Patents

Literature

41results about How to "Reduce the annealing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

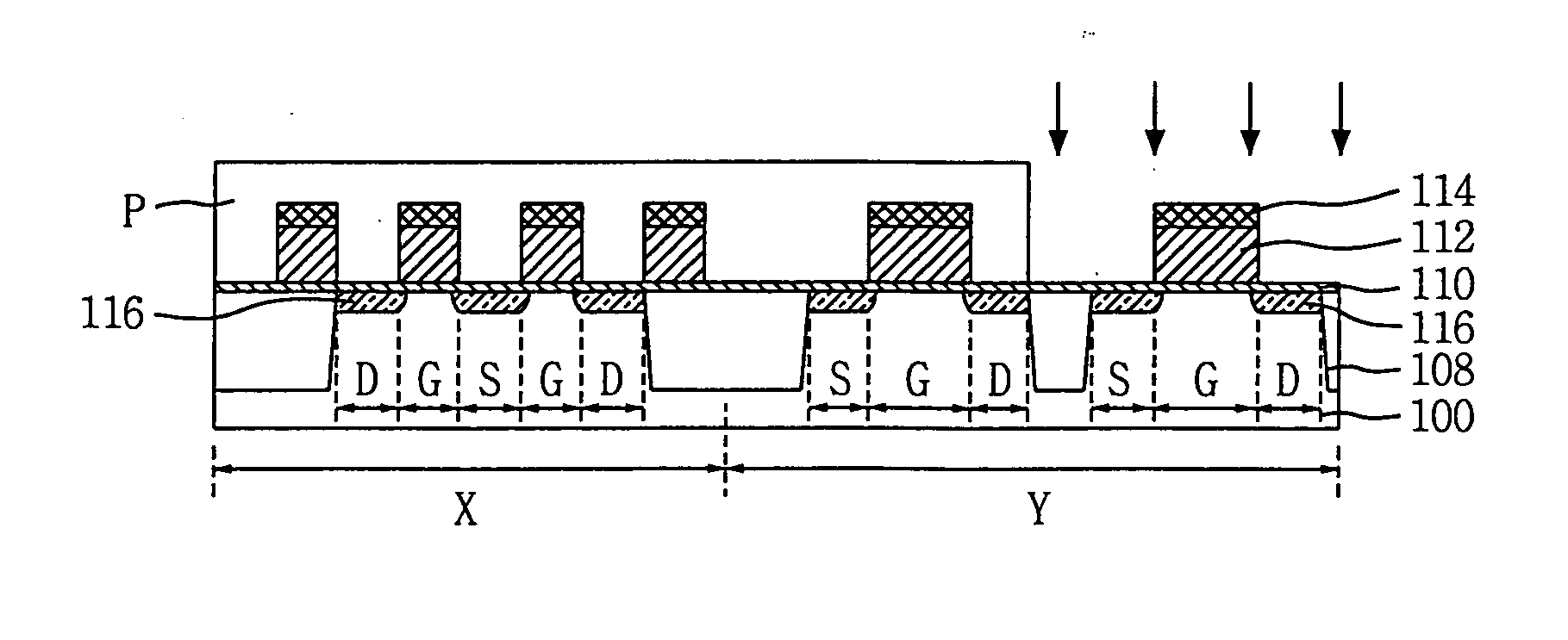

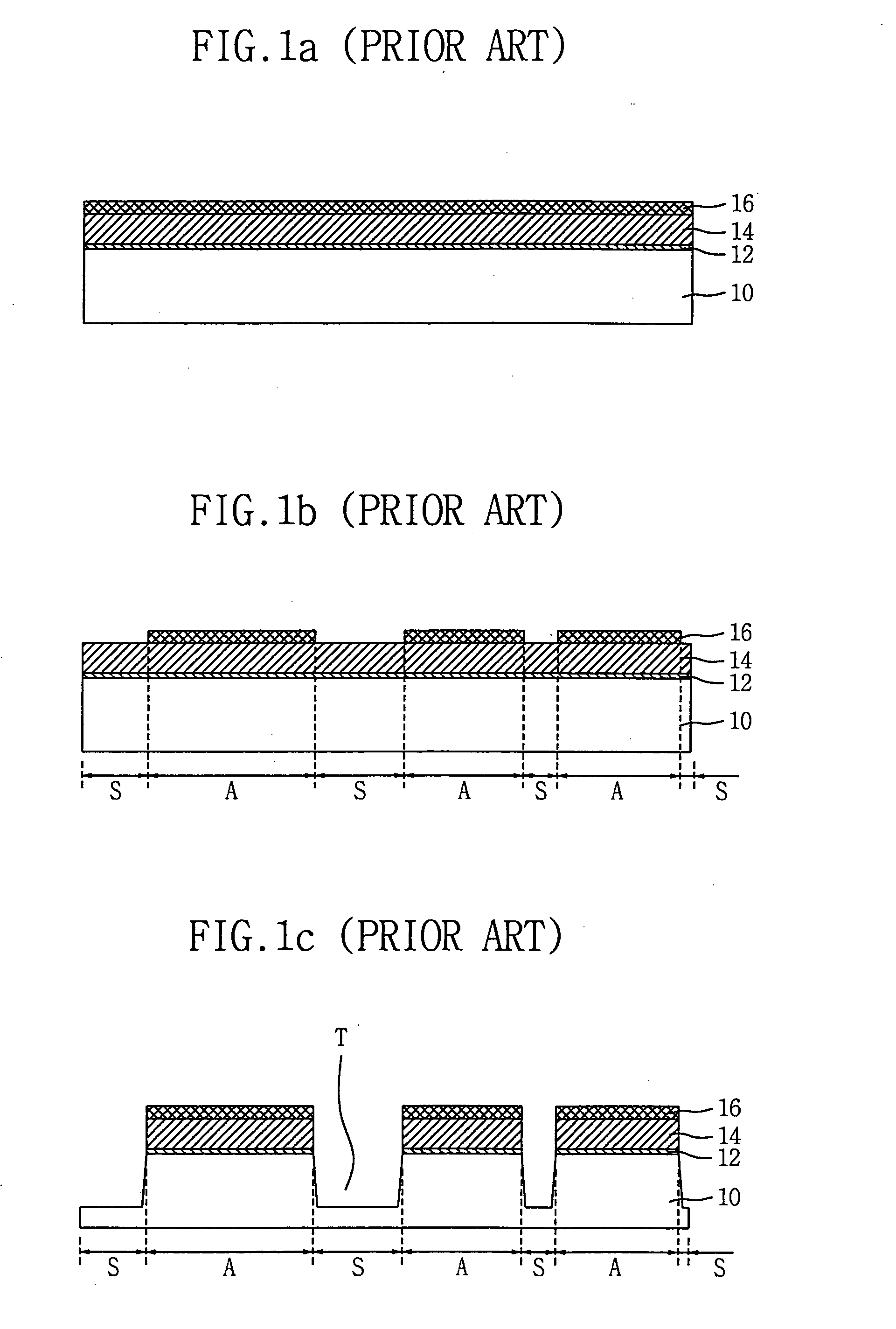

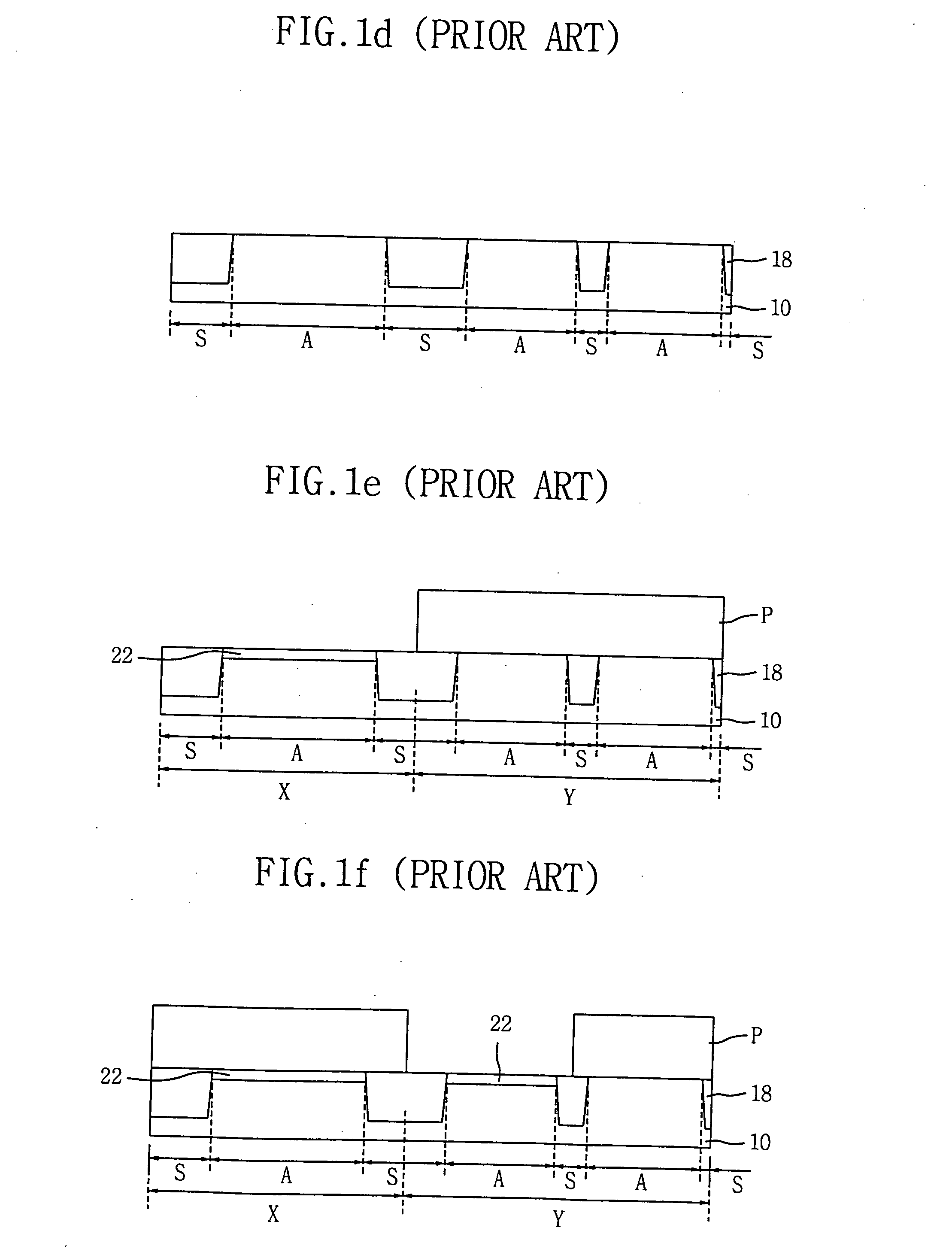

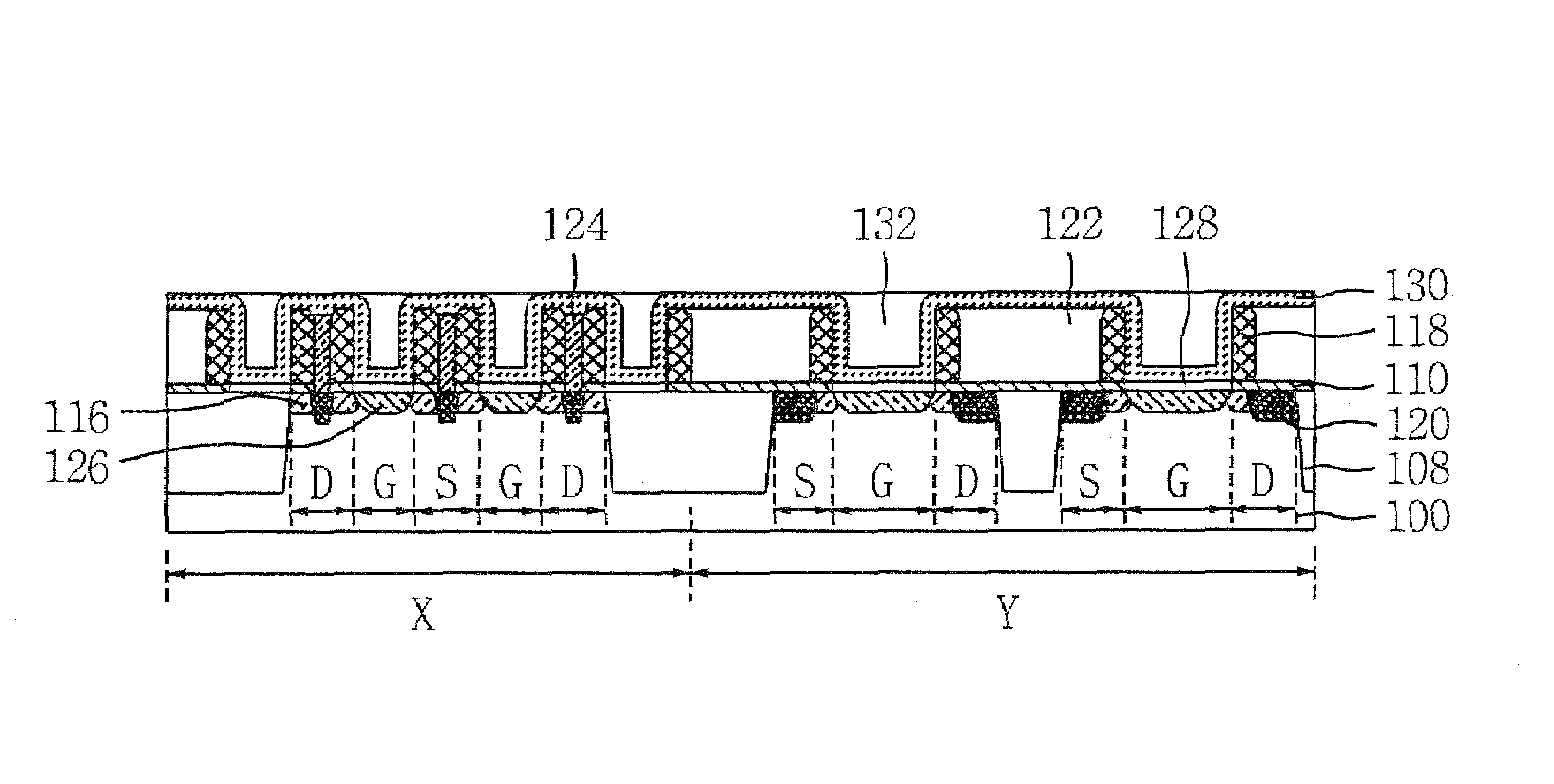

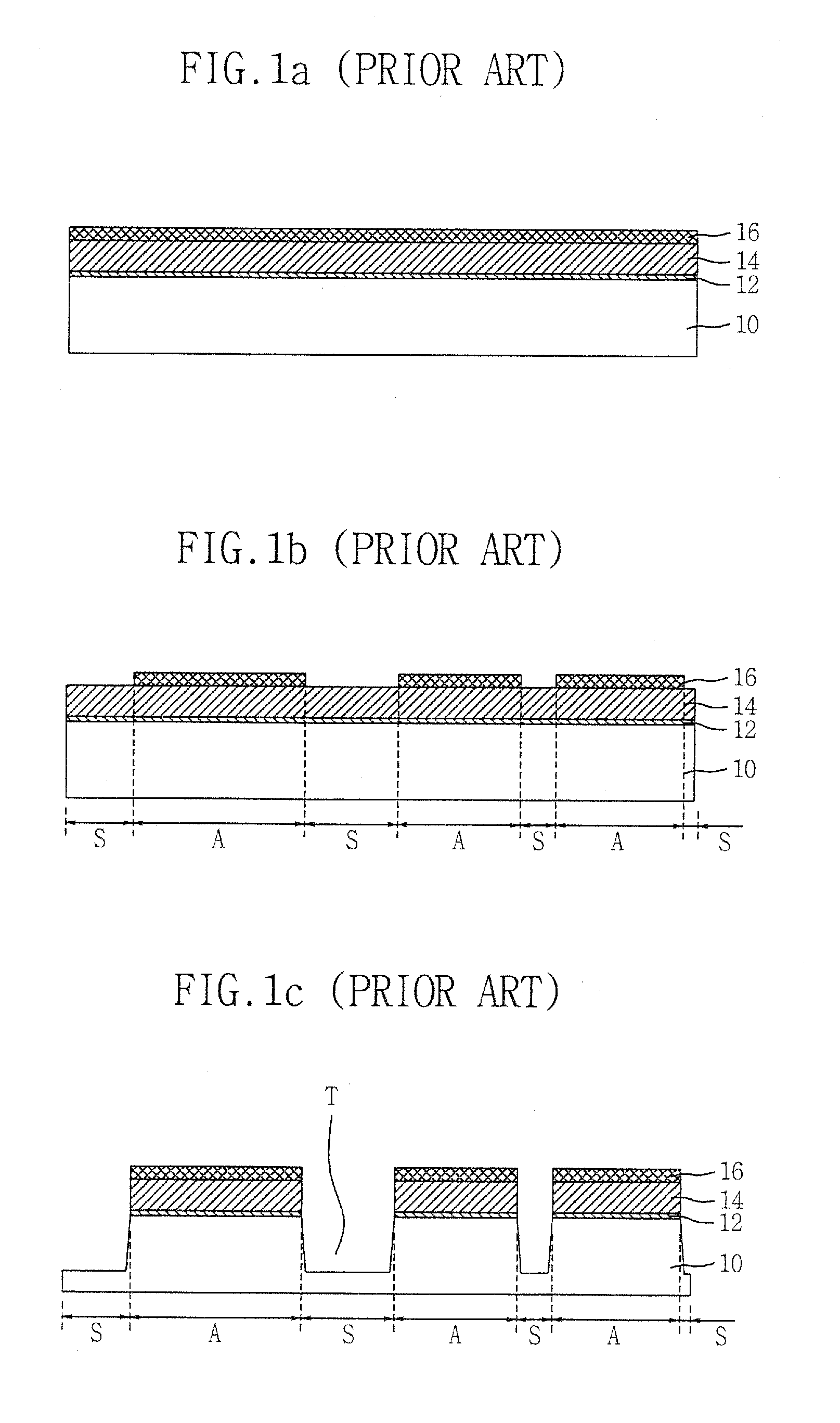

Method of manufacturing a transistor

InactiveUS20050048729A1Avoid leakage currentReduce the annealing processSemiconductor/solid-state device manufacturingSemiconductor devicesInsulation layerGate oxide

A method of manufacturing a transistor according to some embodiments includes sequentially forming a dummy gate oxide layer and a dummy gate electrode on an active region of a semiconductor substrate, ion-implanting a first conductive impurity into source / drain regions to form first impurity regions, and ion-implanting the first conductive impurity to form second impurity regions that are overlapped by the first impurity regions. The method includes forming a pad polysilicon layer on the source / drain regions, sequentially removing the pad polysilicon layer and the dummy gate electrode from a gate region of the semiconductor substrate, annealing the semiconductor substrate, and ion-implanting a second conductive impurity to form a third impurity region in the gate region. The method includes removing the dummy gate oxide layer, forming a gate insulation layer, and forming a gate electrode on the gate region.

