Preparation method for high-magnesium aluminum alloy O-state plate of 5XXX series

A high-magnesium aluminum alloy and aluminum alloy ingot casting technology, which is applied in the field of aluminum alloy processing, can solve the problems of increasing production costs, uneven surface brightness, and adding an annealing process for finished products, so as to save production costs, improve product yield and Production efficiency and the effect of reducing the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

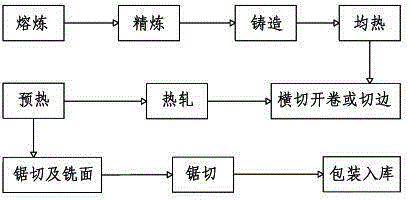

Method used

Image

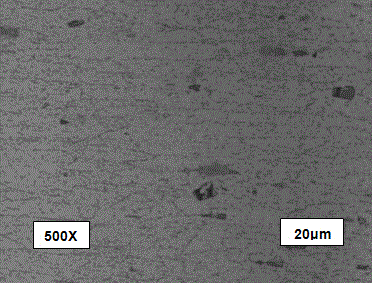

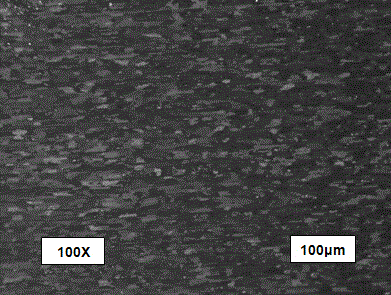

Examples

Embodiment 1

[0029] Take the production of 5083 aluminum alloy O-state plate as an example:

[0030] (1) Smelting: Put aluminum ingots into the melting furnace for smelting, put aluminum ingots with a purity of 99.70% and above into the melting furnace for smelting, and add aluminum-magnesium master alloy, aluminum-manganese master alloy, aluminum-titanium-boron wire, refining Use electromagnetic stirring to accelerate the smelting speed, and carry out the slag removal operation on the slag inclusions in the molten aluminum. After removing the slag, take samples for component analysis to make the alloy composition meet the requirements;

[0031] (2) Refining: Heat the molten aluminum to 720-760°C and then transfer it to the holding furnace for heat preservation, and add alloy elements that are easy to burn, and then refine in the furnace; after the molten aluminum is transferred to the holding furnace, turn on electromagnetic stirring, And reheat to 720 ~ 760 ℃, stop electromagnetic stirri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com