Production method of 3005-H16 aluminum alloy plate strip

An aluminum alloy strip and production method technology, applied in metal rolling and other directions, can solve the problems of high annealing temperature uniformity requirements, high temperature control requirements of annealing furnaces, unstable performance, etc., so as to save the annealing process, Eliminate the uneven structure of the ingot and the effect of stable and qualified mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

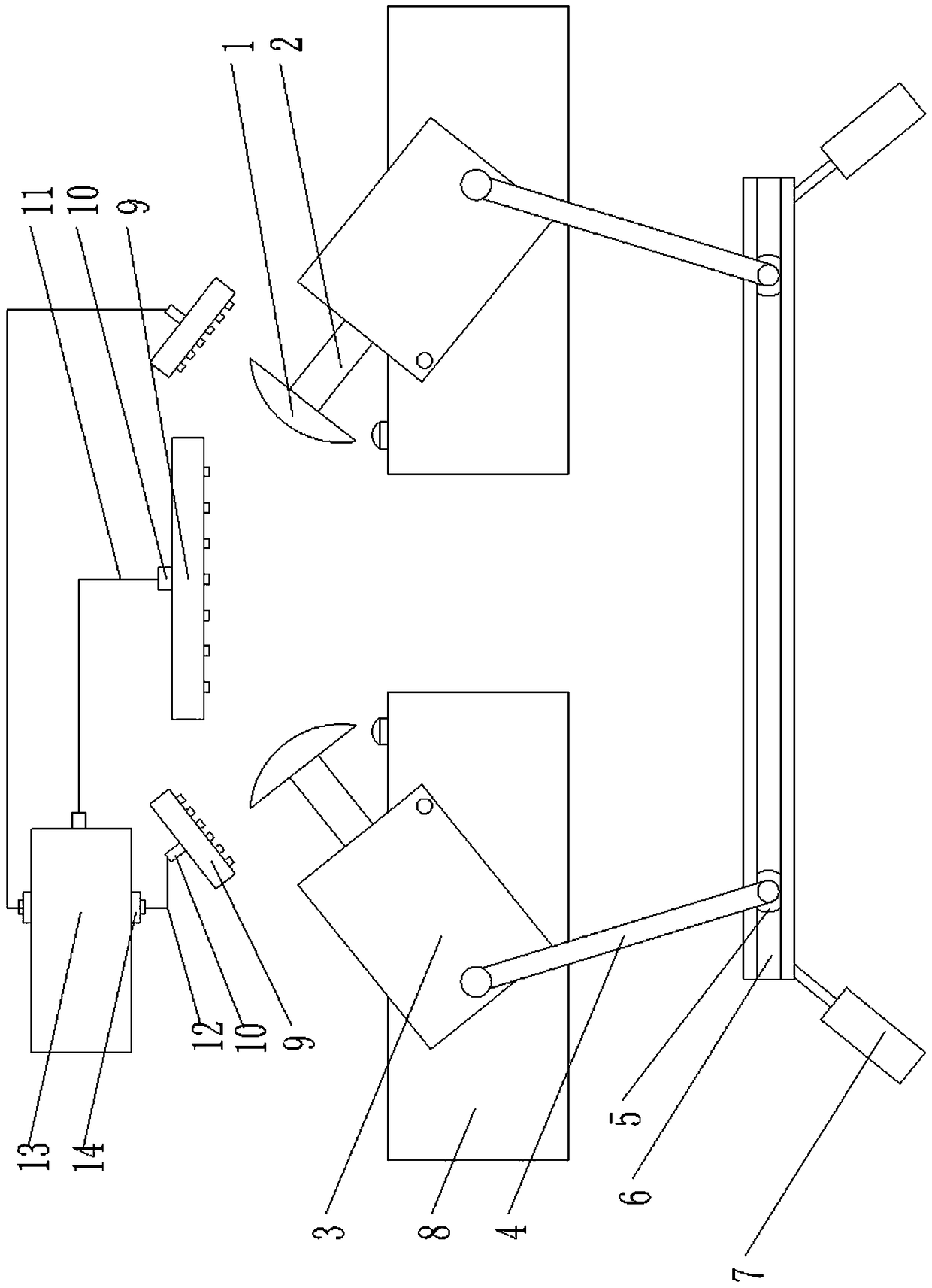

[0027] Embodiment: the production method of a kind of 3005-H16 aluminum alloy plate strip of this example, its steps are:

[0028] (1) Melting and casting: The mass percentage of the chemical composition of the ingot after melting and casting is: Si≤0.5%, Fe: 0.4-0.6%, Cu≤0.2%, Mn: 1.0-1.25%, Mg: 0.3-0.5%, Ti: 0.015-0.03%, other impurities individually ≤0.05%, other impurities total ≤0.10%, and the rest is Al. The melting temperature is 740--760°C, the refining temperature is 730--750°C, the casting temperature is 685--700°C, and the casting speed is 50--60mm / min;

[0029] (2) Face milling: use a milling machine to mill the large face and the small face of the ingot respectively, and the milling amount is 8mm and 6mm respectively;

[0030] (3) Heating: the heating temperature of the ingot is set at 540°C, the holding time is 2 hours, and the furnace is turned to 510°C for 3 hours;

[0031] (4) Hot rolling: After hot rough rolling at 500°C, the ingot is roughly rolled to a th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com