Owner:SAMSUNG ELECTRONICS CO LTD

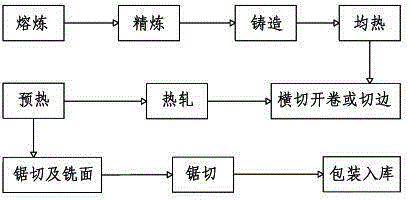

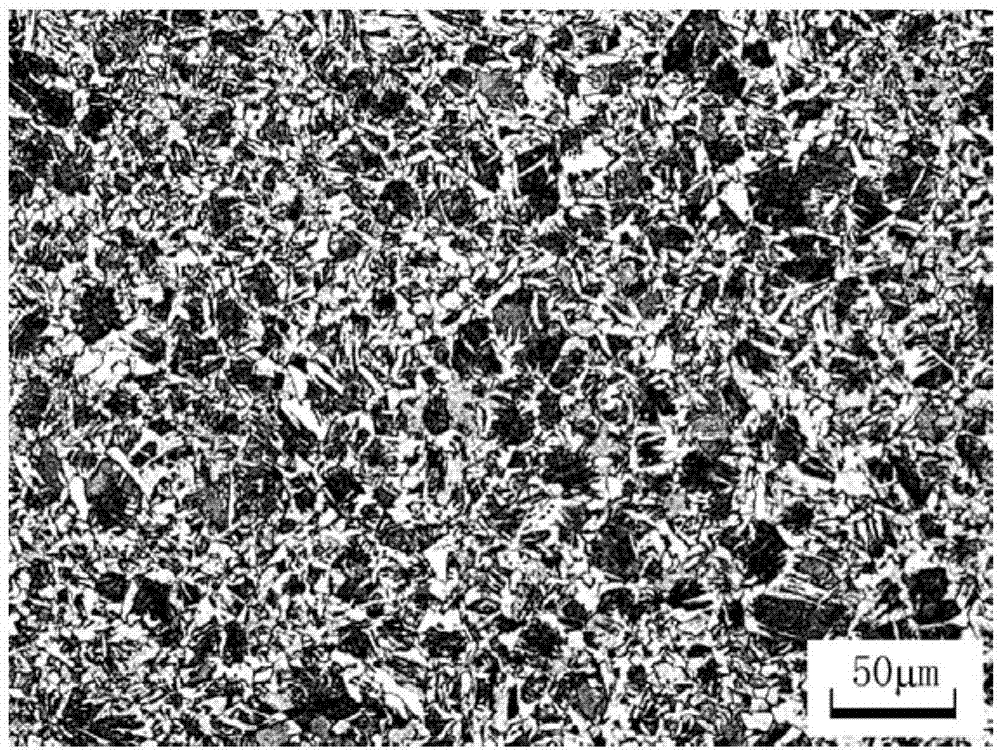

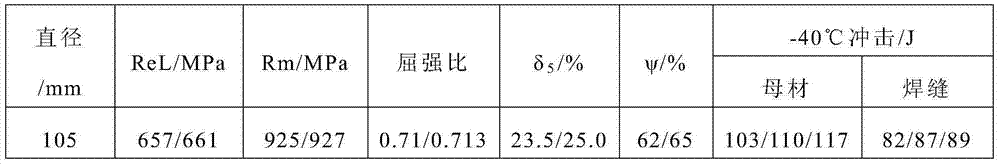

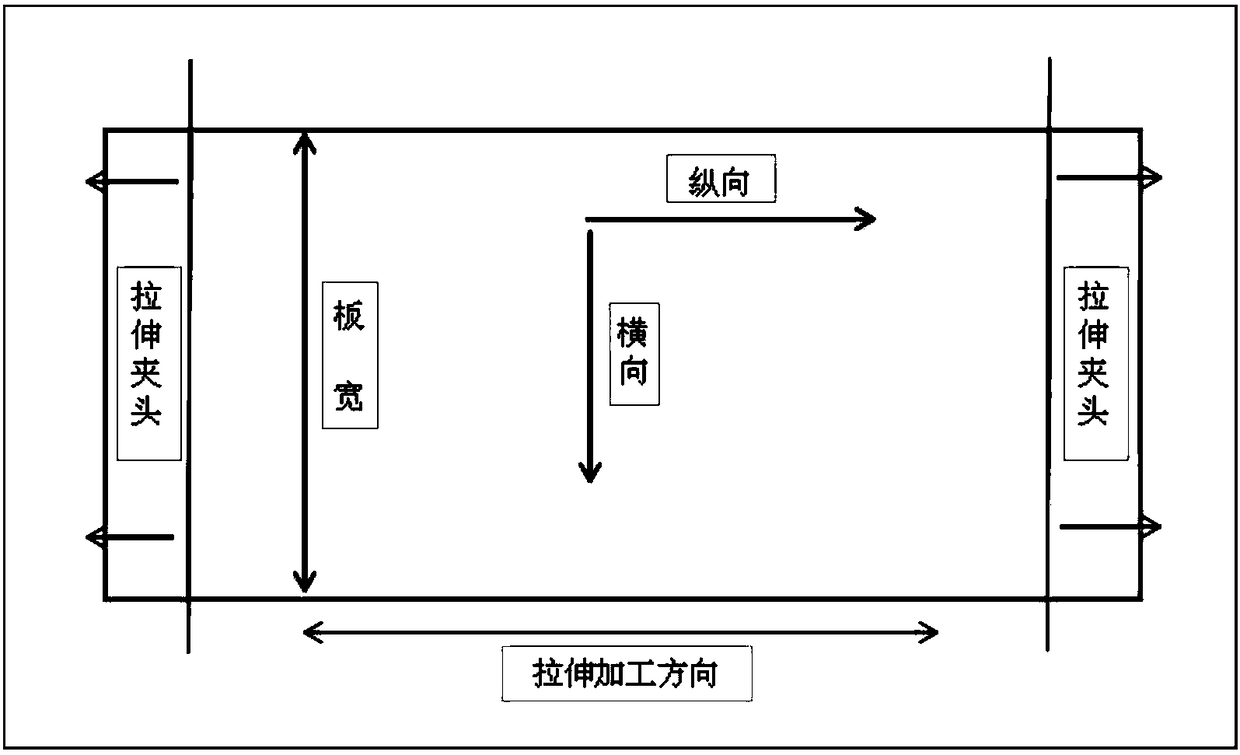

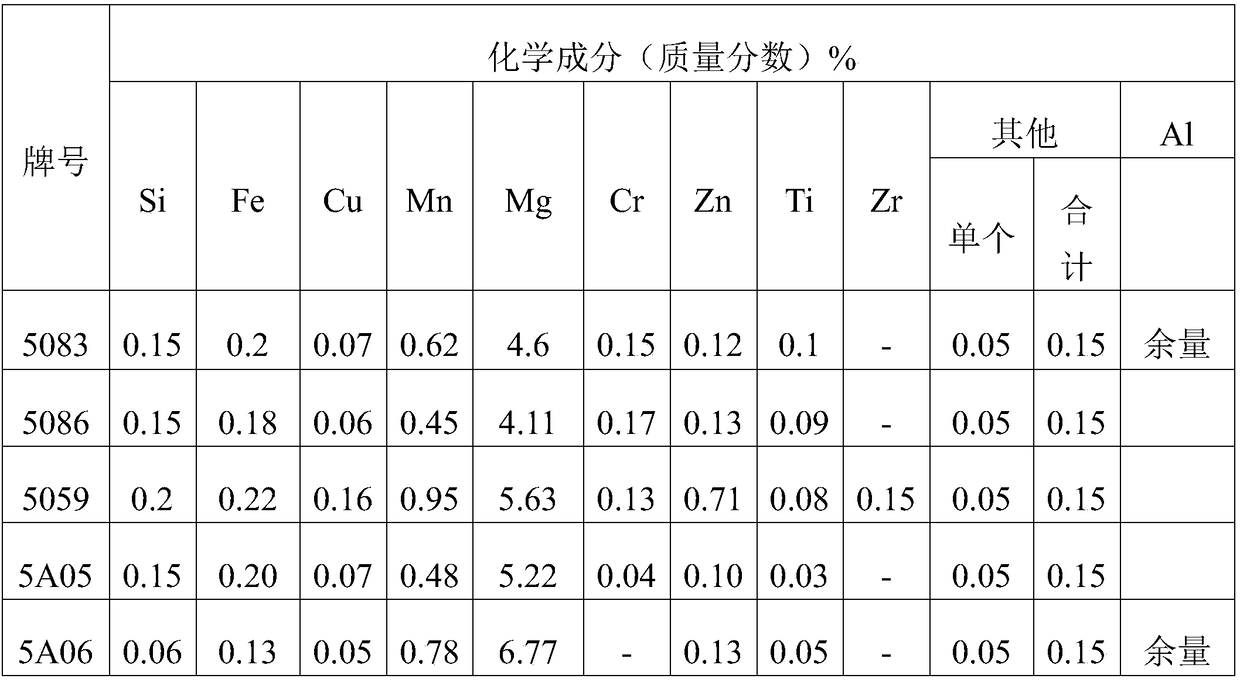

Preparation method for high-magnesium aluminum alloy O-state plate of 5XXX series

InactiveCN105177327AReduce the production process of annealingReduce production processHigh magnesiumAlloy

The invention relates to a preparation method for a high-magnesium aluminum alloy O-state plate of 5XXX series. The method comprises the steps of smelting, refining, casting, soaking, saw cutting, surface milling, preheating, hot rolling, cross-cutting and uncoiling or edge trimming, saw cutting, packaging and warehousing and the like. According to the preparation method, the high-magnesium aluminum alloy O-state plate of the 5XXX series is prepared through a new production process, under the condition that the performance and structure stability of high-magnesium aluminum alloy are maintained, the production procedures can be reduced, and surface quality defects of the high-magnesium aluminum alloy can be reduced; products can be directly produced after the aluminum alloy plate with the thickness being equal to or larger than 3 mm is subjected to hot rolling, the product yield can be substantially increased, and production efficiency can be improved sufficiently.

