Patents

Literature

131results about How to "Reduce the number of passes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

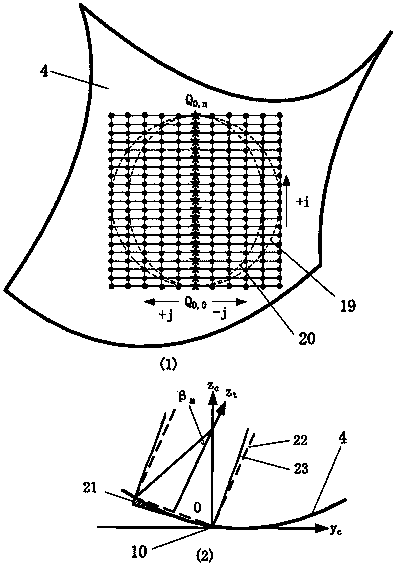

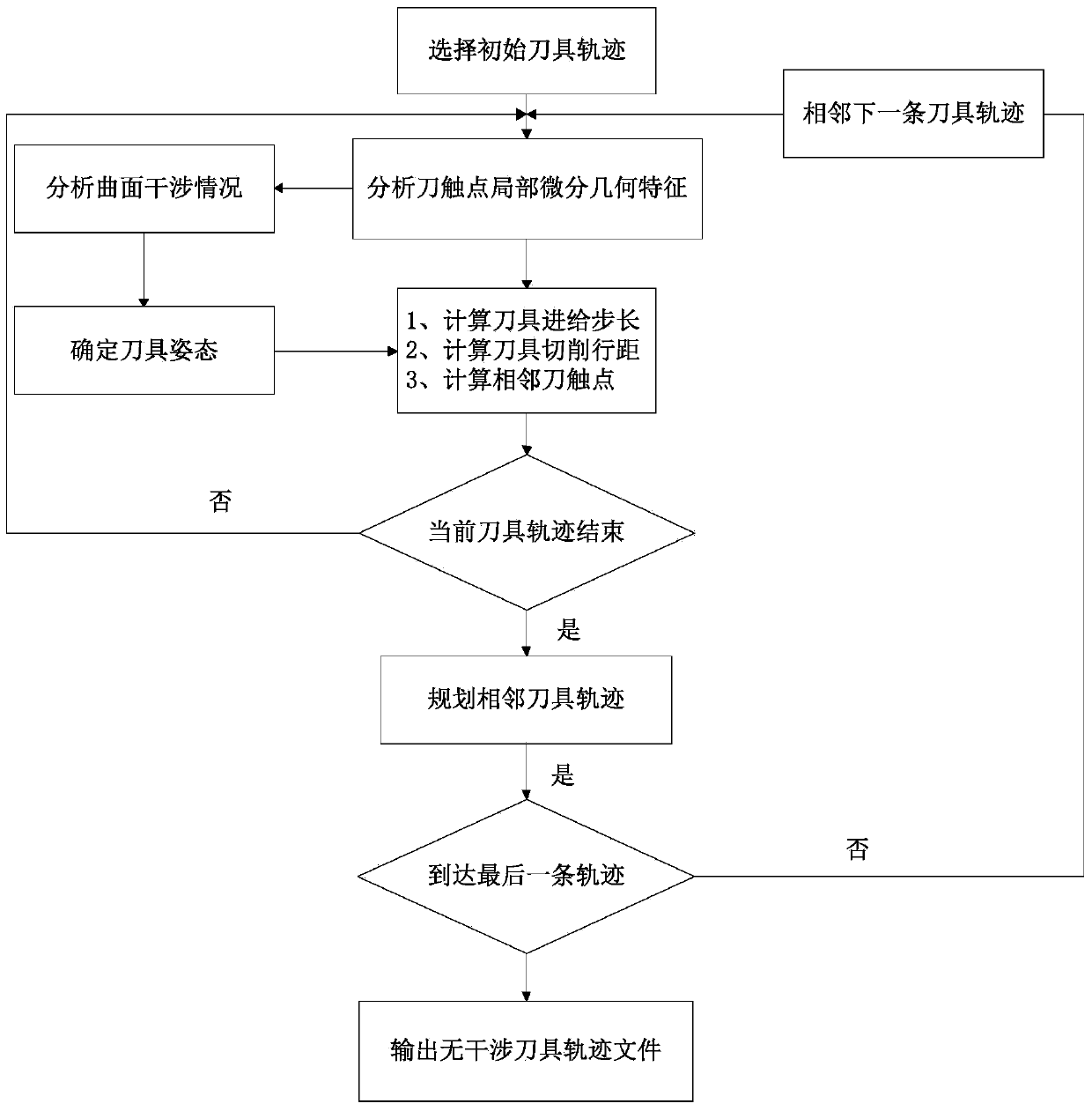

Interference-free tool path generation method in machining of transitional surfaces by flat-end milling cutter

InactiveCN103744349AImprove processing efficiencyReduce surface roughnessNumerical controlMilling cutterPath generation

The invention discloses a method for generating interference-free flat-end milling cutter process path along the ridge direction of transitional surfaces. The method comprises the following steps: (1) initial machining tool path is set, a tool is processing along the ridges of transitional surfaces, a current tool contact is calculated to obtain effective curvature of the machining tool at the tool contact; (2) curvature interference analysis of transitional surface machining is carried out according to the effective curvature of the machining tool at the tool contact, tool bottom interference is analyzed, and the angle of the tool is deflected at the tool contact to obtain interference-free tool posture; (3) parameter calculation is carried out on the adjusted tool path so as to obtain step-length and cut row distance; and (4) adjacent tool path lines are calculated, including calculation of adjacent tool contacts and calculation of tool location data, and interference-free tool path is finally obtained. By the method, automatic planning of interference-free tool path can be realized; large cut row distance is obtained; cutting efficiency is high; machining surface roughness is low; surface fairness is good; and problems of low cutting efficiency, poor machining surface quality and the like by machining of a ball-end milling cutter are solved.

Owner:HUAZHONG UNIV OF SCI & TECH

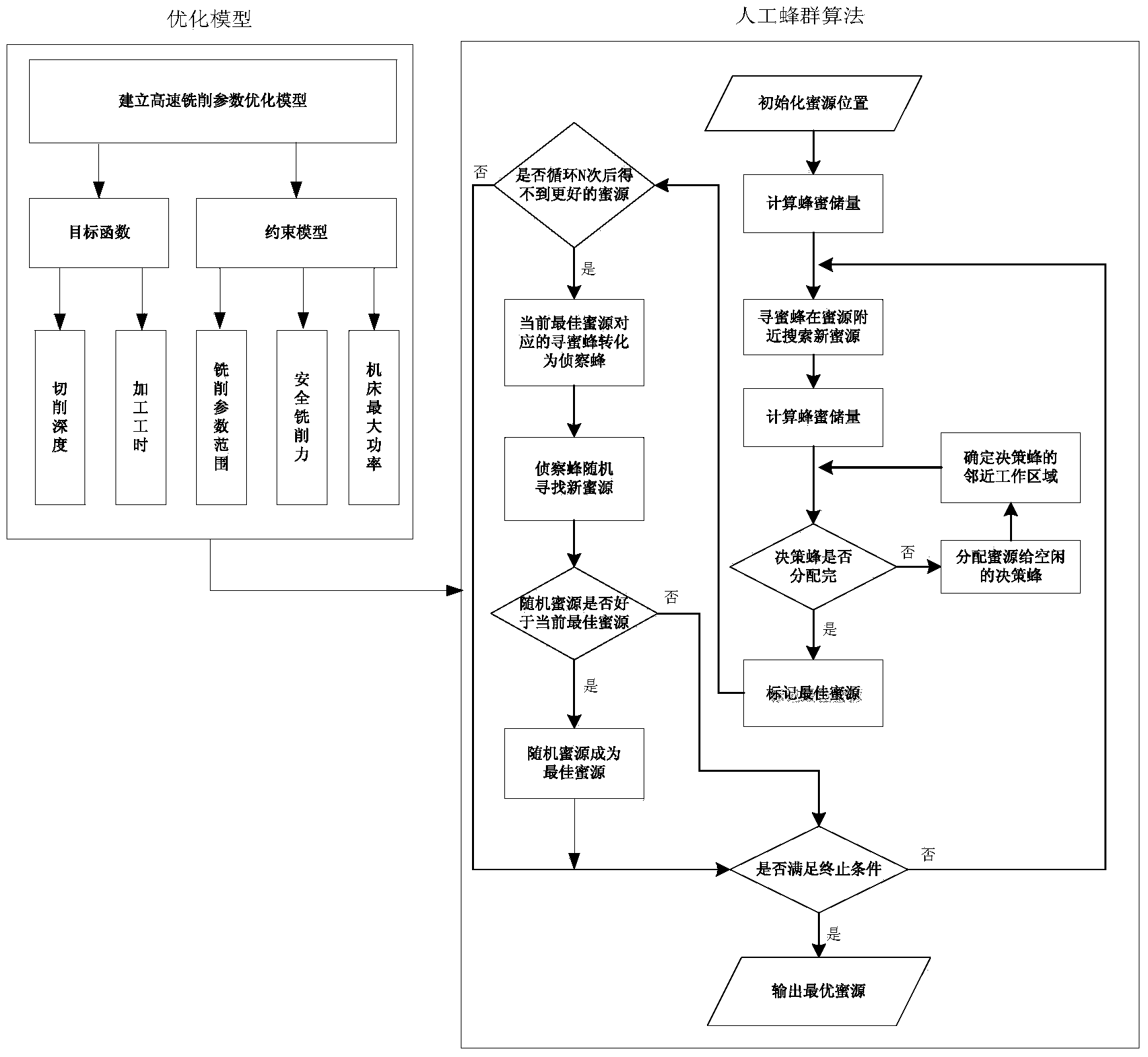

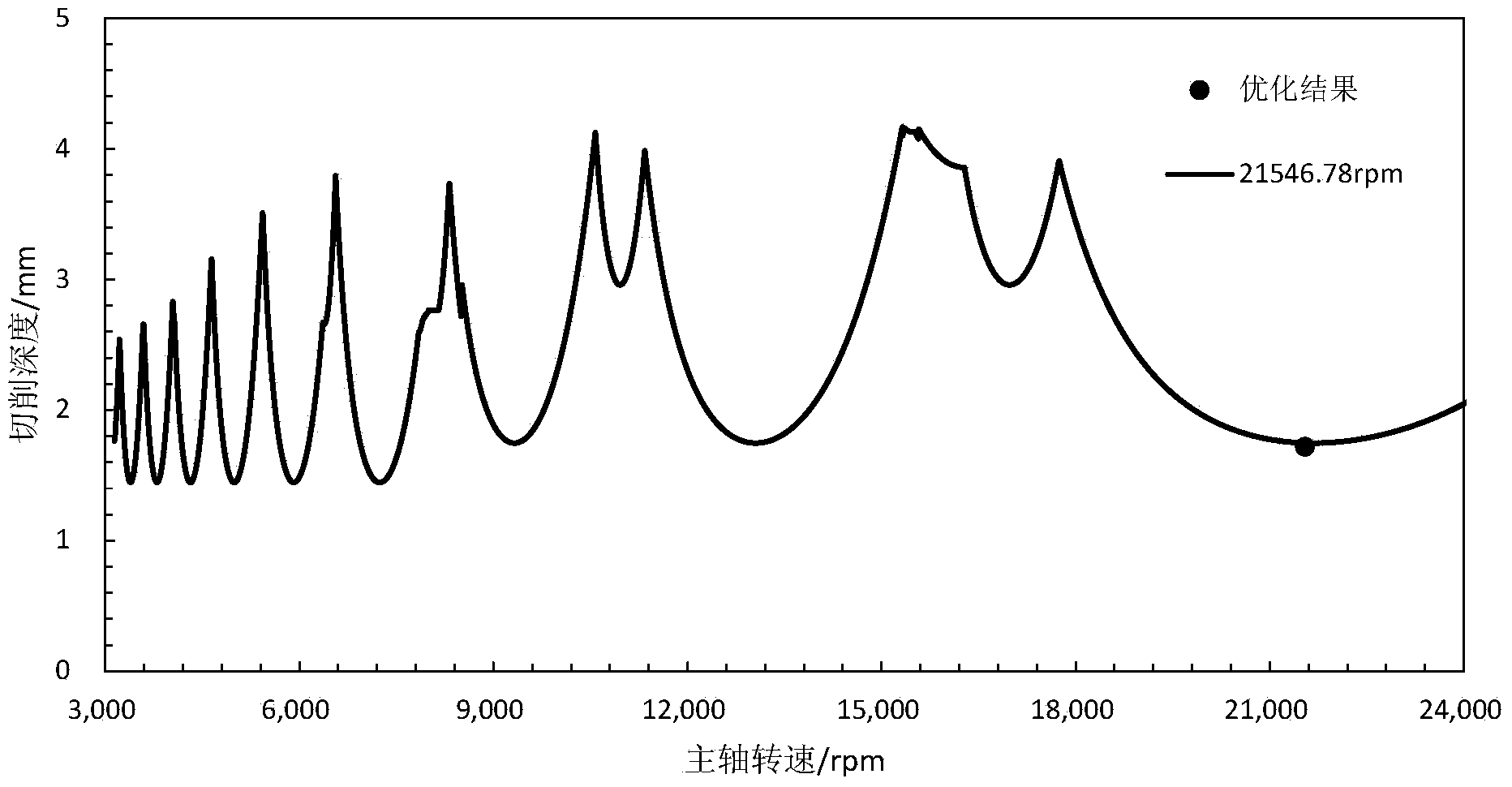

Milling process parameter optimization method

ActiveCN104076733AExcellent milling process parametersImprove productivityNumerical controlProduction rateProcess engineering

The invention provides a milling process parameter optimization method and belongs to the field of cutting machining processes. The coupling effect of a machining device dynamic behavior and the high-speed milling process is considered in the method, the maximum milling extreme cutting depth changing with the rotating speed of a machine tool spindle and shortest machining time of single part are regarded as optimization targets, a milling process parameter optimization model based on cutting stability and productivity is established, and optimal milling process parameters of a milling process parameter combining scheme under the condition that a cutting state is stable when the productivity is maximum are calculated. The milling process parameter optimization method can improve the cutting depth to the most extent during milling, decrease feed times, obtains maximum productivity, meanwhile ensures the cutting stability and avoids flutter. In addition, the milling process parameter optimization method can be applied to the high-speed milling process, the defect that the interactive effect of the machining device dynamic behavior and the milling process parameters is not considered in the high-speed milling process at present is overcome, and optimal high-speed milling process parameters can be obtained.

Owner:TONGJI UNIV

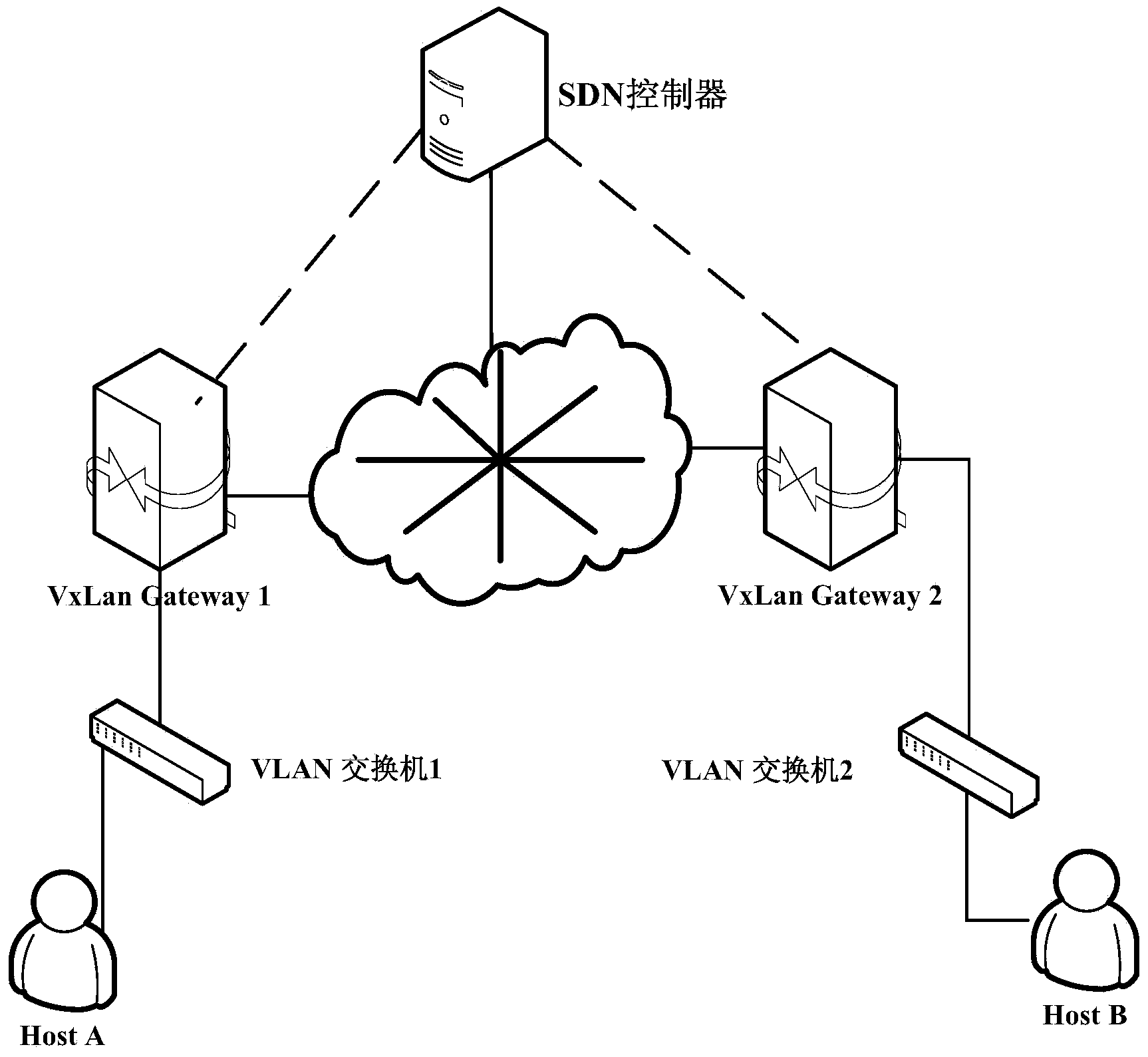

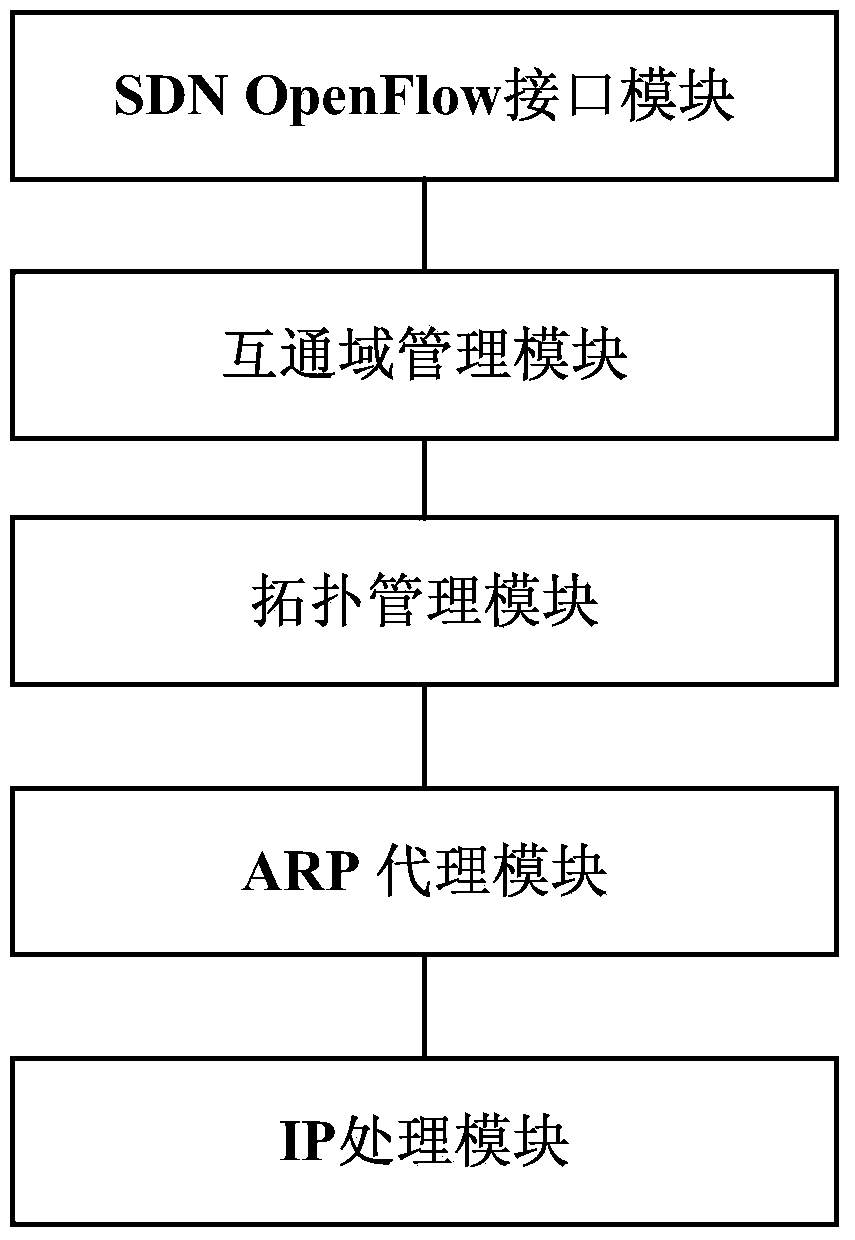

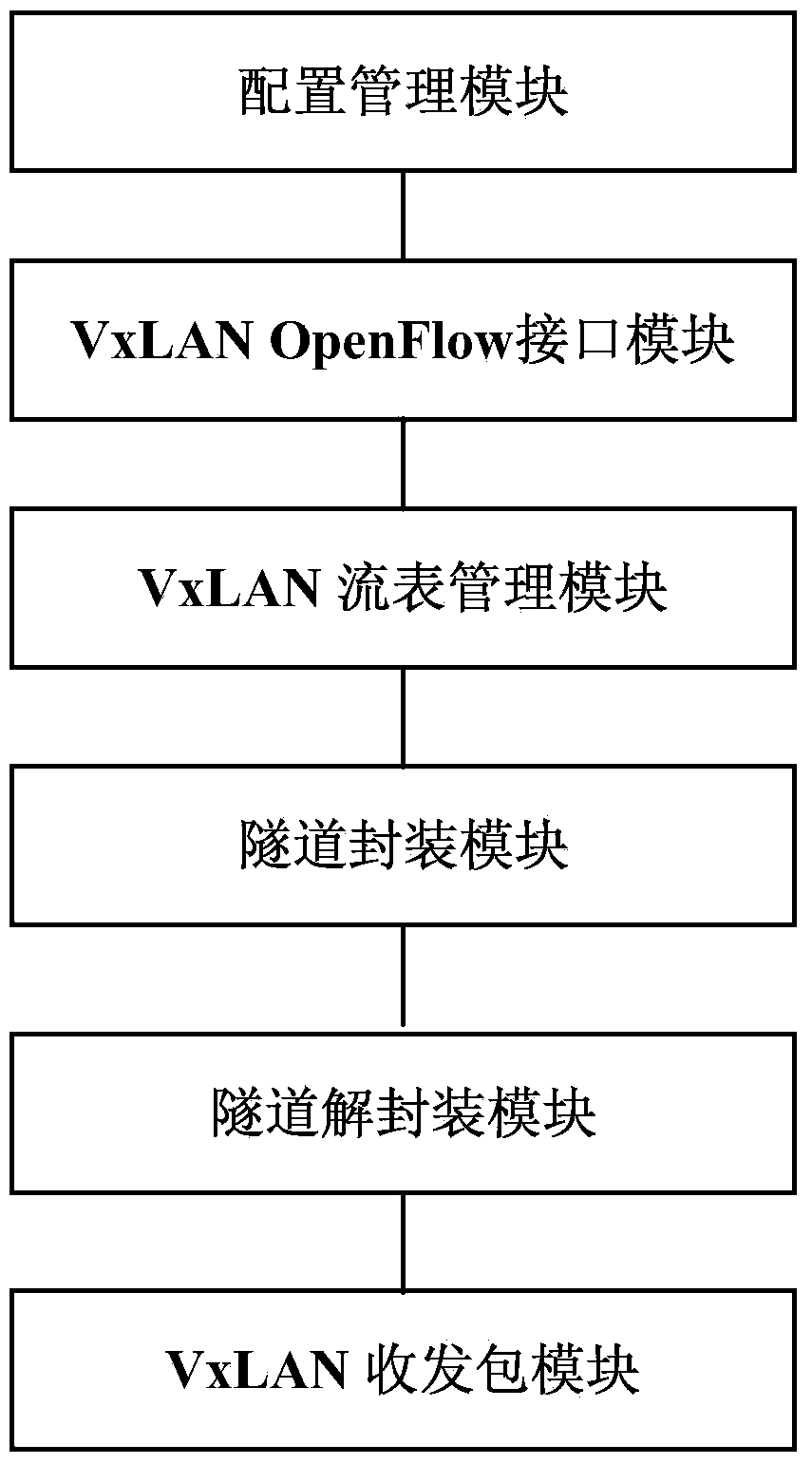

ARP broadcast restraining system and method for achieving VxLAN based on SDN framework

ActiveCN104320267AReduce the number of passesEasy to useSpecial service provision for substationTopology managementIp processing

The invention discloses an ARP broadcast restraining system and method for achieving a VxLAN based on an SDN framework and relates to the field of the VxLAN in a data center. The system comprises an SDN controller, VxLAN Gateways and VLAN interchangers. The SDN controller comprises an SDN OpenFlow interface module, a communication domain management module, a topology management module, an ARP proxy module and an IP processing module, wherein all the modules are sequentially connected. Each VxLAN Gateway comprises a configuration management module, a VxLAN OpenFlow interface module, a flow meter management module, a tunnel encapsulation module, a tunnel decapsulation module and a VxLAN package receiving and sending module, wherein all the modules are sequentially connected. Each VLAN interchanger comprises a VLAN package receiving and sending module and a VLAN ID module. The system and method are easy to achieve, the number of transmission times of ARP broadcast messages can be remarkably reduced, ARP broadcast in various scenes can be avoided, the broadcast restraining effect is good, and the system and method can be used by people conveniently.

