Preparation process of continuous extrusion special-shaped hollow conductive plate for electrolysis

A preparation process and a technology for conductive plates, which are applied in the field of preparation technology of continuous extrusion special-shaped hollow conductive plates for electrolysis, can solve the problems of complex production process, difficult product quality control, large inventory of raw materials, etc., and achieve the yield and product quality. The effect of improving and improving material utilization rate and shortening production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] As shown in Figure 5(a)-(c), the structure of this embodiment is figure 2 The mold schematic diagram of the product, a product forming cavity is opened in the product mold 11, one end of the product forming cavity is the product mold outlet 10, and the other end of the product forming cavity 16 is the product mold inlet 12; the product forming cavity is a transition cavity Body 16 and forming section cavity 17 combined structure, the product mold inlet 12 is located at the outer end of the transition section cavity 16, the transition section cavity 16 adopts a horn-shaped transition structure, and a mold corresponding to the product conductive rib is set in the product forming cavity Conductive rib 13.

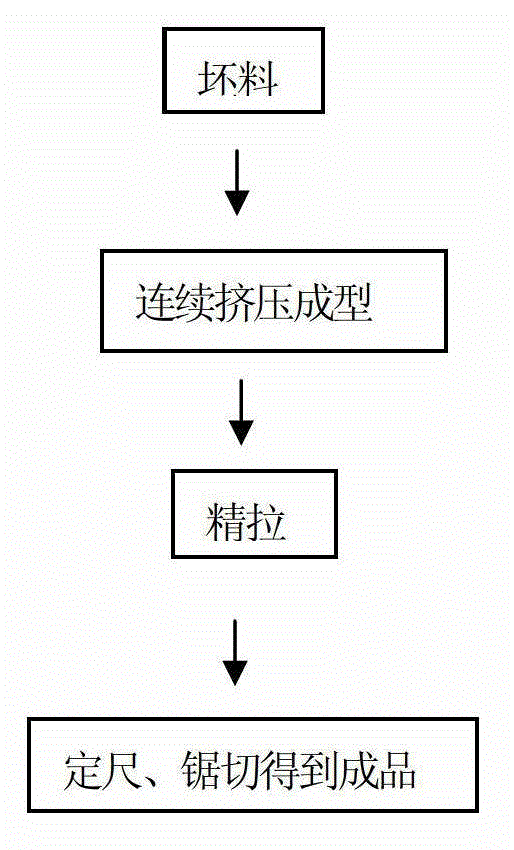

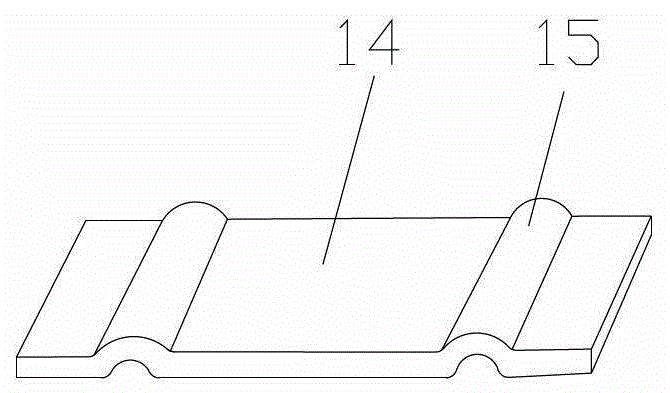

[0071] This embodiment adopts a fully automatic production line to produce special-shaped hollow conductive plates for electrolysis (see figure 2 ), there are two product conductive ribs 15 on the product 14 (conductive flat plate), the preparation process is: blank→...

Embodiment 2

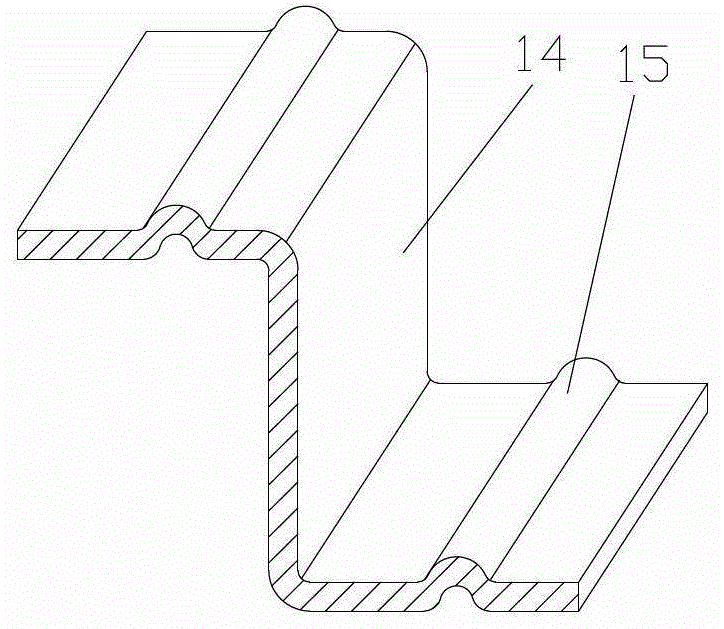

[0086] The difference from Embodiment 1 is that, as shown in Figure 6(a)-(c), the structure of this embodiment is image 3 The mold schematic diagram of the product, a product forming cavity is opened in the product mold 11, one end of the product forming cavity is the product mold outlet 10, and the other end of the product forming cavity 16 is the product mold inlet 12; the product forming cavity is a transition cavity Body 16 and forming section cavity 17 combined structure, the product mold inlet 12 is located at the outer end of the transition section cavity 16, the transition section cavity 16 adopts a horn-shaped transition structure, and a mold corresponding to the product conductive rib is set in the product forming cavity Conductive rib 13.

[0087] This embodiment adopts a fully automatic production line to produce special-shaped hollow conductive plates for electrolysis (see image 3 ), the plate is bent twice, and the transition between the two parallel flat plat...

Embodiment 3

[0102] The difference from Embodiment 1 is that, as shown in Figure 7(a)-(c), the structure of this embodiment is Figure 4 The mold schematic diagram of the product, the product mold 11 has a product forming cavity, one end of the product forming cavity is the product mold outlet 10, and the other end of the product forming cavity 16 is the product mold inlet 12; the product forming cavity is a transition cavity Body 16 and forming section cavity 17 combined structure, the product mold inlet 12 is located at the outer end of the transition section cavity 16, the transition section cavity 16 adopts a horn-shaped transition structure, and a mold corresponding to the product conductive rib is set in the product forming cavity Conductive rib 13.

[0103] This embodiment adopts a fully automatic production line to produce special-shaped hollow conductive plates for electrolysis (see Figure 4 ), the plate is bent, the cross-section is right-angled, and the product 14 is provided ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com