Owner:广西南南铝加工有限公司

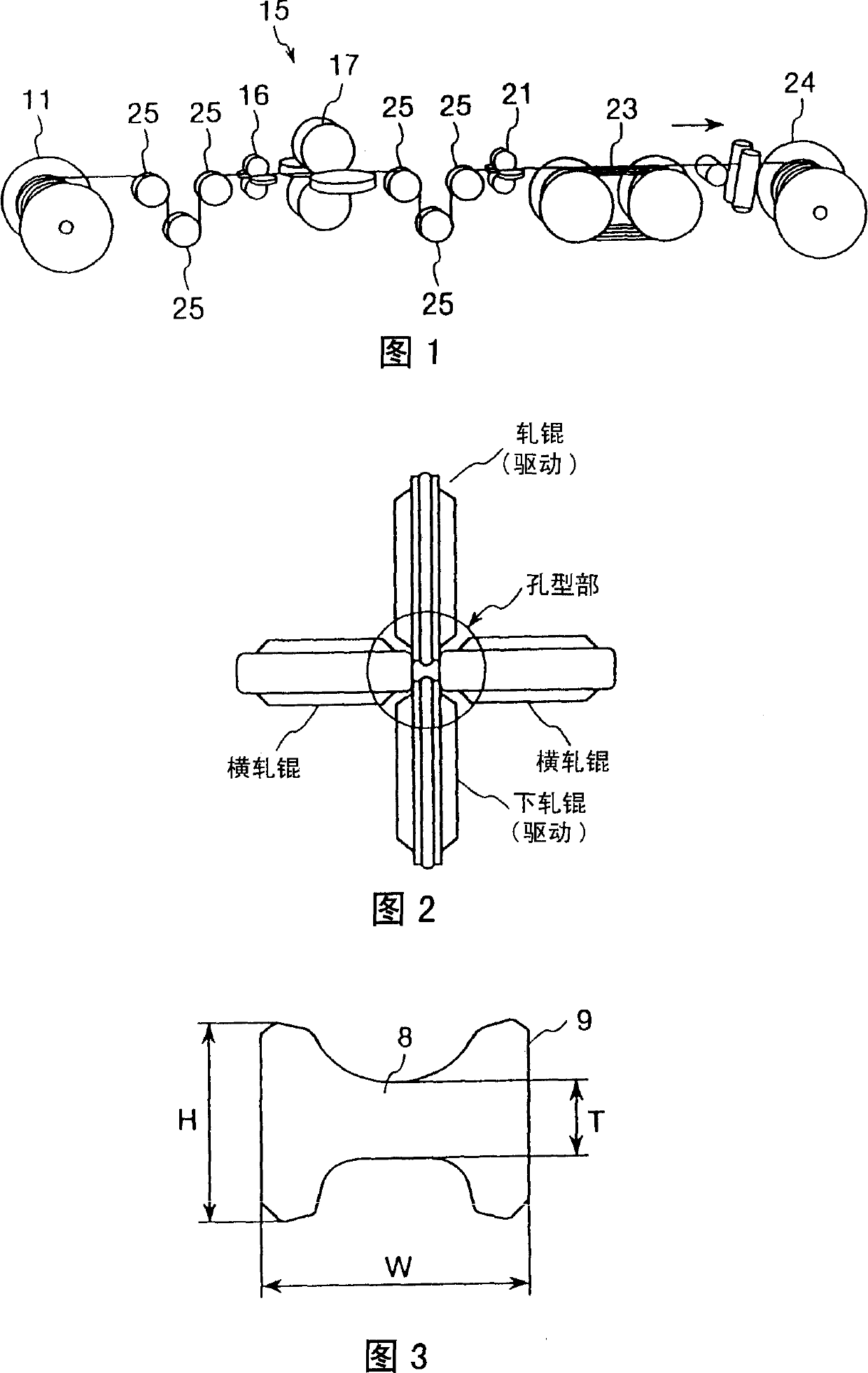

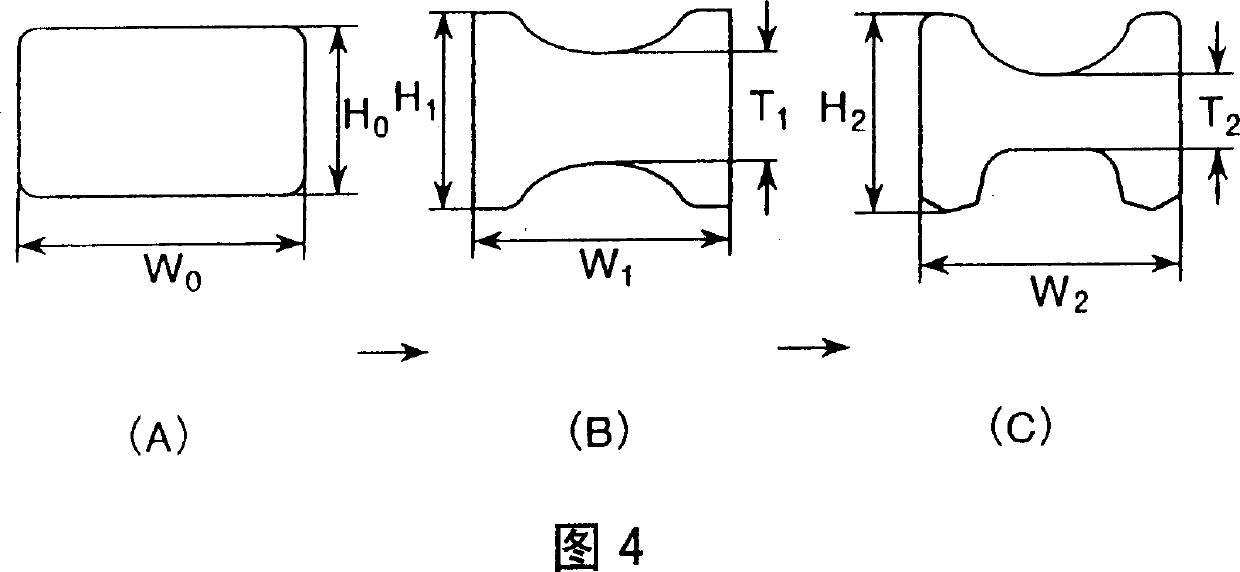

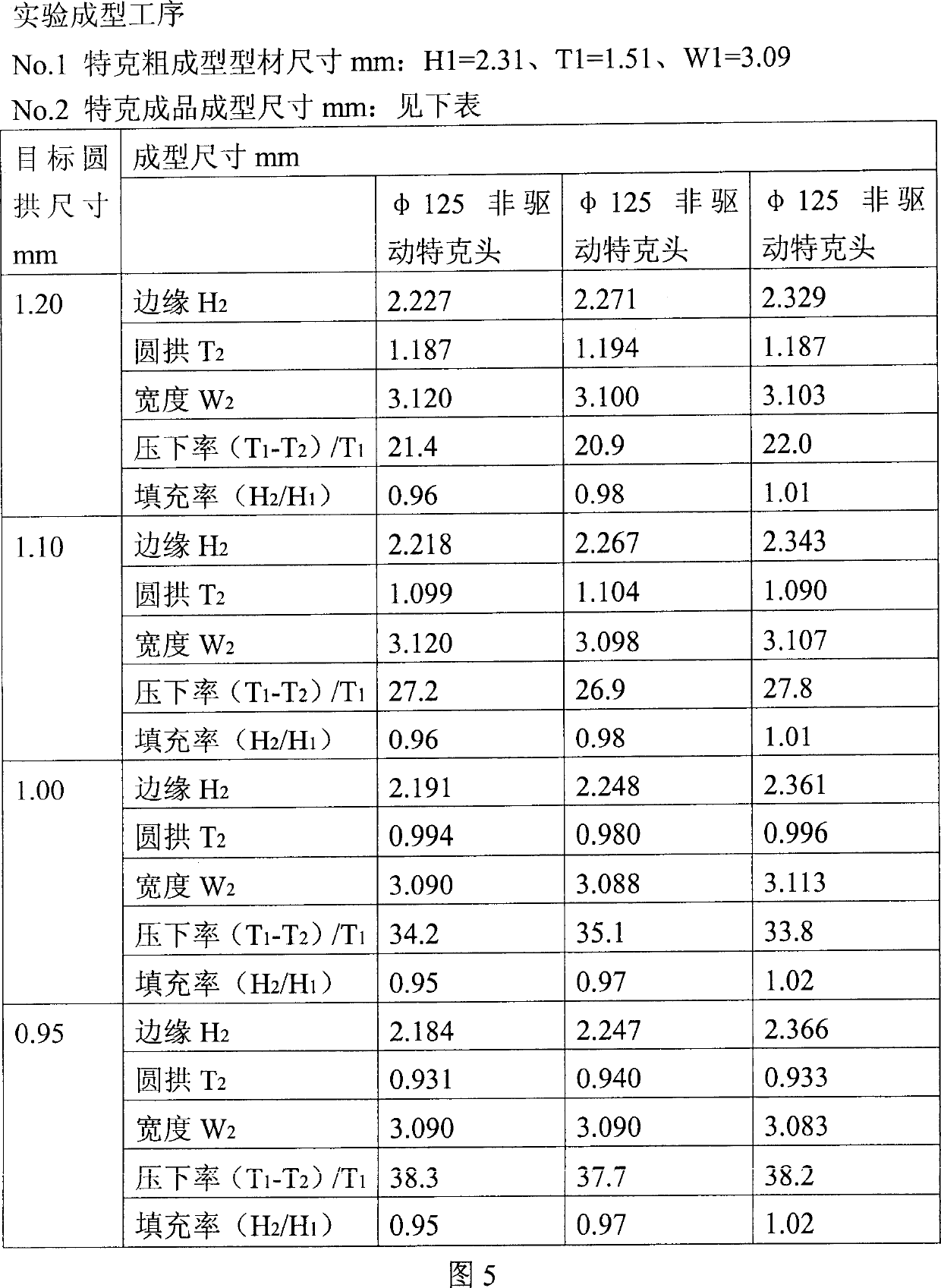

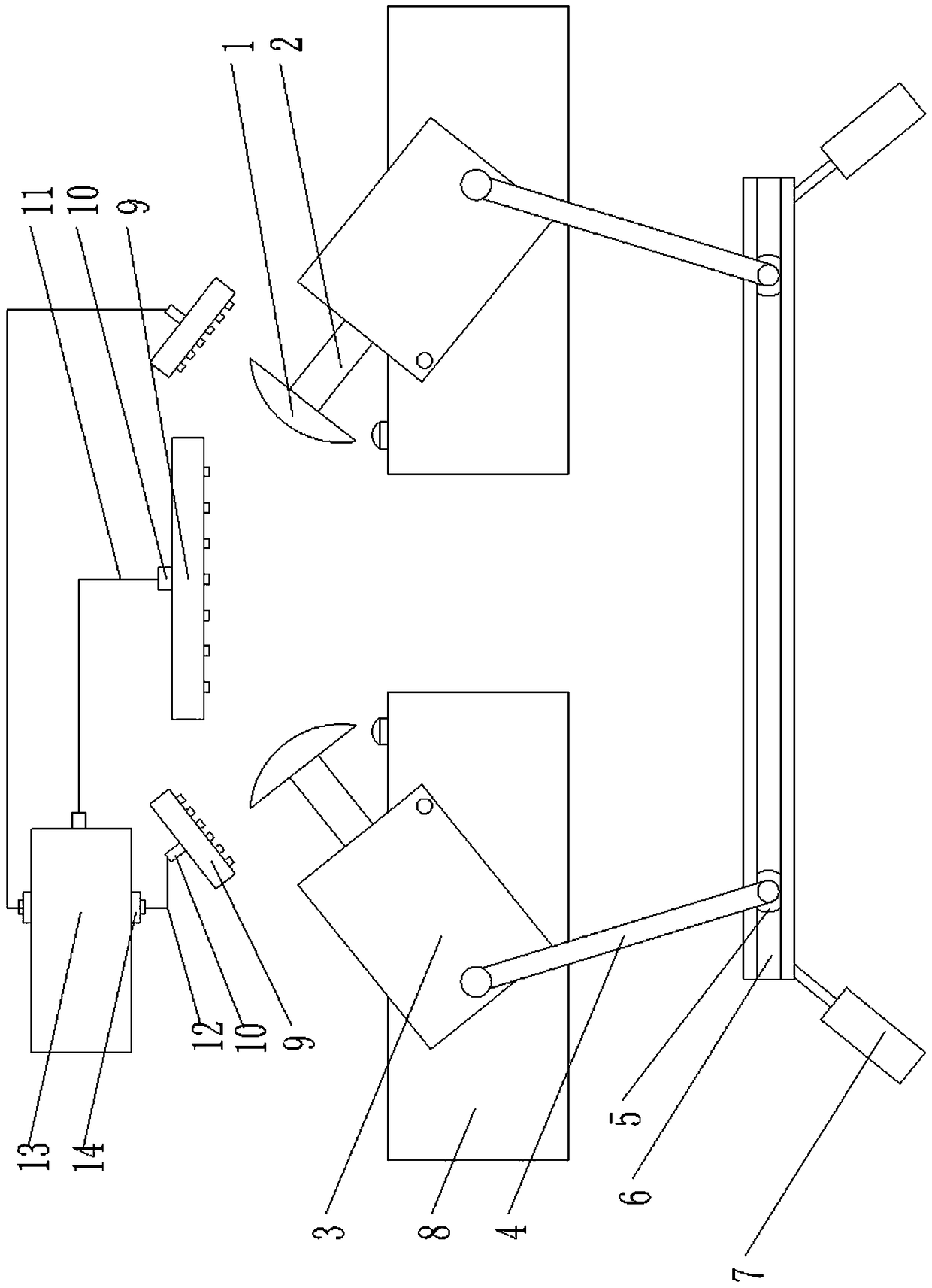

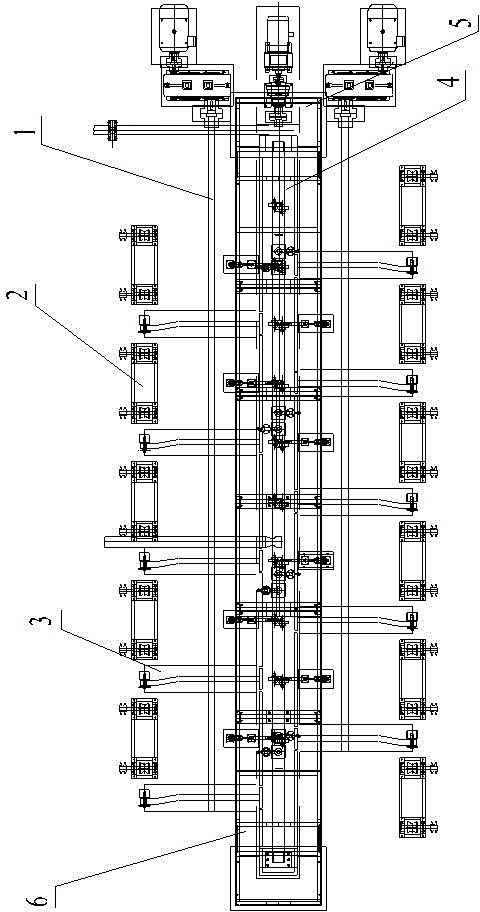

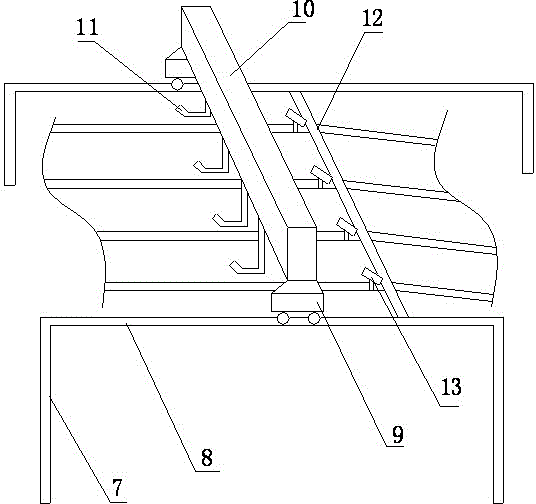

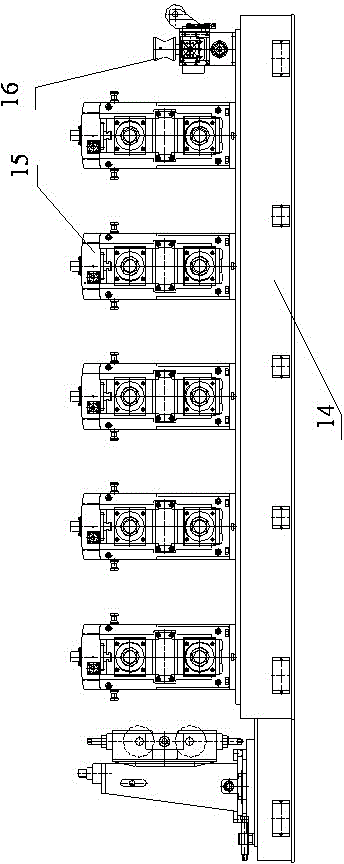

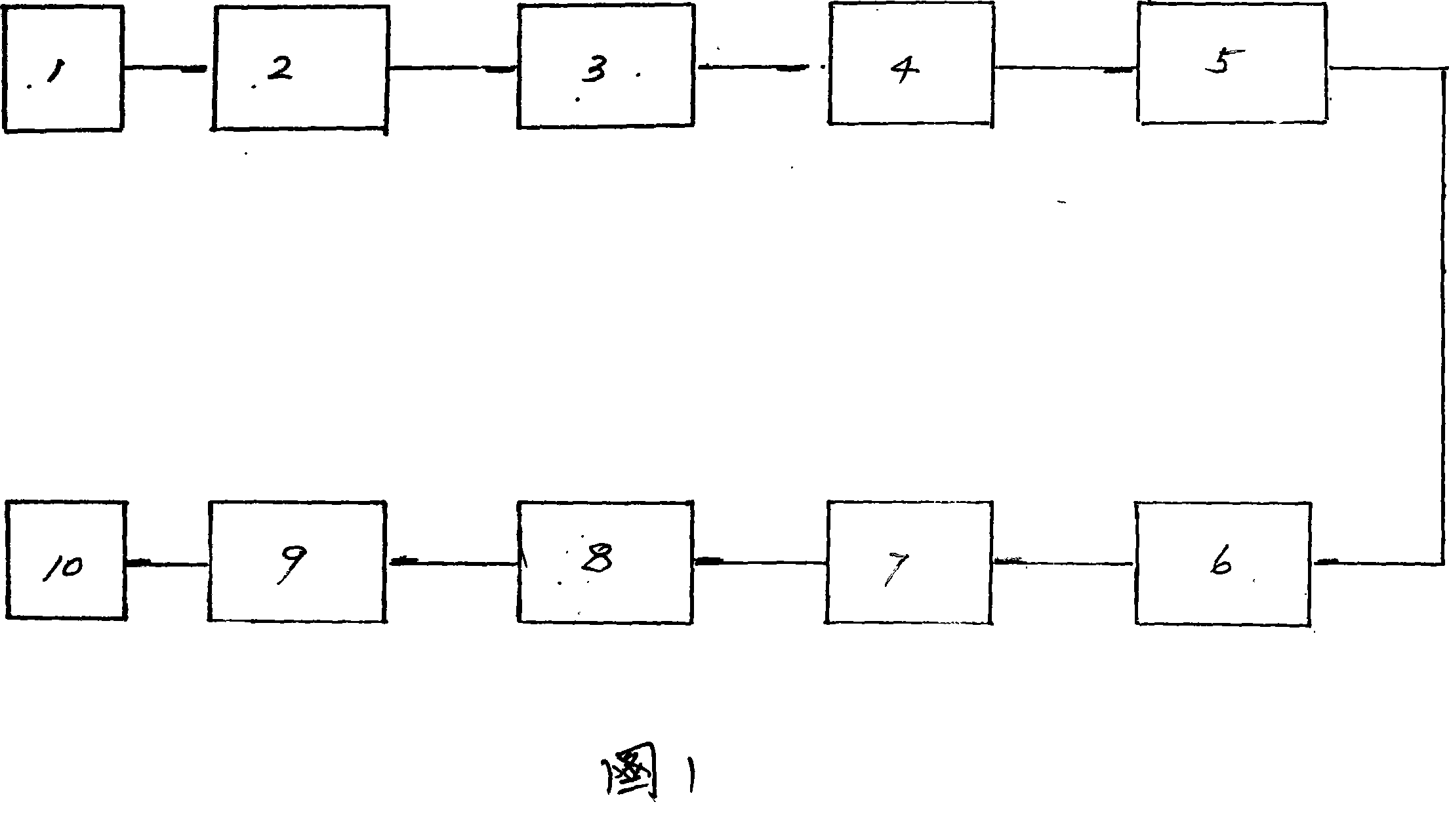

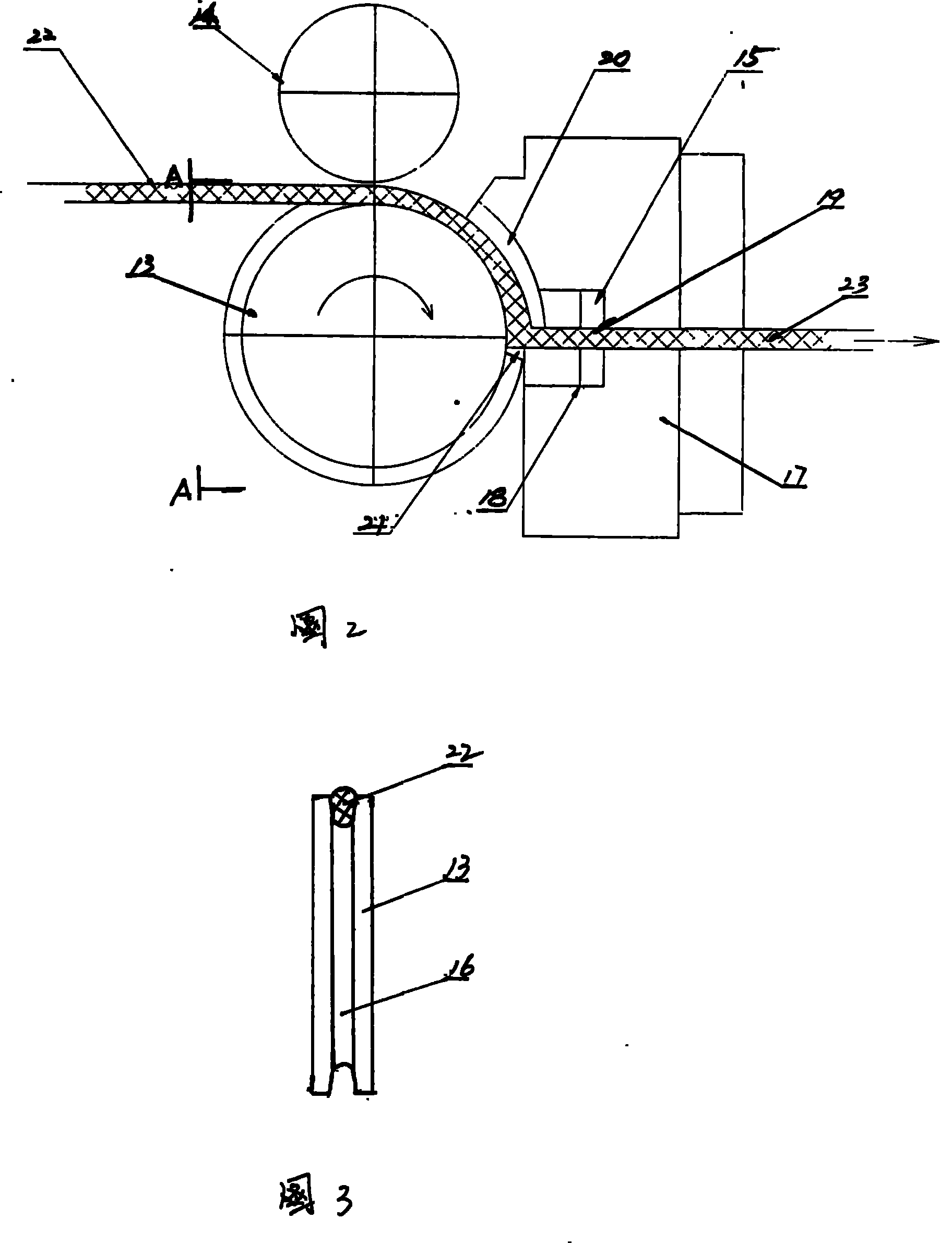

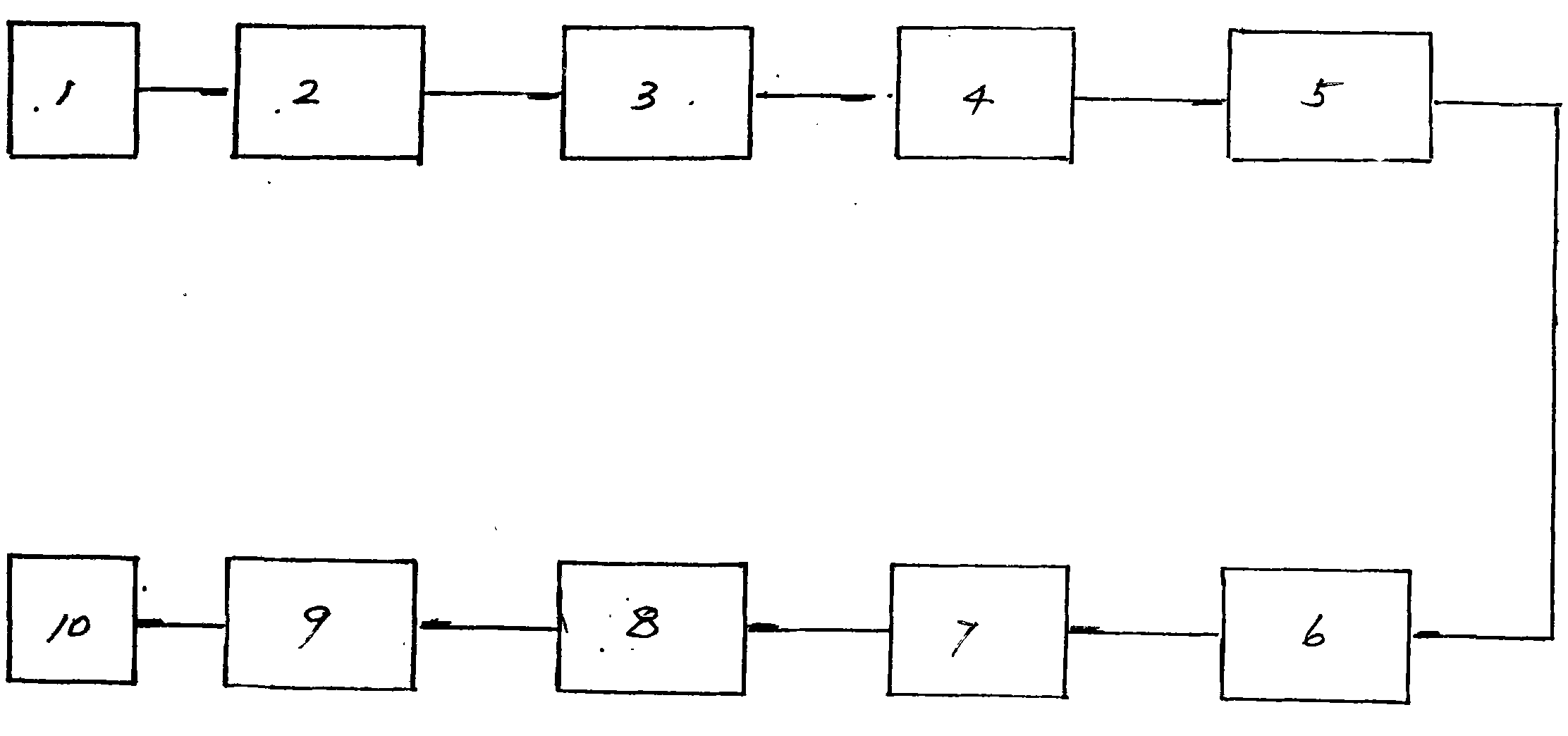

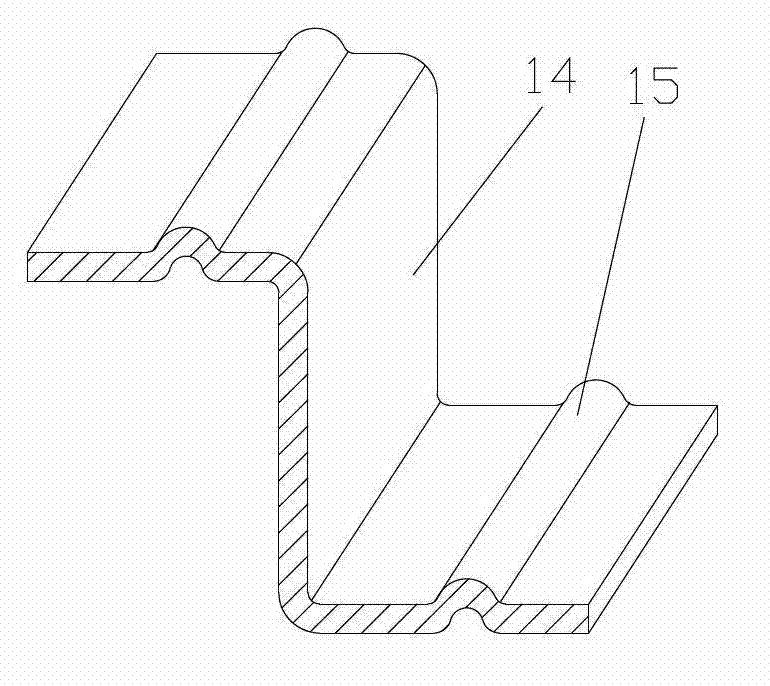

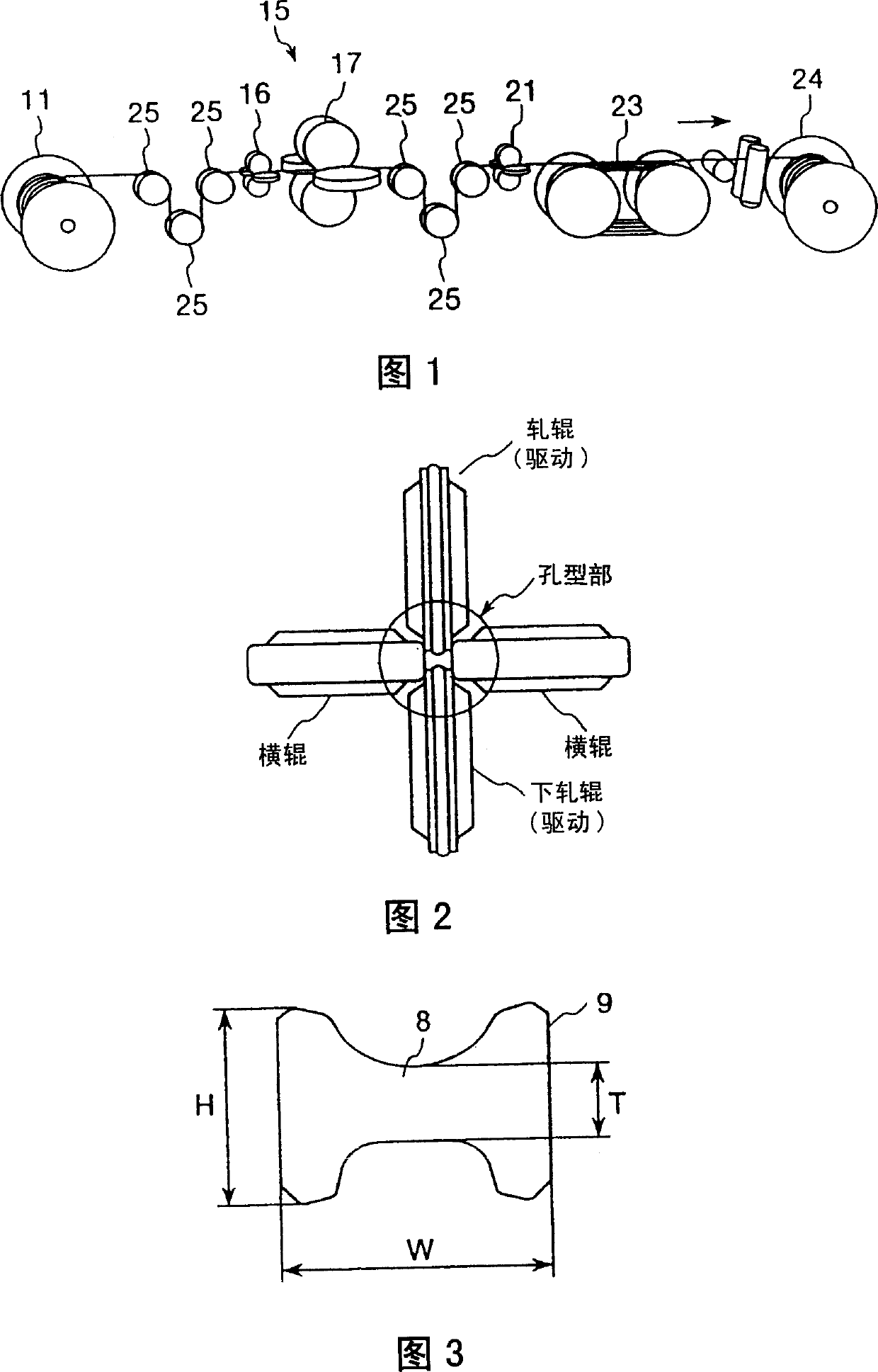

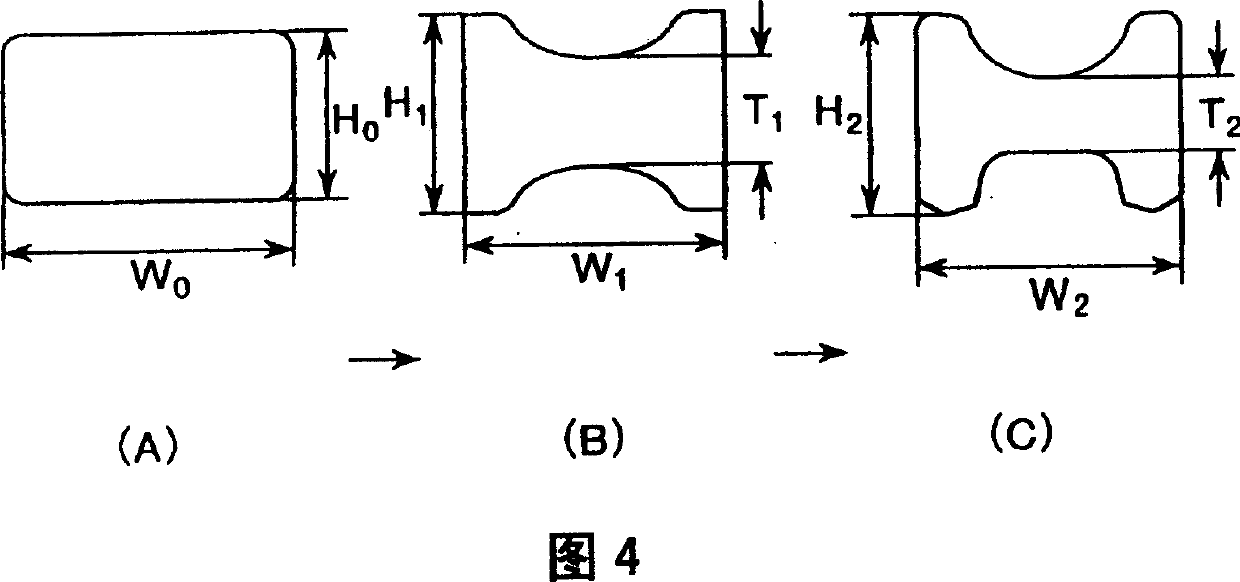

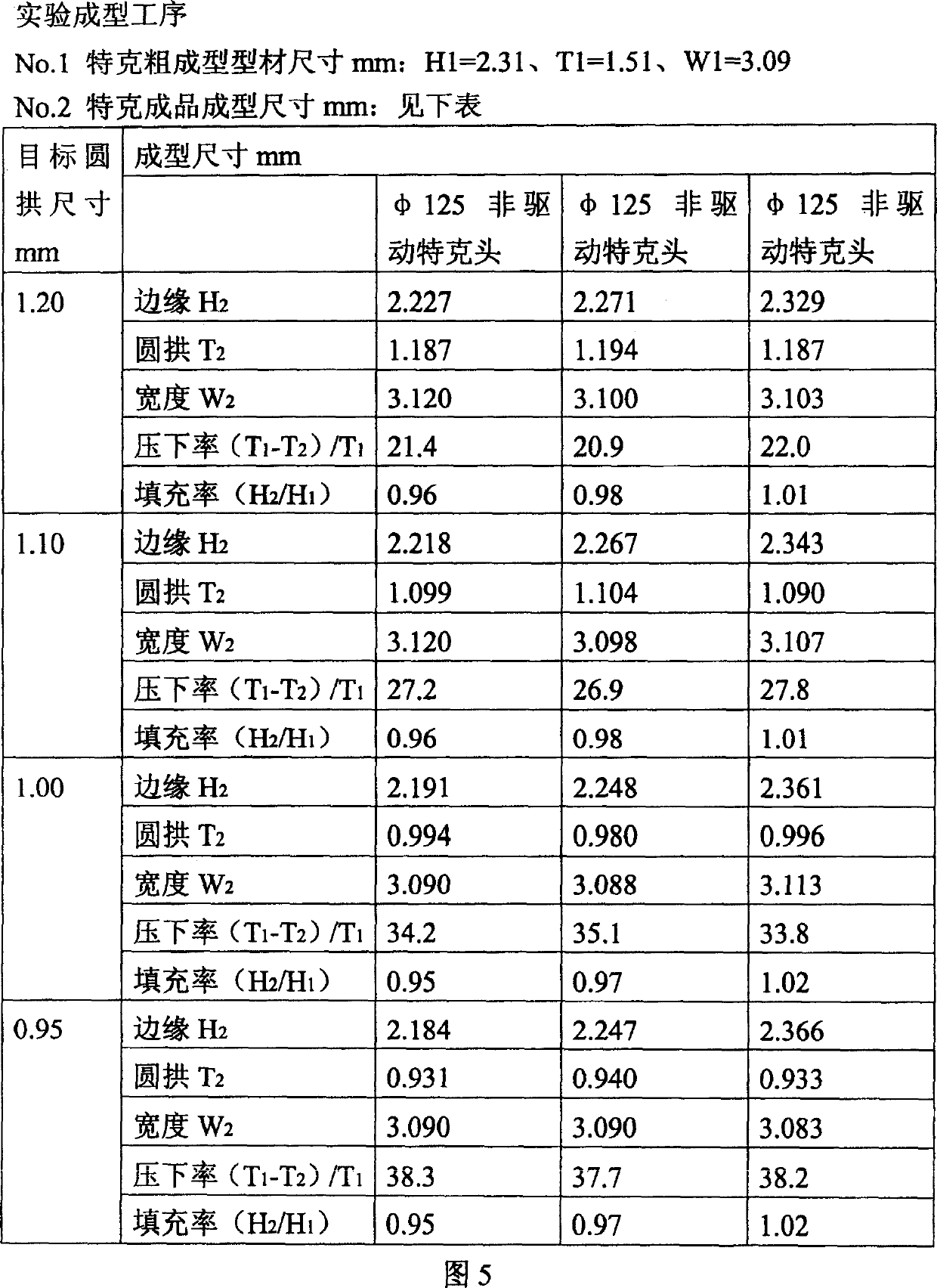

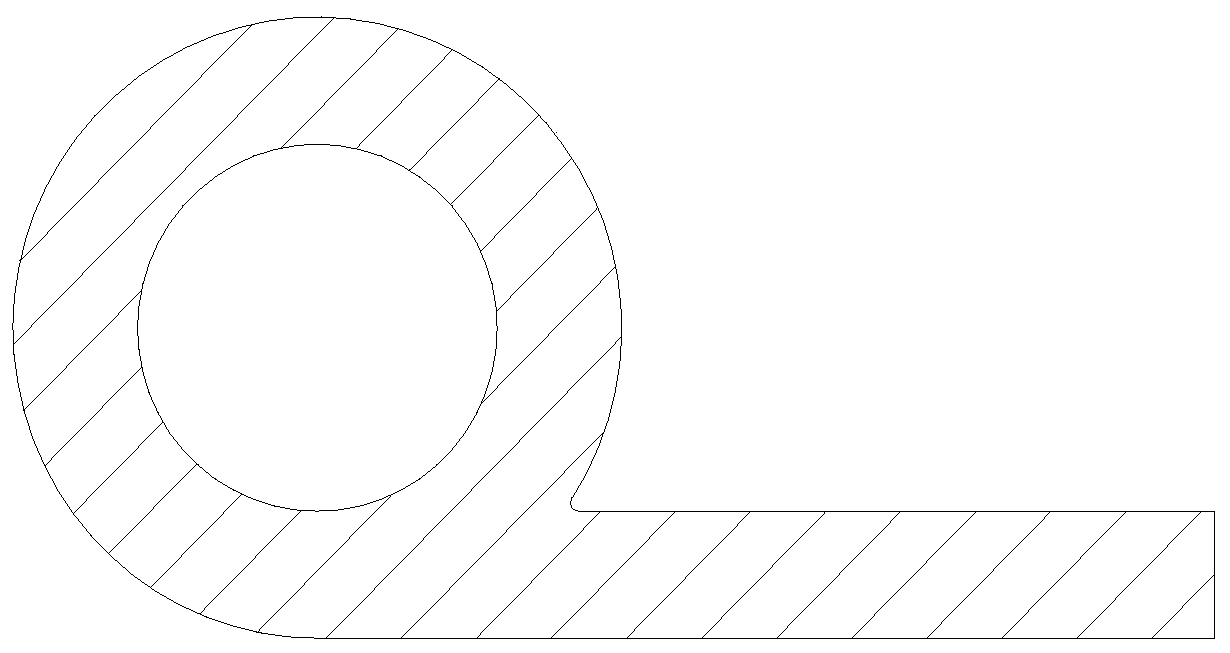

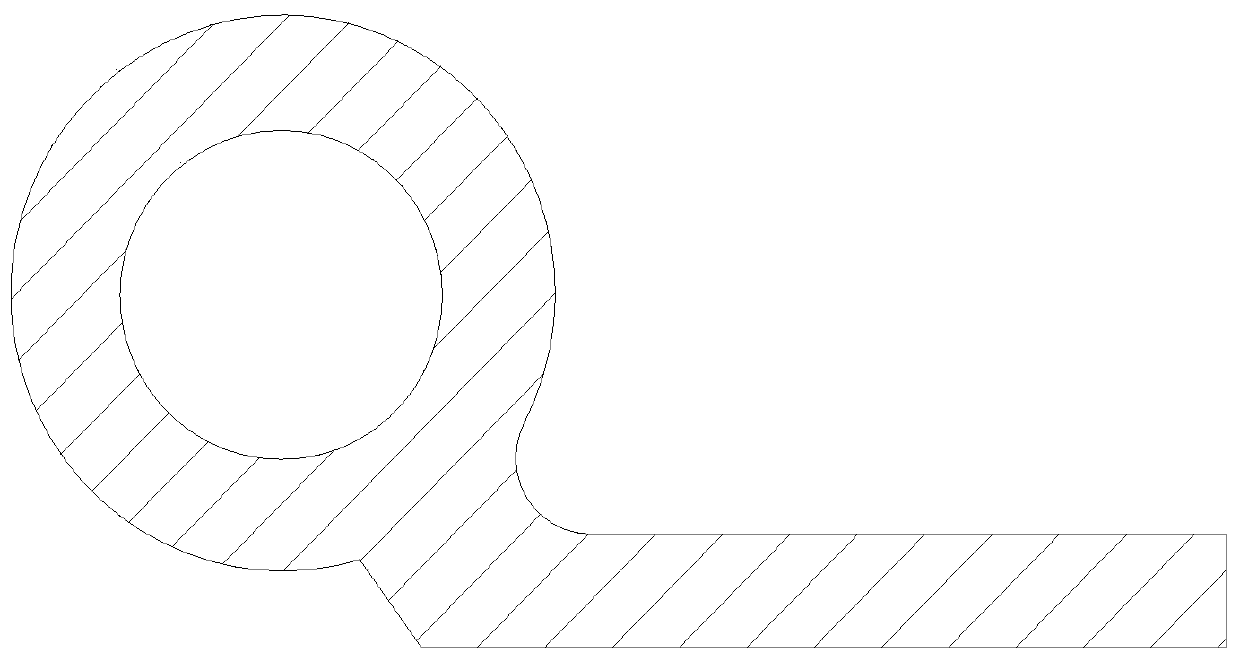

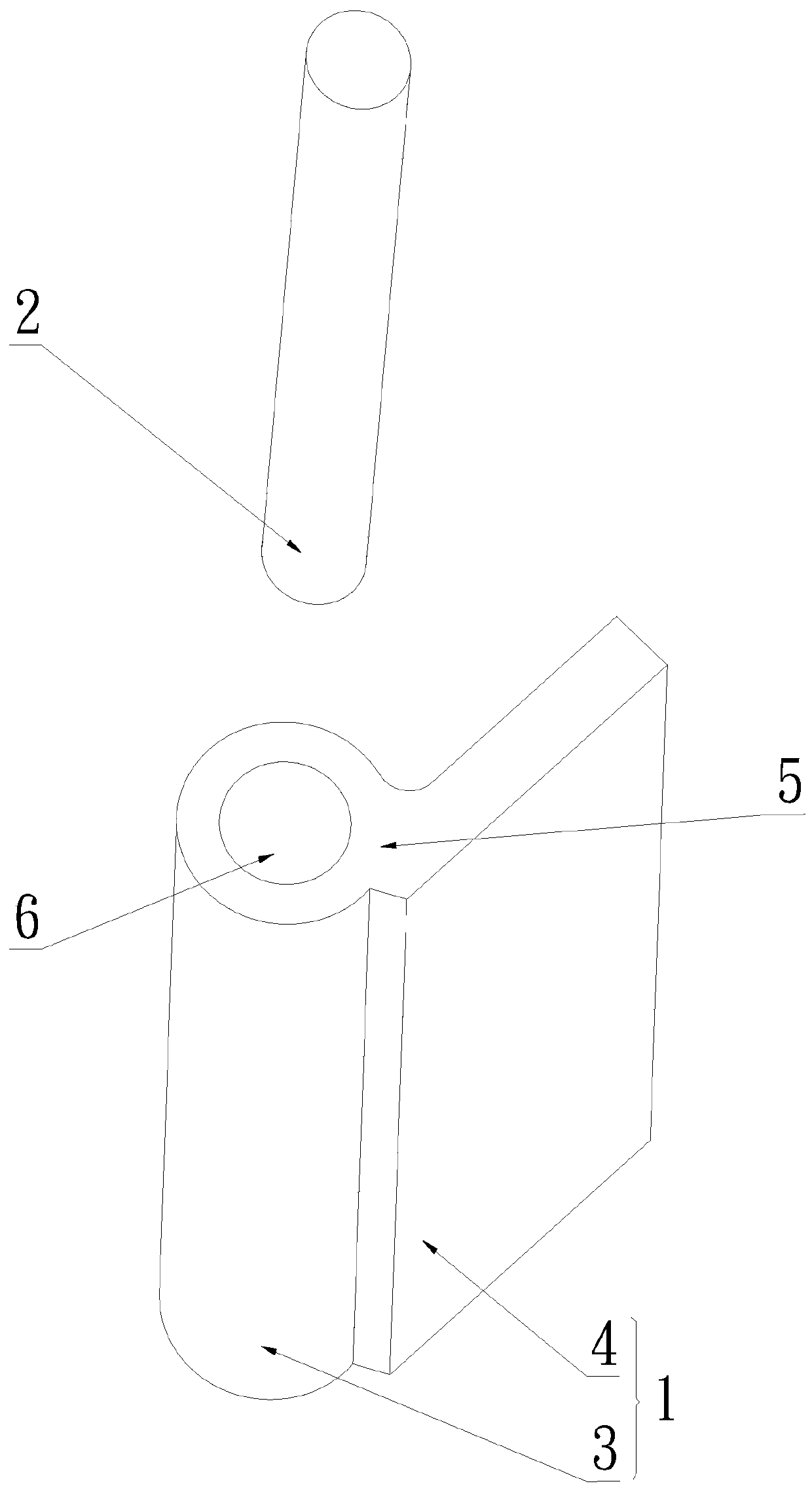

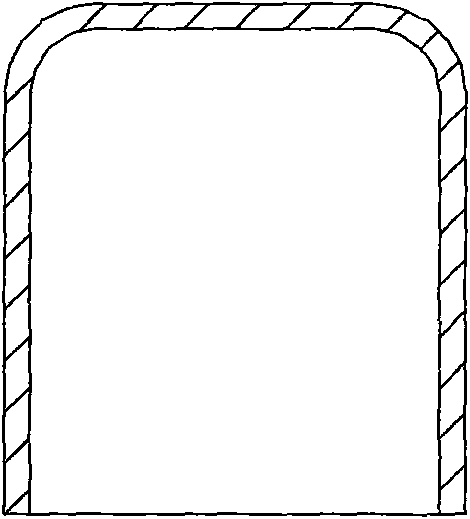

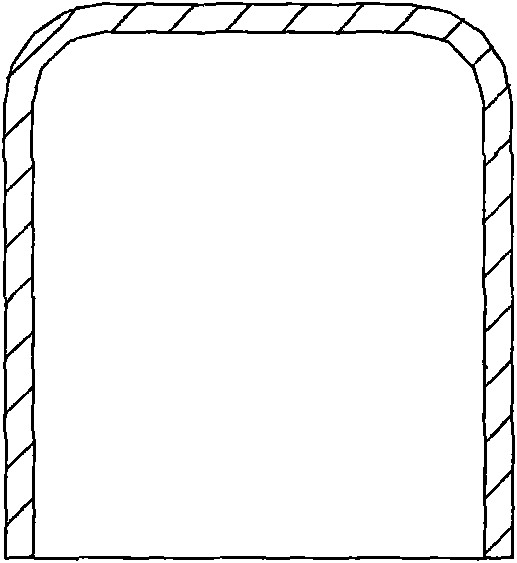

Method and apparatus for forming special-shaped wire material

InactiveCN1507960AImprove fill rateThe number of forming times is reducedMetal rolling arrangementsEngineeringTension control

The present invention provides a forming method of shaped wire material and its equipment. Said equipment has a forming unit formed from combination of non-driven front part 4 square roll turks heads and power-driven rear part 4 square roll turks heads, and the rear portion of the forming unit is equipped with successively and straight-line arranged non-driven 4 square roll turks heads with finishing roll line. The forming roll of power-driven turks head has the diameter which is above 70 times greater than height of edge of formed material, and the tension beared by formed material between the above-mentioned non-driven turks heads and power-driven turks head can be controlled below 300N. Said invention can high-effectively and high-accurately produce shaped wire material.

Owner:HITACHI METALS LTD

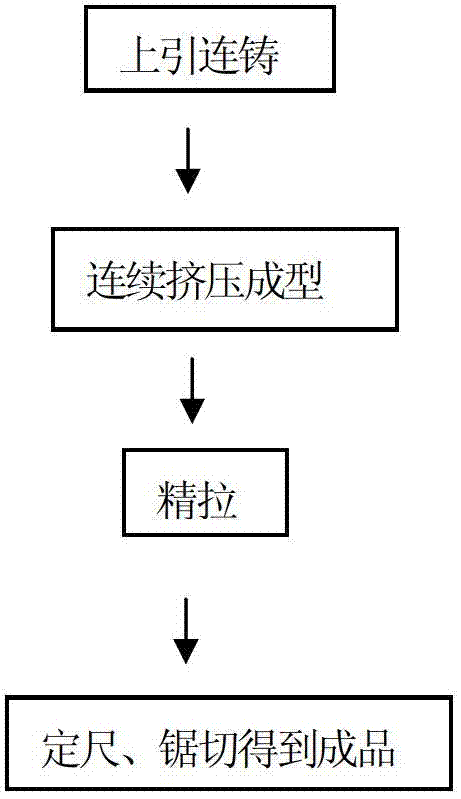

