A non-annealed tio 2 Preparation method and application of buffer layer

A technology of annealing treatment and buffer layer, which is used in semiconductor/solid-state device manufacturing, photovoltaic power generation, electrical components, etc., can solve problems such as low efficiency, and achieve the effect of reducing annealing process, obvious efficiency, and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

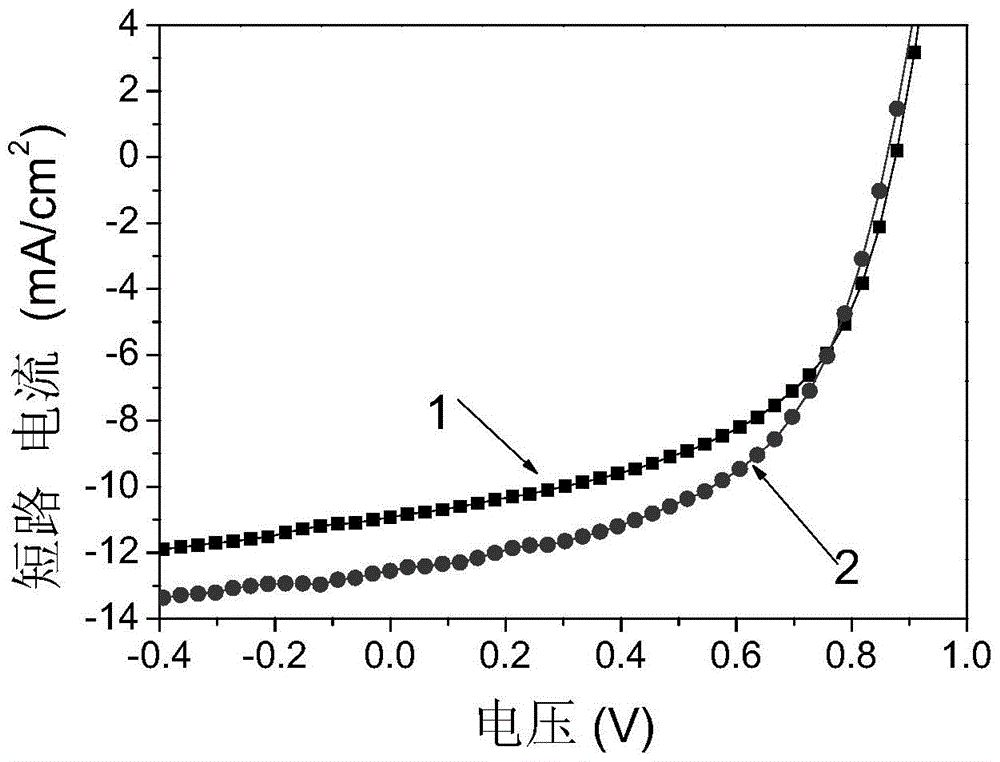

[0054] TiO of the present invention 2 Specific examples of NPs synthesis and improving the efficiency and stability of OPV devices, the specific steps are as follows:

[0055] 1) Mix 50mL of n-butanol and 1.6mL of nitric acid in a wide-mouth Erlenmeyer flask, stir thoroughly for 10 minutes, and add 5mL of acetic acid at the same time, and wait until the mixture is uniform. At this time, the pH of the system is 0.2, and the system is heated to 40°C;

[0056] 2) Slowly add 24mL tetrabutyl titanate dropwise to the above solution, and stir at 40°C for 40min;

[0057] 3) Add 8 mL of deionized water dropwise to the solution in B at a rate of 0.02 mL / S. After it is completely hydrolyzed to form a gel, add 100 mL of deionized water and continue stirring at 40°C for 24 hours to obtain a transparent sol;

[0058] 4) After standing for 24 hours, stop stirring, and use a separatory funnel to separate n-butanol;

[0059] 5) Heat the sol to 80°C for 60 minutes, then react at 150°C for 30 ...