Owner:WUHAN GREENET INFORMATION SERVICE

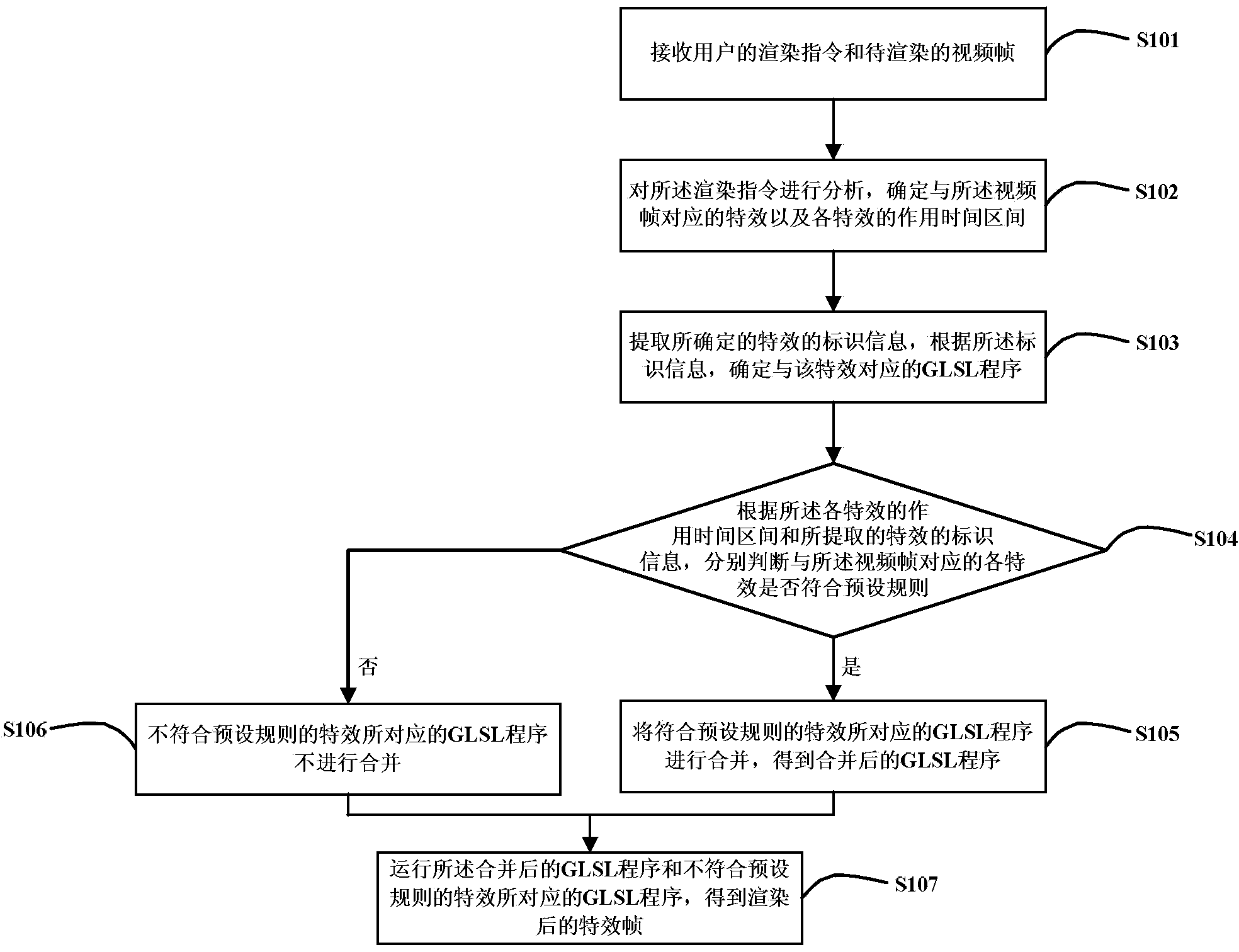

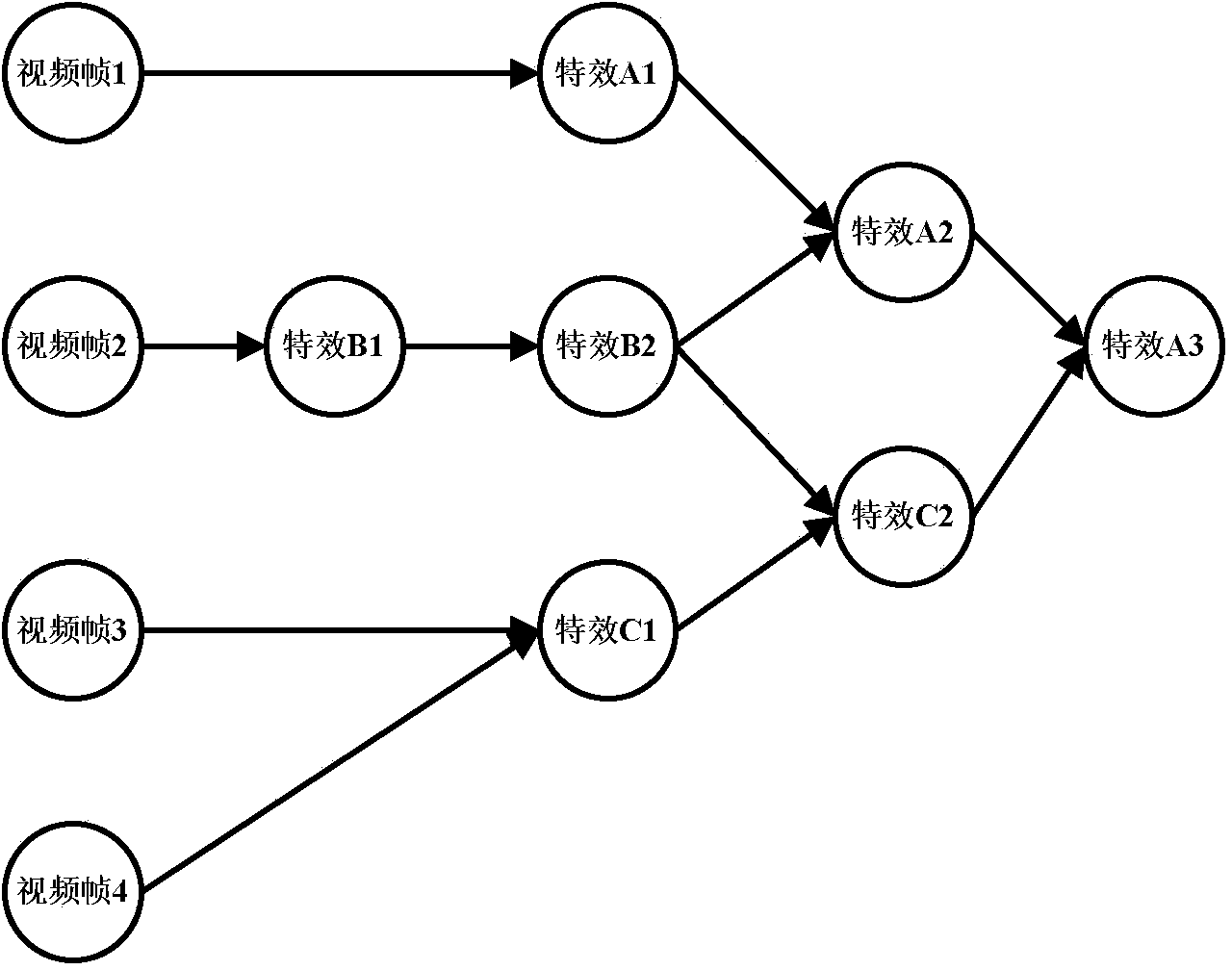

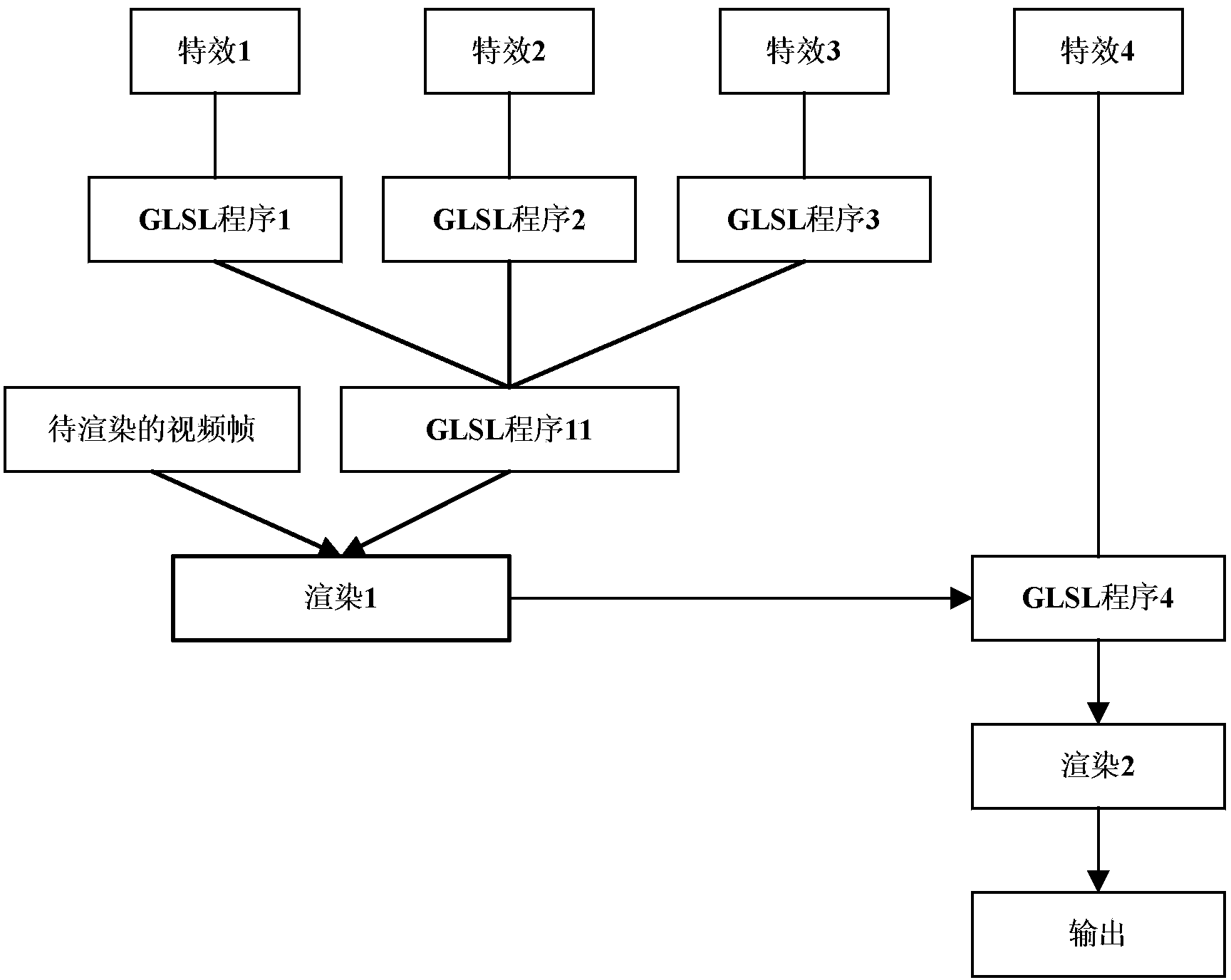

Video frame rendering method and device

ActiveCN103853562AReduce the number of runsAchieve renderingSpecific program execution arrangementsGraphicsComputer vision

The embodiment of the invention discloses a video frame rendering method and a video frame rendering device. The video frame rendering method comprises the following steps: receiving a rendering instruction of a user and a to-be-rendered video frame; analyzing the rendering instruction, and determining special effects corresponding to the video frame and an action time interval of each special effect; extracting the identifier information of the determined special effects, and determining GLSL (open graphics library shading language) programs corresponding to the special effects, wherein each special effect corresponds to one GLSL program; respectively judging whether each special effect corresponding to the video frame meets a preset rule according to the action time interval of each special effect and the extracted identifier information of each special effect; combining the GLSL programs corresponding to the special effects which meet the preset rule to obtain a combined GLSL program; executing the combined GLSL program and the GLSL programs corresponding to the special effects which do not meet the preset rule to obtain a rendered special-effect frame. According to the technical scheme, the execution frequency of the GLSL programs is reduced, and the transfer frequency of repeating data is reduced, so that the rendering efficiency is improved.

Owner:BEIJING QIYI CENTURY SCI & TECH CO LTD

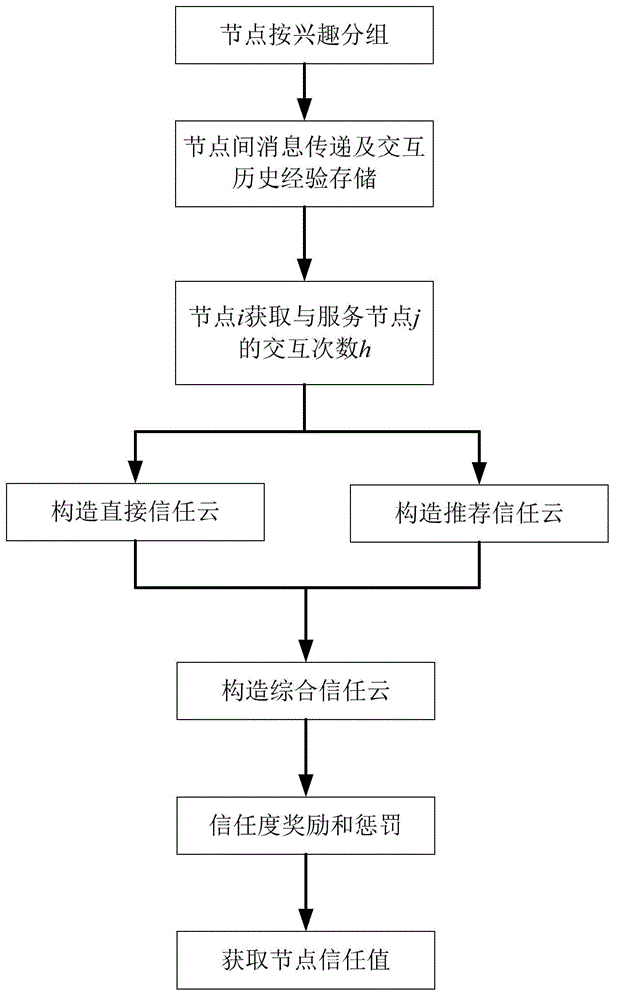

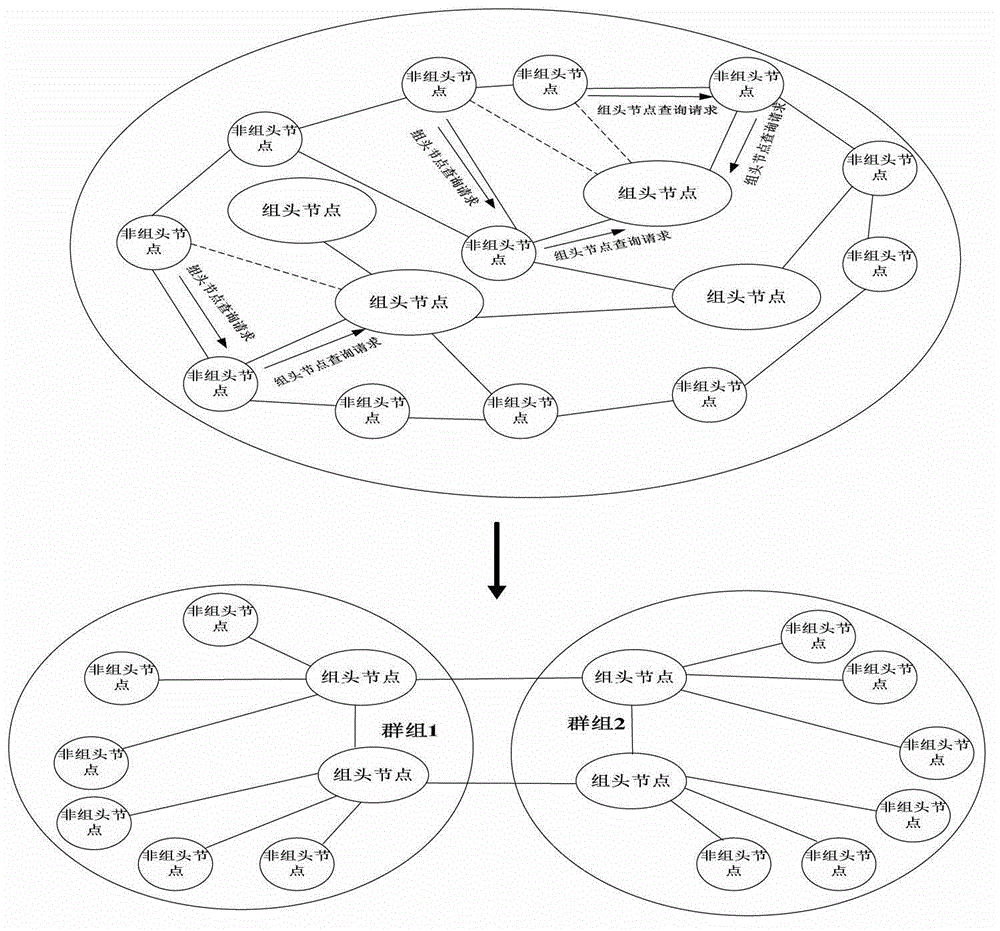

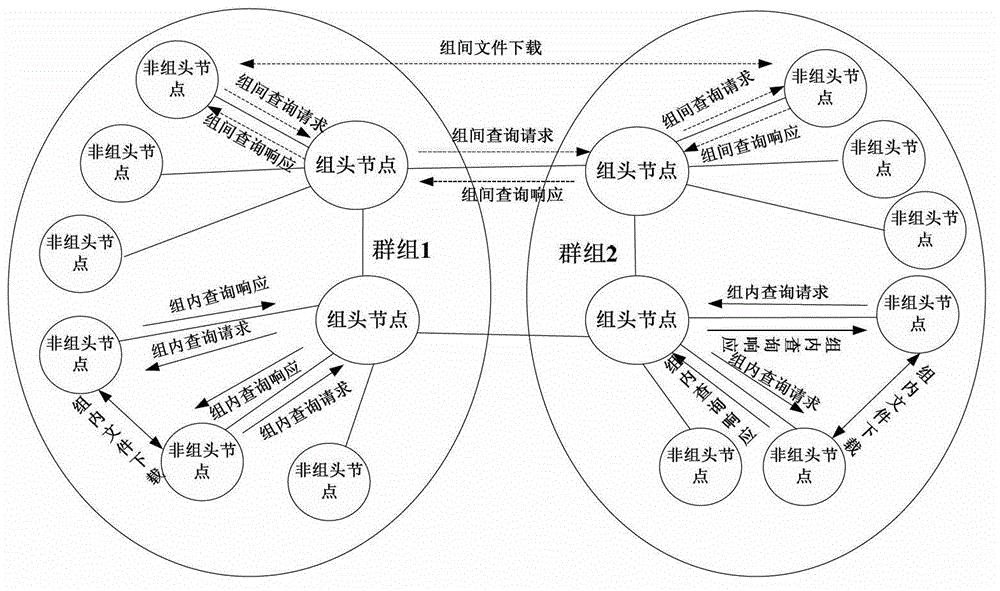

P2P network trust cloud model calculating method based on interest groups

InactiveCN103561047ASimplify complexityEasy to distinguishSpecial service provision for substationTrust levelTrust relationship

The invention discloses a P2P network trust cloud model calculating method based on interest groups. The method of the invention is composed of the interest group division and message passing process, the trust cloud establishment process and the node trust level evaluation process. The interest group division and message passing process is that a network is divided into different groups according to the interest of each group, and the intra-node message passing mode and the inter-node message passing mode are determined separately. The trust cloud establishment process is that a node trust relationship is expressed through three numerical characteristics, i.e. the expectation, the entropy and the hyper entropy, of a cloud model to establish a comprehensive trust cloud which is composed of a direct trust cloud and a recommended trust cloud. The node trust level evaluation process is that a node comprehensive trust value is evaluated through a trust value calculation method which gives priority to the direct experience. The method of the invention not only can be used to solve the problem that the trust relationship is hard to establish due to excessive message passing in the P2P network and asymmetric interests, and but also can be used to reduce the risk of obtaining unreliable recommended information.