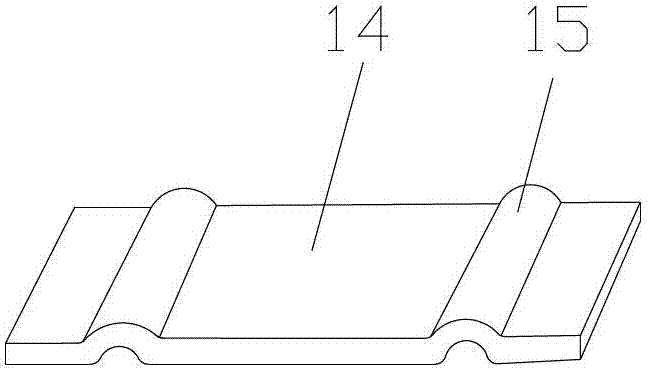

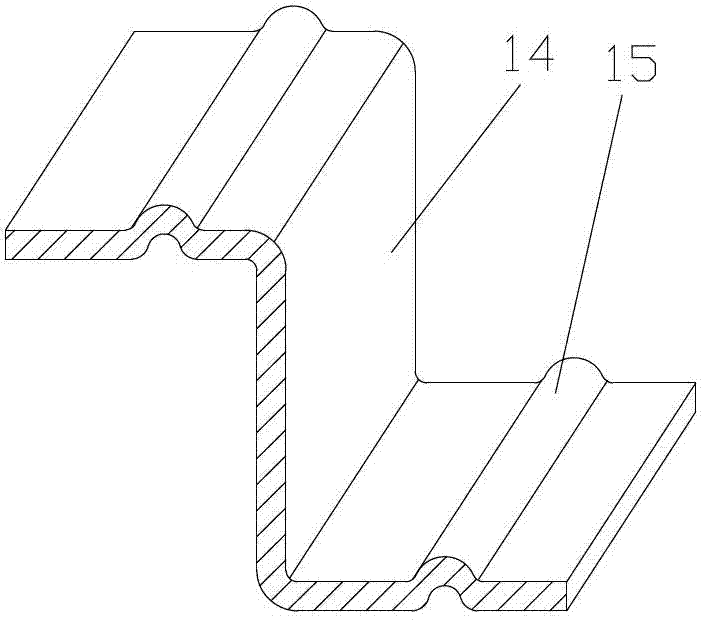

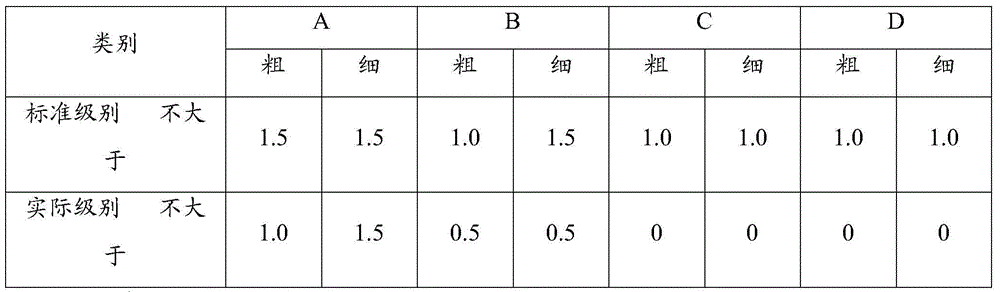

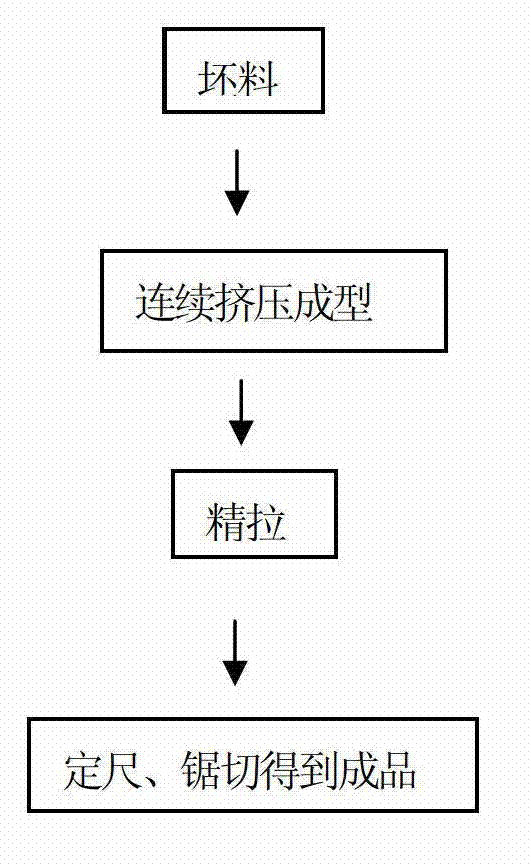

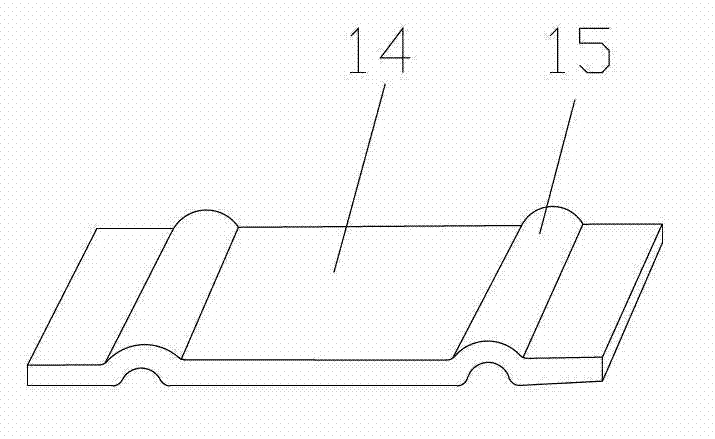

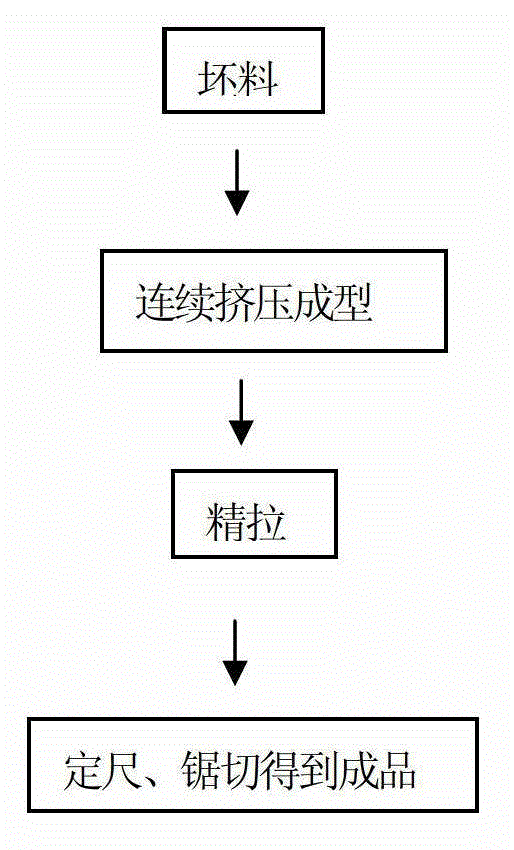

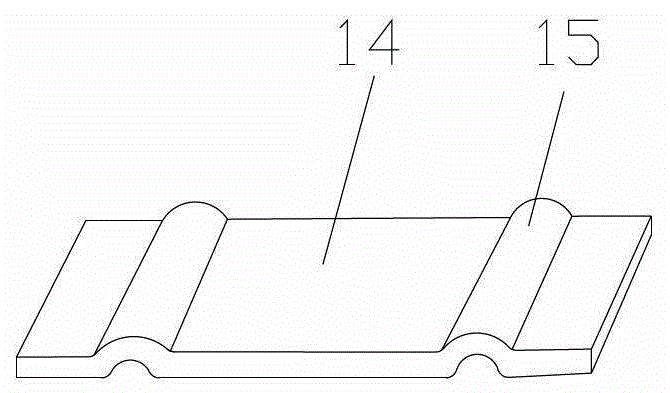

Continuous production technique of special-shaped hollow current conducting plates for electrolysis

ActiveCN102862027AImprove organization and performanceShorten the production cycleContinuous productionEngineering

The invention relates to the field of special-shaped hollow current conducting plates for copper electrolysis technique and especially relates to a continuous production technique of special-shaped hollow current conducting plates for electrolysis, and the continuous production technique comprises: upward continuous casting, continuously extrusion forming, precise drawing and determining the dimension and sawing to obtain a finished product. The current continuous extruding mainframe equipment is reformed, and the invention provides a continuous production technique of deformed hollow current conducting plates for electrolysis, which has short procedure, little investment, high efficiency and energy conservation is provided. The special-shaped hollow current conducting plate for electrolysis produced by the technique has the advantages of high yield, dense product tissue, small crystalline grain, excellent metallographic structure and excellent mechanical property and electrical conductivity, and the forming precision required by the copper electrolysis technique is satisfied; and the good drapability and reliable conductive contact of cathode plates and anode plates are guaranteed. The invention can solve such problems in the prior art as large raw material inventory, complex production technique procedures and difficult control of product quality, etc.

