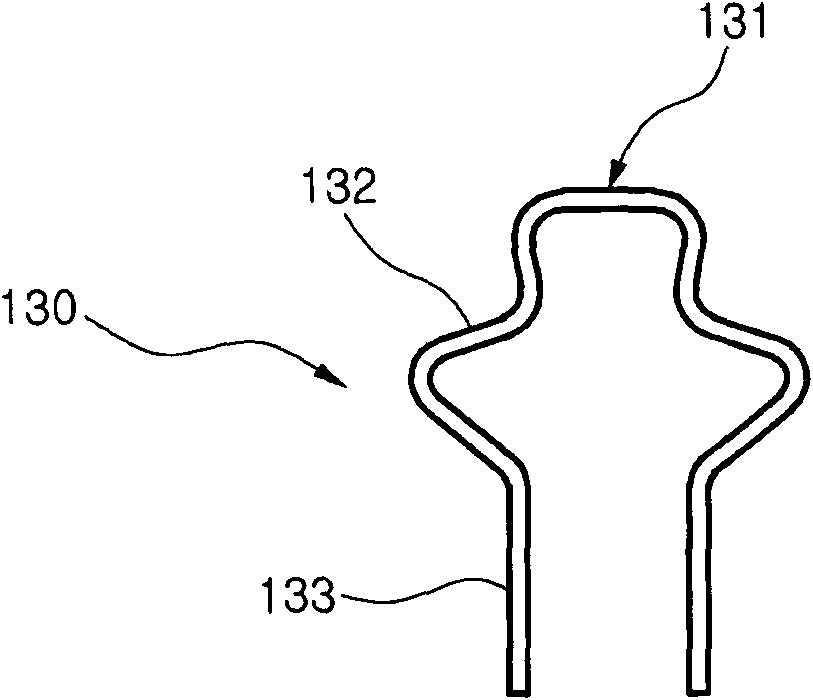

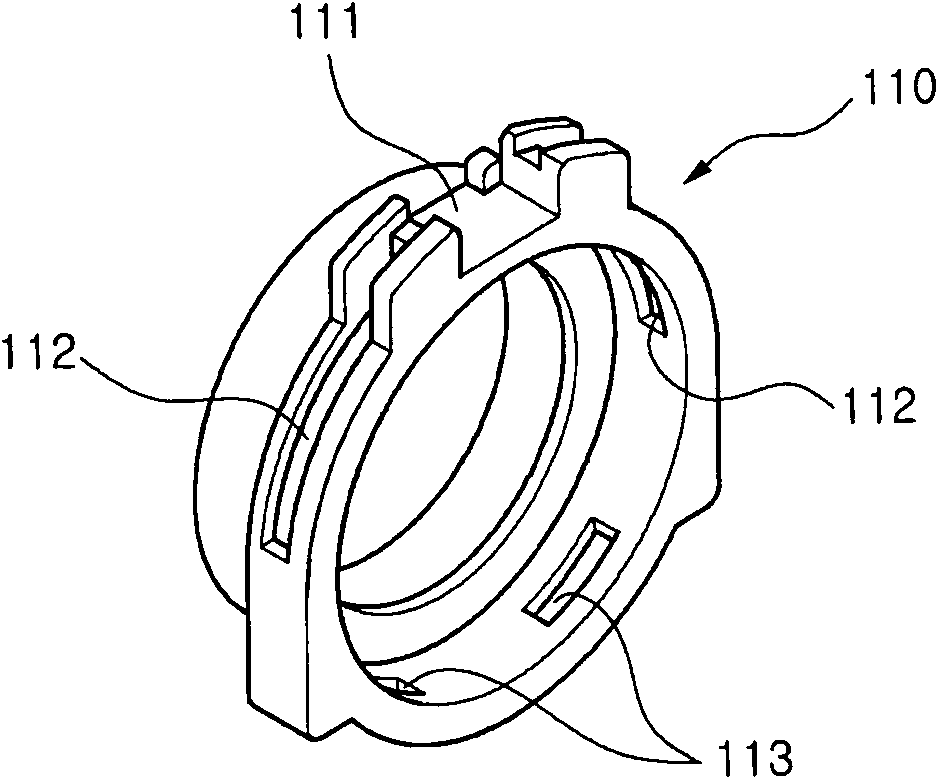

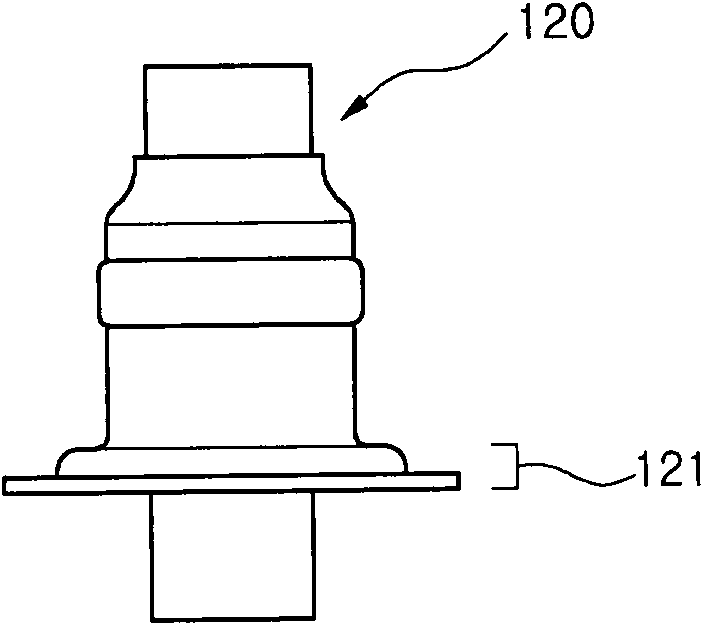

[0022] Figure 1a To illustrate a plan view of a clip 130 of an apparatus 100 for connecting an intake manifold and an EGR pipe according to an embodiment of the present invention, Figure 1b To show a perspective view of the intake manifold connector 110 of the device 100 for connecting the intake manifold and the EGR pipe according to the embodiment of the present invention, Figure 1c It is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com