Owner:NANJING UNIV OF SCI & TECH

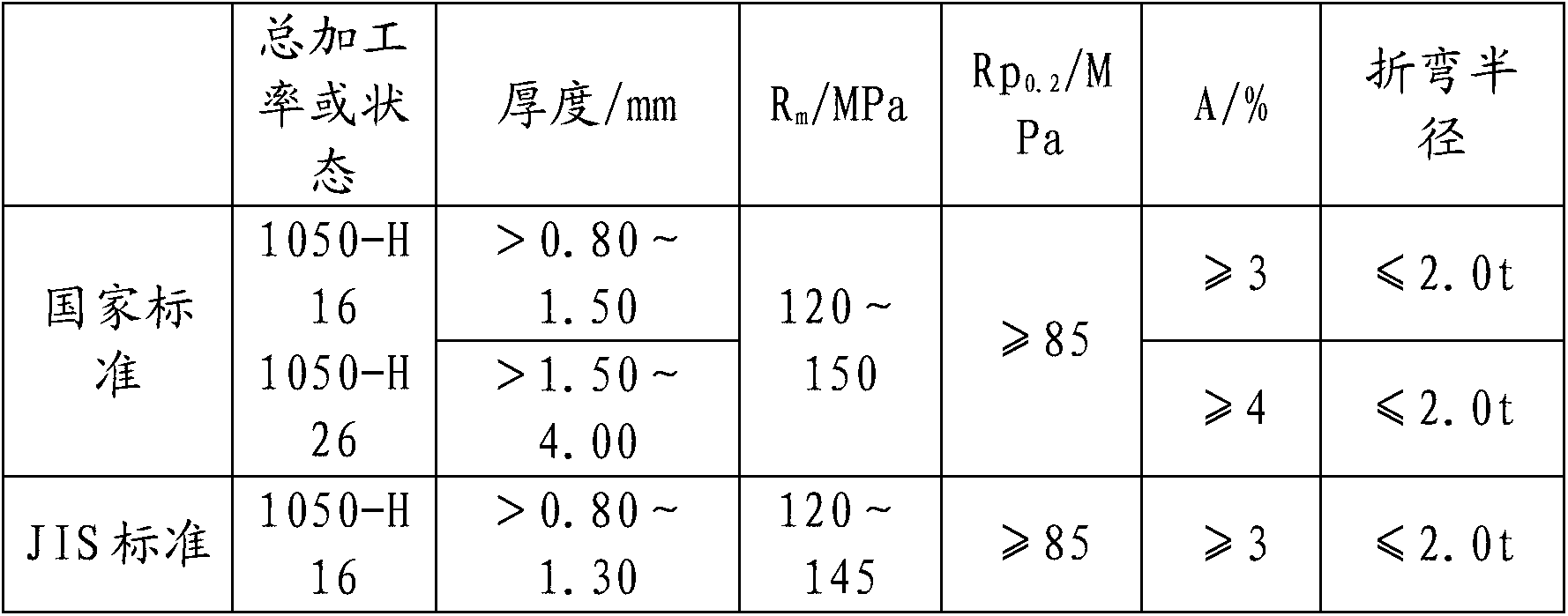

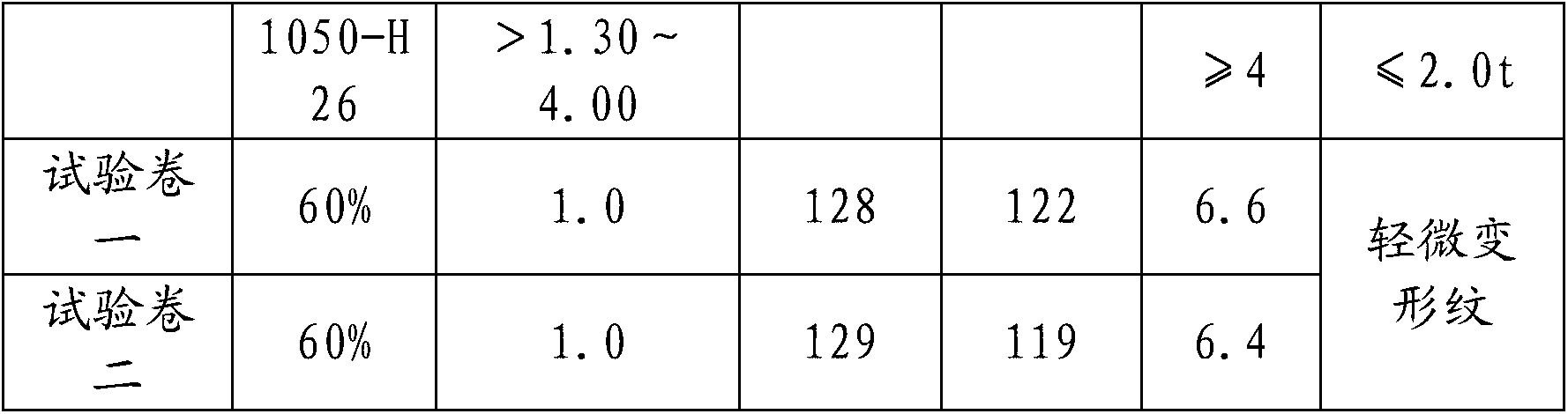

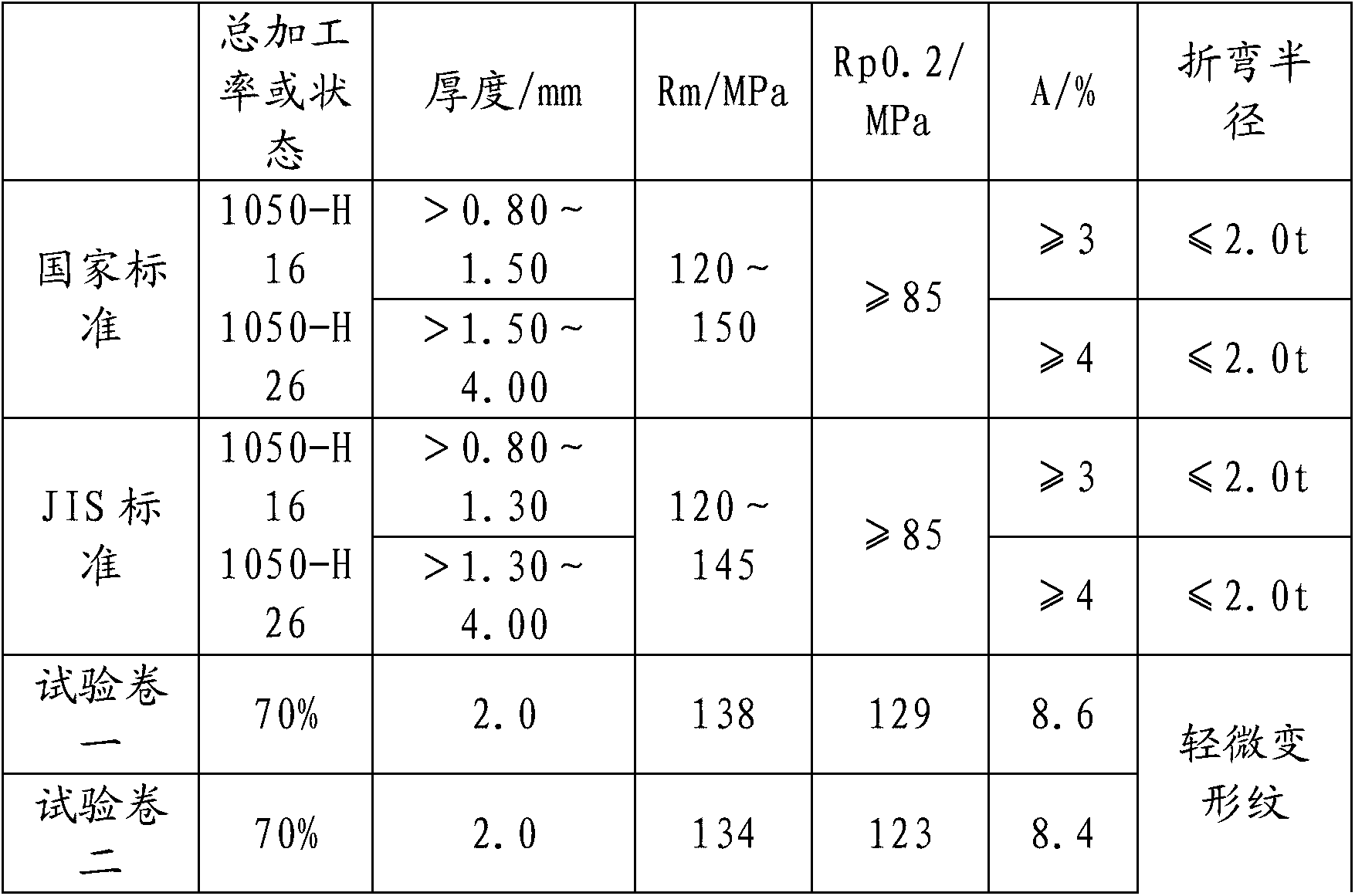

1050-H16 aluminum alloy plate strip and production method thereof

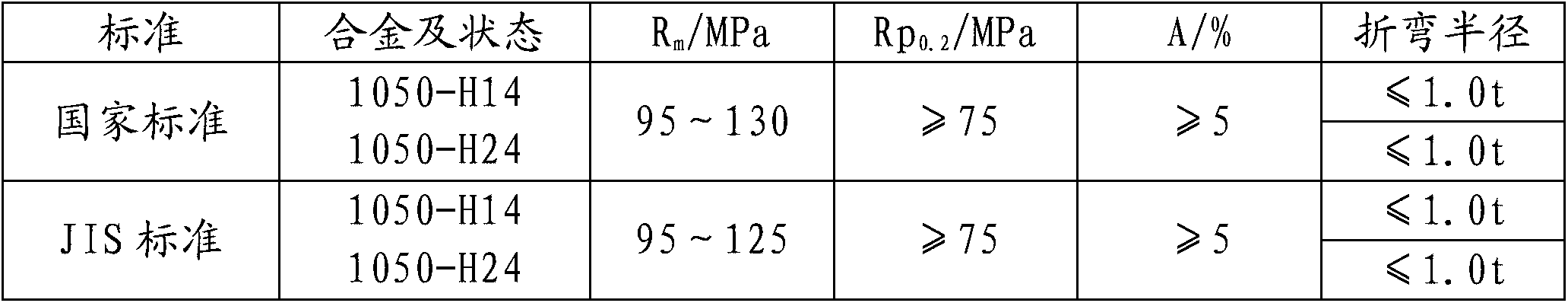

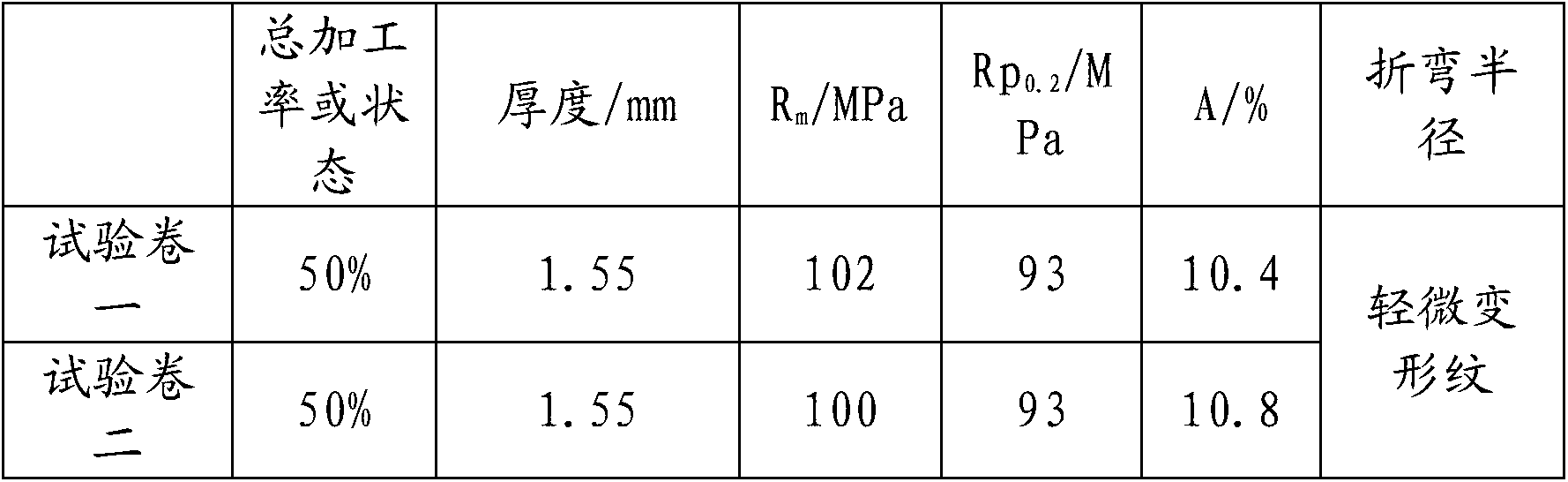

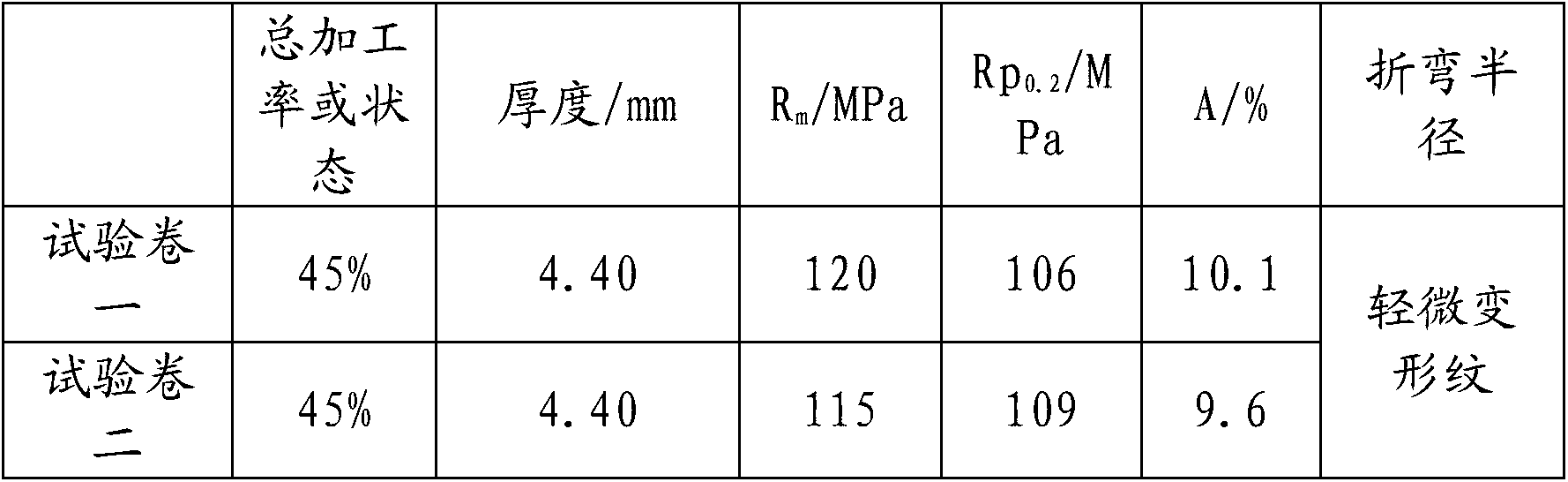

The invention discloses a 1050-H16 aluminum alloy plate strip and a production method thereof. The production method comprises the following production processes of: fusion casting, saw cutting, plane milling, heating, hot rolling and cold rolling, wherein in the fusion casting process, an ingot casting subjected to fusion casting comprises the following chemical components in percentage by mass: not more than 0. 2 percent of Si, 0.20-0.40 percent of Fe, not more than 0.05 percent of Cu, not more than 0.05 percent of Mn, not more than 0.05 percent of Mg, not more than 0.05 percent of Zn, 0.01-0.03 percent of Ti, not more than 0.02 percent of each of other impurities, and the balance of Al, wherein the other impurities are not more than 0.10 percent in total; blooming forging is carried out at 450-500 DEG C through hot rough rolling, wherein the stock thickness is 30-60mm, and the intermediate slab temperature is 400-460 DEG C; and in the hot rolling process, the finish rolling temperature is 300-320 DEG C, and the reeling thickness is 2.5-8mm. The production method disclosed by the invention ensures that the mechanical property of the 1050-H16 aluminum alloy plate strip is stable and qualified and has the advantages of shortening the production flow and improving the production efficiency.

Owner:ALUHOUSE TECHGD CO LTD

Cutting method for digital controlled flame cutter

InactiveCN1928756AImprove appearance qualityIncrease profitTotal factory controlGas flame welding apparatusFlameoutEngineering

The disclosed cutting method with digital-control flame cutter comprises: a. designing pattern, which includes: according to product detail shape and target plate material, drawing the pattern figure with some closed ring figure element with same shape as the product; b. designing the cutting path and defining cutting processing codes; c. loading codes; d. cutting. During the procedure of startup, warm-up, perforating, cutting and flameout, this invention can process scores even hundreds details for one time.

Owner:陈晓坚

1050-H14 aluminum alloy plate strip and production method thereof

The invention discloses a 1050-H14 aluminum alloy plate strip and a production method thereof. The production method comprises the following production processes of: fusion casting, saw cutting, plane milling, heating, hot rolling and cold rolling, wherein an ingot casting subjected to fusion casting comprises the following chemical components in percentage by mass: not more than 0. 2 percent of Si, 0.15-0.40 percent of Fe, not more than 0.05 percent of Cu, not more than 0.05 percent of Mn, not more than 0.05 percent of Mg, not more than 0.05 percent of Zn, 0.01-0.03 percent of Ti, not more than 0.02 percent of each of other impurities, and the balance of Al, wherein the other impurities are not more than 0.10 percent in total; the melting temperature is 730-750 DEG C, the refining temperature is 720-750 DEG C, the casting temperature is 670-700 DEG C, and the casting speed is 55-65mm / min; and in the hot rolling step, blooming forging is carried out at 450-500 DEG C through hot rough rolling, wherein the finish reeling temperature is 300-320 DEG C, and the rolling thickness is 2.5-8mm. The production method disclosed by the invention ensures that the mechanical property of the 1050-H14 aluminum alloy plate strip is stable and qualified and has the advantages of shortening the production flow and improving the production efficiency.

Owner:ALUHOUSE TECHGD CO LTD

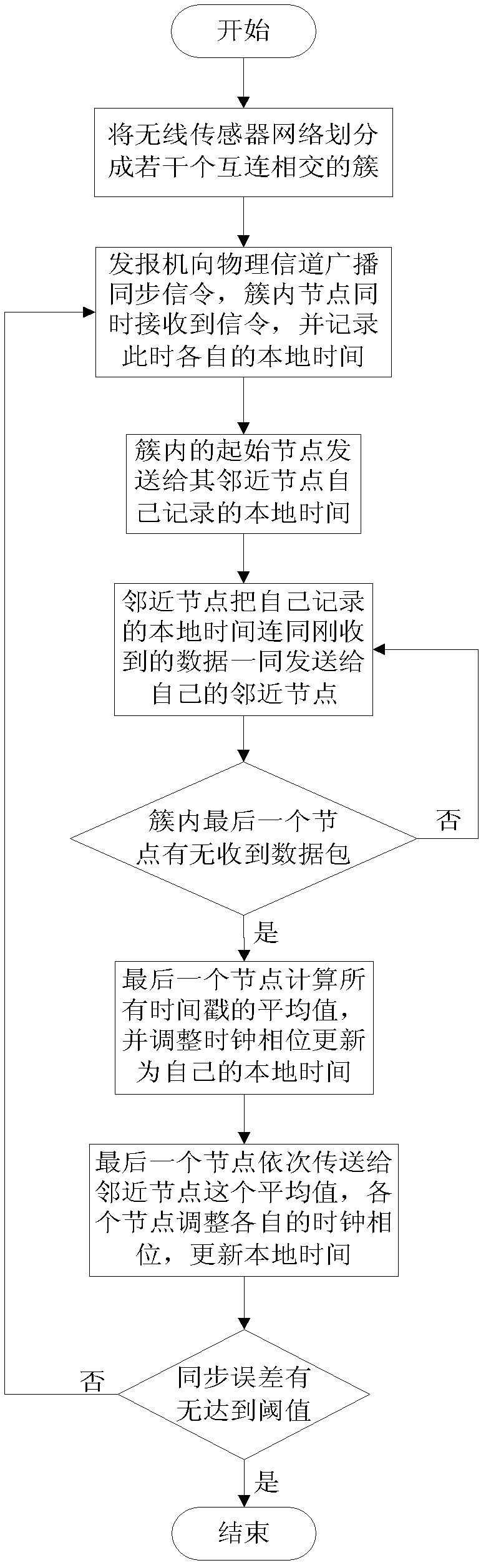

Method for realizing average clock synchronization of wireless sensor network through cluster averaging

InactiveCN102196554AExtend your lifeImprove scalabilityEnergy efficient ICTSynchronisation arrangementWireless sensor networkingComputer science

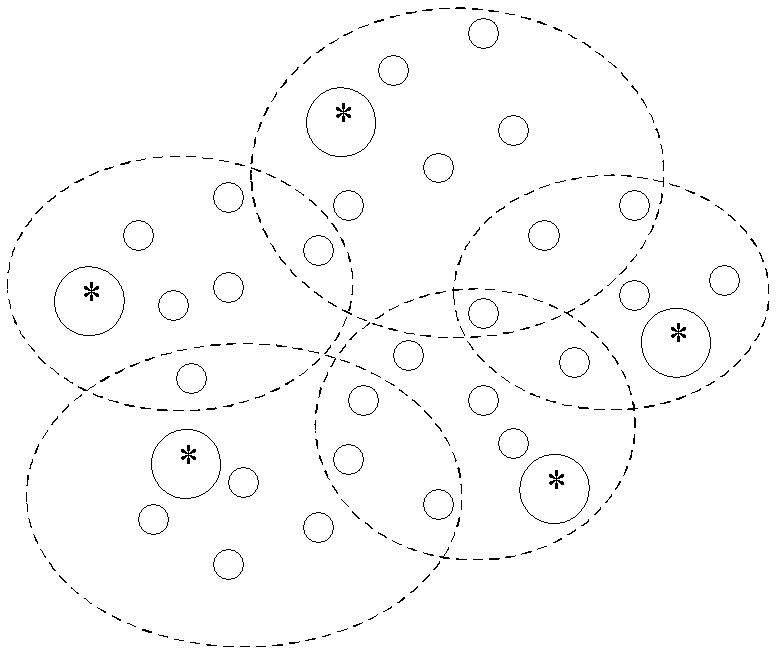

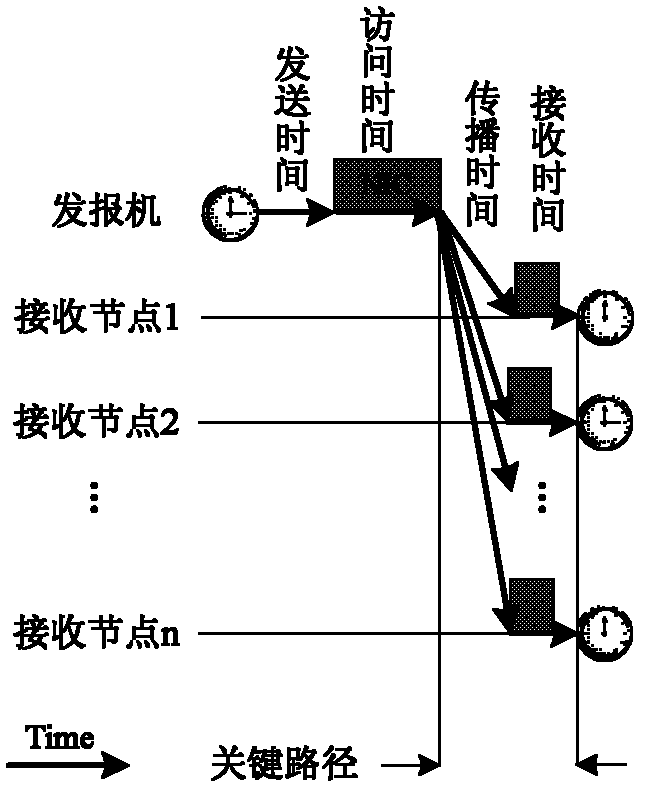

The invention discloses a method for realizing the average clock synchronization of a wireless sensor network through cluster averaging, which comprises the following steps of: (1) dividing the wireless sensor network into a plurality of interlinked intersectant clusters; (2) broadcasting a synchronous signaling to a physical channel at one time by using a transmitter, and respectively recording the local signaling-received time of each inter-cluster node by the inter-cluster nodes; (3) sequentially sending the recorded local times to other nodes by the inter-cluster node until the last node receives the local times, calculating the average value of all the local times, and sequentially sending the average value to other nodes, so that all nodes adjust the phases of the local clocks thereof according to the average value so as to update the local clock of each inter-cluster node to the average value, thereby realizing the local synchronization of the inter-cluster nodes; and (4) repeating the steps (2) and (3) until a synchronization error reaches a threshold, then stopping circulating, thereby realizing the integral clock synchronization of the whole network. By using the method disclosed by the invention, the energy consumption is reduced, and the time synchronization accuracy and the network expandability are improved, therefore, the method can be applied to large-scale network clock synchronization.

Owner:XIDIAN UNIV

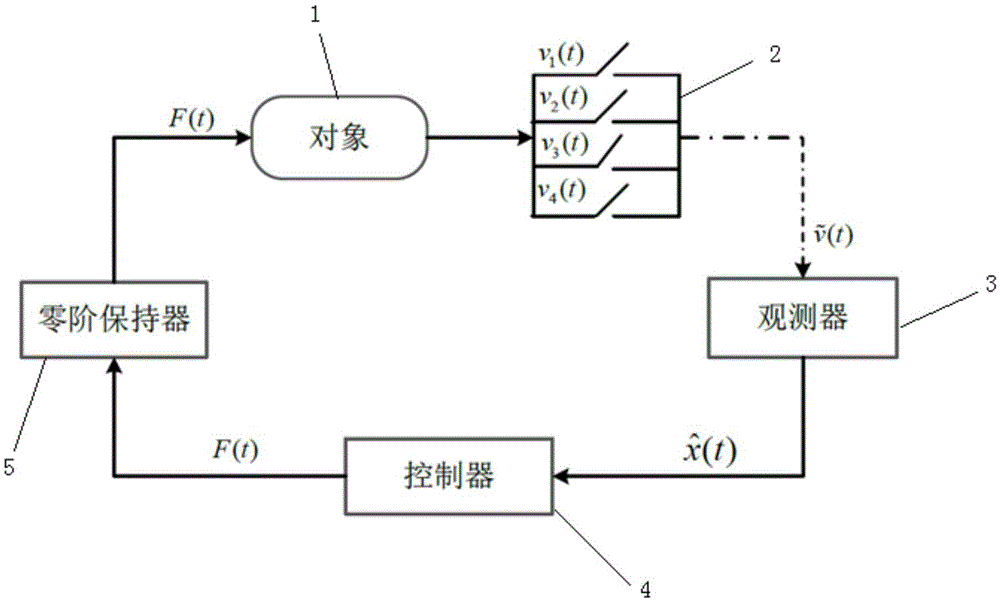

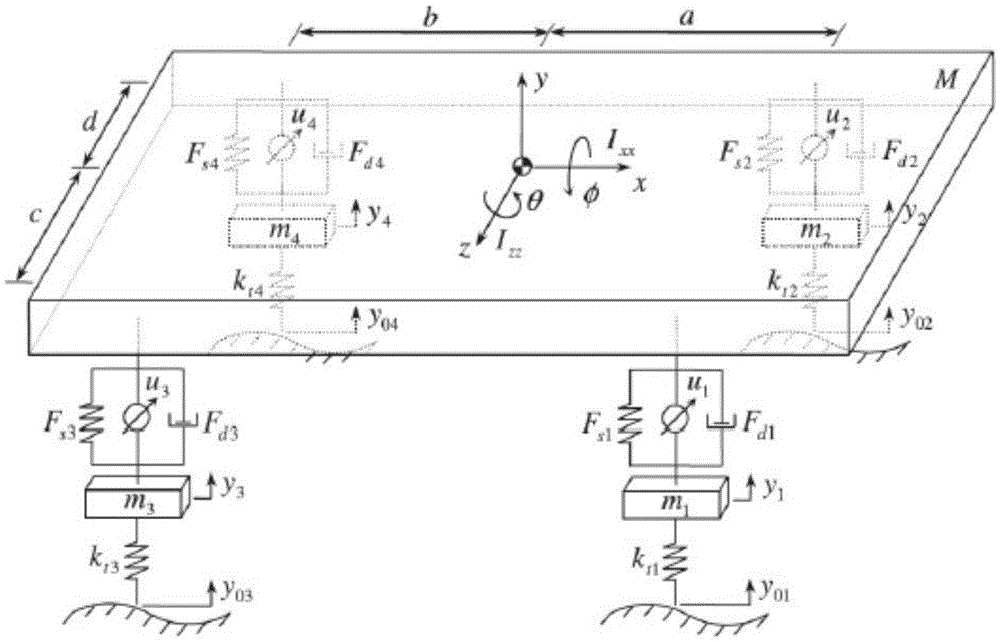

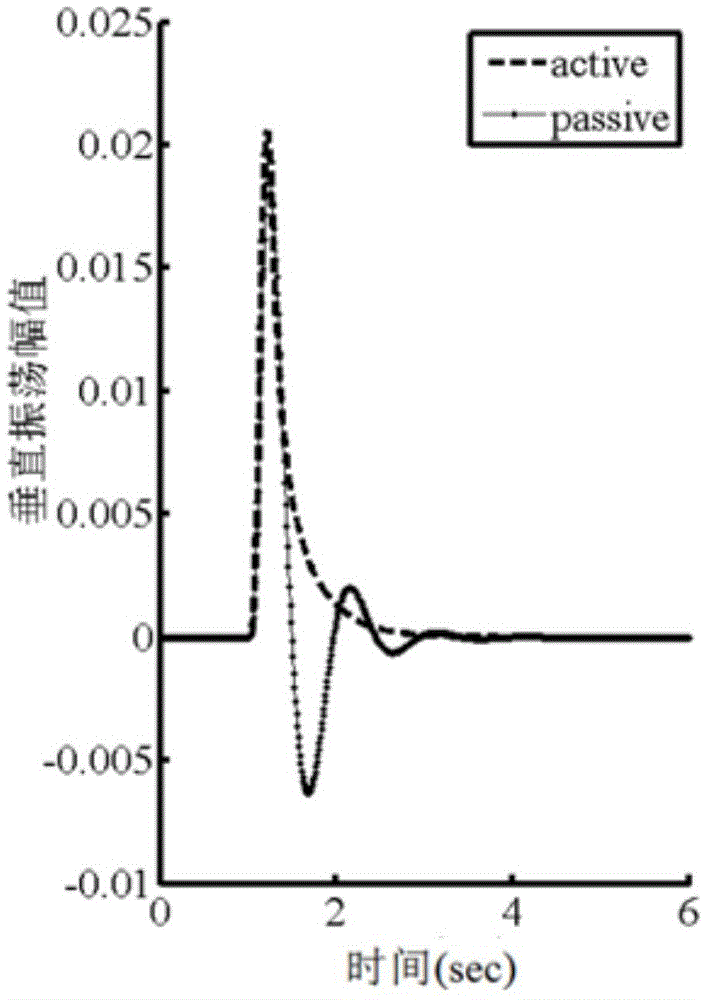

Automobile suspension control system based on event trigger mechanism and design method thereof

InactiveCN105487384ASimple requirementsLoose requirementsAdaptive controlControl systemEvent trigger

The invention relates to an automobile suspension control system based on an event trigger mechanism and a design method thereof. An automobile suspension includes four active suspensions. The control system includes an event trigger device, a state observer, a controller and a zero-order holder, which are connected in order. The output end of the automobile suspension is connected to the event trigger device. The zero-order holder and the input end of the automobile suspension are connected to form a control loop. The event trigger device includes triggers corresponding to the four active suspensions respectively. Each trigger triggers and works according to a set event trigger condition, and transmits output information of one corresponding active suspension to the state observer. The state observer transmits observed state information to the controller. The controller outputs corresponding control force according to the state information observed by the state observer, and then controls the corresponding active suspensions to work. Compared with the prior art, the automobile suspension control system has the advantages that the number of times of data transmission is reduced, resources are saved, the control cost is low, the system is highly practical and highly safe, etc.

Owner:TONGJI UNIV

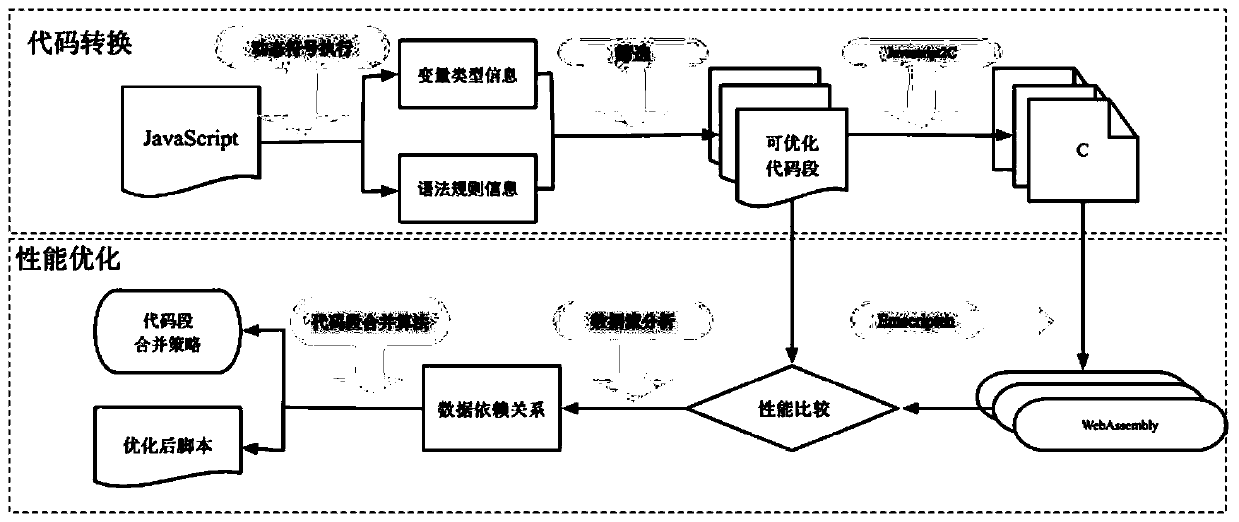

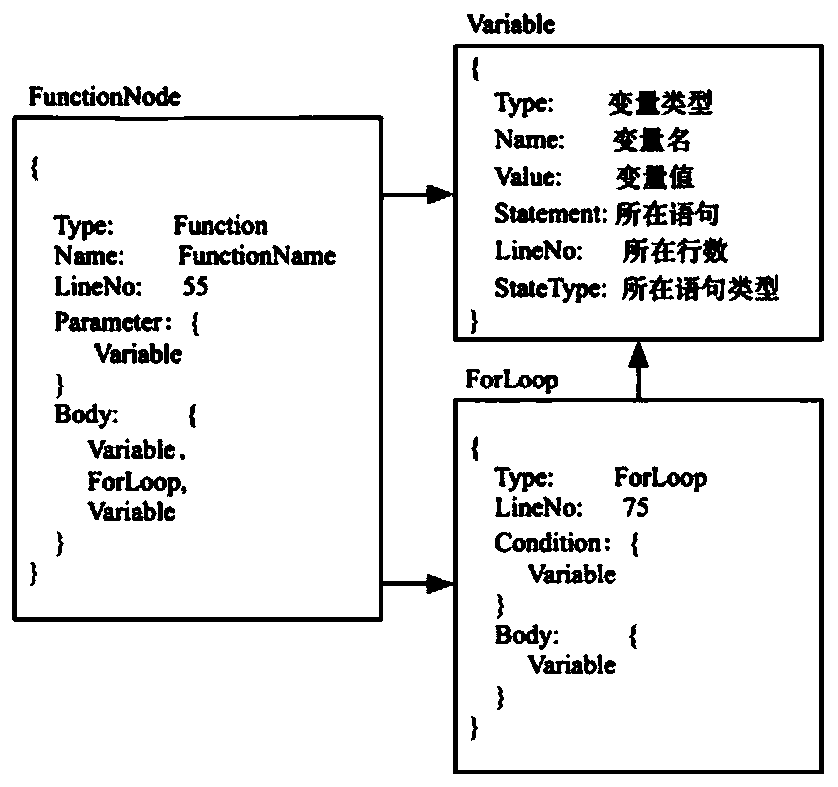

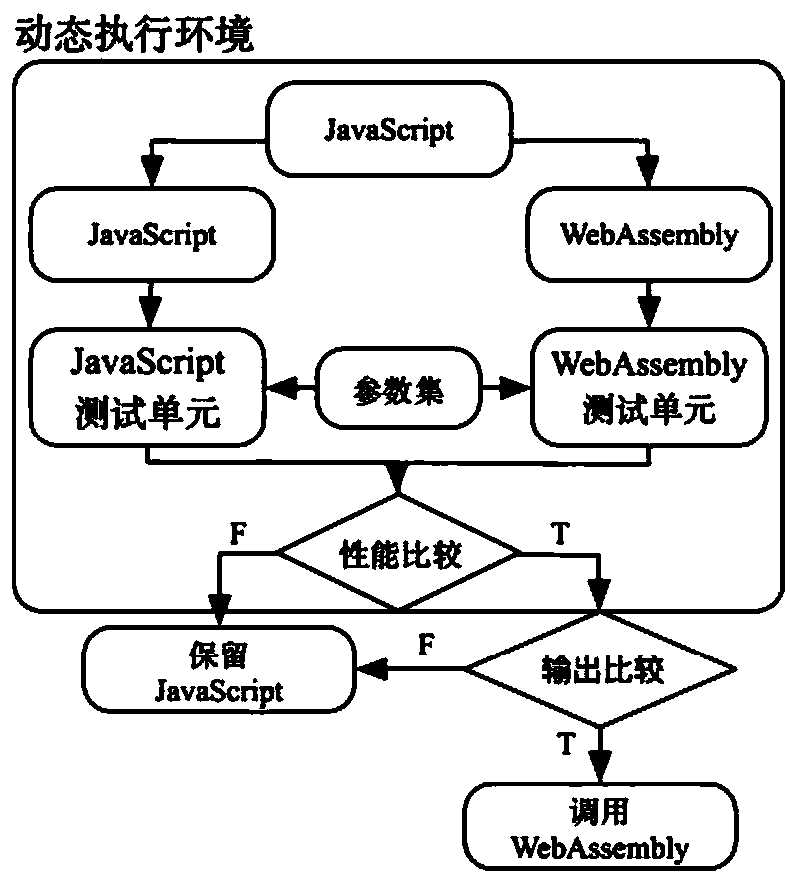

JavaScript code optimization method based on front-end byte code technology

ActiveCN110399133AReduce the number of passesReduce the number of callsCode compilationUnit testingData dependence

The invention discloses a JavaScript code optimization method based on a front-end byte code technology. According to the method, a conversion tool chain from JavaScript to WebAssembly is provided, acode segment merging strategy is designed, and then a JavaScript performance optimization scheme is provided; and variable type information of each execution path of the program is obtained through dynamic symbolic execution, and a code statement according with a conversion condition is obtained through a screening rule, a C code is generated from a JavaScript code by designing a JavaScript 2C conversion rule, and a WebAssembly code segment is generated through Exscript compiling. And finally, the performance and function consistency before and after optimization are compared through a unit test idea, and the optimization of the code segment is given up if the performance is reduced or the functions are inconsistent. On the other hand, a code segment merging strategy is designed, on the basis of the data dependence relation between the code segments, the code segment merging strategy is provided as the basis of user code reconstruction, the purpose of reducing data interaction performance losses is achieved, and the execution efficiency of the program is further improved.