Owner:江西九星铜业有限公司

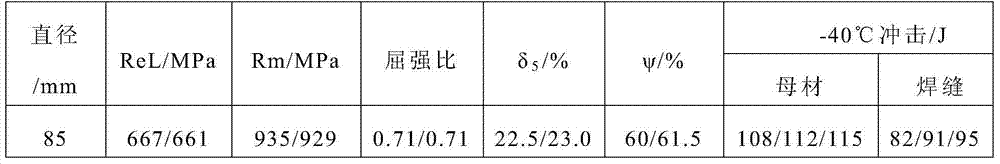

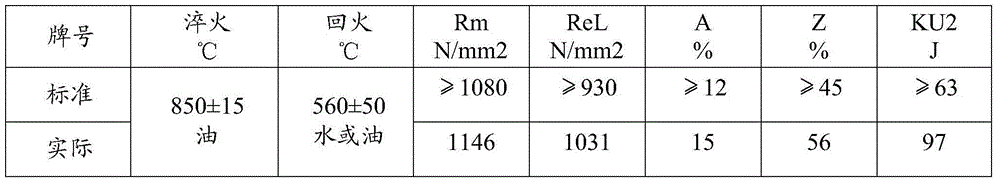

Steel for R4-grade mooring cables and preparation method thereof

InactiveCN103882346AReduce C contentAvoid organizational transformationTemperature control deviceChemical compositionHigh intensity

The invention discloses a steel for R4-grade mooring cables and a preparation method thereof. The steel comprises the following components in percentage by weight: 0.15-0.24% of C, 0.15-0.30% of Si, 1.2-1.60% of Mn, at most 0.025% of P, at most 0.025% of S, at most 0.02% of Cu, 0.8-1.3% of Cr, 0.70-1.30% of Ni, 0.2-0.50% of Mo, 0.02-0.05% of Al, at most 0.0050% of As, at most 0.0050% of Sb, at most 0.0050% of Sn, at most 0.0050% of N, at most 0.0020% of O, at most 0.0020% of H, and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: molten iron desulfurization, converter smelting, argon blowing, LF (ladle furnace) refining, RH vacuum treatment, continuous casting, square billet heating, rolling, air cooling and nondestructive flaw detection. The steel for R4-grade mooring cables has the advantages of high strength, high toughness, low cost and corrosion resistance.

Owner:武汉钢铁有限公司

Method for calculating drawing force in aluminum alloy plate preparation process and application thereof

InactiveCN108388706AImprove stabilityHigh dimensional accuracyDesign optimisation/simulationSpecial data processing applicationsUltimate tensile strengthMaterials science

The invention discloses an application of a method for calculating drawing force in an aluminum alloy plate preparation process to production of high-magnesium aluminum alloy plates. The application comprises the following steps of: (1) taking a raw material of high-magnesium aluminum alloy, and carrying out smelting, refining and casting; (2) carrying out two-stage uniform heat treatment and thencarrying out saw cutting and face milling; (3) carrying out preheating and hot rolling; and (4) carrying out side cutting after cooling, and carrying out drawing so as to a high-magnesium aluminum alloy plate, wherein drawing force required by the drawing is F=D*W*R*Kr, and a drawing speed is 1.0-15mm / s. Plates produced by the application keep tissues and corrosion property of high-temperature rolled plates, so that the high-temperature using stability and corrosion property stability of the plates in the later stage are improved; and the plates can be used for ship oceanographic engineering,tanks, armor plates, war industry or high-temperature environment. According to the application, the production processes are simplified, a cold rolling process and an annealing process can be decreased, the yield strength of finished products can be accurately controlled, the plate size precision is improved, the production period is shortened and the production costs of the products are reduced.

Owner:广西南南铝加工有限公司

Production method of 3005-H16 aluminum alloy plate strip

ActiveCN109048222AEliminate unevennessEliminate coarse grainsMetal rolling arrangementsFurnace temperatureChemical composition

The invention relates to an aluminum alloy plate strip, in particular to a production method of a 3005-H16 aluminum alloy plate strip, and aims at solving the technical problems that the requirement for annealing temperature uniformity is relatively high, the requirement for annealing furnace temperature control is relatively high, the performance, especially the yield strength, is unstable duringthe intermediate annealing process of the aluminum alloy plate strips, and surface defects such as oil patches and the like are easy to generate to cause waste products if cold rolling strips are notspecially cleaned in the prior art. The method comprises the following steps of: carrying out casting, wherein the ingot casting obtained through the casting comprises the following chemical components in mass percent: less than or equal to 0.5% of Si, 0.4-0.6% of Fe, less than or equal to 0.2% of Cu, less than or equal to 0.05% of each of other impurities, less than or equal to 0.10% of a sum ofthe other impurities and the balance of Al, a smelting temperature is 740-760 DE C, a refining temperature is 730-750 DEG C, a casting temperature is 685-700 DEG C, and a casting speed is 50-60 mm / min; and carrying out milling, heating, hot rolling and cold rolling to obtain the finished 3005-H16 aluminum alloy plate strip.

Owner:ZHEJIANG YONGJIE ALUMINUM CO LTD

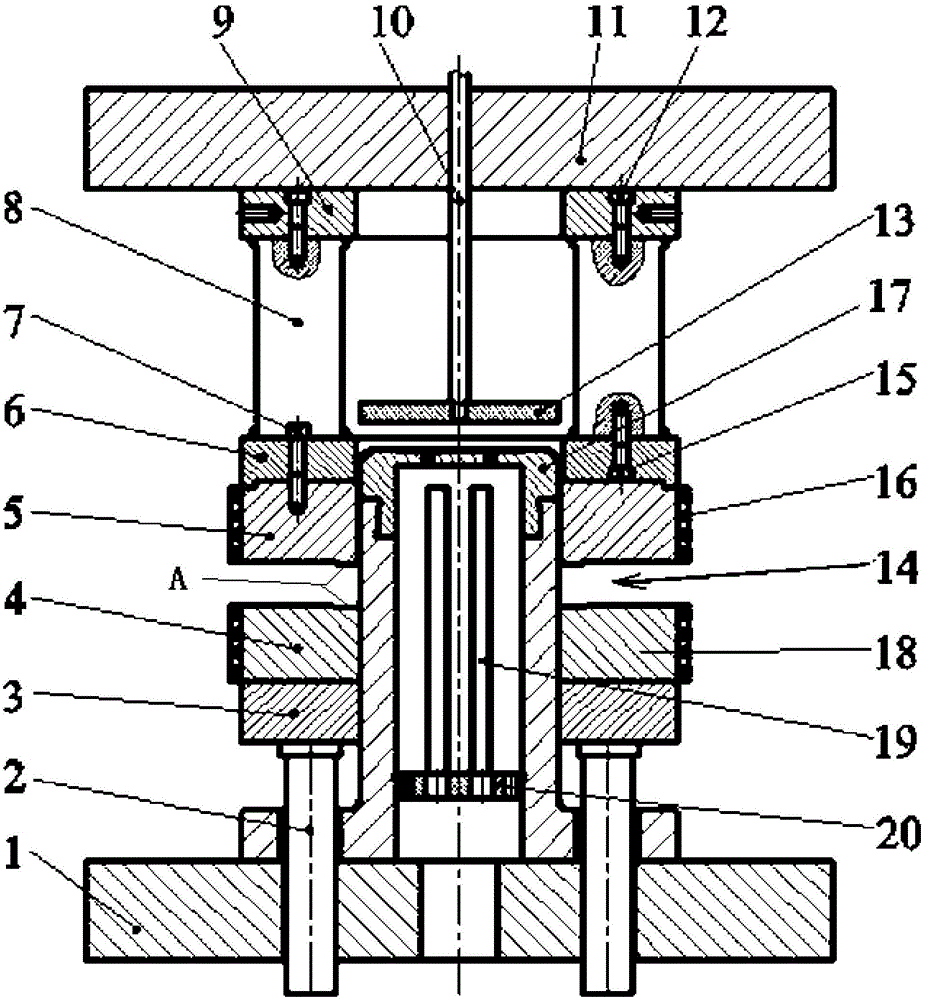

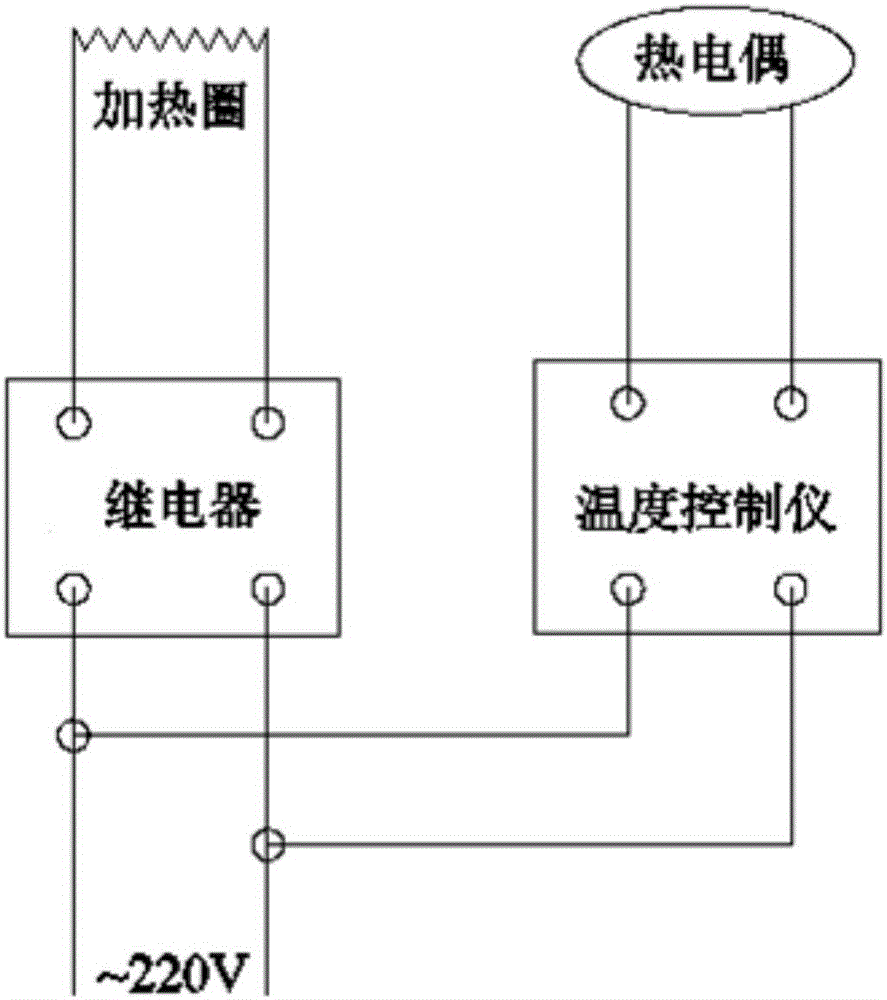

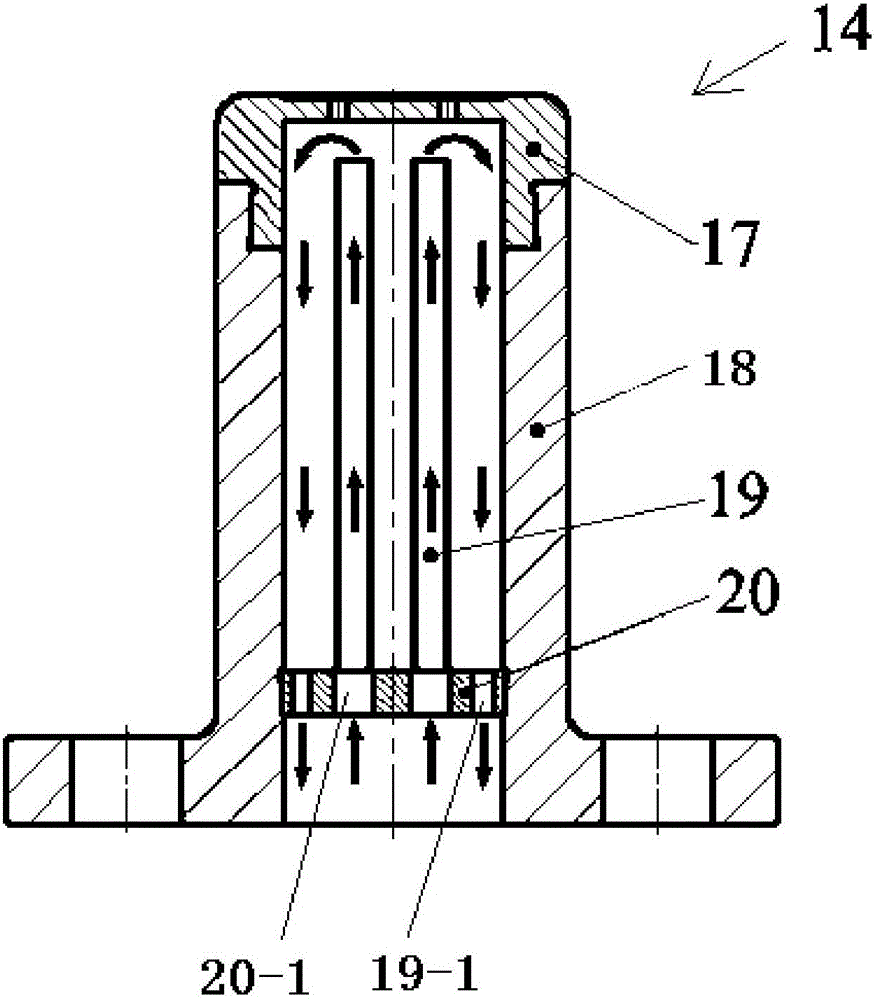

Nickel-saving stainless steel differential temperature drawing and forming device and method

InactiveCN106001232AHigh tensile strengthSolve aging cracking defectsShaping toolsMartensite transformationFlange

The invention discloses a nickel-saving stainless steel differential temperature drawing and forming device and method. The device comprises a heating device used for heating a female die and an edge pressing ring, a cavity is formed in a male die, and an air cooling device used for cooling a male die body is arranged in the cavity. By heating the female die and the edge pressing ring, the temperature of the female die and the edge pressing ring is kept between 100 DEG C and 150 DEG C, stability of a nickel-saving stainless steel flange deformation area is improved, martensitic transformation is not generated in the plastic deformation process, and the material ageing cracking defect is overcome. Meanwhile, the male die is cooled, the temperature of the male die is kept below 40 DEG C, tensile strength of a dangerous section of a drawing part is improved, and primary deformation capacity of materials is improved. The device and method reduce ageing cracking sensitivity of nickel-saving stainless steel, the conventional annealing procedure for preventing cracking of the drawing part is omitted, the primary drawing deformation limit of materials is improved, and forming passes are reduced.

Owner:SOUTH CHINA UNIV OF TECH +1

Method of manufacturing a transistor

InactiveUS7265011B2Avoid leakage currentReduce the annealing processSemiconductor/solid-state device manufacturingSemiconductor devicesInsulation layerEngineering

A method of manufacturing a transistor according to some embodiments includes sequentially forming a dummy gate oxide layer and a dummy gate electrode on an active region of a semiconductor substrate, ion-implanting a first conductive impurity into source / drain regions to form first impurity regions, and ion-implanting the first conductive impurity to form second impurity regions that are overlapped by the first impurity regions. The method includes forming a pad polysilicon layer on the source / drain regions, sequentially removing the pad polysilicon layer and the dummy gate electrode from a gate region of the semiconductor substrate, annealing the semiconductor substrate, and ion-implanting a second conductive impurity to form a third impurity region in the gate region. The method includes removing the dummy gate oxide layer, forming a gate insulation layer, and forming a gate electrode on the gate region.

