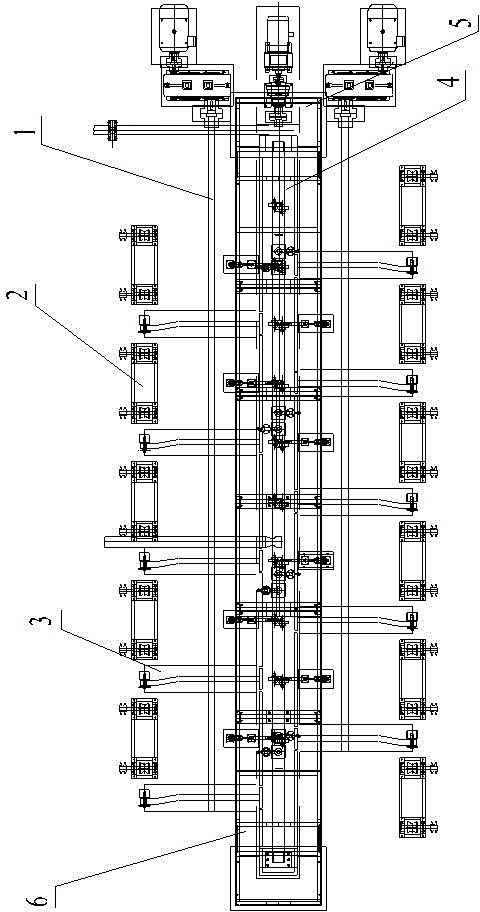

Manufacturing method and manufacturing equipment for online hot rolling and rolling forming of seamless special pipes

A special-shaped pipe and seamless technology, which is applied in other manufacturing equipment/tools, manufacturing tools, metal processing equipment, etc., can solve the problems of easy-to-strain inner and outer surfaces of steel pipes, complex cold drawing processing technology, and low metal yield. Achieve the effect of reducing the annealing process of finished products, reducing the straightening process, and shortening the process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

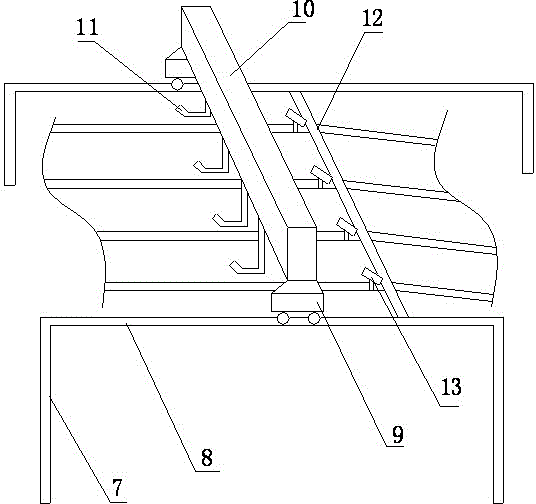

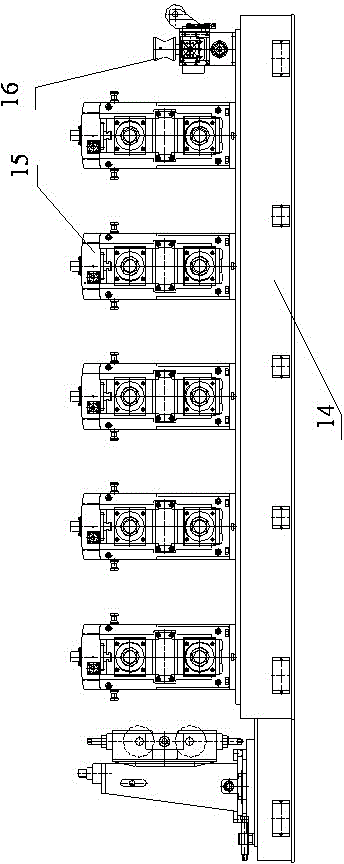

[0048] The present invention relates to a method for preparing hot-rolled and rolled-on-line seamless special-shaped pipes. The process steps of the method are as follows:

[0049] Production example: material Q345B specification: 140*80*7mm length: over 6m

[0050] Step 1, cutting off

[0051] The material is Q345B, and the round tube billet with a diameter of Φ150 is cut into a suitable length, and the cutting length is 1800-1900mm / piece.

[0052] Step 2. Heating

[0053] Put the finished circular tube billet into the ring furnace and heat it to 1220-1250°C.

[0054] Step three, hot rolling

[0055] The round tube billet heated to the specified temperature is hot-rolled into a 140*7mm round tube through the processes of piercing, cross rolling and sizing. (outer diameter Φ=(140+80)*2 / 3.14≈140mm)

[0056] Step 4. Control cooling

[0057] The hot-rolled finished round tube (temperature is usually above 800°C) is passed through the rapid cooling device at the back of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com