Owner:NORTHWEST UNIV(CN)

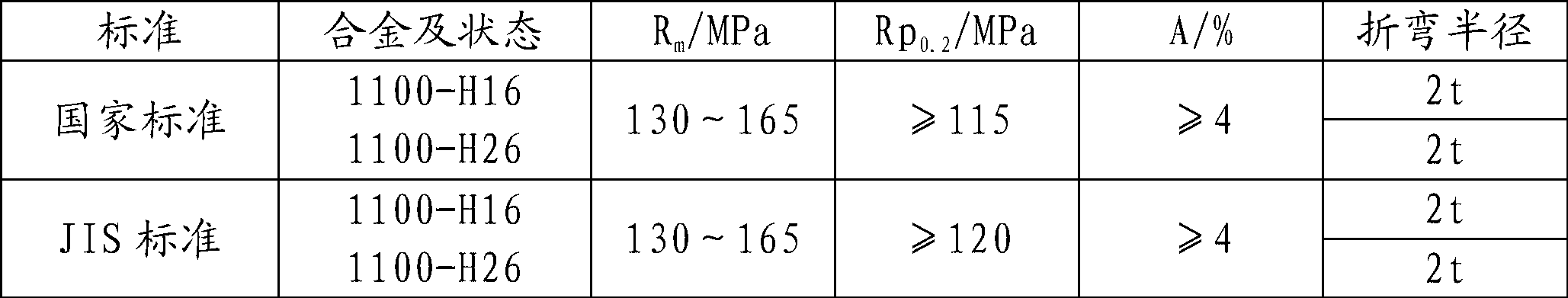

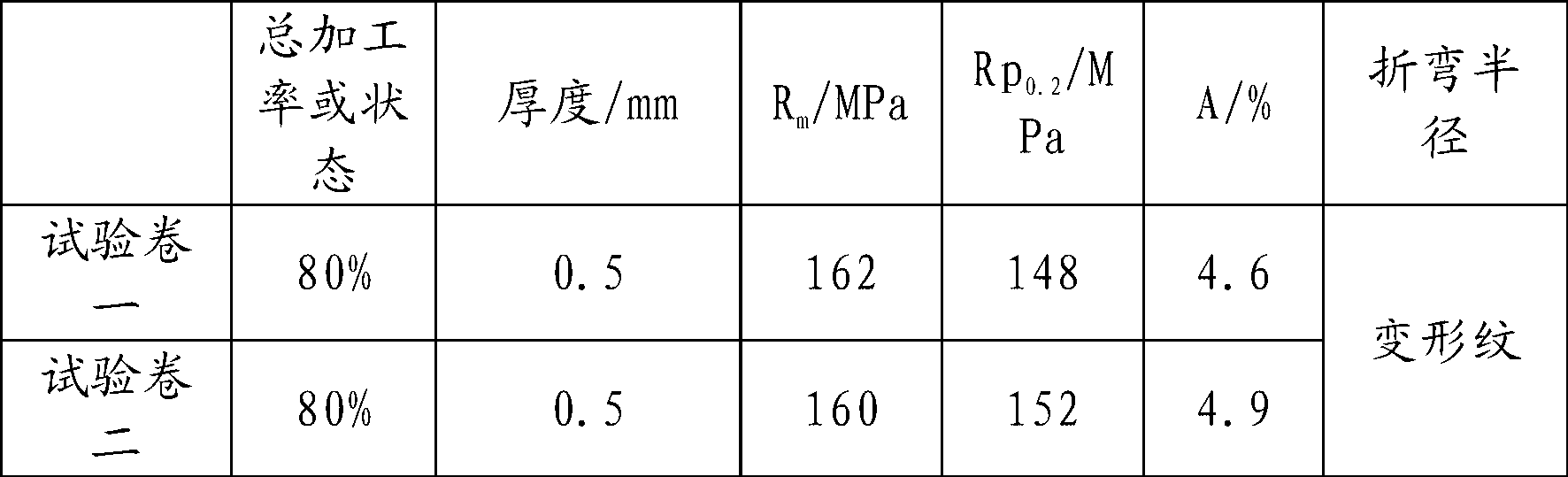

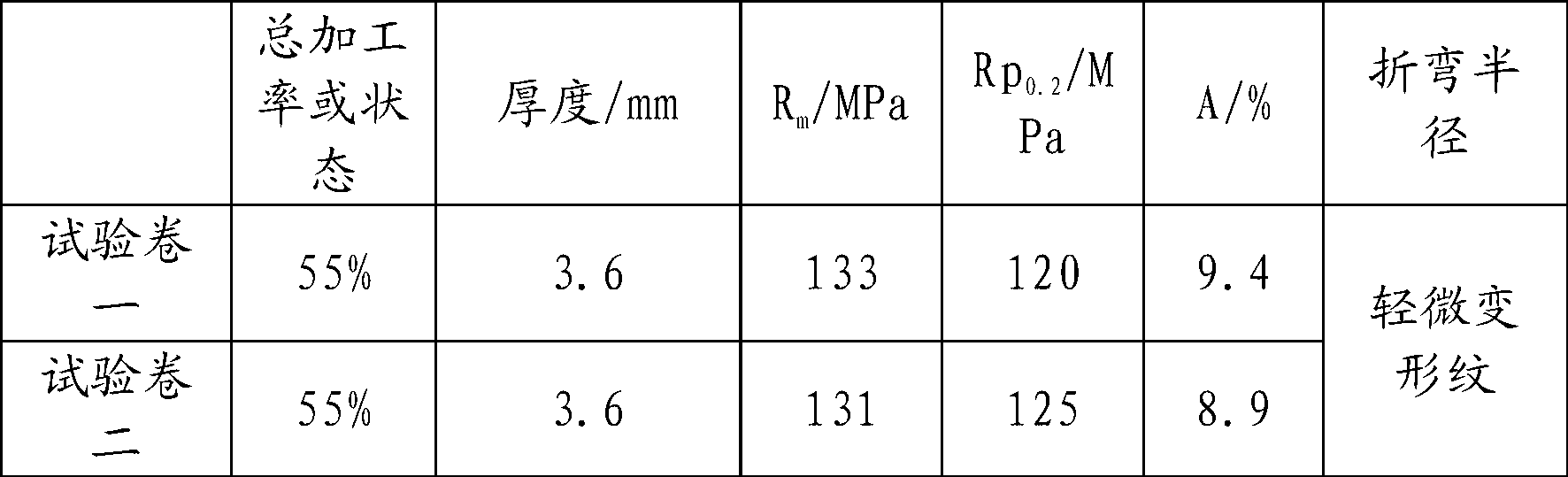

1100-H16 aluminum alloy plate/strip and production method thereof

ActiveCN103060621AEliminate unevennessEliminate coarse grainsMetal rolling arrangementsChemical compositionIngot

The invention discloses a 1100-H16 aluminum alloy plate / strip and a production method thereof. The production method comprises the following steps of casting, sawing, surface milling, heating, hot rolling and cold rolling. A cast ingot obtained by casting comprises, by mass, less than or equal to 0.20% of Si, 0.30 to 0.60% of Fe, 0.05 to 0.20% of Cu, less than or equal to 0.05% of Mn, less than or equal to 0.05% of Mg, less than or equal to 0.05% of Zn, 0.01 to 0.03% of Ti, less than or equal to 0.10% of total impurities and the balance Al, wherein and the content of a single impurity is less than or equal to 0.02% by mass. A melting temperature is in a range of 740 to 760 DEG C, a refining temperature is in a range of 735 to 755 DEG C, a casting temperature is in a range of 685 to 705 DEG C, and a casting rate is in a range of 55 to 65mm / min. The hot rolling process comprises that a hot rough rolling cogging-down process is carried out at a temperature of 450 to 500 DEG C; a finish rolling temperature is in a range of 310 to 330 DEG C; and coiling thickness is in a range of 2.5 to 8mm. The production method guarantees table and qualified mechanical properties of the 1100-H16 aluminum alloy plate / strip, shortens a production flow and improves production efficiency.

Owner:ALUHOUSE TECHGD CO LTD

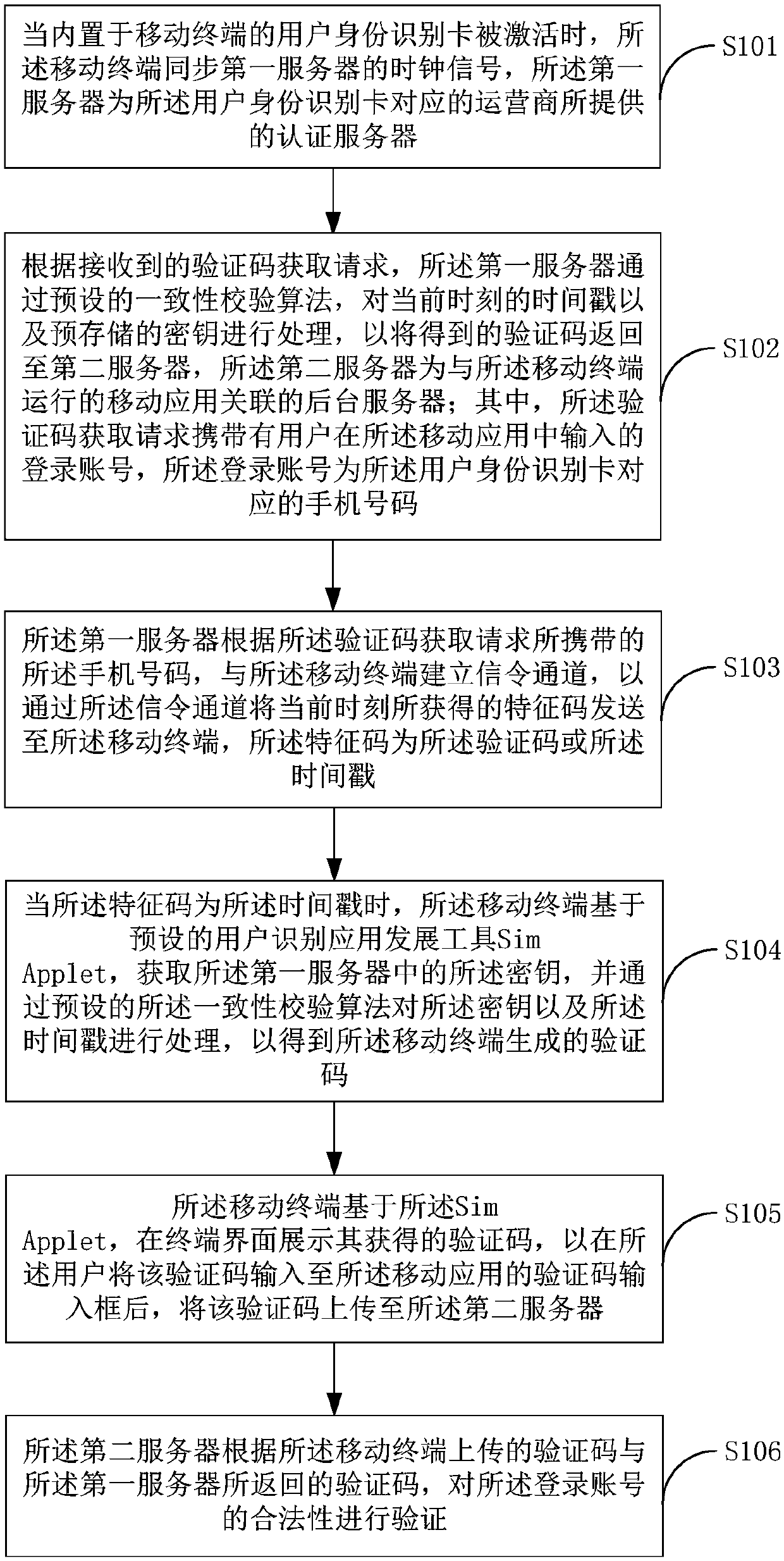

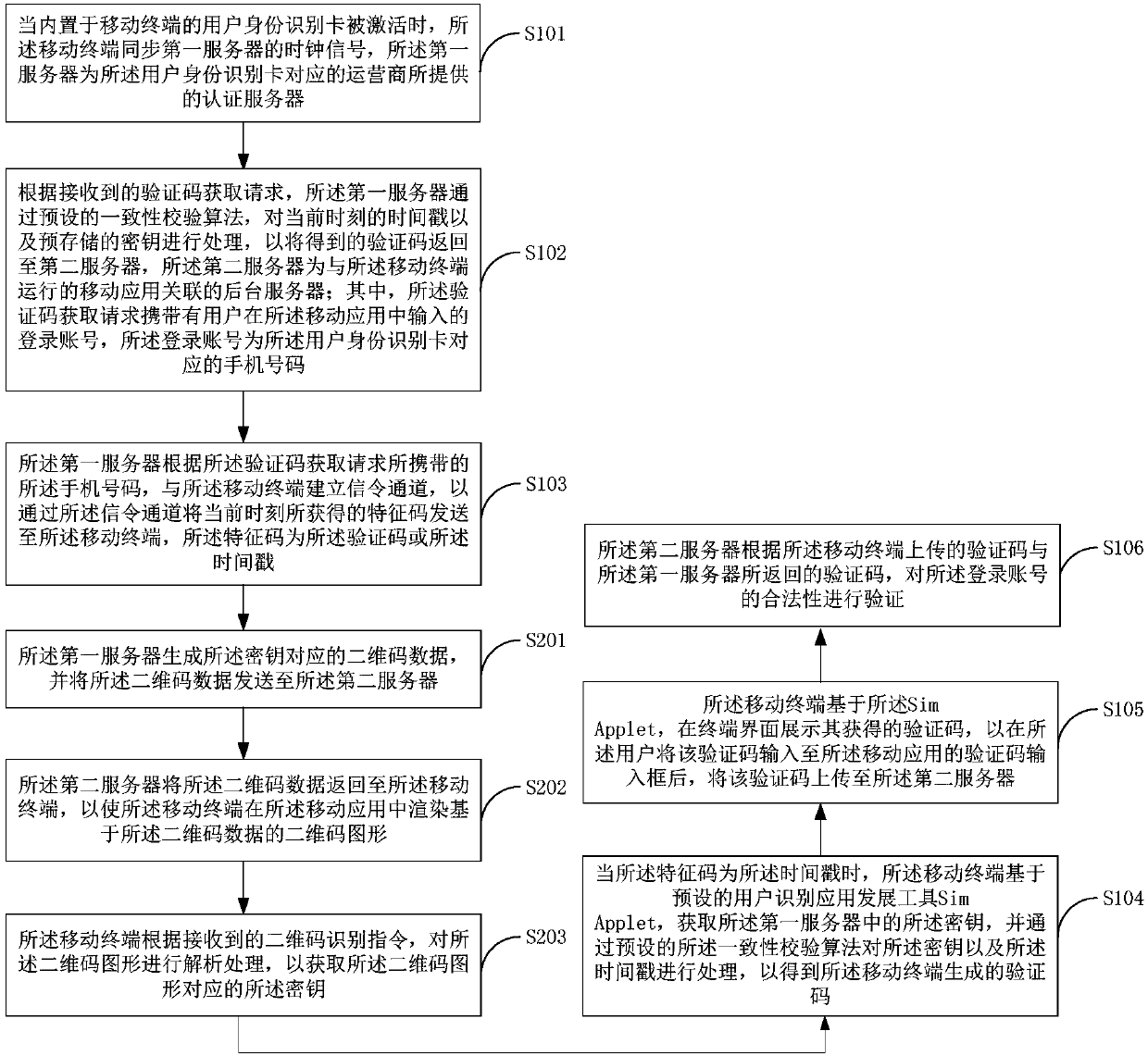

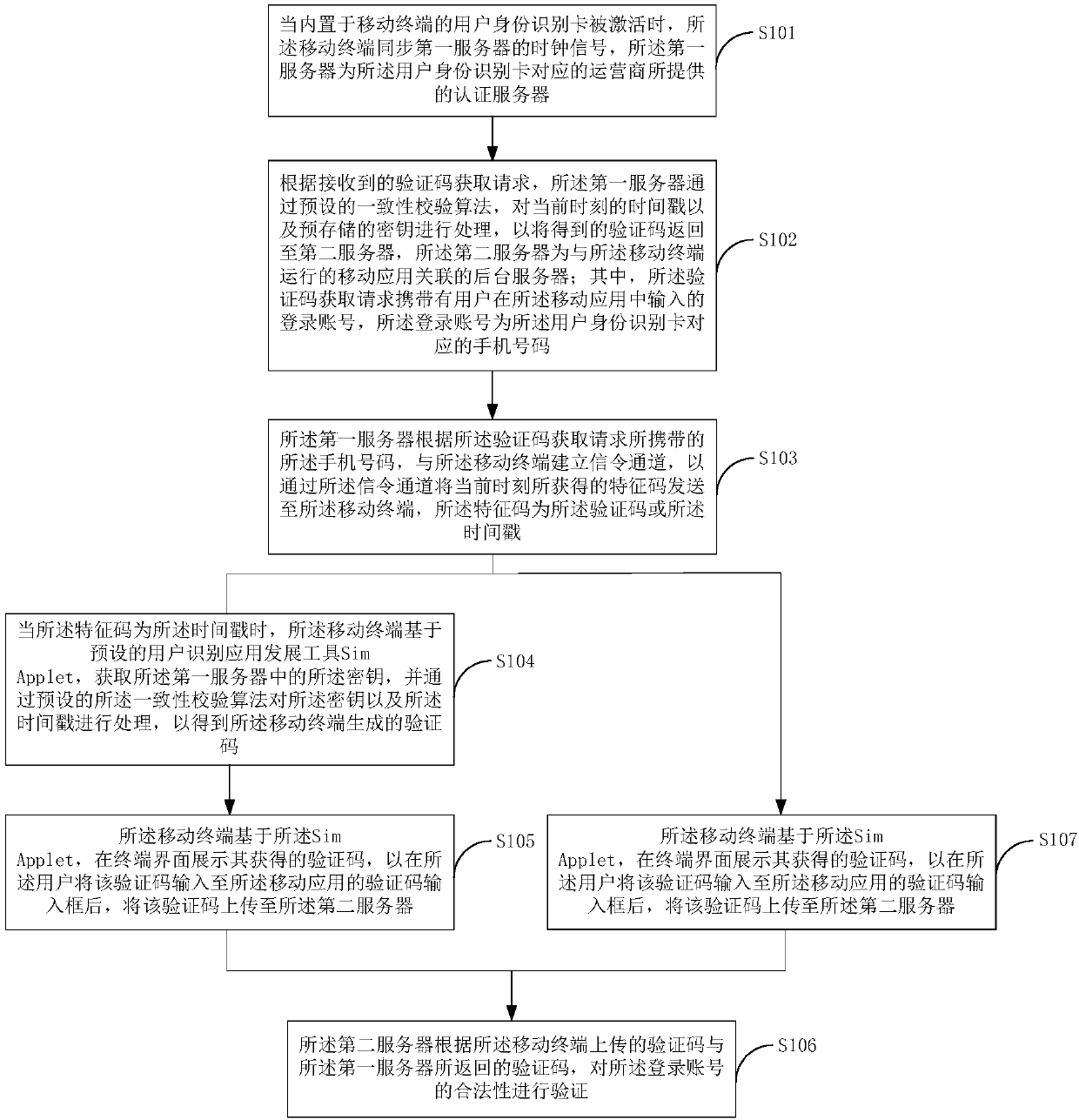

Account verification method and system

ActiveCN108055238AEnsure normal loginSuccessfully confirmed normal loginTransmissionMobile Telephone NumberTimestamp

The invention is applied to the technical field of the Internet, and provides an account verification method and system. The method comprises the steps that according to a received verification code acquisition request, a first server returns a generated verification code to a second server; the first server sends a timestamp of the current moment to a mobile terminal; the mobile terminal acquiresa key in the first server on the basis of a Sim Applet and processes the key and the timestamp through a consistency verification algorithm to obtain a verification code generated by the mobile terminal; the mobile terminal displays the obtained verification code on the basis of the Sim Applet to upload the verification code to the second server after a user inputs the verification code to a verification code input box; and the second server verifies the legitimacy of a login account according to the verification code uploaded by the mobile terminal and the verification code returned by the first server. According to the account verification method and system, an illegal user cannot remotely control a smart phone to automatically login a mobile application through a mobile phone number mode, and therefore the security of account verification based on the mobile phone verification code is improved.

Owner:PINGAN PUHUI ENTERPRISE MANAGEMENT CO LTD

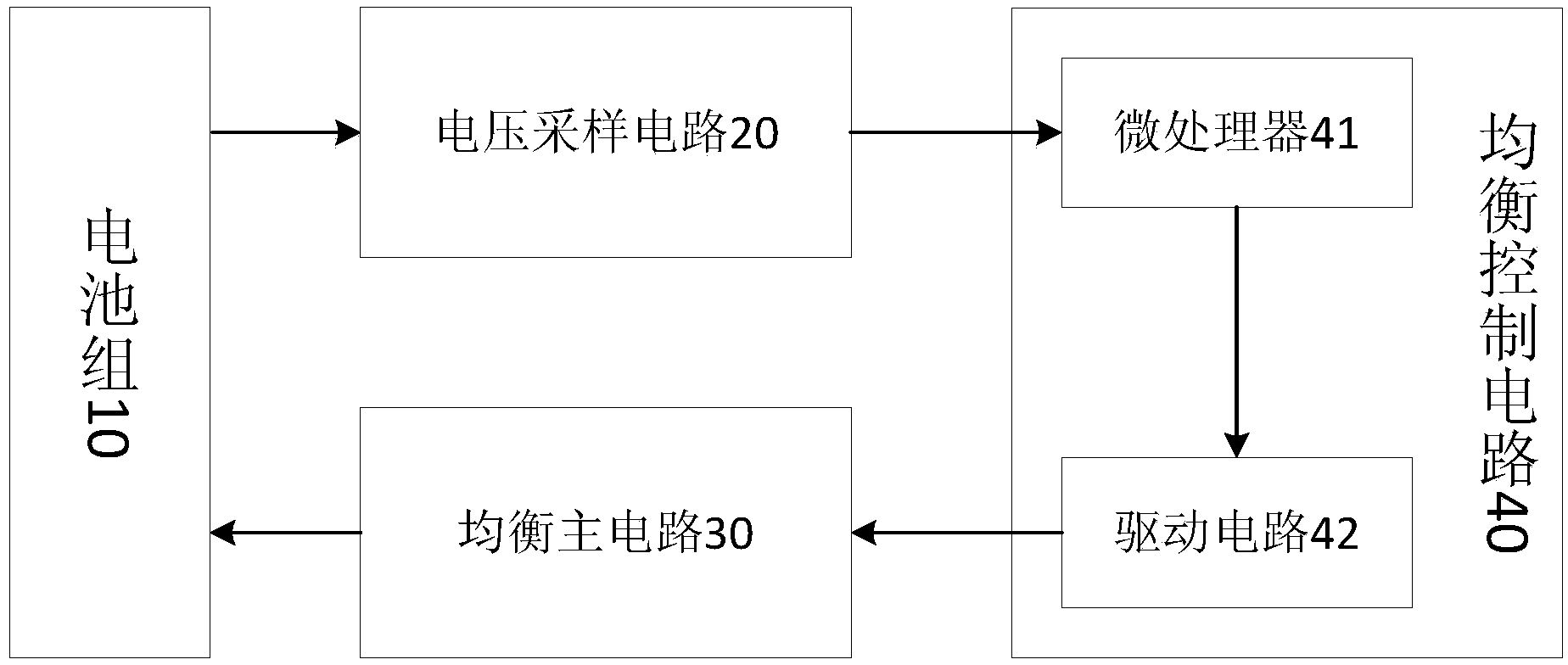

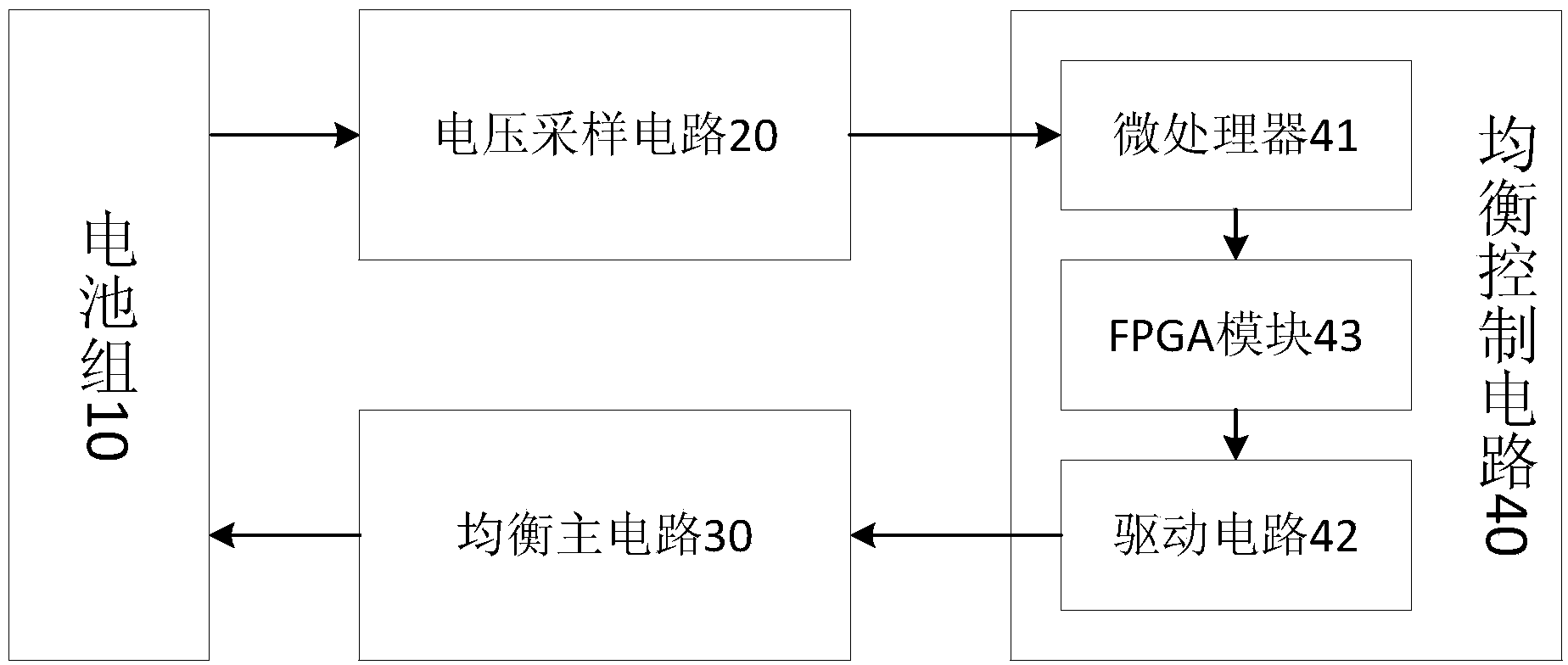

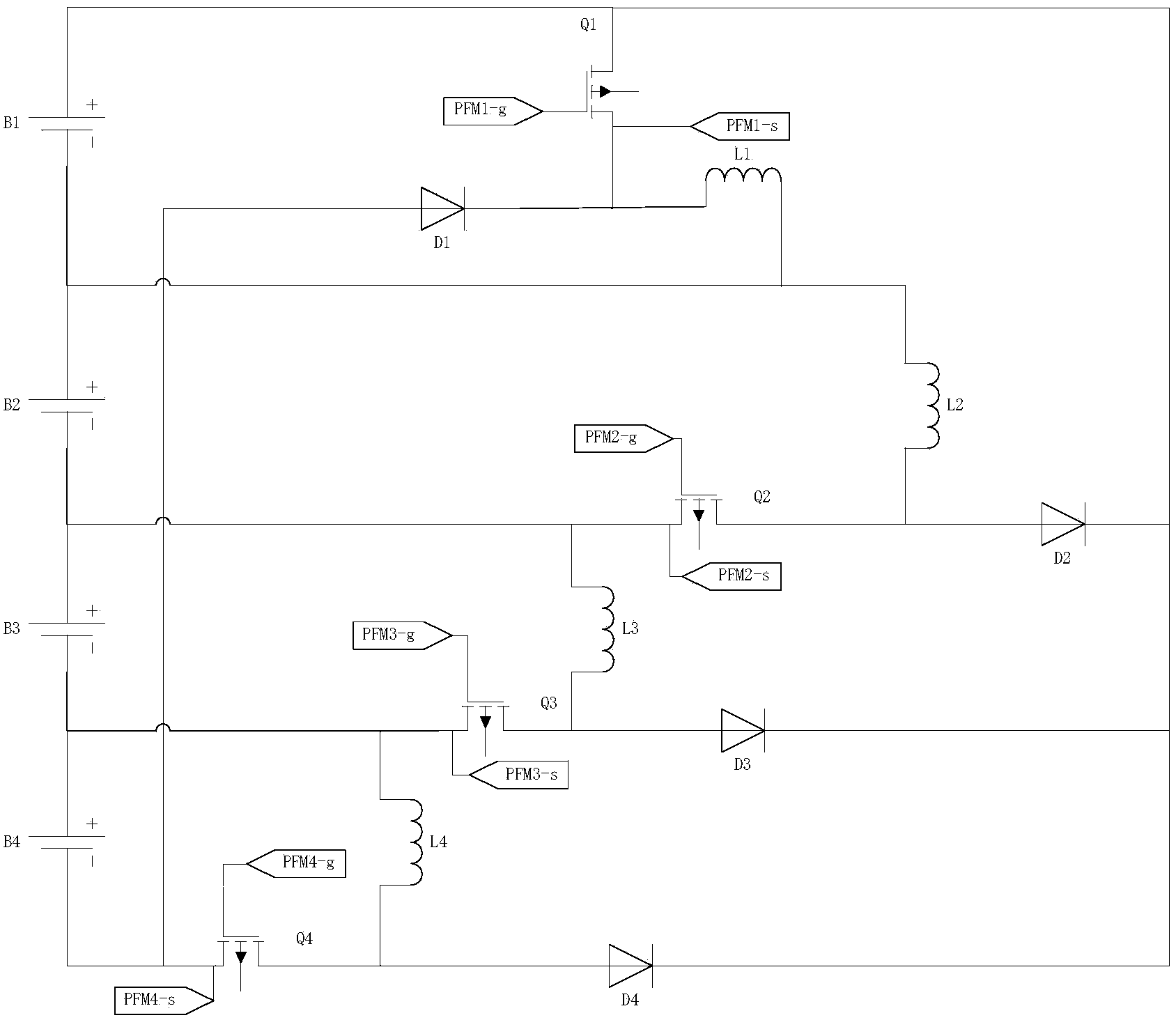

Battery pack balancing control system and control method on basis of dynamic balance point

ActiveCN103532189AExtended service lifeReduce the number of passesBatteries circuit arrangementsElectric powerElectrical batteryControl system

The invention discloses a battery pack balancing control system and a control method on the basis of a dynamic balance point. The system comprises a battery pack, a voltage sampling circuit, a balancing main circuit and a balancing control circuit. The balancing control circuit is used for comparing a voltage value of each single battery and respectively regulating frequencies of power switch tubes corresponding to the single batteries and controlling the frequencies of the power switch tubes to track a balance frequency of the battery pack in a dynamic balance state when a voltage difference of different single batteries exceeds a preset threshold value, wherein the dynamic balance state is a state when energy released by each battery of the battery pack and energy adsorbed by the battery in each switching period are equal; and the balance frequency is the frequency of each power switch tube in the dynamic balance state. According to the invention, all the single batteries in the battery pack can almost simultaneously reach balance, the balancing speed and efficiency are improved, overcharge and over-discharge damage caused by inconsistency of the single batteries is prevented, and service life of the battery pack is prolonged.