Owner:SAMSUNG ELECTRONICS CO LTD

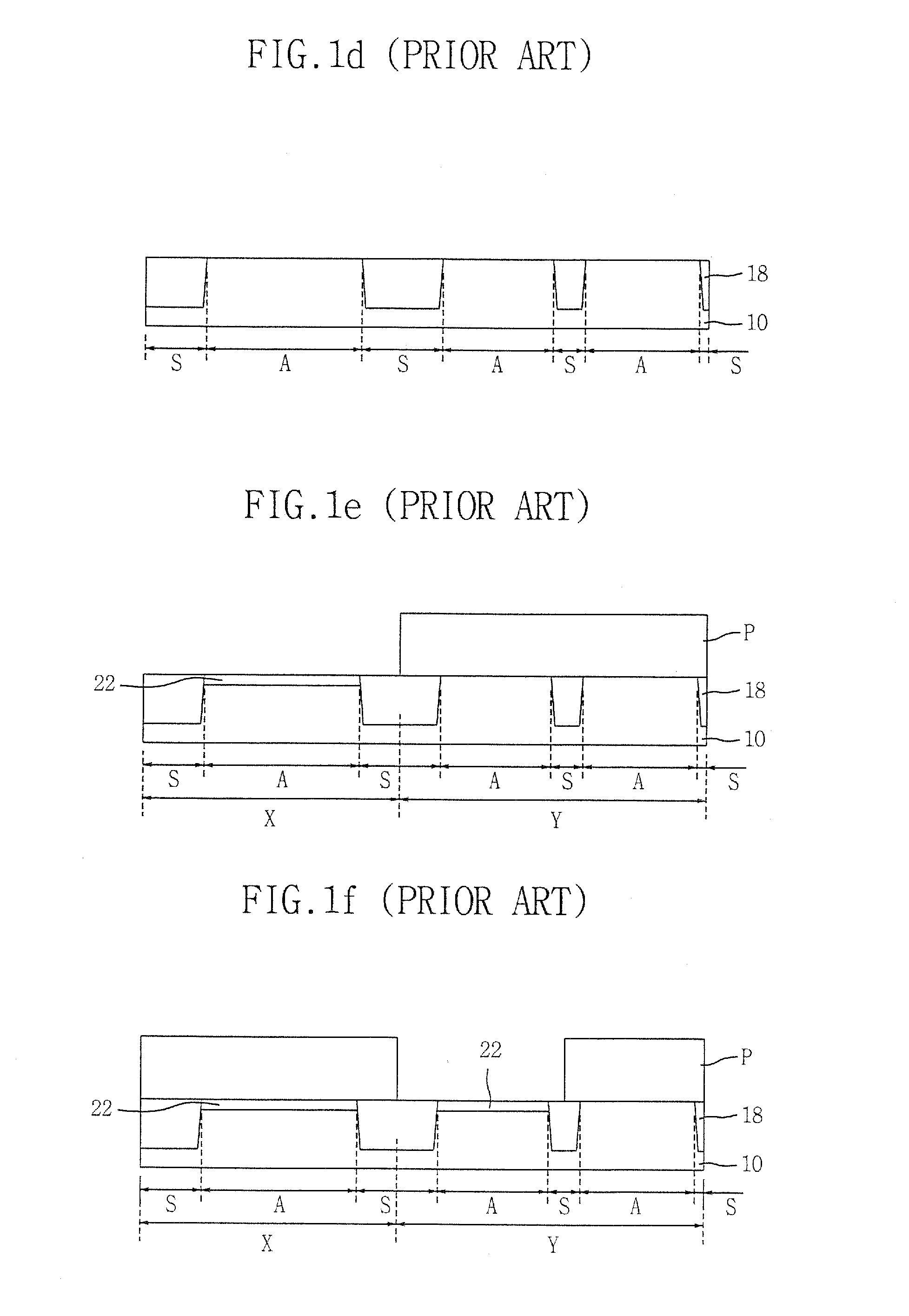

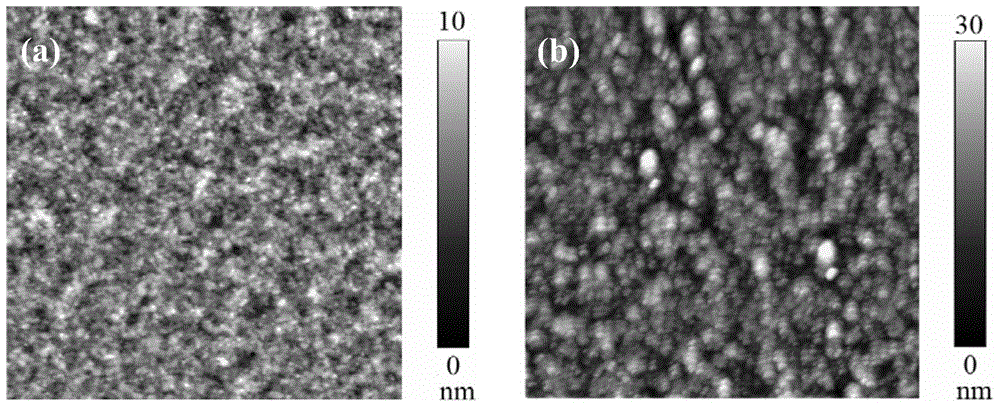

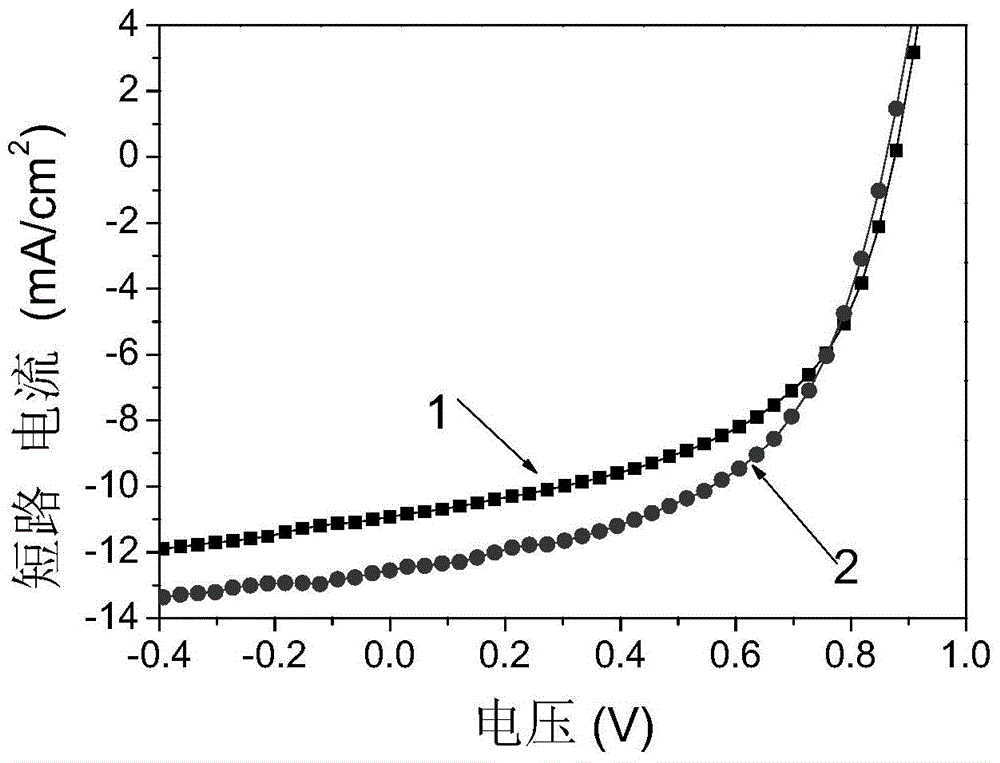

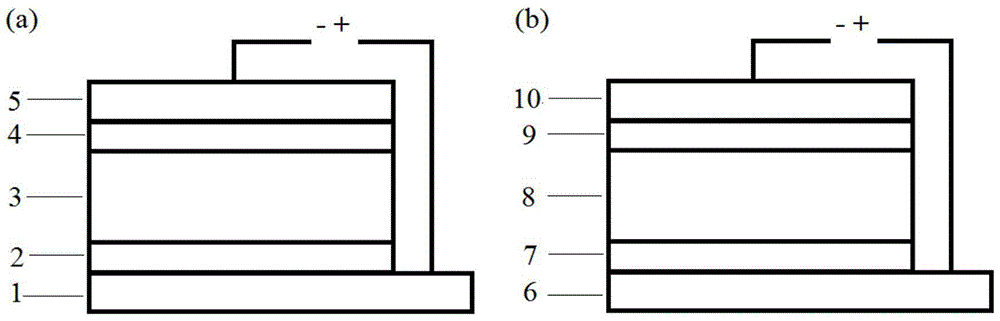

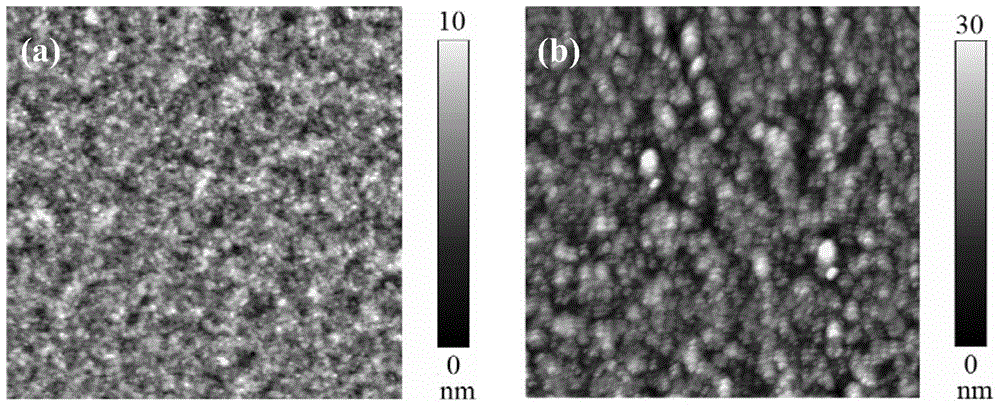

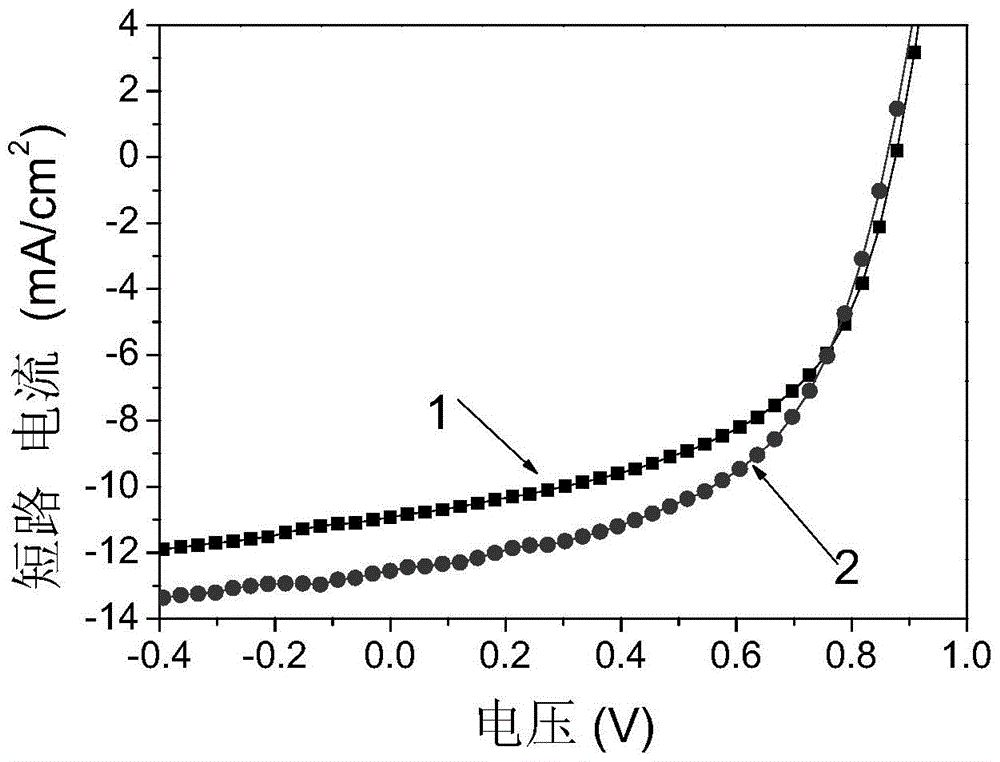

Preparation method and application of TiO2 buffer layer not subjected to annealing treatment

ActiveCN104103761AReduce the annealing processImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingDispersityState of art

The invention relates to a preparation method and an application of a TiO2 buffer layer not subjected to annealing treatment, and belongs to the technical field of organic solar cell preparation. The preparation method comprises the steps of taking tetrabutyl titanate as a raw material, obtaining collosol by hydrolysis, reacting for 60-120min at 70-90 DEG C, heating to 140-160 DEG C, reacting for 20-30min, cooling to 70-90 DEG C, reacting for 60-120min, heating to 140-160 DEG C, reacting for 20-30min, repeating the operation for 2-5 times, obtaining high-dispersity TiO2 nanocrystalline collosol, forming the collosol into a film by a film forming technology, directly drying the film at an ambient temperature (15-40 DEG C) without any annealing treatment, and then obtaining the cathode buffer layer applied to an organic solar cell. After the prepared TiO2 buffer layer not subjected to the annealing treatment is applied to the organic solar cell, the cell has excellent photoelectric property, and the stability of the cell has an obvious advantage compared with the prior art. The preparation method is simple and practical in technology, and facilitates roll-to-roll low-temperature printing preparation and industrial production.

Owner:CENT SOUTH UNIV

Manufacturing method and manufacturing equipment for online hot rolling and rolling forming of seamless special pipes

ActiveCN103817493AShort process routeShorten the production cycleOther manufacturing equipments/toolsWork cooling devicesPerformance indexManufacturing engineering

The invention relates to a manufacturing method and manufacturing equipment for online hot rolling and rolling forming of seamless special pipes. The preparation method for the seamless special pipes is simple, easy to implement, low in needed drawing force, energy saving and cost reducing, environmental pollution is reduced, the steel pipes cannot be damaged, and the produced steel pipes can reach the standards on appearance, overall dimensions and comprehensive mechanical performance indexes. The appearance, the overall dimensions and the comprehensive mechanical performance indexes are specifically reflected in that defects of drags, scratches and the like in the appearance are avoided; the overall dimensions, straightness, flatness, R angle and the like meet standard requirements; mechanical performance, impact property, the metallographic structure and the like meet standard requirements. Meanwhile, in the equipment, a forming mill is improved, a quick cooling device and a quick steel feeding device are added, and the production requirement for online hot rolling and rolling forming of the seamless special pipes can be met.

Owner:江苏界达特异新材料股份有限公司

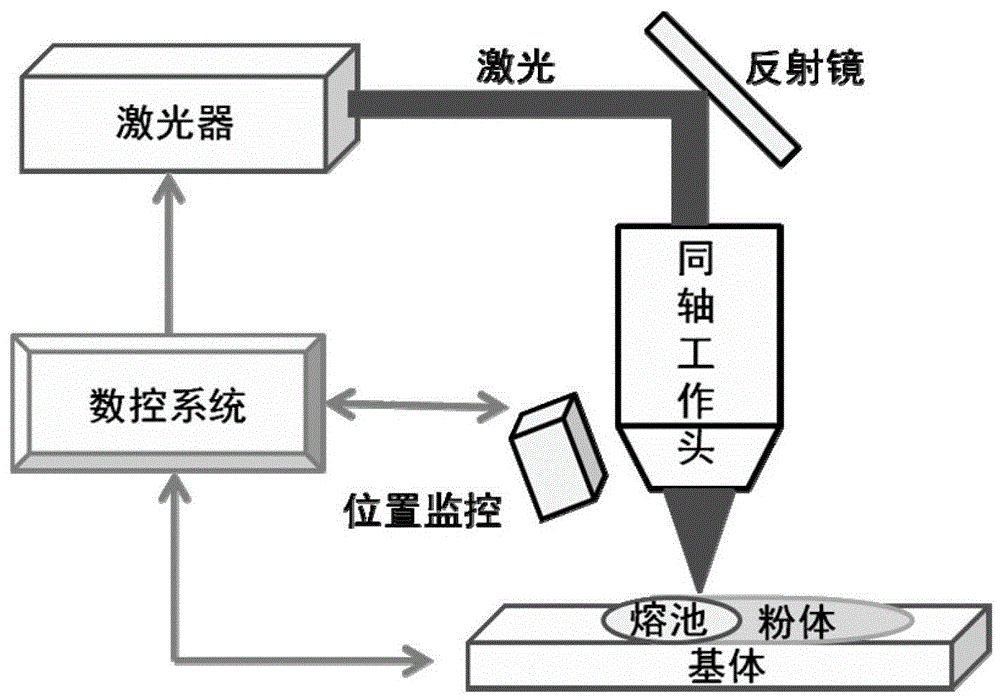

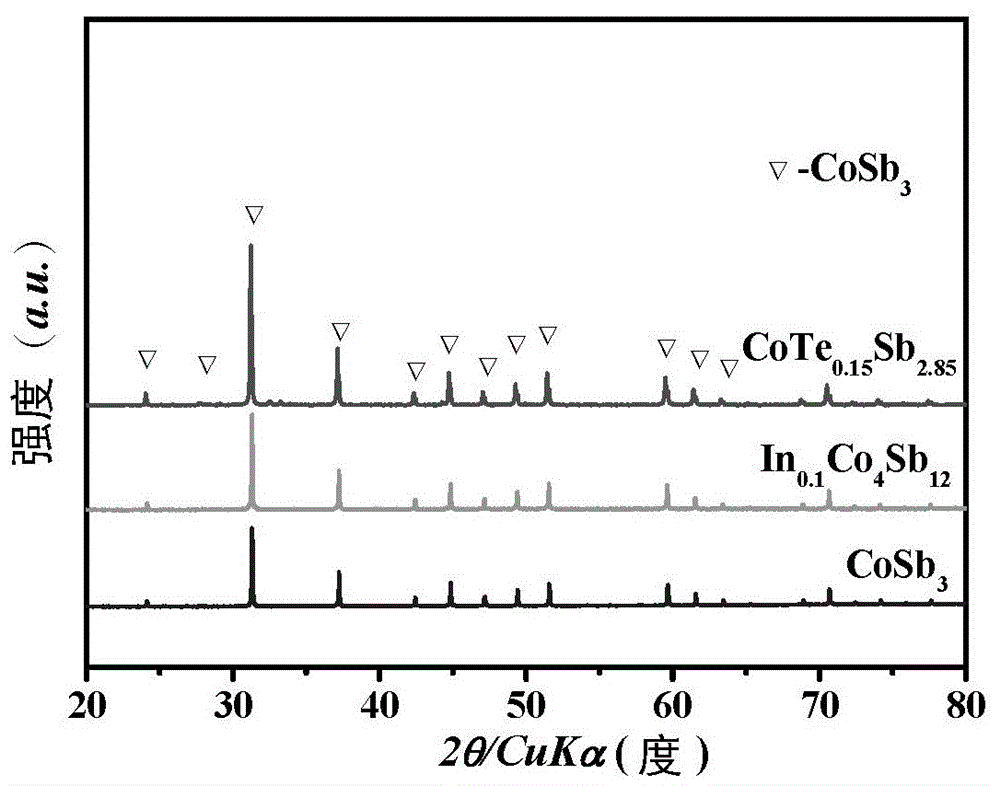

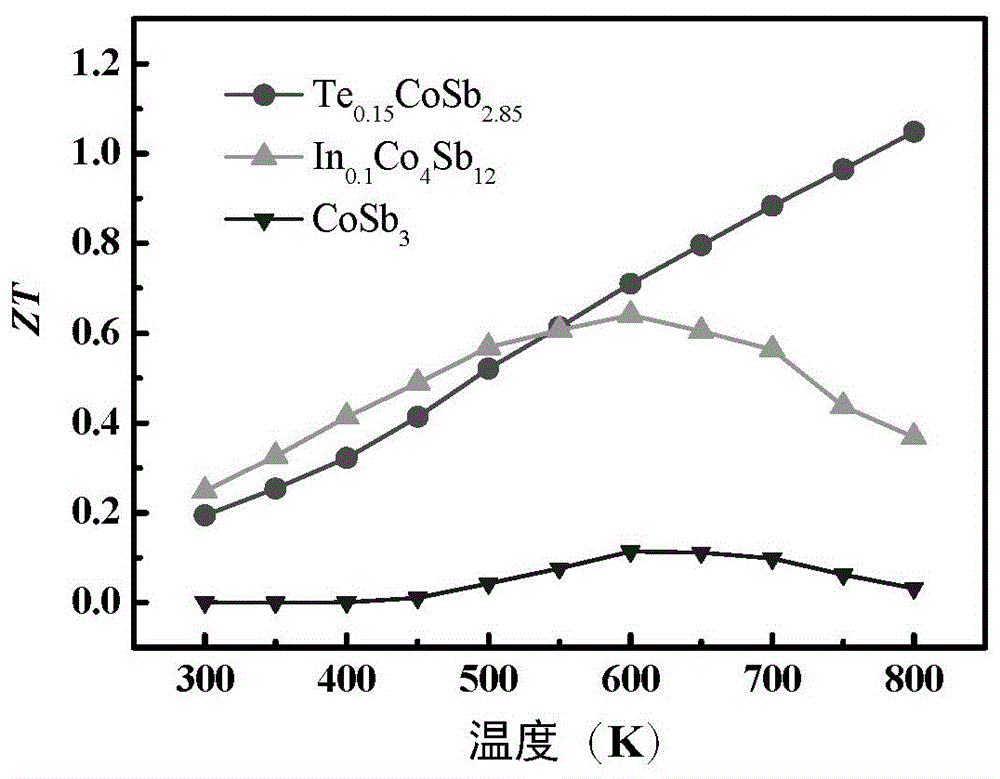

Efficient preparation method for skutterudite thermoelectric material through laser

ActiveCN106191522AReduce lossesEfficient preparationAdditive manufacturing apparatusIncreasing energy efficiencySkutteruditeIngot

The invention relates to an efficient preparation method for a skutterudite thermoelectric material through laser. The efficient preparation method comprises the steps that 1, according to the chemical formula of the skutterudite thermoelectric material, pure metal powder is weighed to serve as raw material powder and is put into a graphite matrix after being uniformly mixed; 2, the graphite matrix loaded with the raw material powder is put into an inert atmosphere, and the raw material powder is heated through the laser melting technology, melted along with movement of laser spots and then condensed, so that a cast ingot is obtained; and 3, the cast ingot prepared in the step 2 is ground into powder, the cast ingot powder is sintered through spark plasmas, and thus the skutterudite thermoelectric material is obtained. According to the efficient preparation method for the skutterudite thermoelectric material through the laser, the local powder is heated through the high-energy laser, rapid melting is achieved, and the loss of Sb phases is reduced; then, small-capacity melt is rapidly condensed, and the segregation size is decreased; and subsequently, the SPS short-time heat treatment process is combined, so that efficient preparation of the skutterudite thermoelectric material is achieved.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Method for making enameled aluminium flat wire

ActiveCN101359523BEasy painting processAvoid unstable performance problems such as unqualified voltageFlat/ribbon cablesCable/conductor manufactureLacquerTransformer

Owner:天津经纬电力科技有限公司

Production method of steel 42CrMo4+HH used for fuel gas electric generator connecting rods

InactiveCN104975217AReduce internal stressReduce the annealing processElectricityElectric arc furnace

The invention belongs to the field of steel smelting, and specifically discloses a production method of steel 42CrMo4+HH used for fuel gas electric generator connecting rods. The production method comprises steps of EBT electric arc furnace smelting, LF refining, VD vacuum treatment, electrode casting, electrode thermal insulation, electroslag remelting, electroslag ingot annealing, and hot working; wherein according to the step of EBT electric arc furnace smelting, the steel 42CrMo4+HH is prepared from following chemical ingredients, by weight percentage, 0.38 to 0.45 part of C, Si<=0.40, 0.60 to 0.90 part of Mn, P<=0.020, S<=0.015, 0.90 to 1.20 part of Cr, 0.15 to 0.30 part of Mo, Ni<=0.30, Cu<=0.20, Alt<=0.015, and the balance Fe. According to the production method, a step of casting electrode annealing is avoided, production period is shortened, and production cost is reduced.

Owner:BENGANG STEEL PLATES

Technology for preparing heterotype hollow conductor for electrolysis through continuous extrusion

The invention relates to the field of heterotype hollow conductor used for copper electrolysis technology, especially to a technology for preparing a heterotype hollow conductor for electrolysis through continuous extrusion. The technology comprises: feeding blanks, continuously extruding and moulding, finely drawing, scaling and sawing to obtain the finished product. According to the invention, through reconstruction of present continuous extrusion host devices, the technology for preparing the heterotype hollow conductor for electrolysis through the continuous extrusion has advantages of short flow process, high qualified rate of finished products and low production cost and investment cost. The hollow conductor for electrolysis produced by using the technology is characterized by high yield, compact structure and excellent microstructure, satisfies requirements of moulding precision of the copper electrolysis technology, and ensures good drapability of cathode and anode plates and reliable conductive contact. The technology can solves problems of large inventory of raw materials, complex production process and hardly controlled product quality existing in prior art.

