Preparation method of stainless steel wire for netting

A technology for stainless steel wire and wire drawing is applied in the field of preparation of stainless steel wire for mesh weaving, which can solve the problems of high cost, long production cycle, complicated procedures, etc., and achieve the effect of shortening production cycle, shortening production process and reducing technological process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

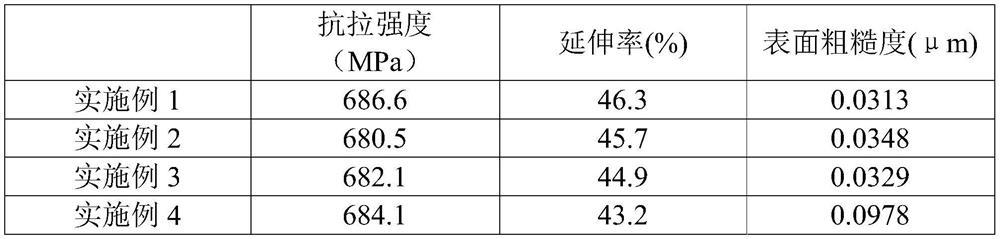

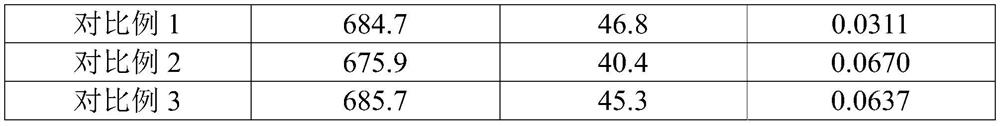

Embodiment 1

[0094] The present embodiment provides a kind of preparation method of stainless steel wire for netting, and described preparation method comprises the following steps:

[0095] (1) Rough extraction: soak the raw material of stainless steel wire rod in 4wt% surface treatment agent of type 0445 produced by Jinan Jinhailong Chemical Co., Ltd. for 20 minutes, and control the temperature at 80°C. Dry at 200°C for 30 minutes to obtain a pretreatment wire with a diameter of 5.5mm. The pretreatment wire is put into the rough drawing mold box at a speed of 300m / min through the gantry pay-off frame, and the drawing process is carried out through six drawing processes. The temperature of the circulating cooling water in the rough drawing wire drawing mold box is 30°C. The six wire drawing processes all use the calcium-based lubricating powder of the model AM300 produced by YADEKA CHEMICAL SUPPLY CORPORATION to obtain an intermediate wire with a diameter of 2.2mm. The six wire drawing pro...

Embodiment 2

[0102] The present embodiment provides a kind of preparation method of stainless steel wire for netting, and described preparation method comprises the following steps:

[0103] (1) Rough pumping: Pull the stainless steel wire material at a speed of 250m / min to 4wt% of the surface treatment agent produced by Jinan Jinhailong Chemical Co., Ltd., the model is 0445, the residence time is 4.08s, and the control temperature is 70 ℃, the raw material of the stainless steel wire after film treatment was dried at 280℃ for 8.08s to obtain a pretreatment wire with a diameter of 5.5mm, and the pretreatment wire was fed into the rough drawing mold box at a speed of 250m / min by the gantry pay-off frame Among them, the drawing process is carried out through six wire drawing processes. The temperature of the circulating cooling water of the rough drawing wire drawing mold box is 25 °C. The six wire drawing processes all adopt the calcium-based lubricant powder of the model AM300 produced by Y...

Embodiment 3

[0110] The present embodiment provides a kind of preparation method of stainless steel wire for netting, and described preparation method comprises the following steps:

[0111] (1) Rough extraction: immerse the raw material of stainless steel wire rod in 4wt% of the surface treatment agent of model 0445 produced by Jinan Jinhailong Chemical Co., Ltd. for 30 minutes, and control the temperature at 70°C. Dry at 250°C for 20 minutes to obtain a pretreatment wire with a diameter of 5.5mm. The pretreatment wire is put into the rough drawing mold box at a speed of 150m / min through the gantry pay-off frame, and the drawing process is carried out through six drawing processes. The temperature of the circulating cooling water in the rough drawing wire drawing mold box is 35°C. The six wire drawing processes all use the calcium-based lubricating powder of the model AM300 produced by YADEKA CHEMICAL SUPPLY CORPORATION to obtain an intermediate wire with a diameter of 2.2mm. The six wire ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com