Owner:WUHAN UNIV OF TECH

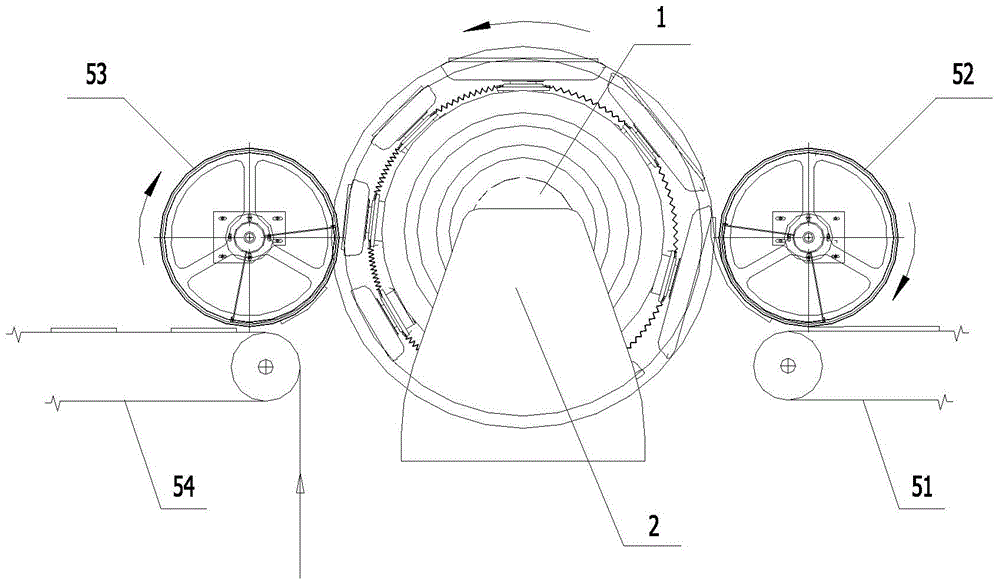

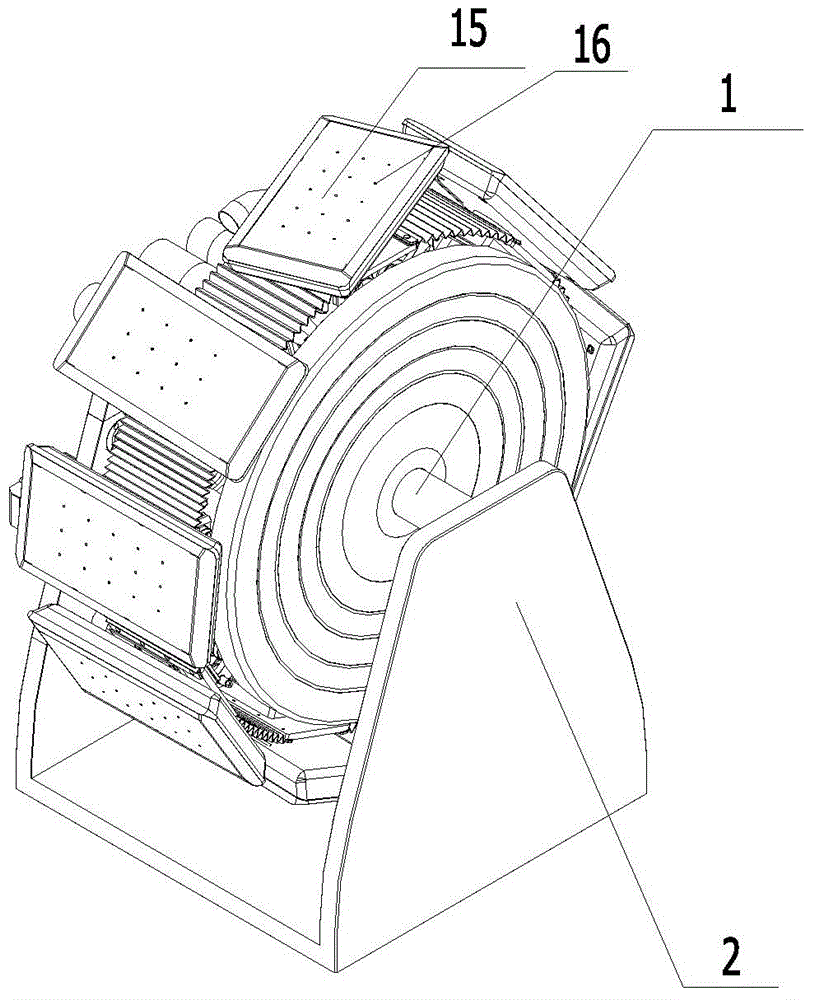

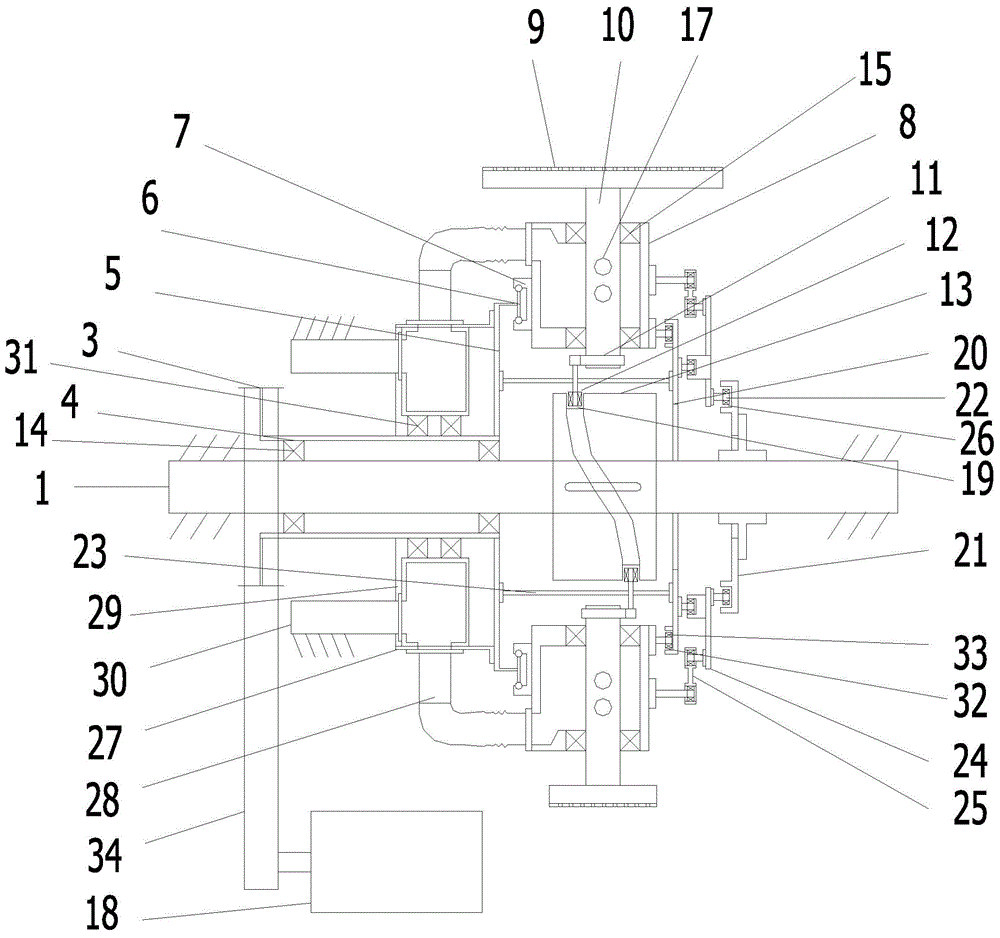

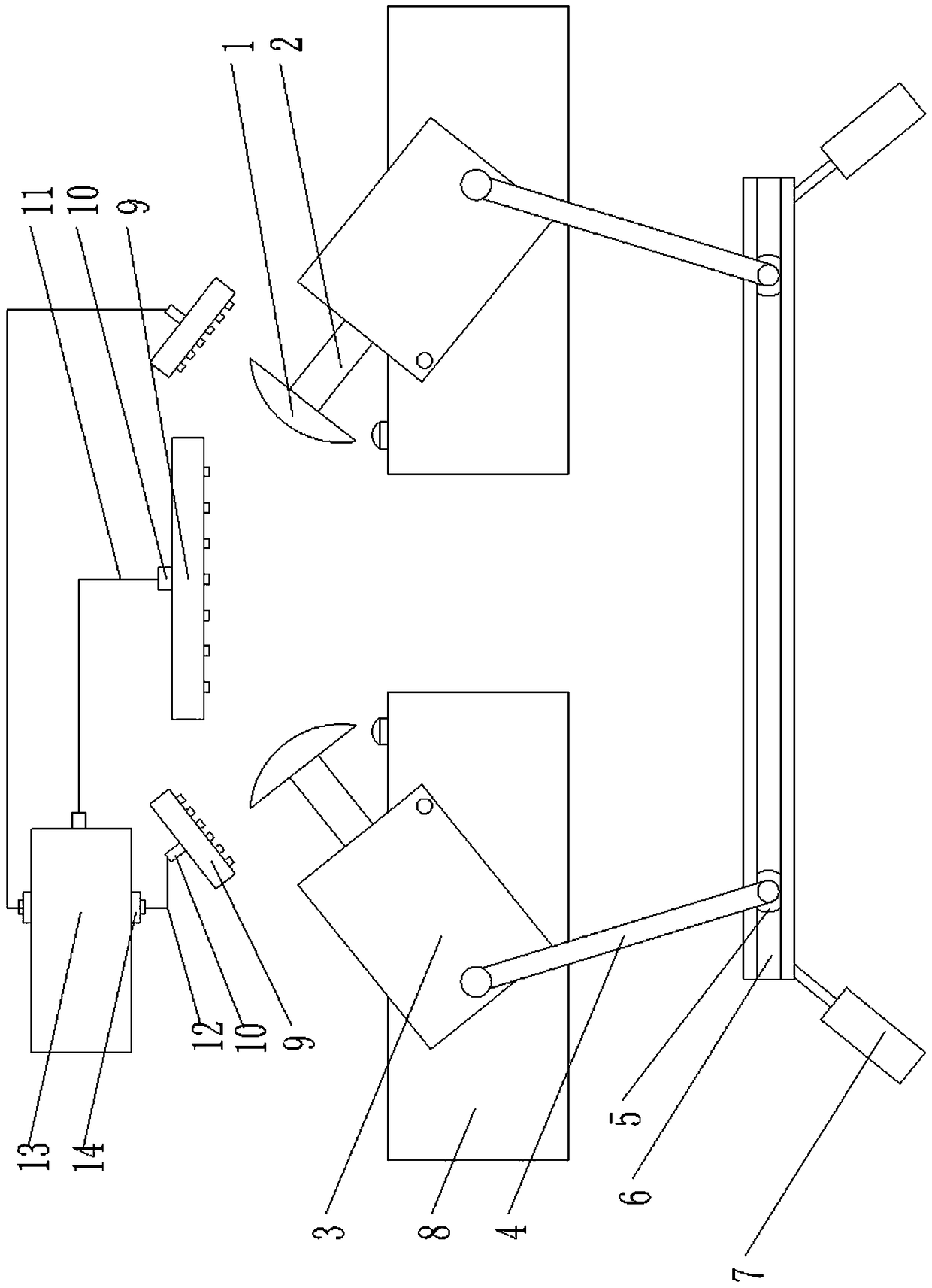

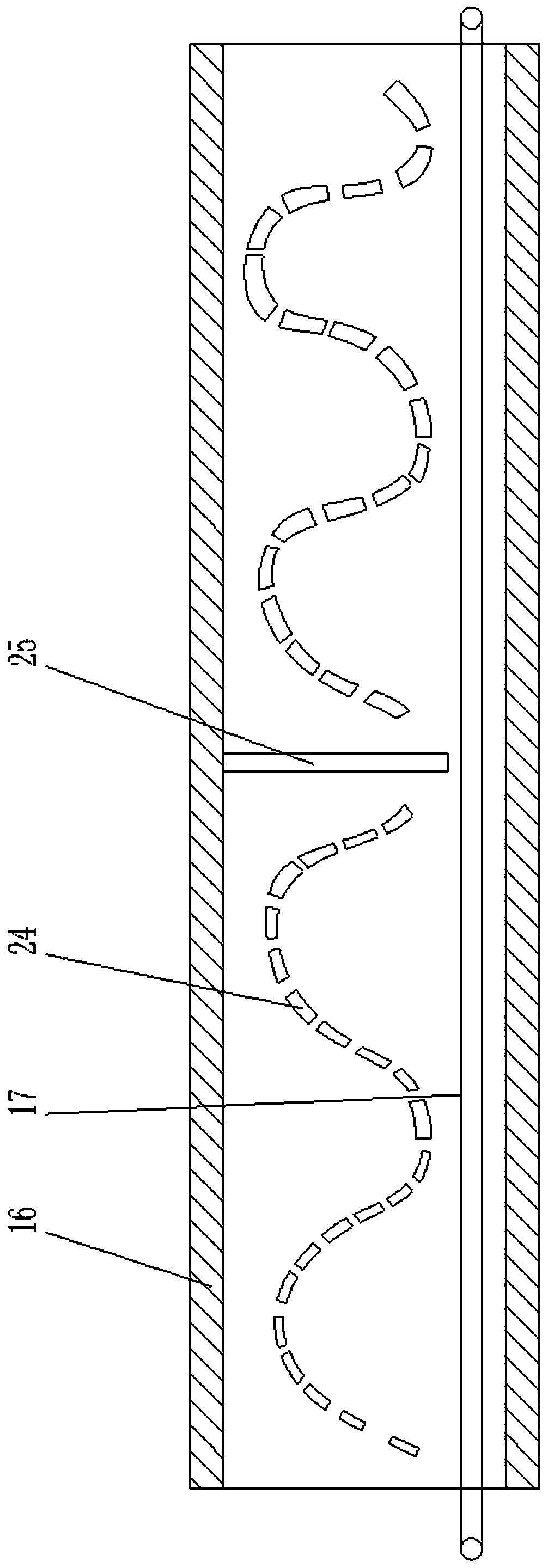

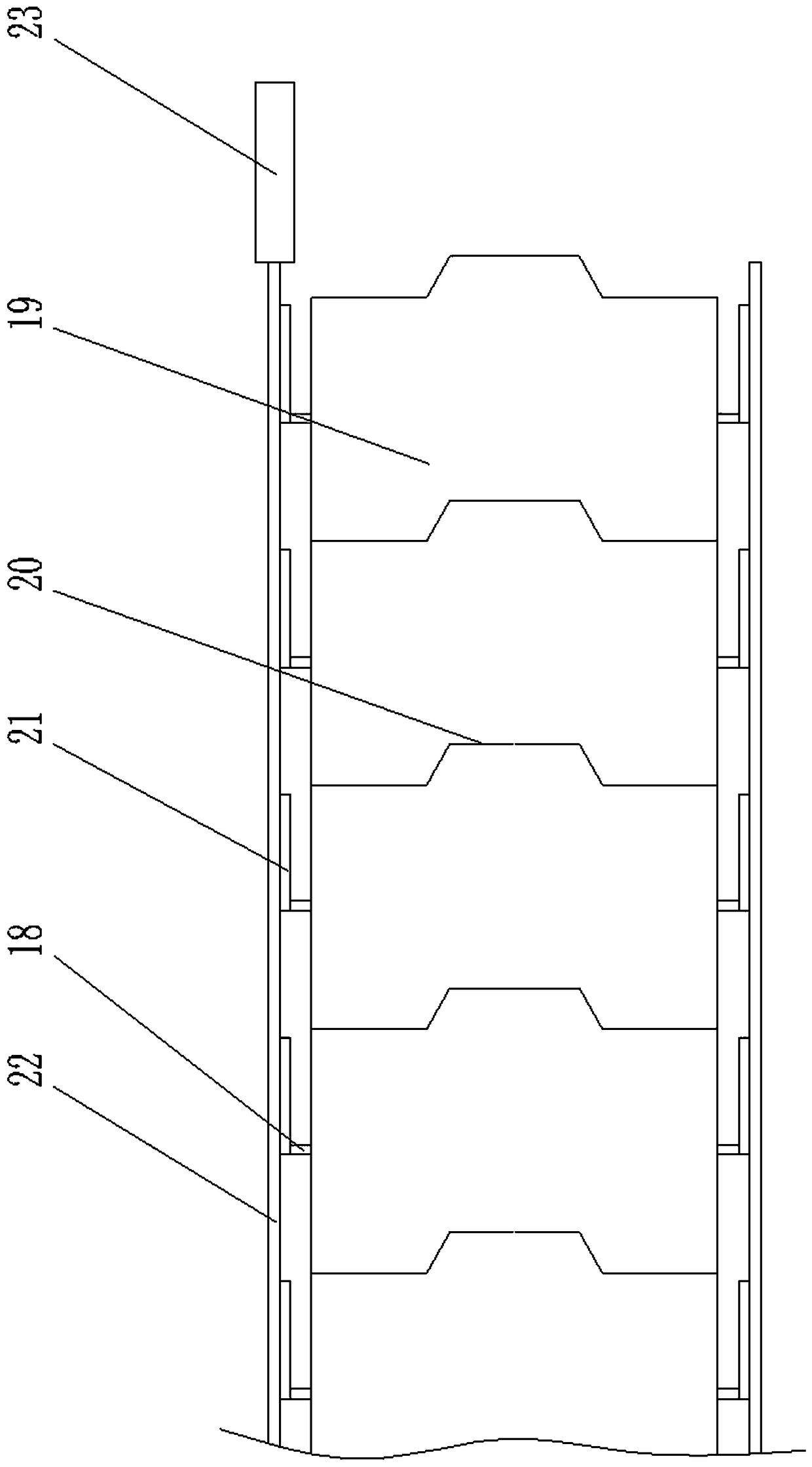

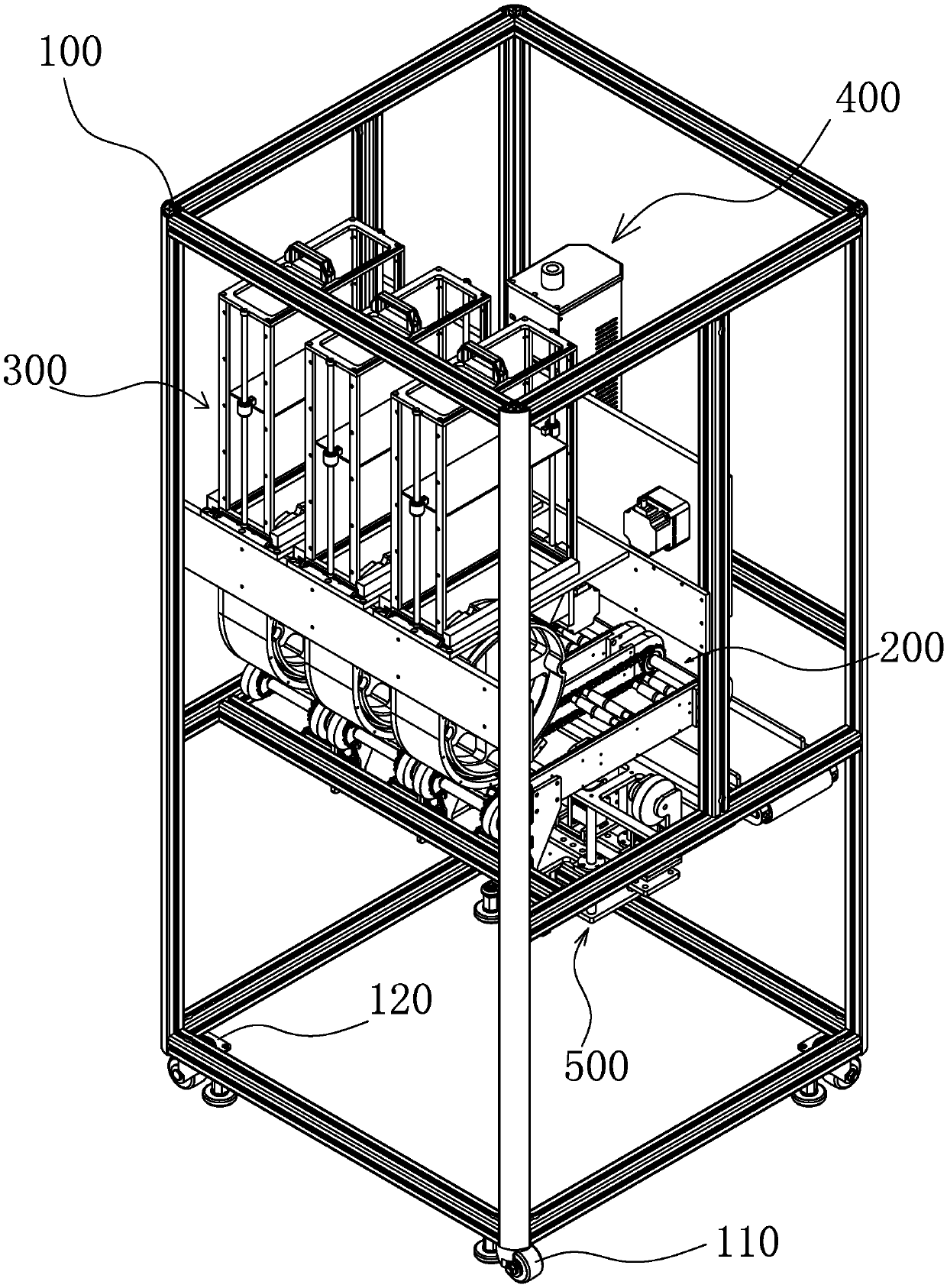

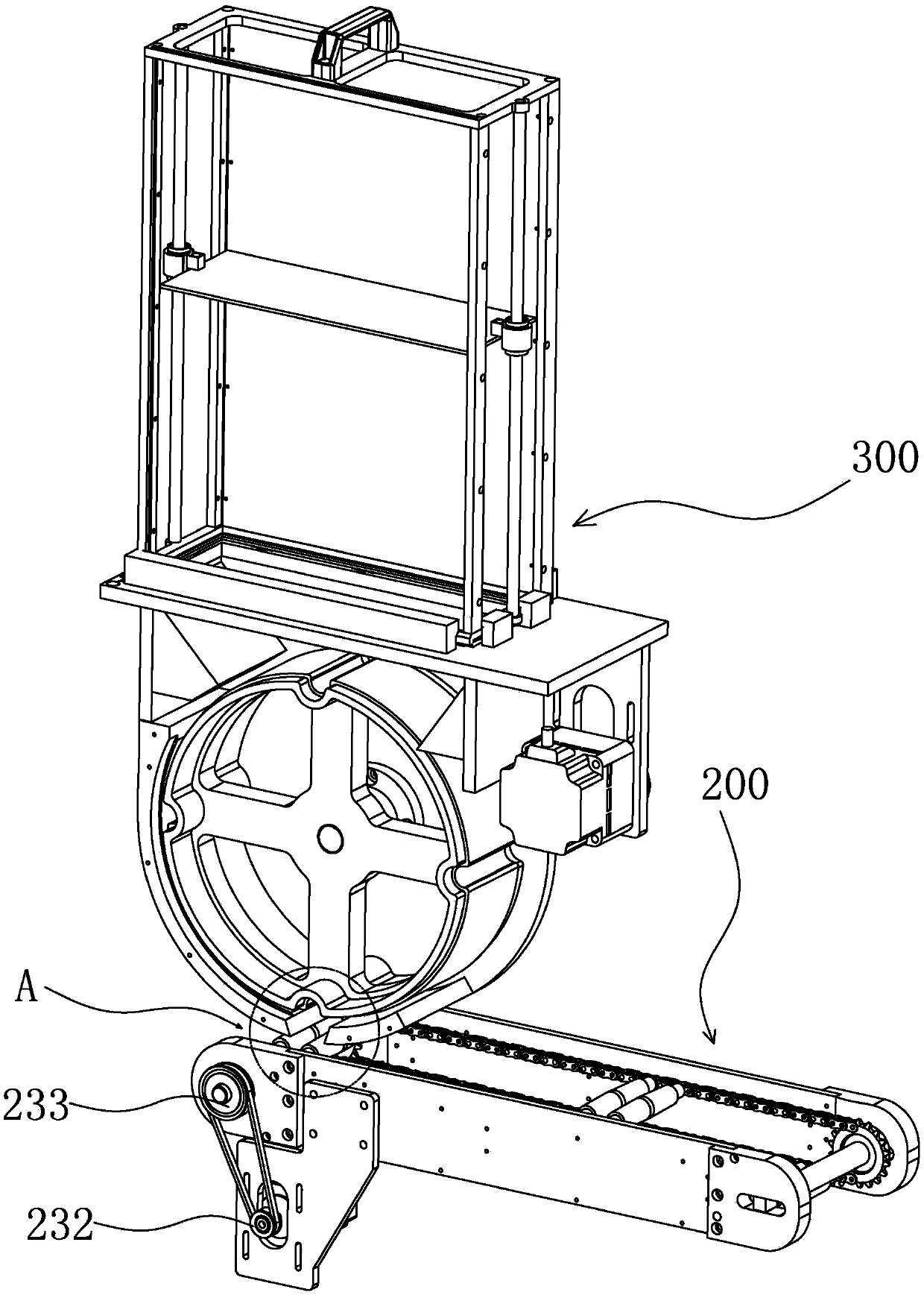

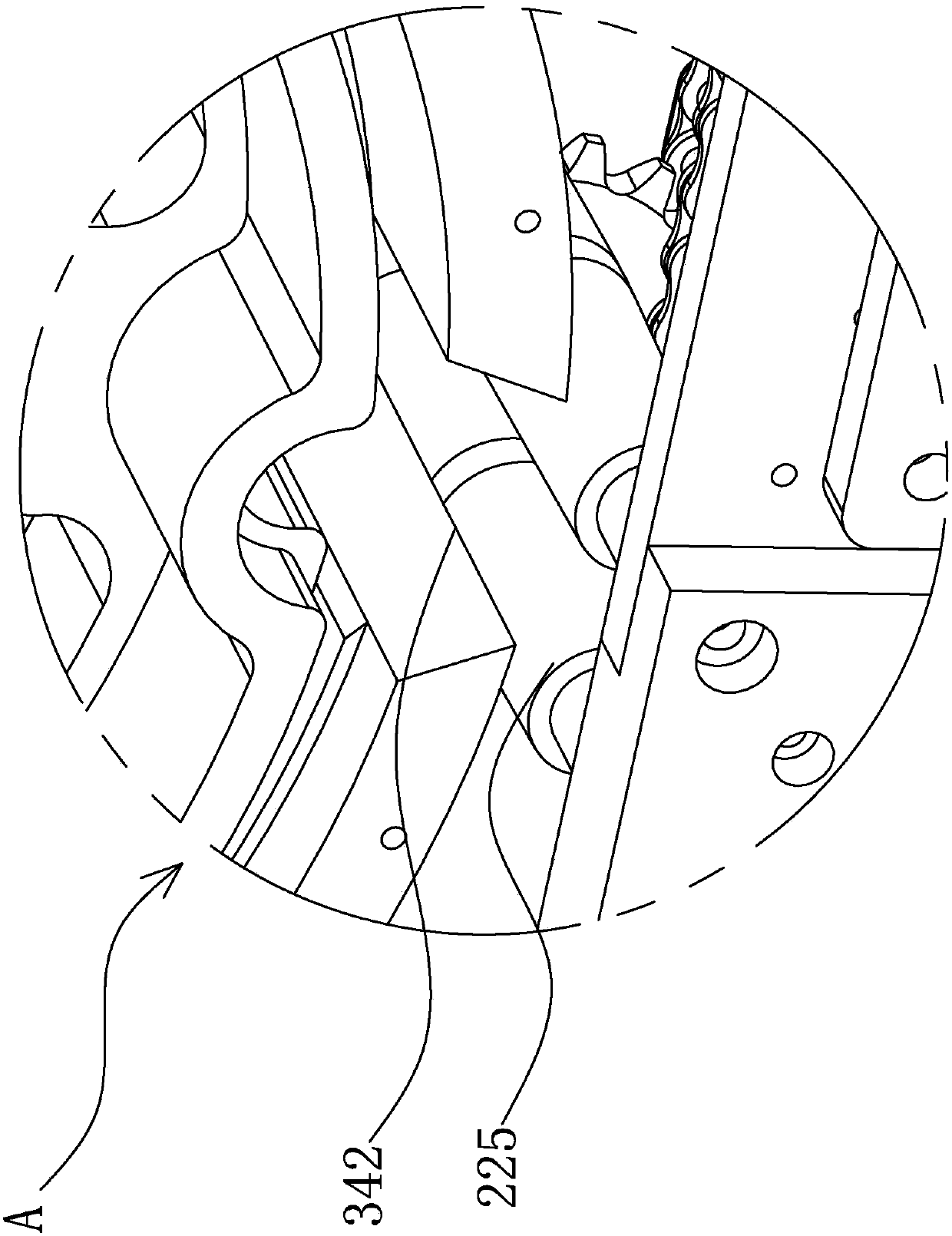

Reversing and pitch control assembly for hygienic products

ActiveCN105213110ATakes up little host spacePowerfulAbsorbent padsBaby linensCamDistribution function

The invention relates to a reversing and pitch control assembly for hygienic products, comprising a reversing mechanism, a pitch control mechanism and a gas distribution mechanism sleeving a spindle in order. The spindle is fixedly connected with a frame. The reversing mechanism comprises a power input wheel, a connecting shaft, a drive disc, an arc guide rail, a slider, a sucker seat, a sucker, a sucker shaft, a rocker, a first guide wheel and a cam disc fixed in the middle of the spindle. The pitch control mechanism comprises a rotating disc, an eccentric disc, a second guide wheel, a support rod, a rocker and a link. The gas distribution mechanism comprises a distribution disc, a distribution port, a negative pressure chamber and an intake port. The reversing, variable speed and gas distribution functions are integrated to a single device, thus the device uses little space of a main unit and has powerful functions and compact structure. By integrating the reversing mechanism and the pitch control mechanism, products are transferred among the suckers of different mechanisms fewer times and have a slimmer chance of deformation.