Owner:JIUXING HLDG GRP

5182-H36 aluminum alloy sheet material for luggage compartment door plate of new energy passenger car and preparation method of 5182-H36 aluminum alloy sheet material

The invention discloses a 5182-H36 aluminum alloy sheet material for a luggage compartment door plate of a new energy passenger car. The 5182-H36 aluminum alloy sheet material comprises the followingcomponents in percentage by mass: 0.05 to 0.10 percent of Si, 0.10 to 0.20 percent of Fe, 0.01 to 0.10 percent of Cu, 0.4 to 0.8 percent of Mn, 4.6 to 5.2 percent of Mg, 0.07 to 0.12 percent of Cr, 0.01 to 0.20 percent of Zn, 0.01 to 0.05 percent of Ti and the balance of Al. A preparation process comprises the following steps: smelting, filtering a melt, casting, carrying out saw cutting on a milling surface, heating a casting ingot, carrying out hot rolling, carrying out cold rolling and carrying out stabilized annealing. The 5182-H36 aluminum alloy sheet material for the luggage compartmentdoor plate of the new energy passenger car, prepared by a preparation method, has good properties including low density, corrosion resistance, high strength, good bending performance and the like, andcan meet requirements of the luggage compartment door plate of the new energy passenger car on light weight and high comprehensive performance of production materials.

Owner:CHINALCO RUIMIN +1

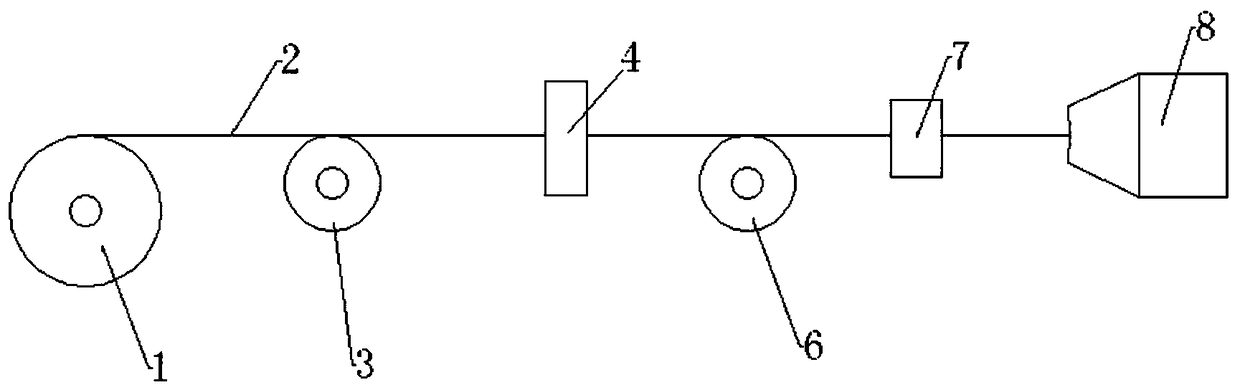

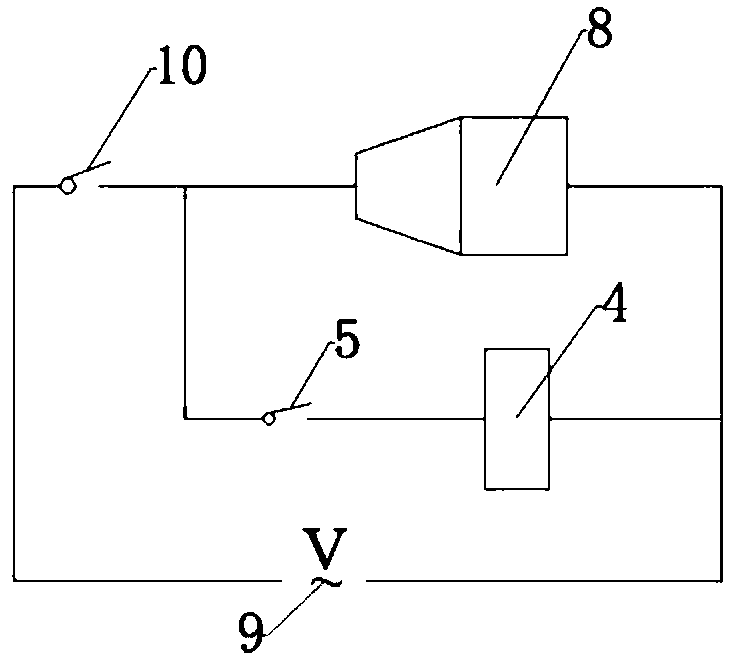

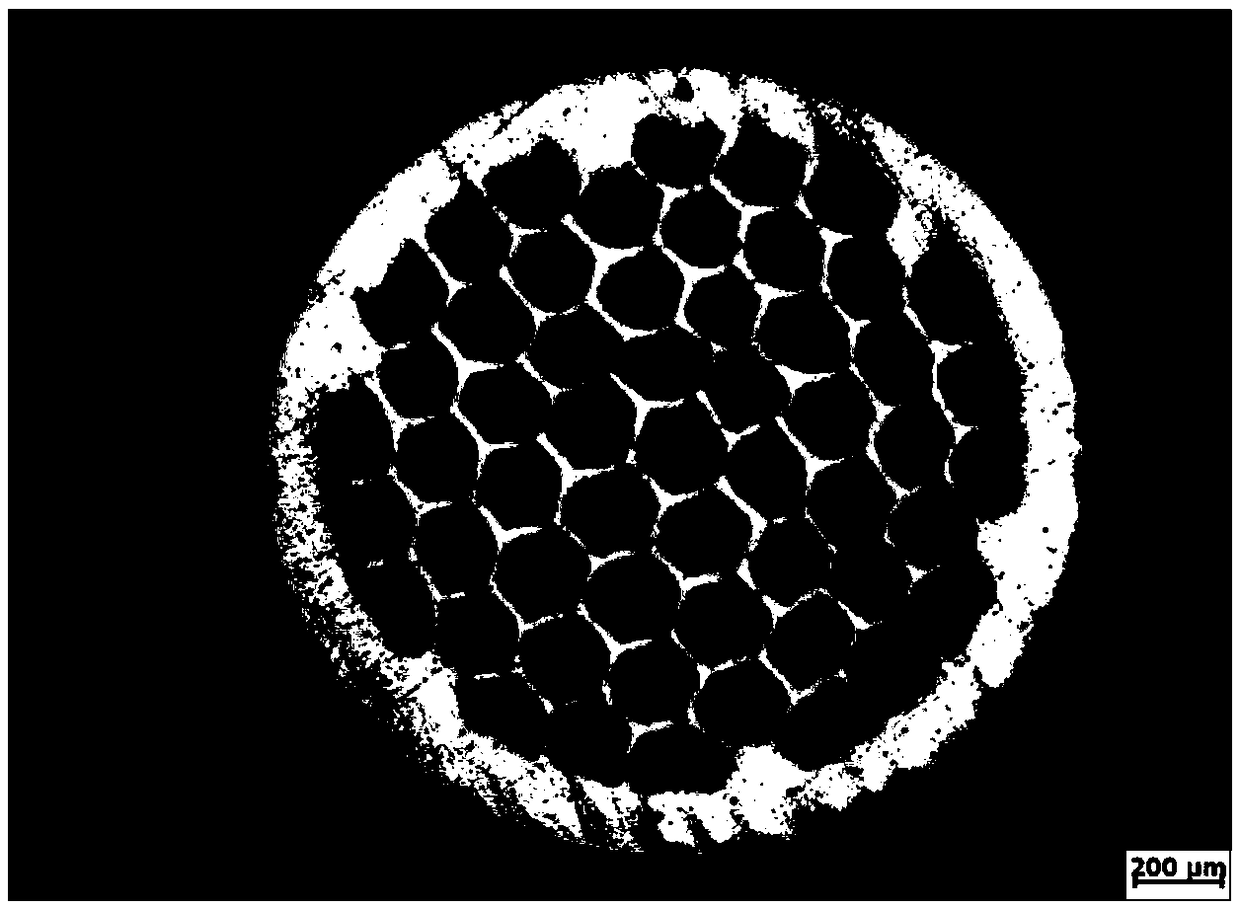

Method for preparing superconducting wire/strip

ActiveCN108878052ASmall temperature changeGuaranteed mechanical propertiesSuperconductors/hyperconductorsFurnace typesMechanical propertyMetal

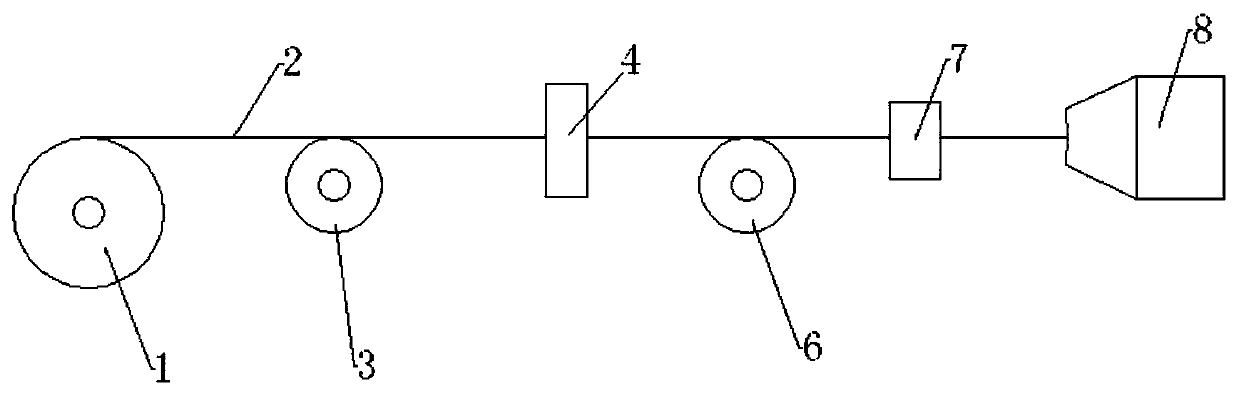

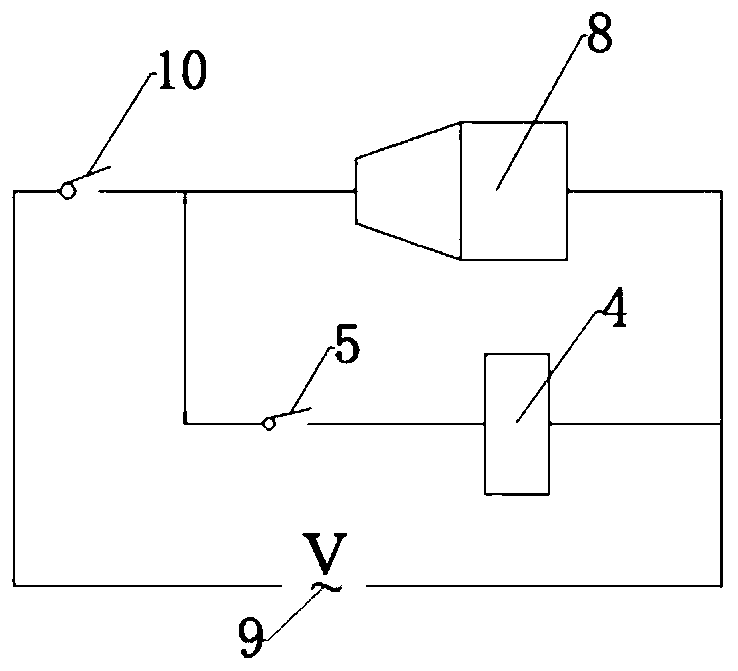

The invention discloses a method for preparing a superconducting wire / strip. The method for preparing the superconducting wire / strip comprises the following steps that 1, a metal package sheathing / ceramic core wire composite wire is wound on a pay-off reel after the metal package sheathing / ceramic core wire composite wire is cleaned, the metal package sheathing / ceramic core wire composite wire penetrates through a first guide pulley, an induction coil device, a second guide pulley and a drawing die in sequence, and the metal package sheathing / ceramic core wire composite wire is clamped on a wire drawing machine drawing device to complete assembling; 2, the wire drawing machine drawing device is started to drive the metal package sheathing / ceramic core wire composite wire to draw; 3, the drawn metal package sheathing / ceramic core wire composite wire is collected, then the assembling and drawing process are repeated, and then the superconducting wire / strip is obtained through heat treatment; and induction annealing and synchronous drawing are carried out on the metal package sheathing / ceramic core wire composite wire during repeated drawing. According to the method for preparing thesuperconducting wire / strip, induction annealing is introduced into the drawing, so that the metal package sheathing of the metal package sheathing / ceramic core wire composite wire rapidly heats up, induction annealing and synchronous drawing are realized, the mechanical properties of the superconducting wire / strip are guaranteed, the core breaking phenomenon is avoided, and the processing uniformity of the superconducting wire / strip is improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

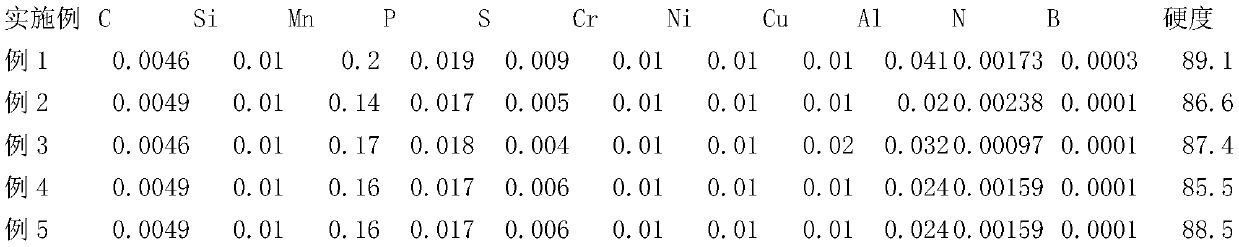

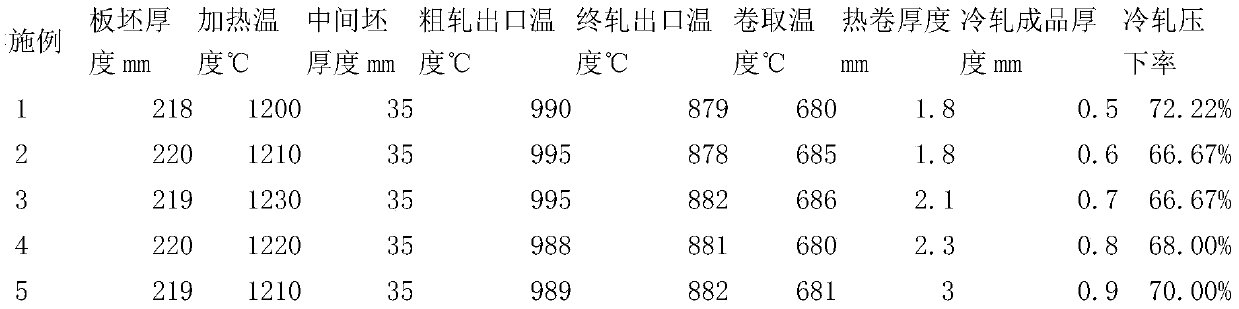

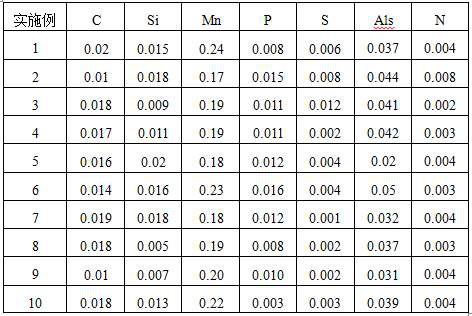

Machining method suitable for transverse and longitudinal 90-degree bent and rolled hard steel coil

The invention relates to a machining method suitable for a transverse and longitudinal 90-degree bent and rolled hard steel coil, and belongs to the field of ferrous metallurgy. The machining processof the bent and rolled hard steel coil comprises the steps of slab continuous casting, slab reheating, rough rolling, finish rolling, cooling, coiling and cold rolling. The machining method is characterized in that in the slab continuous casting stage, a steel billet comprises the chemical components of, by mass, not greater than 0.01% of C, 0.1-0.2% of Mn, not greater than 0.02% of P, not greaterthan 0.012% of S, not greater than 0.03% of Si, 0.01-0.05% of Al, not greater than 60ppm of N and the balance iron and impurities. According to the machining method suitable for the transverse and longitudinal 90-degree bent and rolled hard steel coil, the low-carbon and low-manganese component design, the high-finish-rolling and high-coiling-temperature hot rolling control process and the low-cold-rolling compression ratio control measure are adopted, the hardness of the rolled hard coil is reduced so as to meet the requirement that the transverse and longitudinal 90-degree bent and rolled hard steel coil does not crack, the machining method is used for replacing an annealed coil, and the annealing process is reduced.

Owner:ZHANGJIAGANG YANGTZE RIVER COLD ROLLED PLATE CO LTD +1

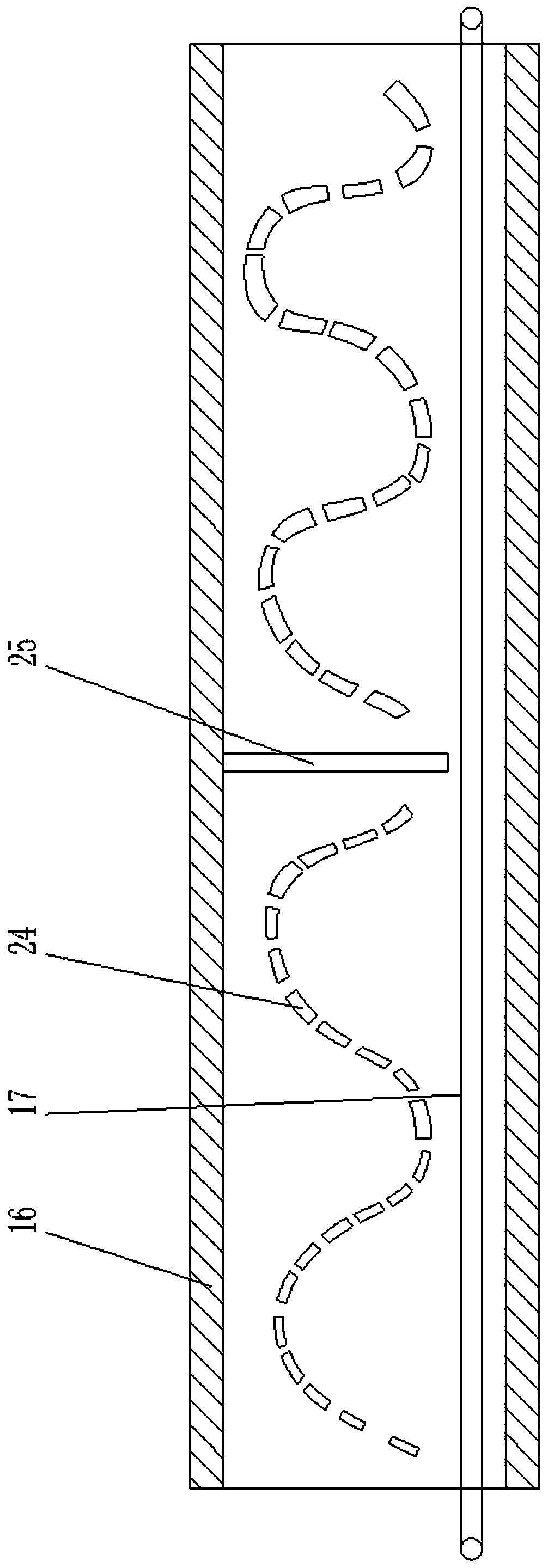

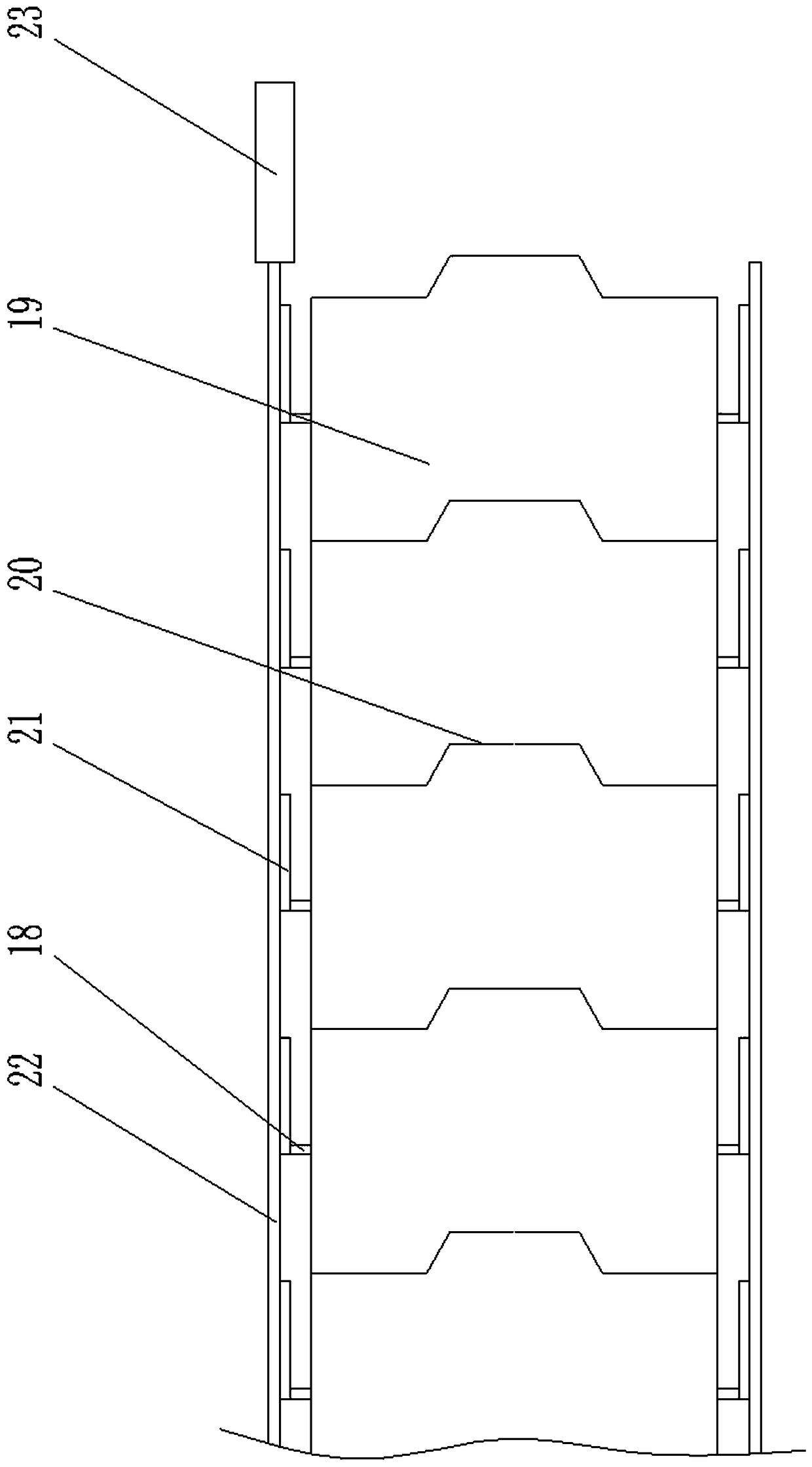

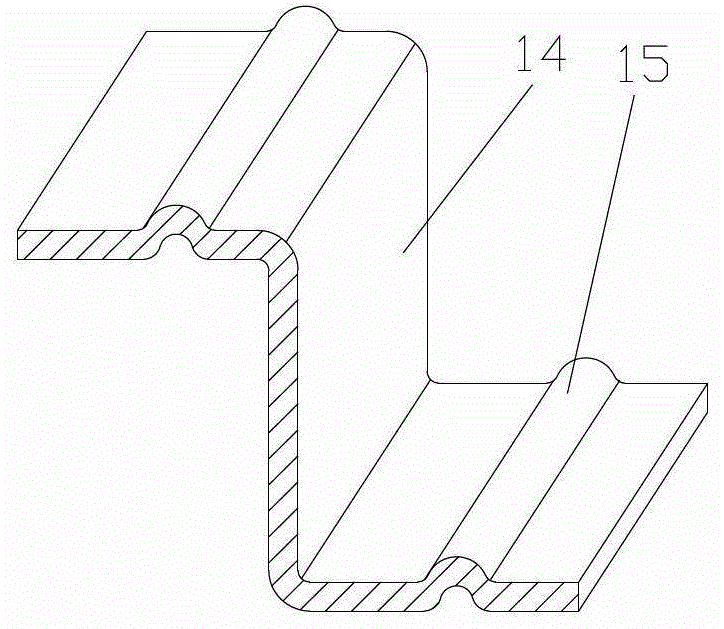

Method and apparatus for forming special-shaped wire material

InactiveCN1233482CReduce the annealing processImprove efficiencyMetal rolling arrangementsWire rodDiameter ratio

The invention provides a forming method and device for special-shaped wire rods. The device is equipped with a combination of a non-driven front 4-roller Turks Head (16) and a power-driven rear 4-roller Turks Head (17). The formed forming unit (15) is configured with a non-driven 4-side roll Turk head (21) of the finishing roll row in a straight row at the rear of the forming unit. The forming roll of the power-driven Turk head (17) has a diameter more than 70 times larger than the edge height of the material to be formed, and the formed roll between the non-driven Turk head (16) and the power-driven Turk head (17) The subject tension of the material is controlled below 300N, and the tension between the molding unit (15) and the complete Retek head (21) is controlled within the range of 50-200N for molding. Thus, special-shaped wires can be formed with high efficiency and high precision.