Embodiment 2

[0075] 1) Mix 20mL of n-butanol and 0.1mL of nitric acid in a wide-mouth conical flask, stir thoroughly for 10 minutes, and add 2mL of acetic acid at the same time, and wait until the mixture is uniform. At this time, the pH of the system is 1, and the system is heated to 30°C;

[0076] 2) Slowly add 10 mL of tetrabutyl titanate dropwise to the above solution, and stir at 30°C for 30 min;

[0077] 3) Add 3 mL of deionized water dropwise to the solution in B at a rate of 0.002 mL / S, add 100 mL of isopropanol after it is hydrolyzed to form a gel, and continue stirring at 40°C for 4 hours to obtain a transparent sol;

[0078] 4) Heat the sol to 70°C for 90 minutes, then react at 160°C for 30 minutes, then cool down to 80°C for 60 minutes, then heat up to 150°C for 30 minutes; repeat three times to obtain highly dispersed TiO 2 Nanocrystalline sol;

[0079] 5) Finally, the above-mentioned high-dispersion TiO 2 The nanocrystalline sol was diluted with alcohol 10 times the volume ...

Embodiment 3

[0085] 1) The commercially purchased ITO was ultrasonically cleaned in acetone, detergent, deionized water, and isopropanol successively. After cleaning, it was dried with nitrogen gas. After being treated with ozone for 10 minutes, it was placed in a Petri dish for use as a cathode;

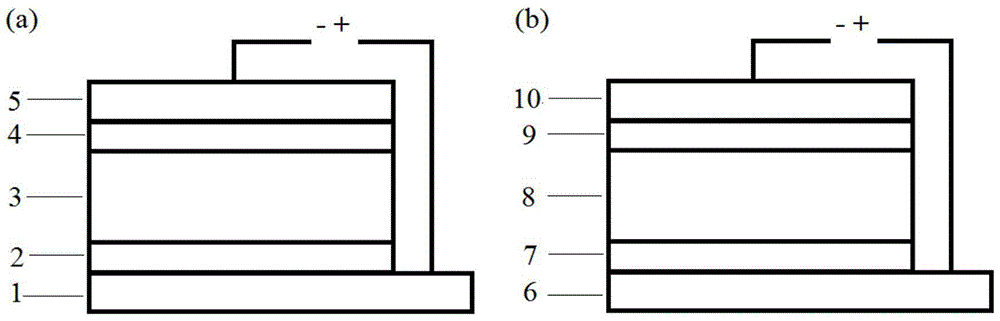

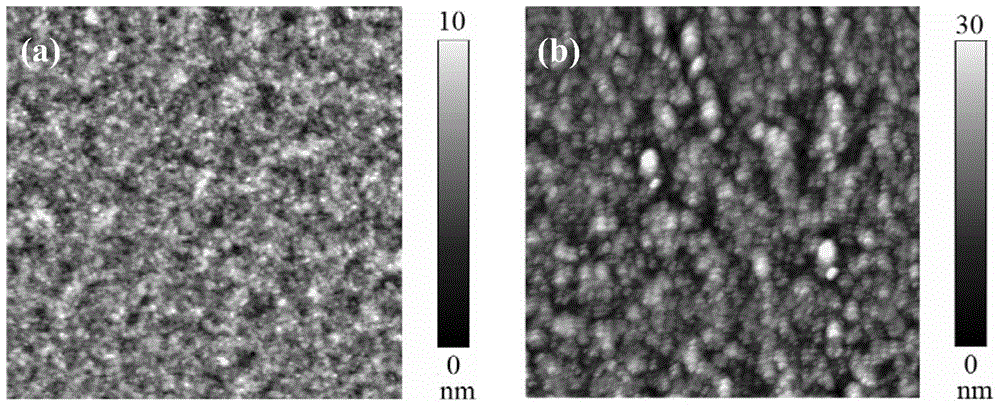

[0086] 2) the TiO in the example 1 2 The nanocrystalline sol is formed into a film on ITO by spin coating process, the film thickness is about 10-20nm, and it is dried in air without annealing, and the temperature of non-annealing drying is 20°C;

[0087] 3) Move the prepared substrate into a vacuum evaporation apparatus, pump the vacuum to below 1×10-4Pa, and evaporate C at a speed of 0.6-3.2A / s 60 (40nm), evaporate 40nm CuPc at a speed of 1-3.2A / s; form a planar heterojunction active layer;

[0088] 4) Evaporate 5nm MoO at a speed of 0.1-0.5A / S 3 As an anode buffer layer;

[0089] 5) Use a strip-shaped mask to steam a 100nm-thick strip of good conductive metal such as Al or Ag at a speed of 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com