Owner:ANQING HENG CHANG MACHINERY

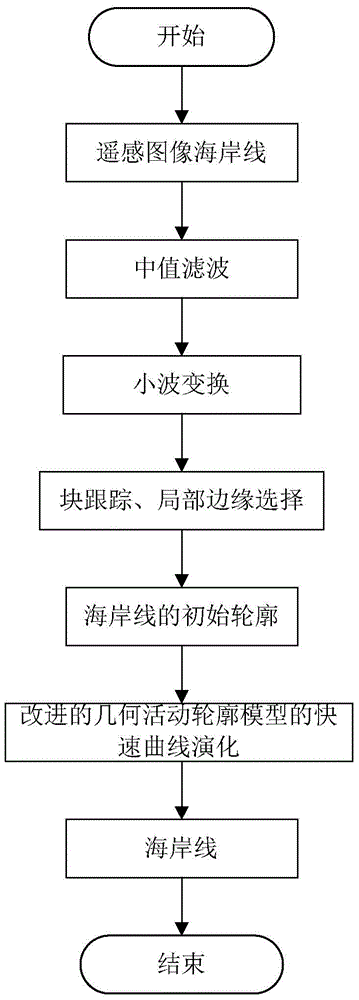

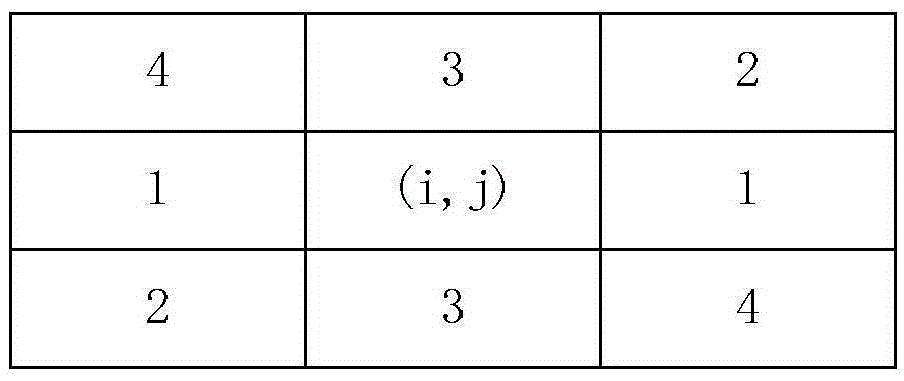

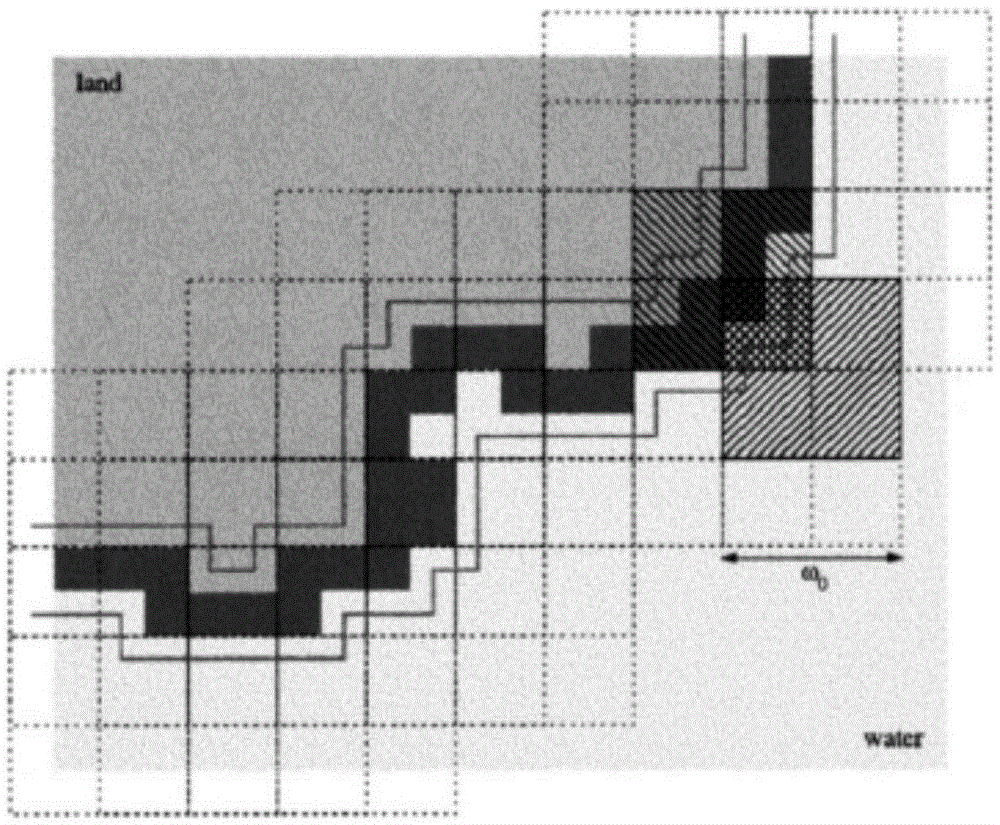

Geometric active contour model-based coastline detection method for remote sensing image

InactiveCN105488787AShorten the timeSolve the weak boundary problemImage enhancementImage analysisWavelet transformActive contour model

The invention discloses a geometric active contour model-based coastline detection method for a remote sensing image. The method comprises the following steps: (1) reading the remote sensing image comprising a to-be-detected coastline target by Matlab software, and filtering a target image by a median filter; (2) obtaining an initial contour of the coastline by a wavelet transformation method; (3) processing the coastline segmented in the step (2) by block tracking and local edge selection methods to obtain the initial contour of the coastline; and (4) with the obtained initial contour of the coastline as an improved input of a geometric active contour model, and finally obtaining the accurate and continuous coastline through processing of the geometric active contour model. According to the geometric active contour model-based coastline detection method for the remote sensing image, the influence on coastline detection caused by noise can be effectively suppressed; and accurate, continuous and complete coastline detection is achieved.

Owner:JIANGSU UNIV OF SCI & TECH

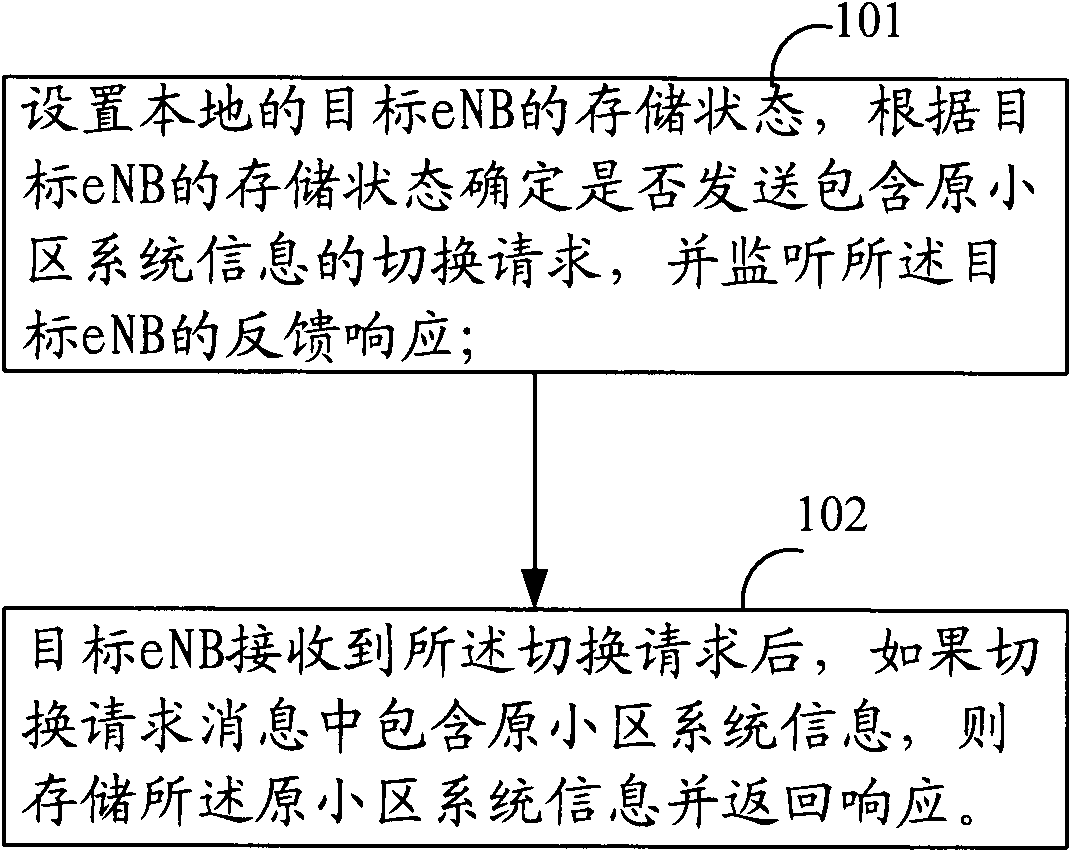

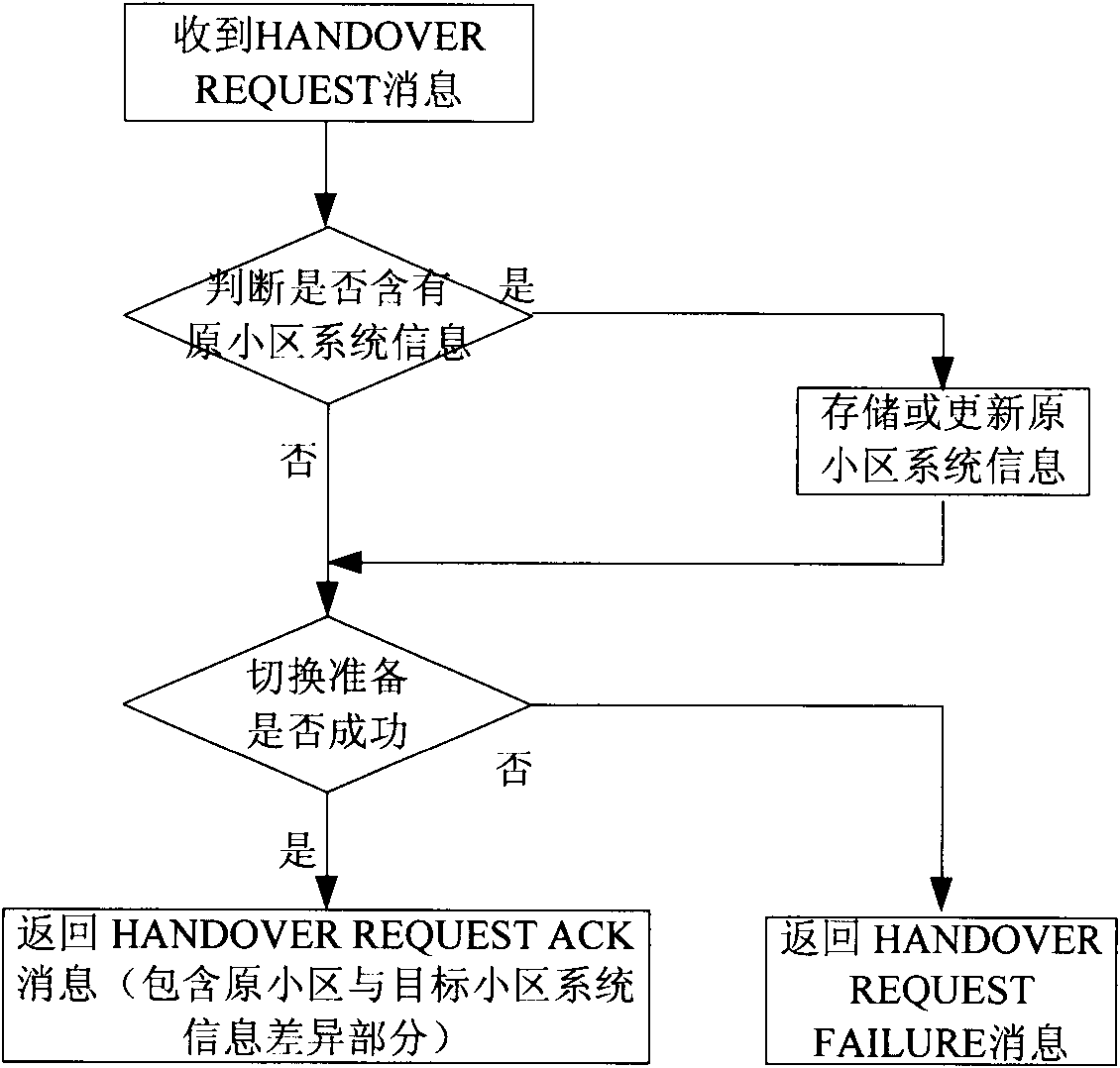

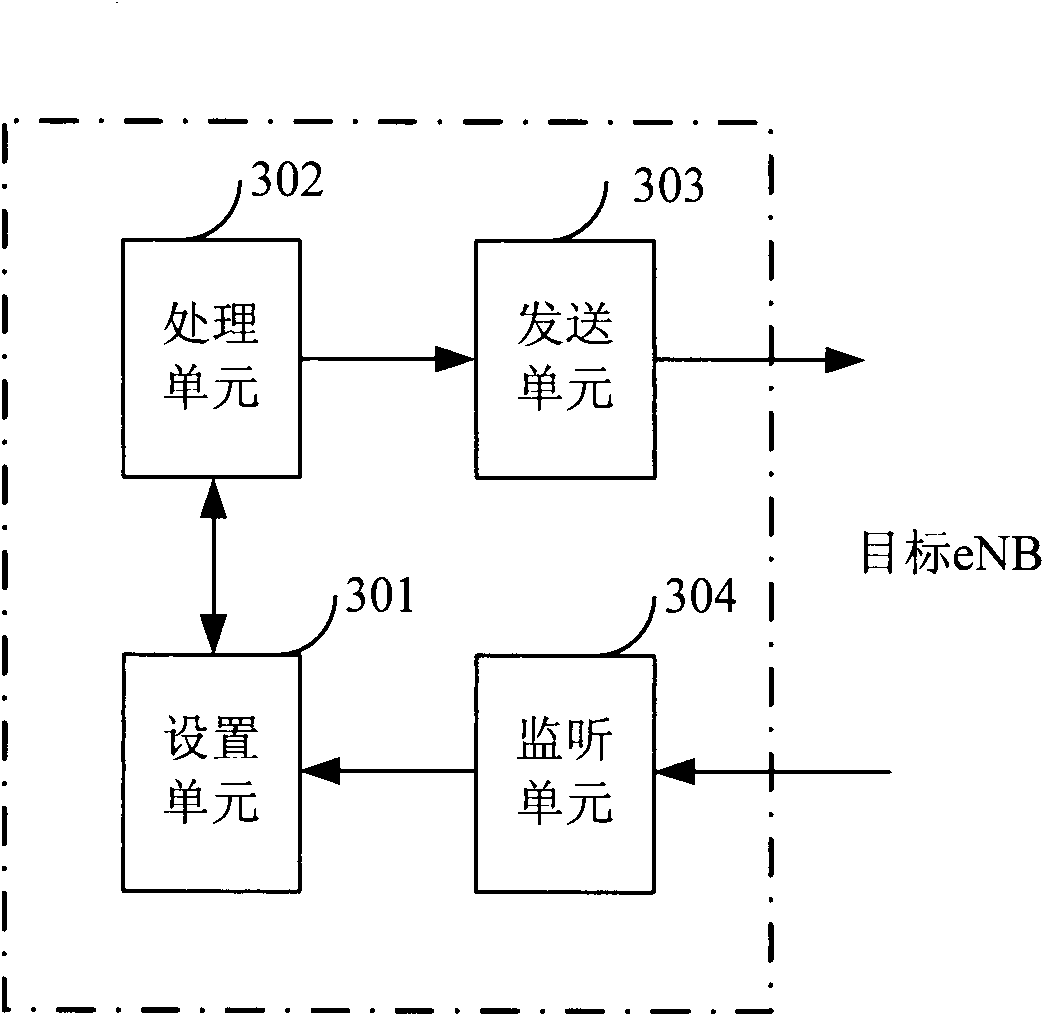

Method and apparatus for transmitting system information between nodes in the Channel Switch preparation process

ActiveCN101677451AControl overheadReduce the number of passesWireless communicationTelecommunicationsSystem information

The invention provides a method for transmitting system information between nodes in the Channel Switch preparation process, which includes: setting storage state of the local target eNB, determiningwhether to transmit the switch request containing system information of the original channel based on the storage state of the target eNB, and monitoring the feedback response of the target eNB; after the target eNB receives the switch request, storing the original channel system information of the UE and returning response, if the original channel system information of the UE is contained in theswitched request message. The invention also provides an apparatus for transmitting system information between nodes in the Channel Switch preparation process. By adoption of the inventive method andapparatus, the transfer frequency of the system information between nodes is reduced, and the internal cost of the wired net is effectively controlled.

Owner:DATANG MOBILE COMM EQUIP CO LTD

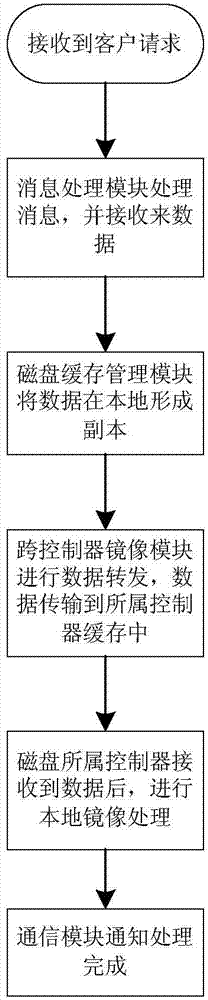

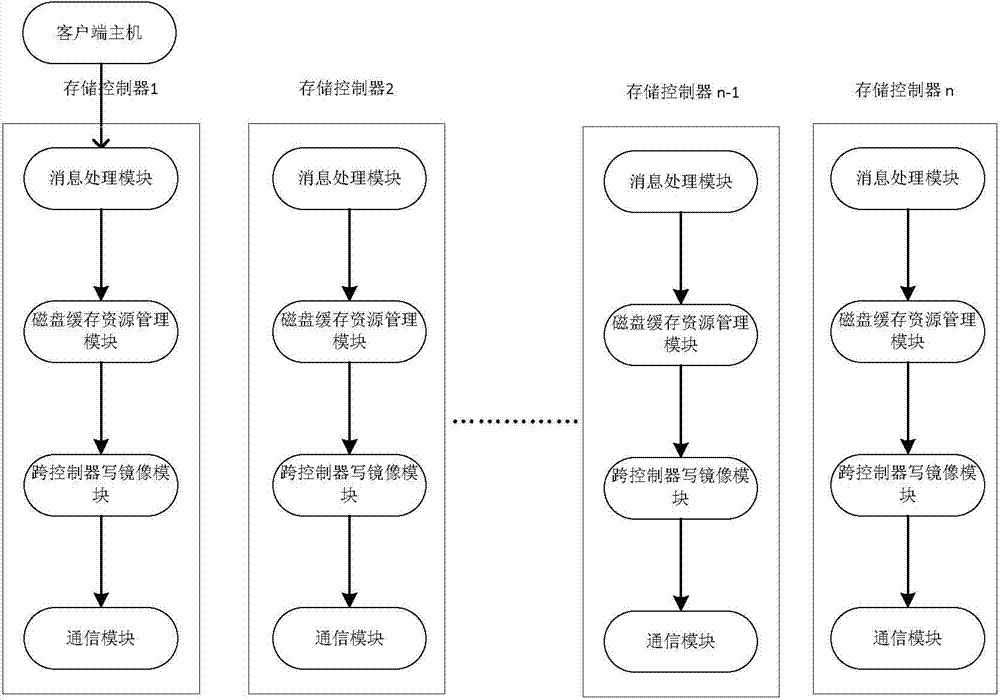

Cross controller group mirror image writing method and device applied to high-end disk array

InactiveCN103577125AReduce the number of data transfersImprove performance and efficiencyInput/output to record carriersData transmissionMemory controller

The invention provides a cross controller group mirror image writing method and device applied to a high-end disk array. If a received writing data request is a cross memory controller group writing data request, a data copy is generated and cached locally, then, the data copy is forwarded to a storage controller, resources required to store the data belong to the storage controller, and the storage controller where the resources belong cache the received data copy and mirror the data to a mirror image storage controller in the same group of storage controllers; and after the data mirroring is finished, the storage controller where the resources belong sends a response message to the storage controller connected with a client host. With the adoption of the method and the device, cross controller group writing data mirroring can be completed only by one-time data forwarding, so that times of data transmission are reduced, and mirroring efficiency and performance are greatly improved.