Owner:HITACHI METALS LTD

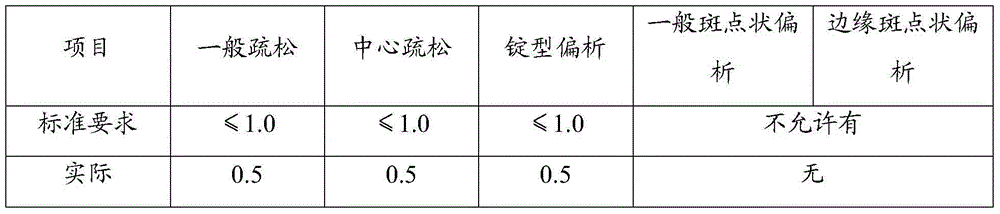

Stainless steel non-annealing direct cold rolling method

InactiveCN113385537AReduce the annealing processSmooth rollingTemperature control deviceMetal rolling arrangementsSS - Stainless steelStrip steel

The invention belongs to the technical field of steel rolling, and specifically relates to a stainless steel non-annealing direct cold rolling method sequentially comprising the steps of hot rolling, cold rolling, cold-rolled coil plate annealing and acid pickling and finishing. According to the stainless steel non-annealing direct cold rolling method, on the premise that the performance of a finished product meets the standard requirement, the annealing (acid pickling) procedure of a hot-rolled coil plate is omitted, the production process is shortened, the production efficiency is improved, the production cost is reduced, and low-cost and high-efficiency production of strip steel is achieved.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Seamless hinge and machining method thereof

InactiveCN110714674AShort process routeShorten the production cycleWing accessoriesPin hingesRotational axisManufacturing engineering

The invention discloses a seamless hinge and a machining method thereof. The seamless hinge comprises a plurality of blades and a rotating shaft which are integrally designed, wherein the blades are arranged on the rotating shaft in a sleeving mode and can rotate relative to the rotating shaft; each blade comprises a rotating part and a connecting part used for being connected with a door and a window; each rotating part is provided with a groove hole or a through hole used for being connected with the rotating shaft in an inserted mode; and the joints of the rotating parts and the connectingparts are smooth curves or in a step shape or in a combination mode. According to the seamless hinge and the machining method thereof, split type design is adopted, the hinge is mounted in a detachable mode, and the advantage of convenient installation is achieved; the step-shaped design of the connecting parts is easy to fix, the accuracy rate of multiple points and one line is high, and the labor cost is saved; the hinge is convenient to weld firmly and does not sink; and the blades are of a hot-rolled integrally-formed structure and have the advantages of being large in welding area, largein stress area and high in bearing capacity.

Owner:上海众冶实业有限公司

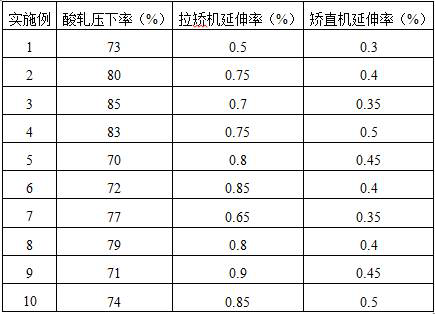

Production method of low-cost high-flatness 650 MPa-grade steel plate

The invention relates to a production method of a low-cost high-flatness 650 MPa-grade steel plate, and belongs to the technical field of metallurgy plate production. The method comprises the procedures of hot rolling, acid rolling, degreasing and straightening; and in the straightening procedure, a withdrawal and straightening machine and a straightening machine are adopted for straightening, the withdrawal and straightening elongation rate is 0.5-0.9%, and the straightening elongation rate is 0.3-0.5%. According to the method, the common wave shape and warping problems of a rolled hard coil can be effectively avoided, and the surface flatness of a final product can meet the surface quality requirement of a continuous annealing cold-rolled plate; the actually measured unevenness of the product is less than or equal to 2mm / m; and compared with an annealed coil, the alloy cost is reduced, the annealing procedure is omitted, and the product alloy cost and the procedure cost are effectively reduced.

Owner:HANDAN IRON & STEEL GROUP +1

Fingerprint-resistant liquid and fingerprint cold-resistant hard roll thereof

PendingCN114752276AImprove conductivityImprove corrosion resistanceLiquid surface applicatorsAnti-corrosive paintsMetallurgyActive agent

The invention provides a fingerprint-resistant liquid and a fingerprint-resistant cold hard roll thereof. The fingerprint-resistant liquid comprises 30-70% of resin, 0.1-5% of inorganic salt, 0.1-1% of nano silicon dioxide, 1-4% of single crystal solid nano silicon dioxide fibers, 0.1-1% of nano copper particles, 0.1-0.5% of a silane coupling agent, 0.1-5% of a surfactant and the balance of a solvent. The preparation method of the fingerprint-resistant cold hard roll comprises the following steps: 1) fully mixing resin, nano silicon dioxide, nano silicon dioxide fibers, nano copper particles, a surfactant, inorganic salt, a silane coupling agent and a solvent, and carrying out ball milling for 24 hours to obtain a fingerprint-resistant solution; 2) rolling the ultrathin hot-rolled coil by 10-40% of deformation to obtain a non-galvanized cold hard coil with the thickness of 0.5-3mm; (3) coating the fingerprint-resistant liquid on the surface of the cold hard coil through a coil bar coating roller; and (4) the coated cold hard roll steel plate is fed into a curing room, and a finished product fingerprint-resistant cold hard roll is obtained after curing. The fingerprint-resistant cold hard roll prepared by the invention has excellent mechanical properties, conductivity and corrosion resistance, also has antiviral property, and is suitable for further popularization and application.

Owner:FUJIAN UNIV OF TECH

Preparation process of continuous extrusion special-shaped hollow conductive plate for electrolysis

The invention relates to the field of heterotype hollow conductor used for copper electrolysis technology, especially to a technology for preparing a heterotype hollow conductor for electrolysis through continuous extrusion. The technology comprises: feeding blanks, continuously extruding and moulding, finely drawing, scaling and sawing to obtain the finished product. According to the invention, through reconstruction of present continuous extrusion host devices, the technology for preparing the heterotype hollow conductor for electrolysis through the continuous extrusion has advantages of short flow process, high qualified rate of finished products and low production cost and investment cost. The hollow conductor for electrolysis produced by using the technology is characterized by high yield, compact structure and excellent microstructure, satisfies requirements of moulding precision of the copper electrolysis technology, and ensures good drapability of cathode and anode plates and reliable conductive contact. The technology can solves problems of large inventory of raw materials, complex production process and hardly controlled product quality existing in prior art.

Owner:JIUXING HLDG GRP

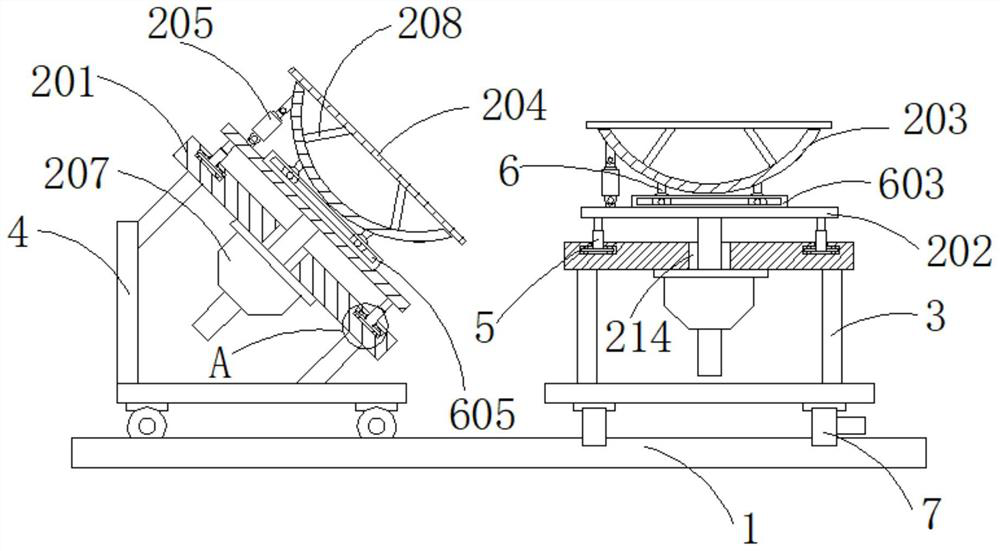

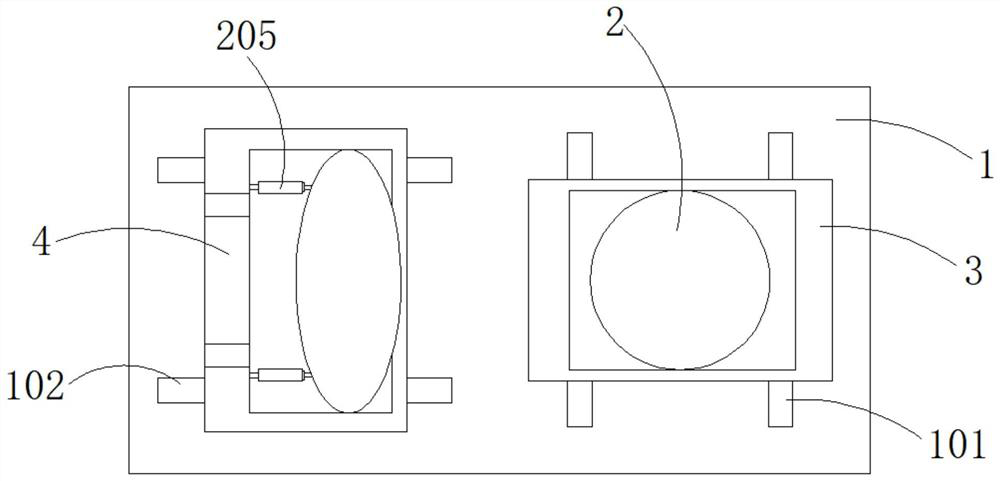

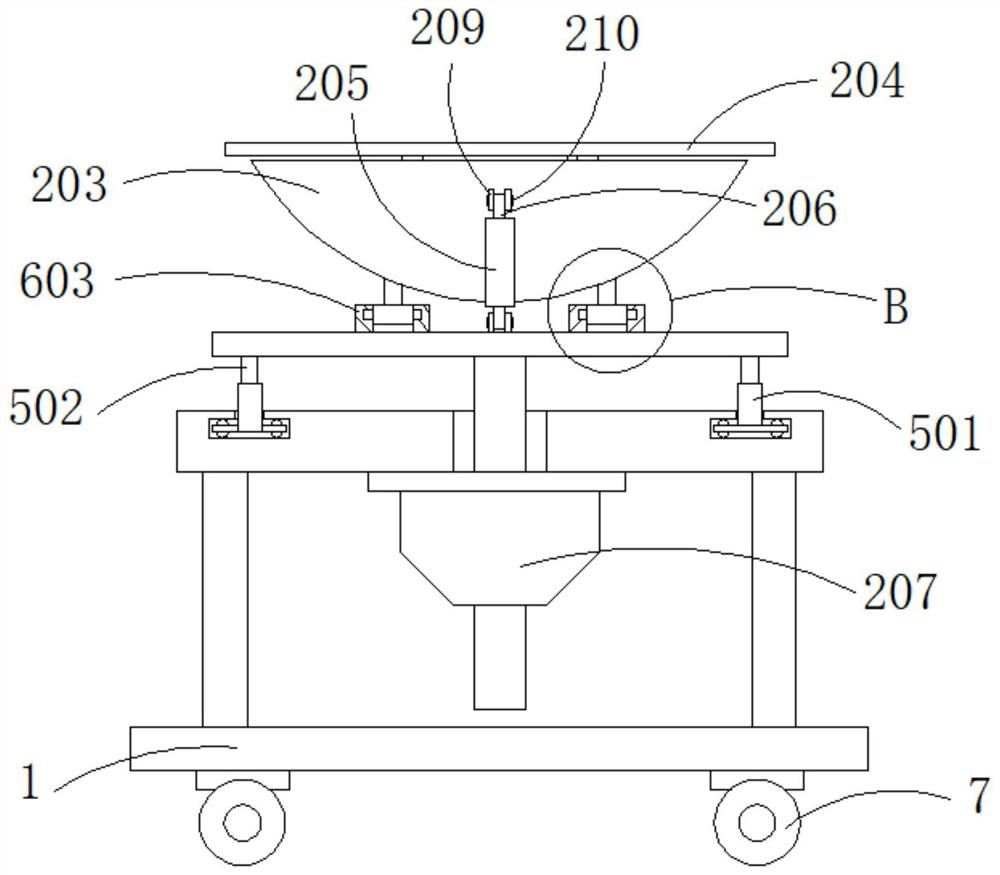

Laser annealing device for laser cutting

ActiveCN110965128BEasy to adjustReduce the annealing processAfter-treatment detailsSemiconductor/solid-state device manufacturingElectric machineryLaser cutting

The invention discloses a laser annealing device for laser cutting. The laser annealing device comprises a working table, wherein two groups of laser reflection assemblies are slidably installed in the working table, a first base and a second base are fixedly mounted at the bottoms of the two groups of the laser reflection assemblies, the included angle between the laser reflection assembly and the second base is 90 DEG, walking wheels are fixedly installed at the four corners of the bottoms of the first base and the second base, the laser reflection assembly comprises a bottom plate, a tray is rotationally mounted in the bottom plate, an arc-shaped plate is arranged at the top of the tray, a reflecting lens is fixedly mounted at the top of the arc-shaped plate, an electric push rod is arranged between the arc-shaped plate and the bottom plate, the output shaft end and the tail end of the electric push rod are hinged to one side of the upper surface of the tray and one side of the lower surface of the arc-shaped plate through lug plates respectively, a lifting motor is fixedly installed in the middle of the bottom of the bottom plate, and sliding assemblies are annularly arrayed atthe bottom of the tray at equal intervals. The laser annealing device improves annealing efficiency.

Owner:ANHUI CHUNGU 3D PRINTING INTELLIGENT EQUIP IND TECH RES INST CO LTD

A non-annealed tio 2 Preparation method and application of buffer layer

ActiveCN104103761BReduce the annealing processImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingOrganic solar cellElectrical battery

Owner:CENT SOUTH UNIV

Manufacturing technology of integrated oil storage cylinder and extension mould

InactiveCN101701614BHigh strengthImprove air tightnessShaping toolsSpringsManufacturing technologyEngineering

The invention discloses a manufacturing technology of an integrated oil storage cylinder and an extension mould, belonging to the machining technology and the mould technical field. The technology comprises the following steps: shearing bar stock, cupping blank, primary extending, leveling opening, annealing, pickling, phosphating, saponifying, secondary extending, third extending, leveling opening, grinding excircle, closing up, leveling overall length, chamfering, burring and machining a circular groove; the mould comprises an upper die base (11) and a lower die base (12), wherein, the upper die base (11) is connected with a stamping terrace die (2) through an upper die pressing ring (1) and an upper die quilt cap (13); the lower die base (12) is provided with an unloading ring (6), a lower die (5), a lower pressing ring (8), an upper die (4), an upper pressing ring (9) and a locating ring (3) from the bottom to top; the lower die (12) is connected with a lower quilt cap (10); and adischarging ring (6) is composed of three isotonic arc blocks and two extension springs (7) embedded in the groove of the external ring of the discharging ring. The manufacturing technology of the invention is suitable for manufacturing oil storage cylinders in shock absorbers for automobiles.

Owner:SICHUAN NINGJIANG SHANCHUAN MACHINERY

A kind of preparation method of superconducting wire/ribbon

ActiveCN108878052BSmall temperature changeGuaranteed mechanical propertiesSuperconductors/hyperconductorsIncreasing energy efficiencyWire rodHeat treating

The invention discloses a method for preparing a superconducting wire / strip. The method for preparing the superconducting wire / strip comprises the following steps that 1, a metal package sheathing / ceramic core wire composite wire is wound on a pay-off reel after the metal package sheathing / ceramic core wire composite wire is cleaned, the metal package sheathing / ceramic core wire composite wire penetrates through a first guide pulley, an induction coil device, a second guide pulley and a drawing die in sequence, and the metal package sheathing / ceramic core wire composite wire is clamped on a wire drawing machine drawing device to complete assembling; 2, the wire drawing machine drawing device is started to drive the metal package sheathing / ceramic core wire composite wire to draw; 3, the drawn metal package sheathing / ceramic core wire composite wire is collected, then the assembling and drawing process are repeated, and then the superconducting wire / strip is obtained through heat treatment; and induction annealing and synchronous drawing are carried out on the metal package sheathing / ceramic core wire composite wire during repeated drawing. According to the method for preparing thesuperconducting wire / strip, induction annealing is introduced into the drawing, so that the metal package sheathing of the metal package sheathing / ceramic core wire composite wire rapidly heats up, induction annealing and synchronous drawing are realized, the mechanical properties of the superconducting wire / strip are guaranteed, the core breaking phenomenon is avoided, and the processing uniformity of the superconducting wire / strip is improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

A kind of annealing-free wire rod for 05-grade high-strength nuts and its production method

ActiveCN103060675BReduce manufacturing costImprove flowTemperature control deviceMetal rolling arrangementsWire rodChemical composition

The invention provides an annealing-free wire rod for a 05-grade high-strength nut and a production method of the annealing-free wire rod. The annealing-free wire rod comprises the following chemical components in percentage by weight: 0.19-0.36% of carbon, 0.55-0.85% of manganese, less than or equal to 0.08% of silicon, less than or equal to 0.025% of sulfur, less than or equal to 0.025% of phosphorus and 0.0015-0.004% of boron. The annealing-free wire rod provided by the invention has the tensile strength of 530Mpa or lower, the elongation percentage of high than or equal to 25% and the surface shrinkage percentage of 50% or higher and has qualified 1 / 3 cold heading performance and excellent integral performance. Due to the adoption of the method, the annealing step is omitted, the production cost of the nut is reduced, and significant consumption reducing, energy saving and environment protecting effects are achieved.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Preparation method of stainless steel wire for netting

ActiveCN113814282AReduce handstand pullingReduce the annealing processProcess efficiency improvementWire rodEconomic benefits

The invention provides a preparation method of a stainless steel wire for netting. The preparation method comprises the following steps that the pass deformation in a metal wire drawing procedure is reasonably arranged, the procedures of rough drawing, primary annealing, fine drawing and secondary annealing are carried out, a water-based lubricant is adopted in the last pass in fine drawing, and a lubricant on the surface of a semi-finished product wire is removed. The purpose that the stainless steel wire for netting can be obtained through two times of drawing-annealing is achieved, the produced stainless steel wire is smooth and clean in surface, it is guaranteed that the physical and chemical properties of the wire rod are flush with those of other processes while the technological process is shortened, the using effect is stable, the production process is shortened, economic benefits are good, and the stainless steel wire is suitable for industrial production and use.

Owner:JIANGYIN FASTEN STAINLESS STEEL PROD CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com