Owner:INSPUR BEIJING ELECTRONICS INFORMATION IND

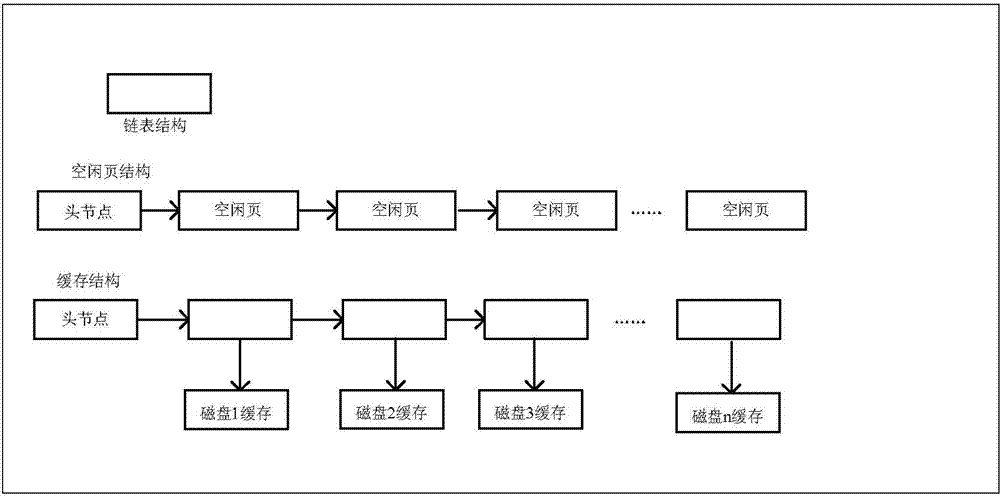

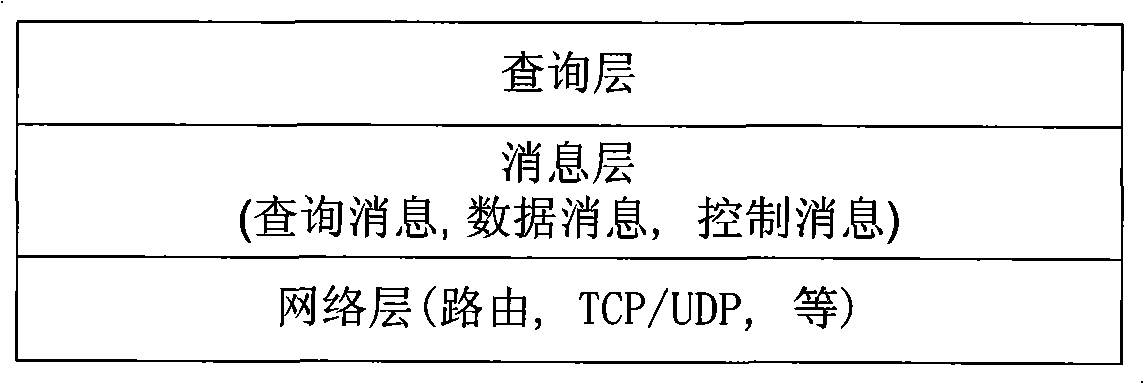

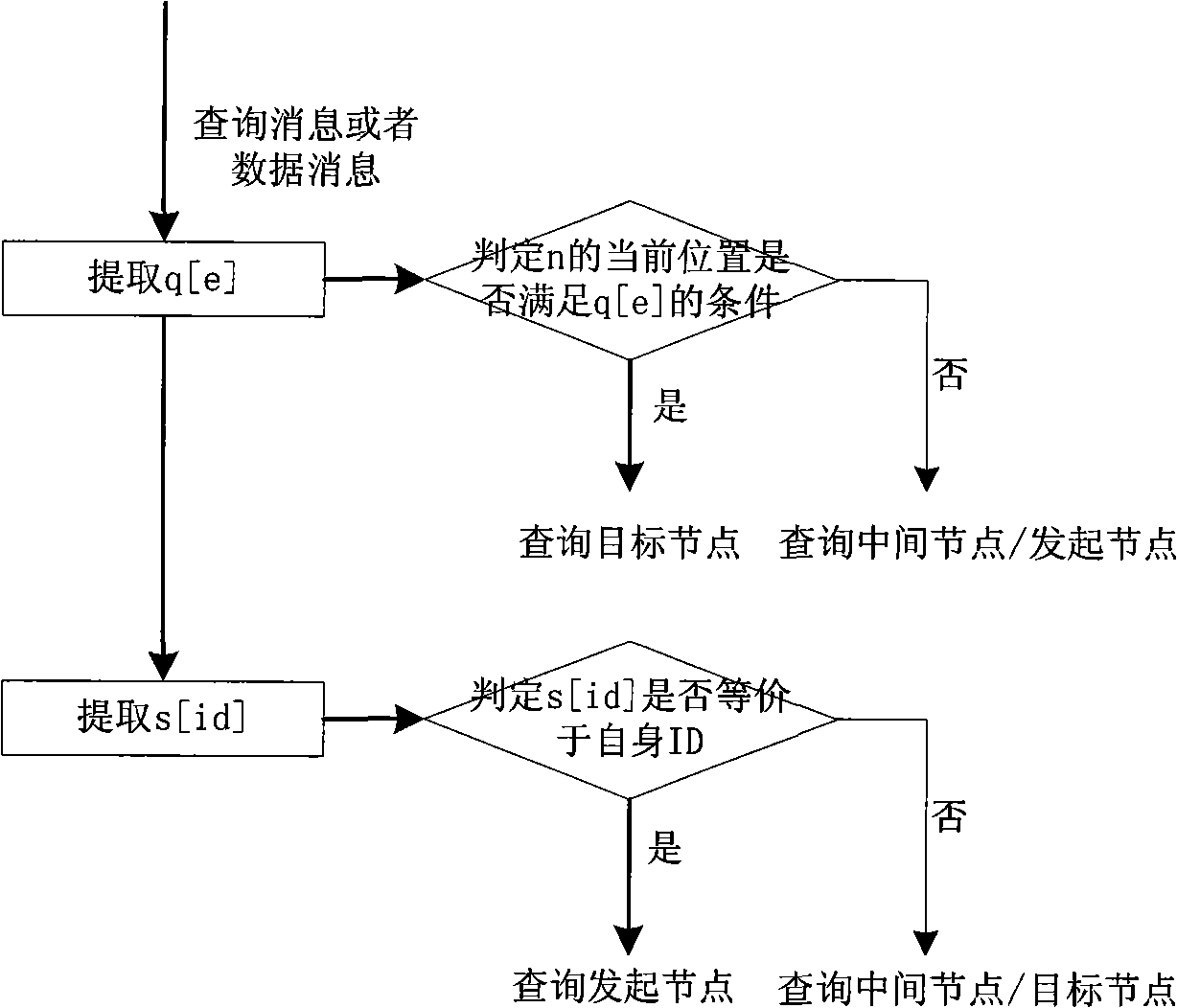

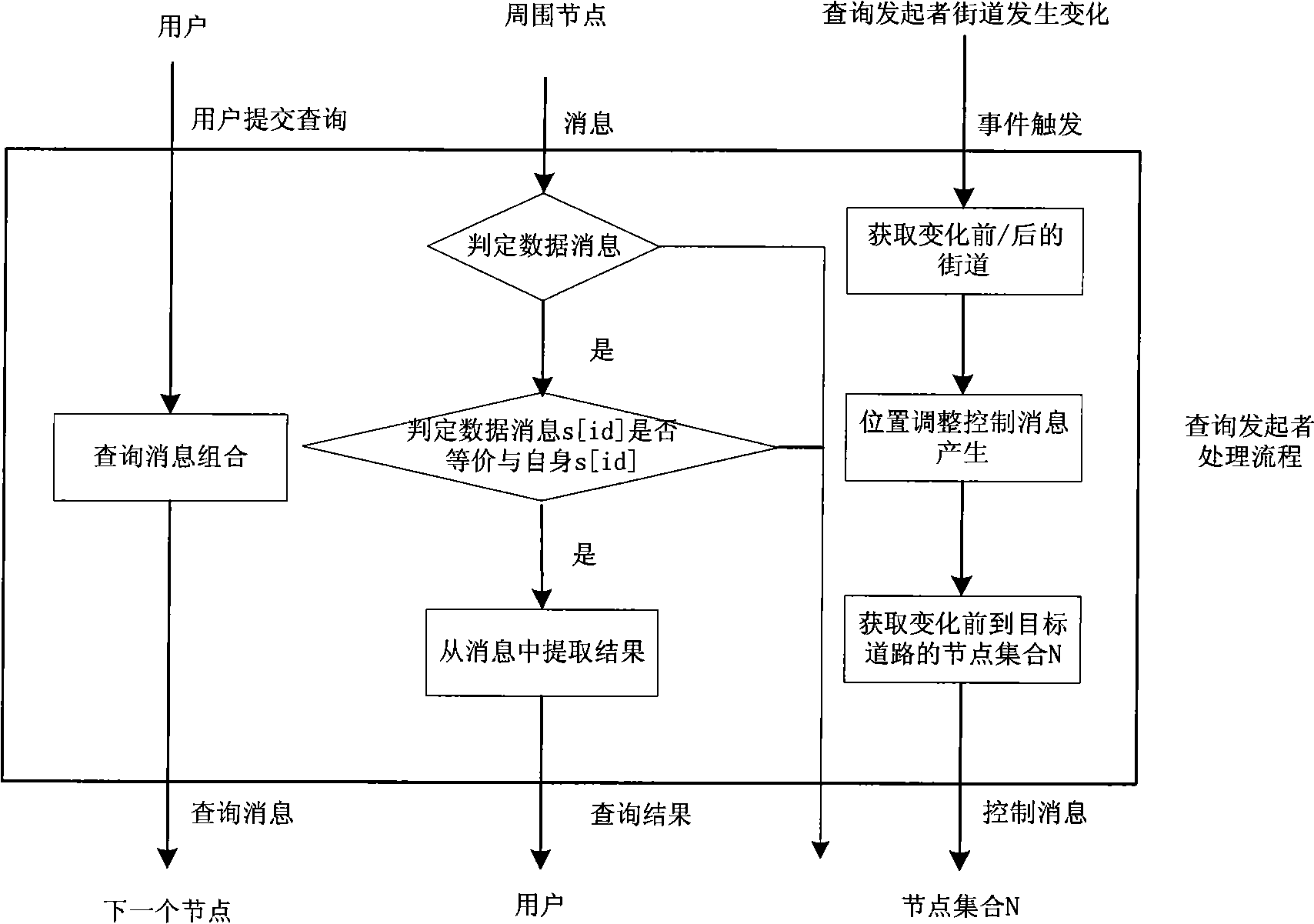

Enquiry method based on road graticule in vehicle self-organizing network

InactiveCN101257443AImprove stabilityReduce loss rateInstruments for road network navigationData switching networksIn vehicleVehicle networks

The invention discloses a road network-based query method in the vehicle self-organization network to support the information acquistion of a multihop distance street situation via the self-organization network. The invention establishes a query executive plan by a relative fixed road network to solve the problem caused by the vehicle dynamic change of the self-organization network and increase the stability of the query plan execution; meanwhile, introduces a control information which presents the position shift of a query starter and dynamic regulates the query plan by the control information; and further provides a time window-based data information collecting mechanism. The query method of the invention is suitable for the dynamic change of vehicle network in the self-organization network so that the information transmission cost in the query process is reduced.

Owner:PEKING UNIV

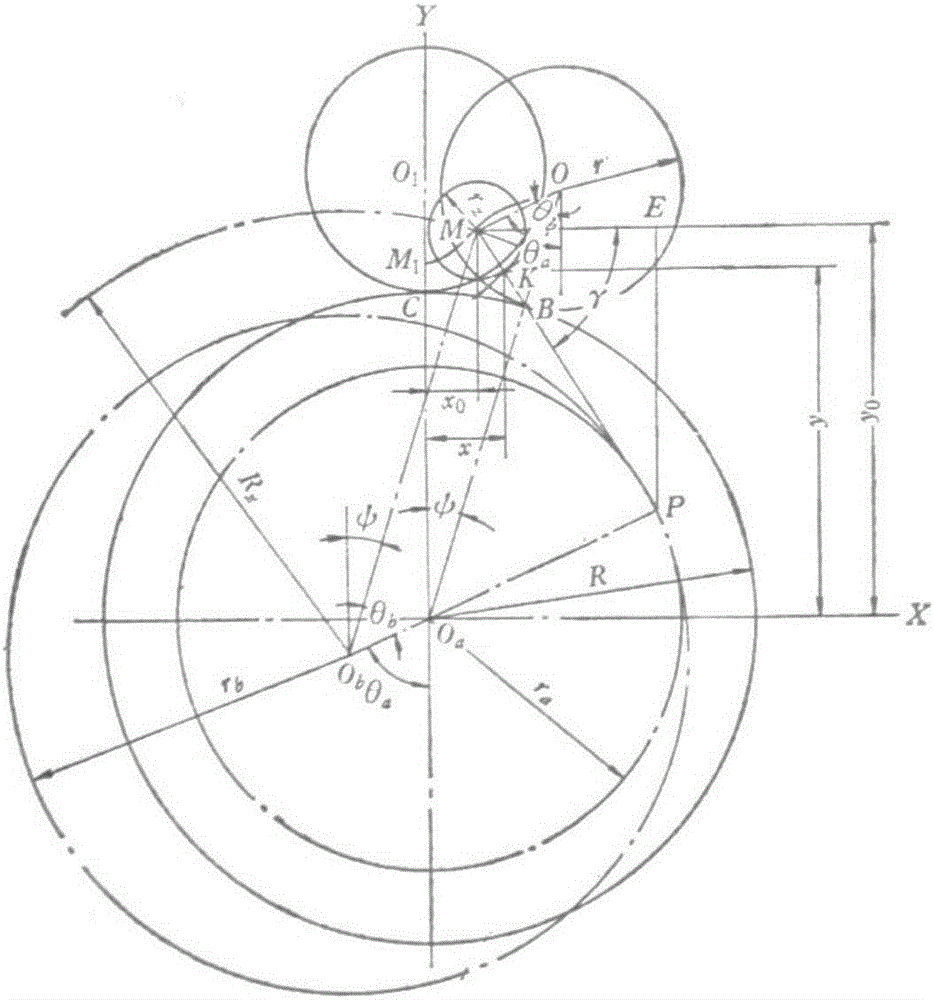

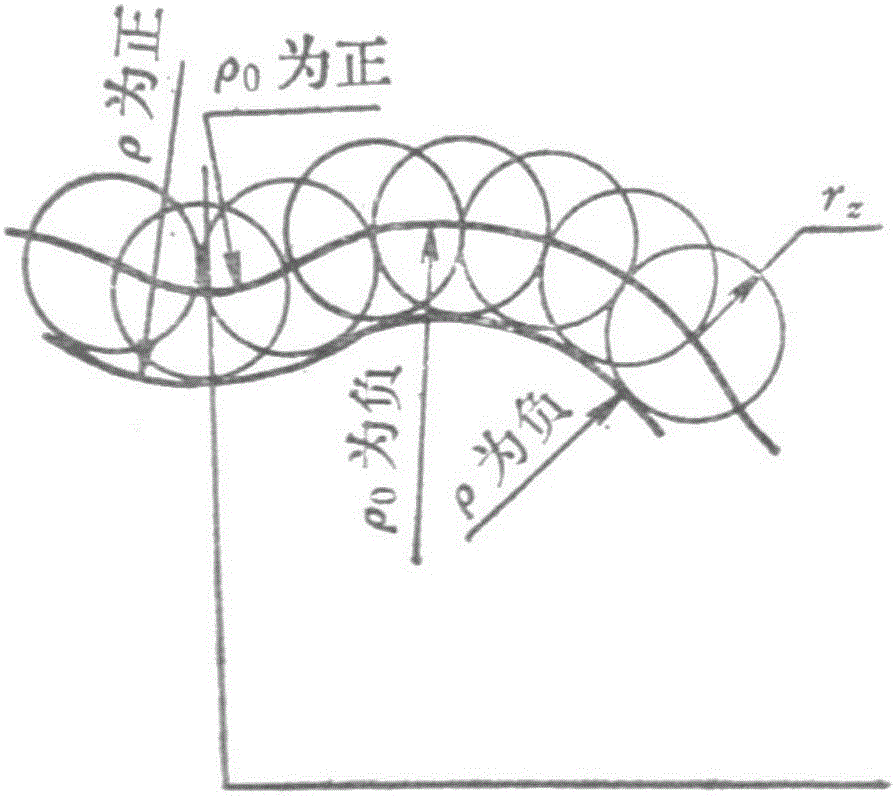

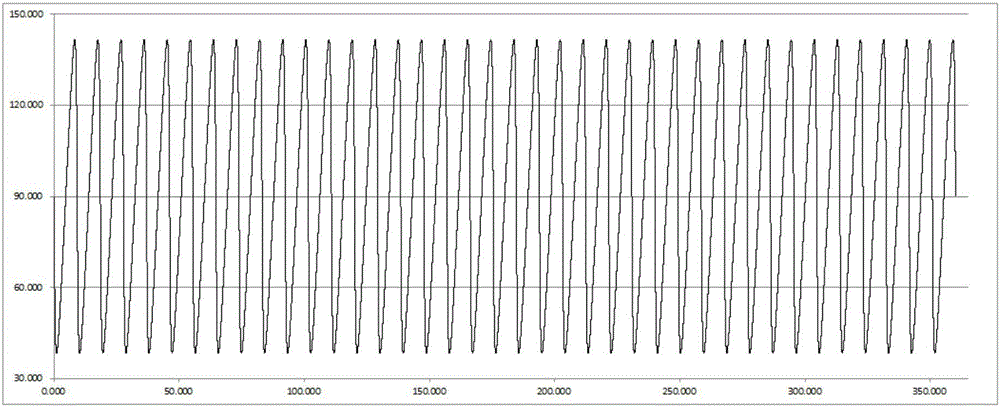

Cycloidal gear tooth curve variable step size discretization method

ActiveCN106372321AReduce the number of passesImprove processing efficiencyGeometric CADPortable liftingMedicineGear tooth

The invention discloses a cycloidal gear tooth curve variable step size discretization method, which comprises the following steps of S1, setting a cycloidal gear tooth curve parameter; S2, deriving out a cycloidal gear tooth curve equation; S3, deriving out a formula of the curvature radius Rho of the practical tooth curve of a cycloidal gear; S4, deriving out an equation of phi relevant to a pressure angle alpha; S5, deriving out an inflexion equation of the cycloidal gear tooth curve; S6, giving the curve linear interpolation initial step size discretization method. The discretization errors and given errors are compared for automatically regulating the closing step size, so that the maximum step size smaller than the closing errors can be obtained; on the premise of meeting the precision requirements, the number of cutting feeding times is reduced; the processing efficiency is improved. The cycloidal gear tooth curve variable step size discretization method provided by the invention has the advantage that the good integral index is realized in the aspects of closing precision, discretization efficiency and calculation speed.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

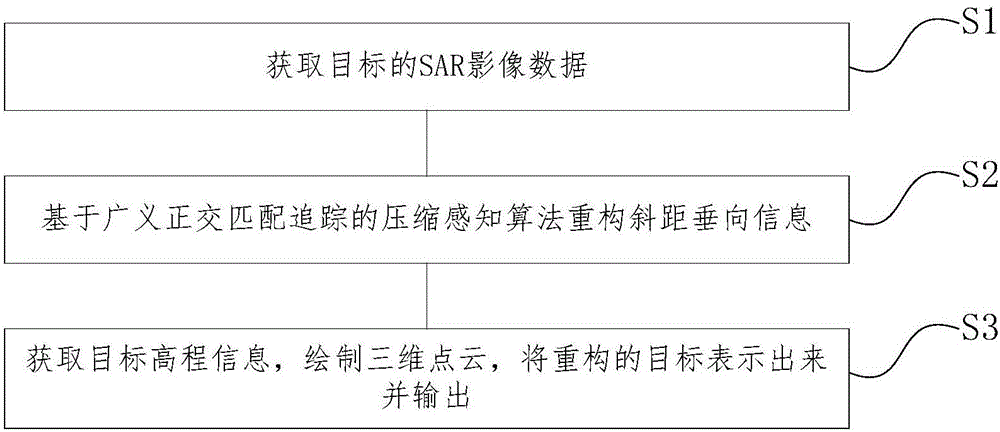

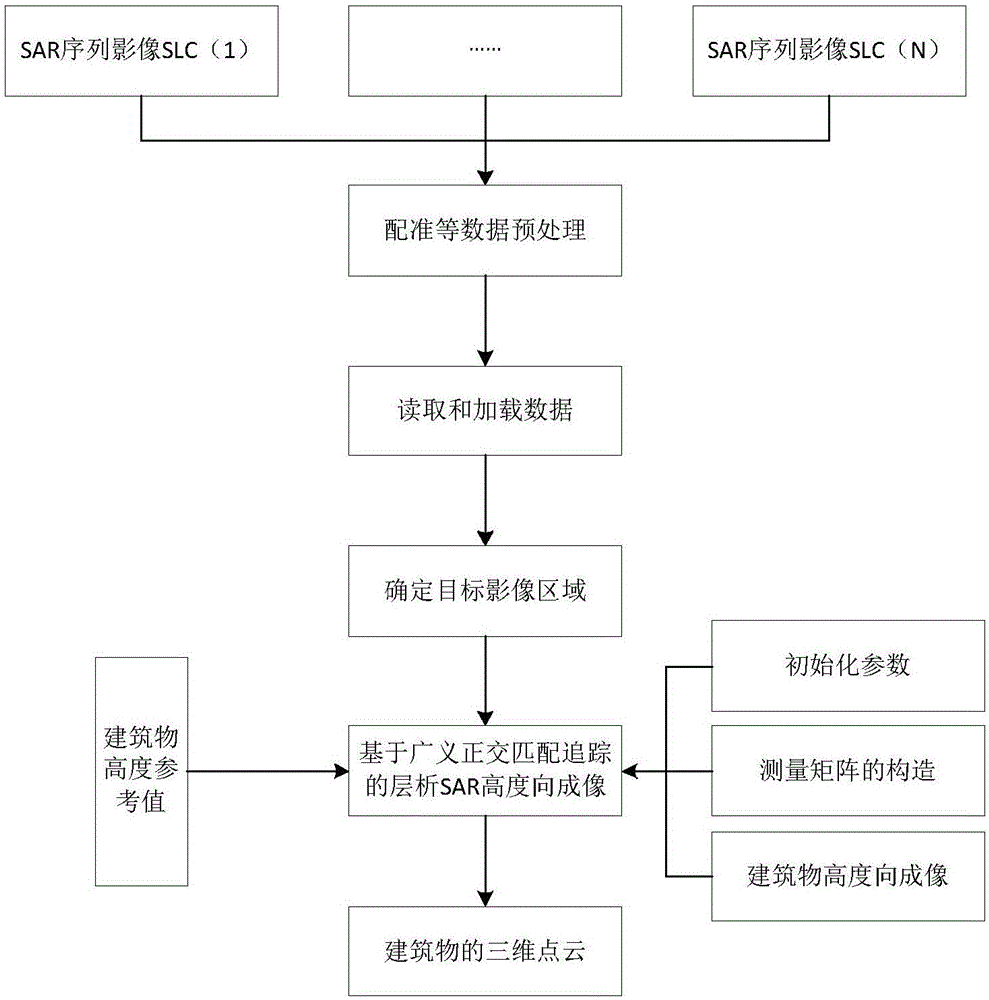

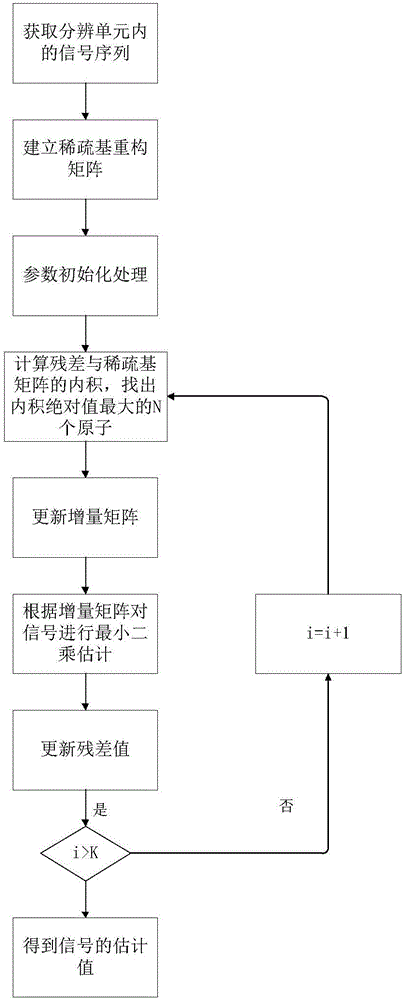

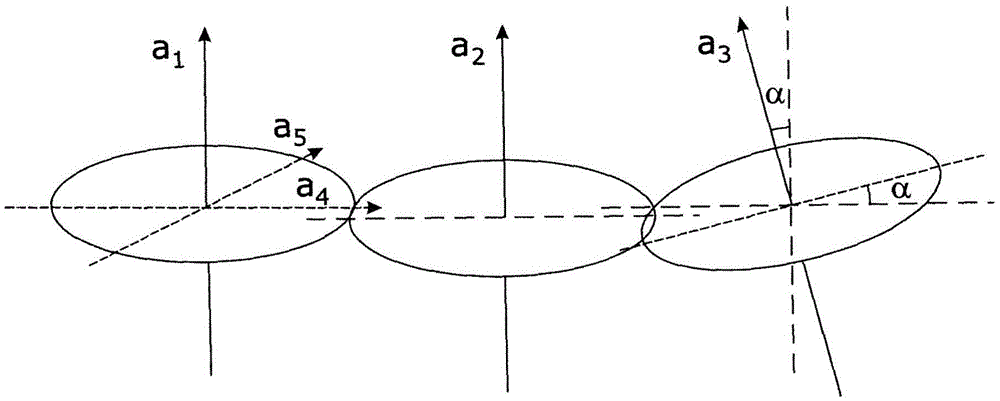

Chromatographic SAR three-dimensional point cloud generation method based on generalized orthogonal matching pursuit

InactiveCN106646470ASimplified Computational ComplexityAvoid restrictionsRadio wave reradiation/reflectionPoint cloudLaws of thermodynamics

The invention discloses a chromatographic SAR three-dimensional point cloud generation method based on generalized orthogonal matching pursuit, and the method comprises the following steps: S1, obtaining multi-temporal SAR image data of a target building; S2, carrying out the high-dimensional (slant-range vertical) focusing through a compressed sensing algorithm based on the generalized orthogonal matching pursuit; S3, obtaining the target elevation information, encrypting point cloud through an interpolation method, and expressing and outputting a reconstructed target. The method obtains the high-dimensional information of the target building through the compressed sensing algorithm based on the generalized orthogonal matching pursuit. During iterative operation, N atoms is selected at each time from optimal atoms at most, thereby guaranteeing the robustness of the algorithm while simplifying the calculation complexity of an orthogonal matching pursuit algorithm, and overcoming the constraint that can a signal be restored only if a conventional chromatographic SAR imaging method has to meet the Nyquist sampling law.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

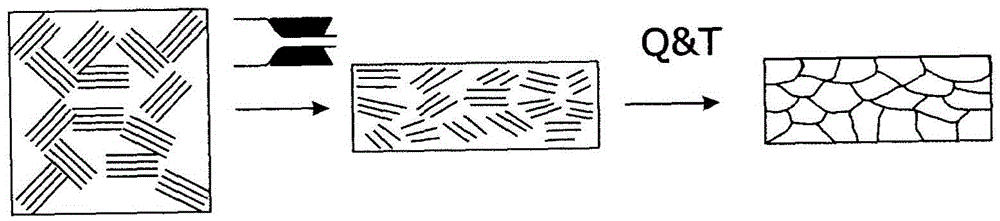

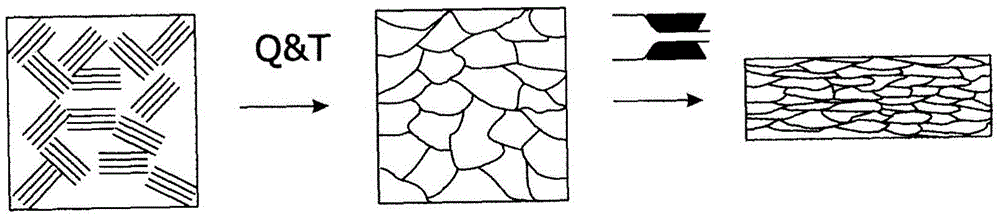

High tensile strength steel wire

InactiveCN105579595AExcellent mechanical propertiesHigh surface finishFurnace typesHeat treatment furnacesMartensiteSilicon

A high tensile strength steel wire having as steel composition: a carbon content ranging from 0.20 weight percent to 1.00 weight percent, e.g. from 0.3 weight percent to 0.85 weight percent, e.g. from 0.4 weight percent to 0.7 weight percent, e.g. from 0.5 weight percent to 0.6 weight percent, a silicon content ranging from 0.05 weight percent to 2.0 weight percent, e.g. from 0.2 weight percent to 1.8 weight percent, e.g. from 1.2 weight percent to 1.6 weight percent, a manganese content ranging from 0.40 weight percent to 1.0 weight percent, e.g. from 0.5 weight percent to 0.9 weight percent, a chromium content ranging from 0.0 weight percent to 1.0 weight percent, e.g. from 0.5 weight percent to 0.8 weight percent, a sulfur and phosphor content being individually limited to 0.05 weight percent, e.g. limited to 0.025 weight percent, contents of nickel, vanadium, aluminum, copper or other micro-alloying elements all being individually limited to 0.5 weight percent, e.g. limited to 0.2 weight percent, e.g. limited to 0.08 weight percent, the remainder being iron, said steel wire having martensitic structure, wherein at least 10 volume percent of martensite are oriented.

Owner:NV BEKAERT SA

Production method of 3005-H16 aluminum alloy plate strip

ActiveCN109048222AEliminate unevennessEliminate coarse grainsMetal rolling arrangementsFurnace temperatureChemical composition

The invention relates to an aluminum alloy plate strip, in particular to a production method of a 3005-H16 aluminum alloy plate strip, and aims at solving the technical problems that the requirement for annealing temperature uniformity is relatively high, the requirement for annealing furnace temperature control is relatively high, the performance, especially the yield strength, is unstable duringthe intermediate annealing process of the aluminum alloy plate strips, and surface defects such as oil patches and the like are easy to generate to cause waste products if cold rolling strips are notspecially cleaned in the prior art. The method comprises the following steps of: carrying out casting, wherein the ingot casting obtained through the casting comprises the following chemical components in mass percent: less than or equal to 0.5% of Si, 0.4-0.6% of Fe, less than or equal to 0.2% of Cu, less than or equal to 0.05% of each of other impurities, less than or equal to 0.10% of a sum ofthe other impurities and the balance of Al, a smelting temperature is 740-760 DE C, a refining temperature is 730-750 DEG C, a casting temperature is 685-700 DEG C, and a casting speed is 50-60 mm / min; and carrying out milling, heating, hot rolling and cold rolling to obtain the finished 3005-H16 aluminum alloy plate strip.

Owner:ZHEJIANG YONGJIE ALUMINUM CO LTD

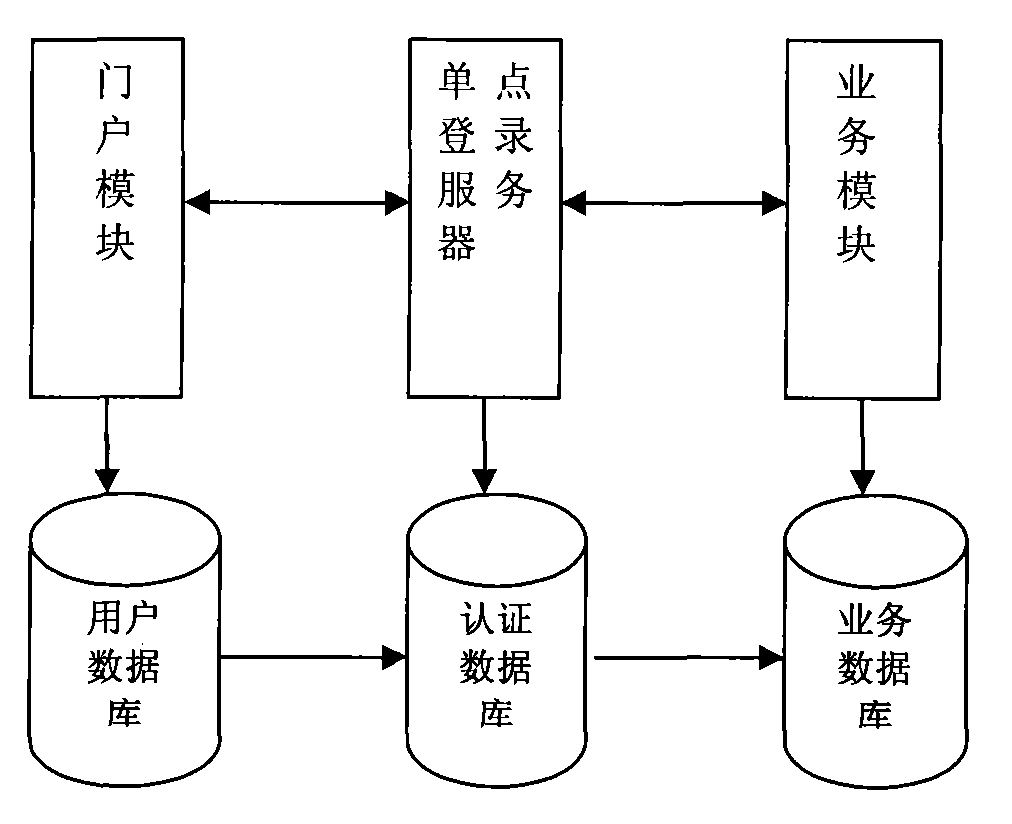

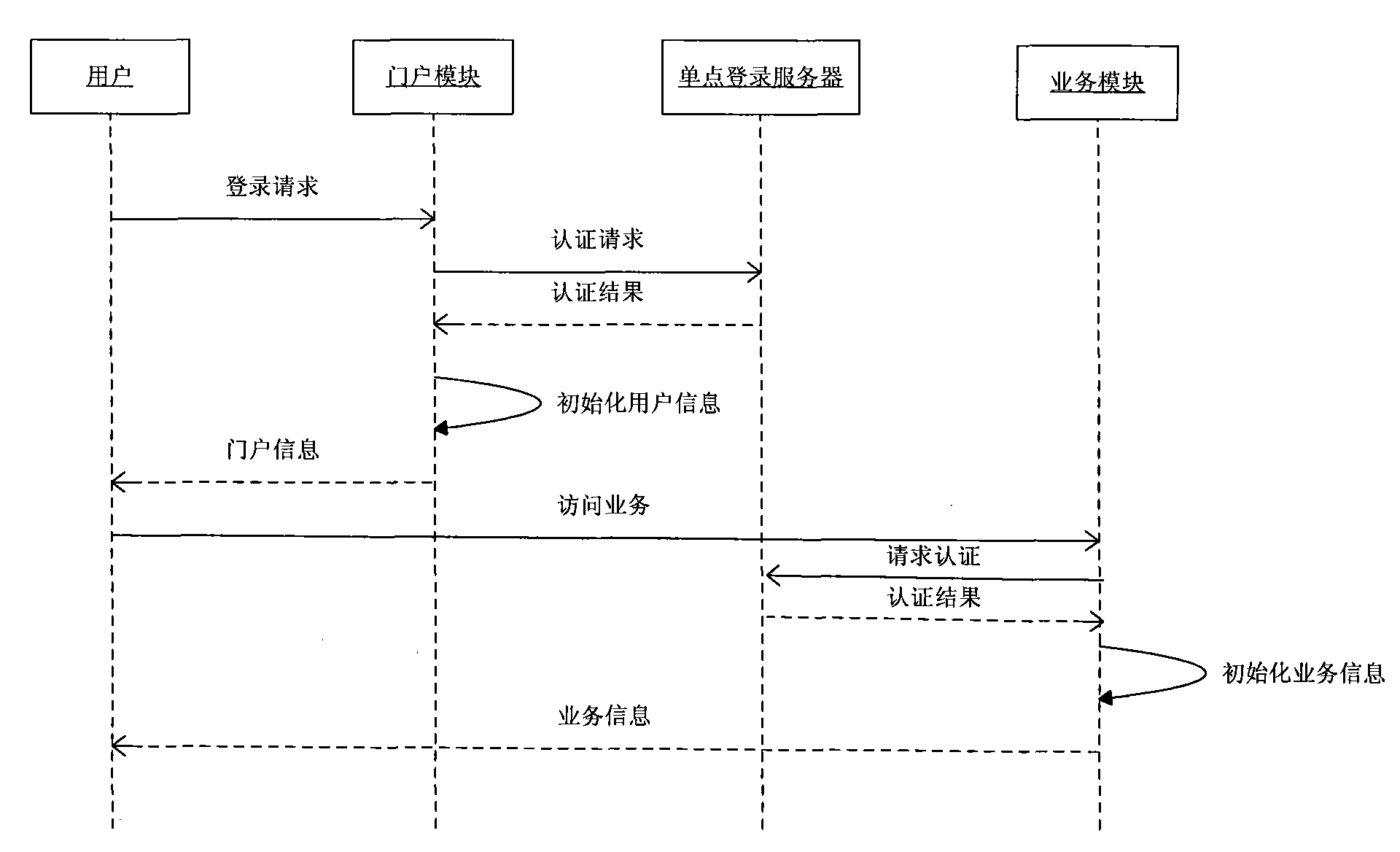

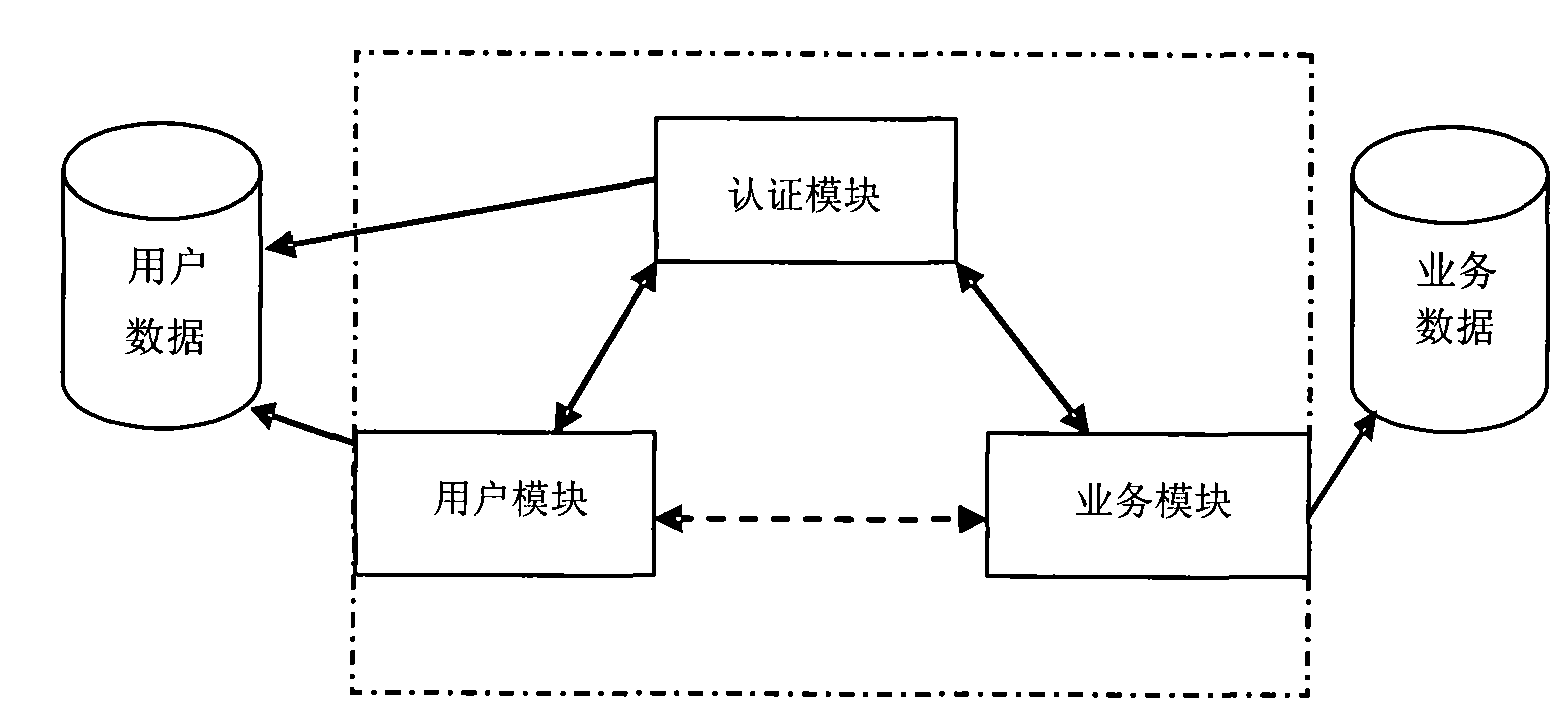

Web network single login system and Web network single login method

InactiveCN101588241AReduce the burden onReduce the number of passesUser identity/authority verificationInformation transmissionWeb application

The invention discloses a Web network single login system and a Web network single login method, belonging to the fields of Web application. The system comprises a user module, an authentication module and a business module. The method comprises the following steps: the user module transmits a business use request to the business module according to a command of a login user; the authentication module authenticates an identity of the user according to information carried in the business use request and authenticates whether the user has the permission for using an indicated business in the business use request nor not; if both authentications pass, a business access request is transmitted to the business module; and after the business module receives the business access request, the business module establishes a relationship with the user module and directly interacts with the user module. The invention reduces hardware investment and later maintenance cost, simplifies the single login authentication process, reduces information transfer frequency during authentication and improves the authentication efficiency.

Owner:ZTE CORP

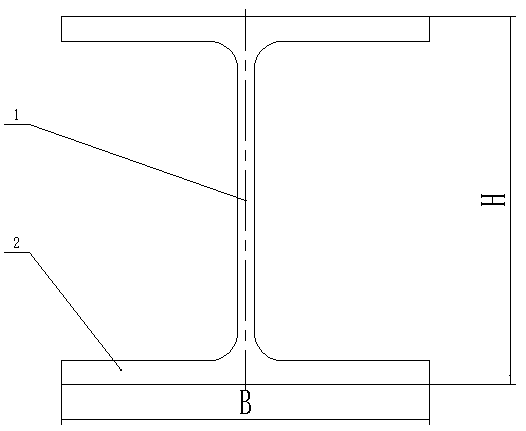

High-strength light H-shaped steel and hot rolling forming process thereof

ActiveCN111468534AHigh strengthReduce weightElongated constructional elementsWork heating devicesEngineeringHigh pressure water

The invention discloses high-strength light H-shaped steel. The high-strength light H-shaped steel comprises a web plate and a wing plate, wherein the height of the web plate is 146 mm, the thicknessof the web plate is 3.3 mm, the width of the wing plate is 95 mm, and the thickness of the wing plate is 4.0 mm. A hot rolling forming process of the H-shaped steel comprises the following steps: carrying out high-pressure water descaling on a heated square steel billet, carrying out head cutting treatment after cogging rough rolling is carried out by two three-roll horizontal rolling mills, carrying out reciprocating rolling 4-6 times through a universal rough rolling unit, finally carrying out reciprocating rolling 1-2 times by a universal finishing rolling unit, and carrying out fixed-length cutting on a rolled piece after the rolled piece is subjected to air cooling by a cooling machine to obtain a finished product. According to the high-strength light H-shaped steel, under the condition that the rolled H-shaped steel has the same height H and width B as standard H-shaped steel, the thickness of the web plate and the thickness of the wing plate are smaller, and the strength of therolled H-shaped steel can be ensured; and in the rolling process, the pass number of cogging rough rolling is obviously reduced, the rolling time is shortened, the temperature drop of the rolled pieceis small, the product quality is guaranteed, the rolling production speed is accelerated, and the production efficiency is improved.

Owner:山东德坊新材料科技有限公司

Outpatient body fluid collecting self-service machine

ActiveCN108053552AImprove automationHigh degree of intelligenceConveyorsDispensing apparatusEngineeringBody fluid

The invention provides an outpatient body fluid collecting self-service machine, which comprises a frame; a conveying mechanism is at least arranged on the frame, and both ends of the conveying mechanism are at least provided with one discharging mechanism and one laser printing mechanism, wherein at least one rotating mechanism is arranged on the same end of the laser printing mechanism; the rotating mechanism and the laser printing mechanism are located at upside and downside of the conveying mechanism. Through cooperation of the discharging mechanism, the conveying mechanism, the rotating mechanism, and the laser printing mechanism, the outpatient body fluid collecting self-service machine can reduce the transfer frequency of a body fluid test tube between an inspector and a patient, and avoid mis-taking; moreover, the body fluid test tube is regularly placed in the discharging mechanism, thus the pollution caused by contacting with outside is avoided, the safety and reliability forplacing the body fluid test tube are improved; besides, the outpatient body fluid collecting self-service machine is high in automatic and intelligent degrees, and convenient to popularize.

Owner:宁波海尔施智造有限公司

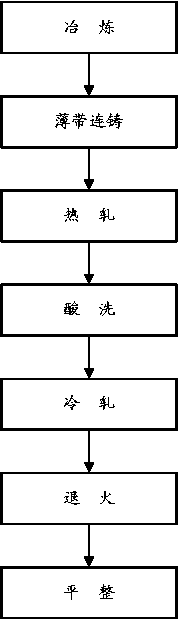

Thin-specification cold-rolled low-alloy high-strength steel and production method thereof based on double-roller cast rolling

ActiveCN111215590AReduce in quantityReduce energy consumptionFurnace typesHeat treatment furnacesAlloyContinuous annealing

The invention relates to a method for producing thin-specification cold-rolled low-alloy high-strength steel based on double-roller cast rolling. Molten steel comprises the following chemical components of, in percentage by mass, less than or equal to 0.05% of C, 0.16%-0.5% of Si, 1.1%-1.5% of Mn, 0.045%-0.065% of Nb, 0.010%-0.040% of Cr, 0.02% of P, and 0.0040% of S. The method comprises the following steps of producing a hot-rolled thin strip with the thickness of 0.9-1.8 mm by adopting a double-roller cast rolling process, then cold-rolling the thin strip into a rolled hard coil with the thickness of 0.3-0.6 mm by using a reversible single-stand rolling mill, cleaning the rolled hard coil, then carrying out continuous annealing, and flattening to obtain an annealed finished coil. Compared with a traditional production process, the method is adopted for producing the thin-specification cold-rolled low-alloy high-strength steel, the rolling reduction and pass in the hot rolling and cold rolling procedures can be reduced, energy consumption is reduced, meanwhile, the production difficulty is reduced, and meanwhile the high-strength thin-specification cold-rolled low-alloy high-strength steel which is difficult to produce through a conventional process can be produced.

Owner:SHAGANG GROUP +2

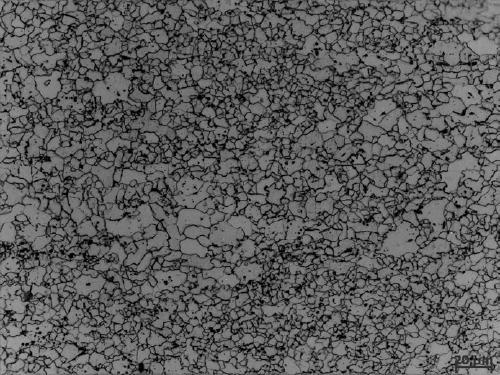

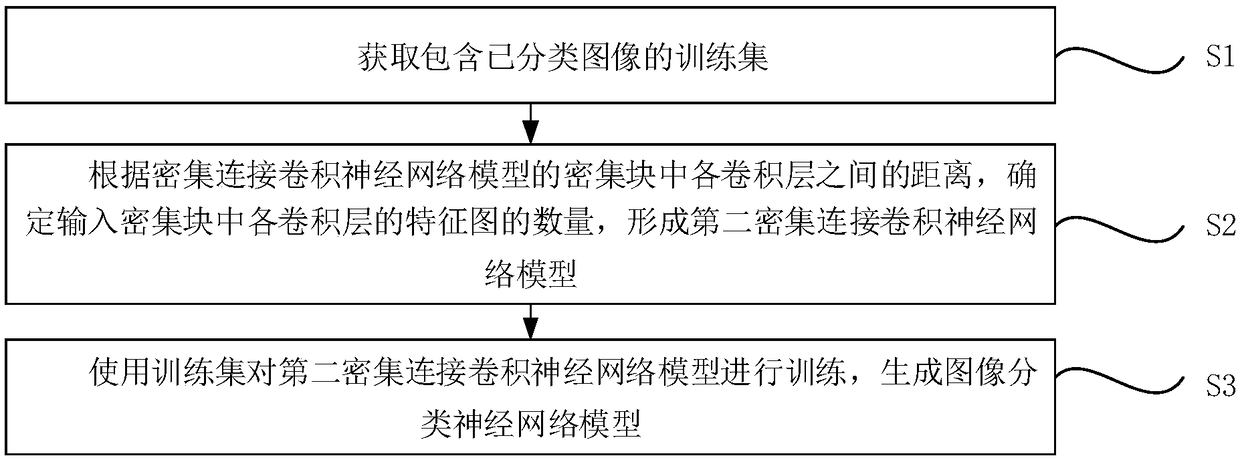

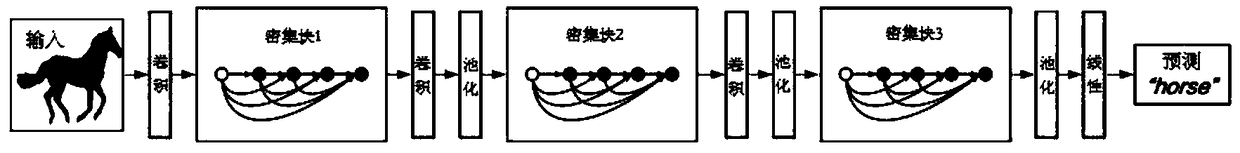

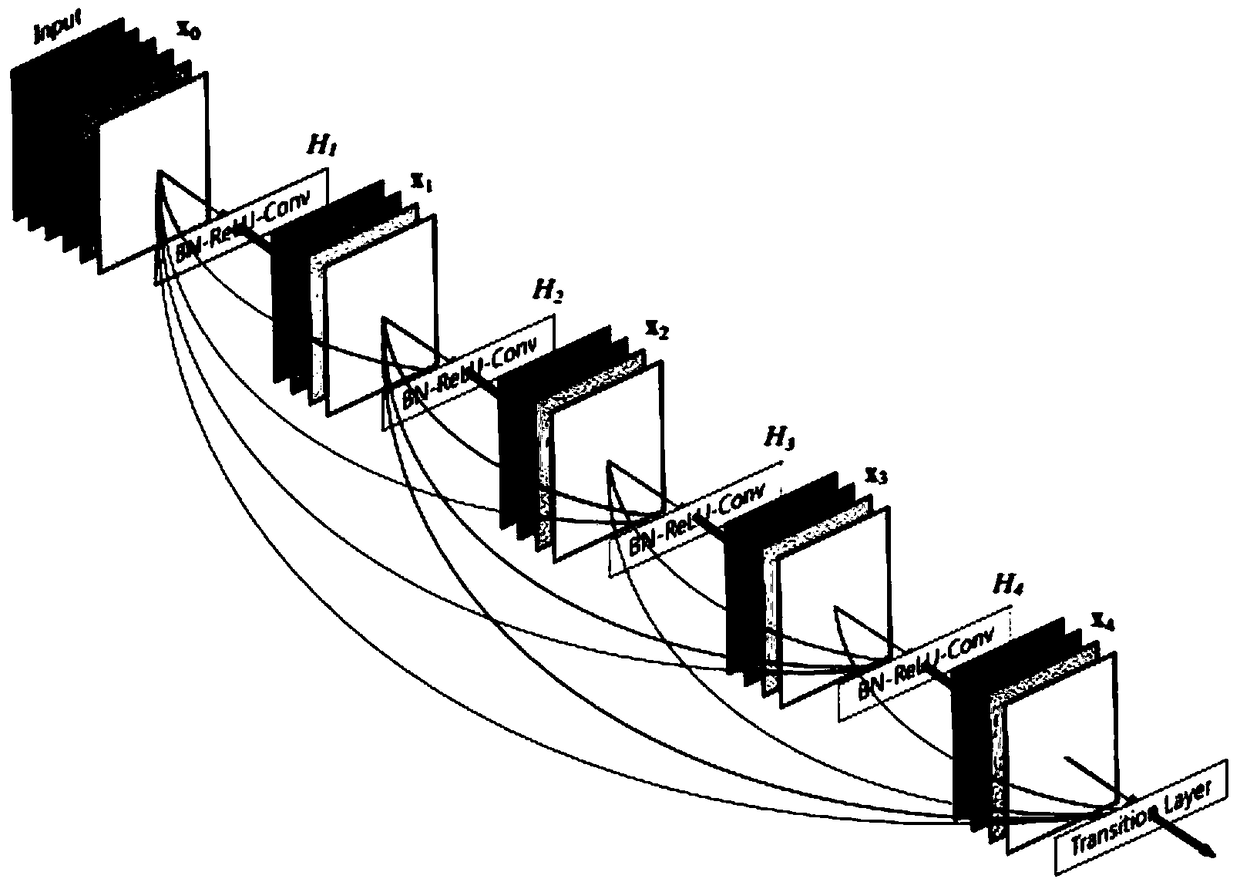

Image classification neural network model building and image classification methods and devices

ActiveCN108805166AReduce the number of passesReduce the amount of network parametersCharacter and pattern recognitionClassification methodsNetwork model

Embodiments of the invention provide image classification neural network model building and image classification methods and devices. The image classification neural network model building method comprises the steps of firstly, acquiring a training set containing classified images; according to the distance between convolutional layers in dense blocks of a densely connected convolutional neural network model, determining the number of characteristic diagrams of the convolutional layers in the input dense blocks; forming a second densely connected convolutional neural network model; training the second densely connected convolutional neural network model by using the training set to generate an image classification neural network model; and classifying to-be-classified image data by using the image classification neural network model. According to the image classification neural network model building and image classification methods and devices, network parameters in an image classification process are reduced.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

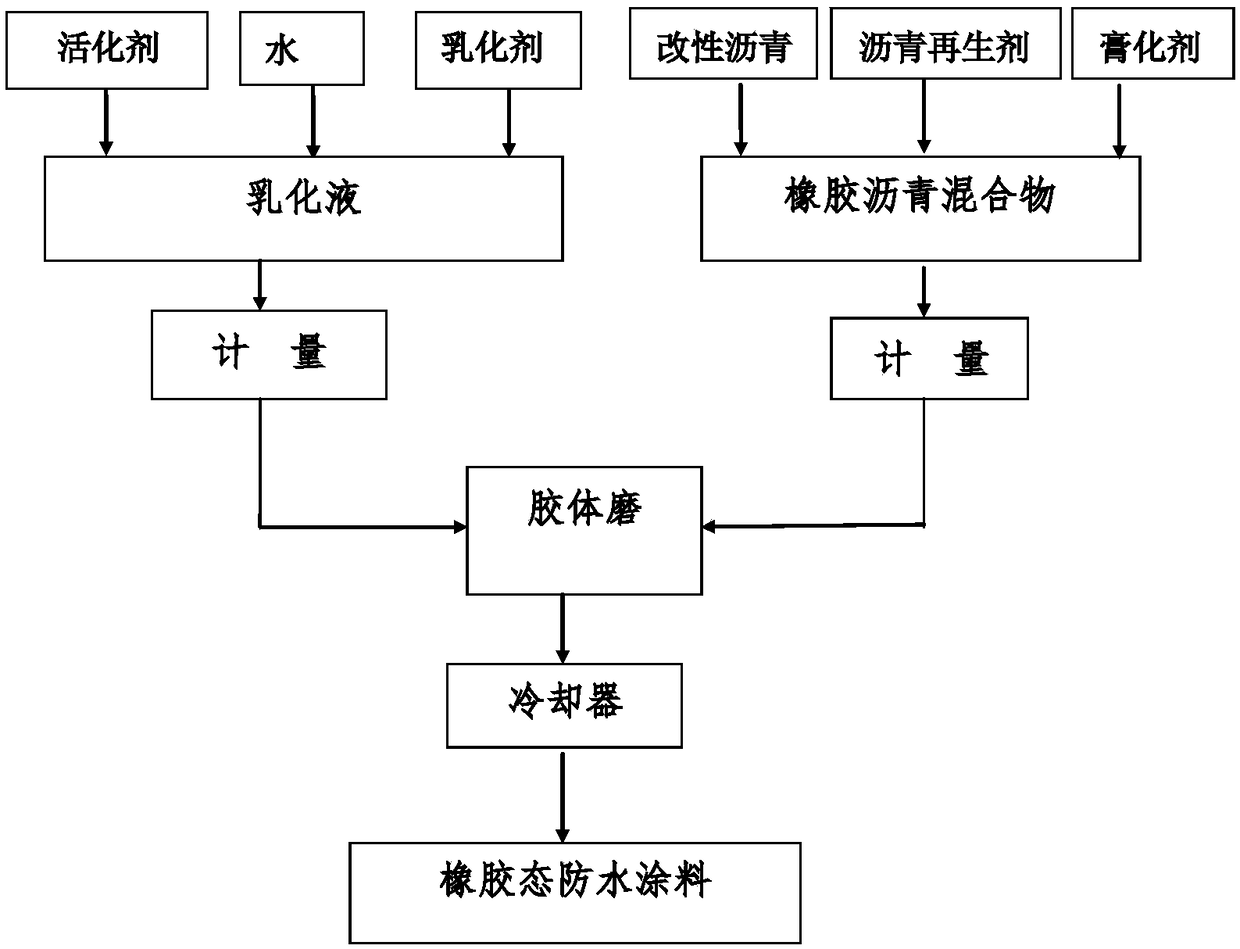

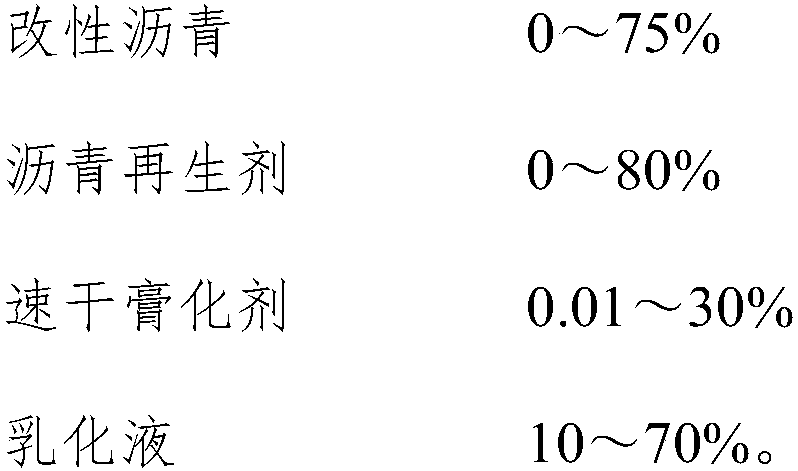

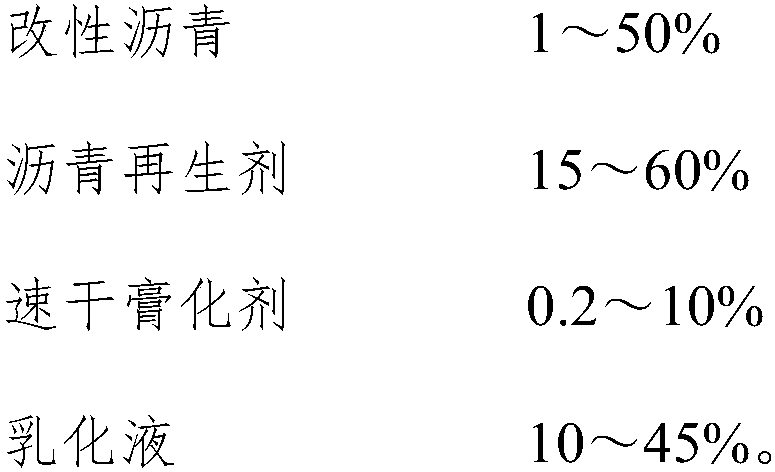

Multi-path thick coating and one-step molded rubber-state waterproof coating and preparation method thereof

InactiveCN108395844AReduce wax contentImprove performanceRoof covering using flexible materialsProtective foundationColloidAsphalt

The invention relates to multi-path thick coating and one-step molded rubber-state waterproof coating and a preparation method thereof and belongs to the technical field of sealing water prevention. The rubber-state waterproof coating provided by the invention is mainly prepared from the following raw materials in percentage by mass: 0 to 75 percent of modified asphalt, 0 to 80 percent of asphaltregeneration agent, 0.01 to 30 percent of quick-drying creaming agent and 10 to 70 percent of emulsified liquid; the rubber-state waterproof coating is prepared through steps of preparing a rubber asphalt mixture, preparing the emulsified liquid, emulsifying and creaming and de-foaming. According to the rubber-state waterproof coating, an inorganic creaming agent is used as the quick-drying creaming agent and the emulsified liquid is used for emulsifying and creaming the rubber asphalt mixture through a colloid mill by adopting a one-pot method and the prepared rubber-state waterproof coatingis uniform, fine and smooth and has high quality; the rubber-state waterproof coating has very good thixotropic performance, rapid dehydration and drying properties and excellent construction and application performance; the production efficiency is improved by applying the one-pot method and quality stability of a product and environment protection are facilitated.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

Gypsum plastering mortar and preparation method thereof

The invention discloses a gypsum plastering mortar which comprises the following components in parts by weight: 40-50 parts of desulfurized gypsum (or 35-45 parts of desulfurized gypsum and 4-6 partsof cement), 40-60 parts of quartz sand, 3-5 parts of heavy calcium carbonate, 0.5-0.9 part of redispersible latex powder, 0.05-0.15 part of a retarder and 0.1-0.3 part of cellulose ether; and a preparation method thereof. The method for manufacturing the gypsum plastering mortar is simple, and the prepared mortar is high in caking property, rapid in hardening, high in strength, low in density, lowin cost, green and environment-friendly.

Owner:潍坊德霖建材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com